Gripper device, and use of a gripper device

a gripper device and gripper body technology, applied in the direction of gripping heads, manipulators, program-controlled manipulators, etc., can solve the problems of limiting the effective service life, affecting the dynamic behaviour of the gripper device, and consuming time and costs, so as to improve the mechanical dynamic properties of the device, improve the structure of the gripper body implementing the gripper device, and not impair the dynamic properties of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

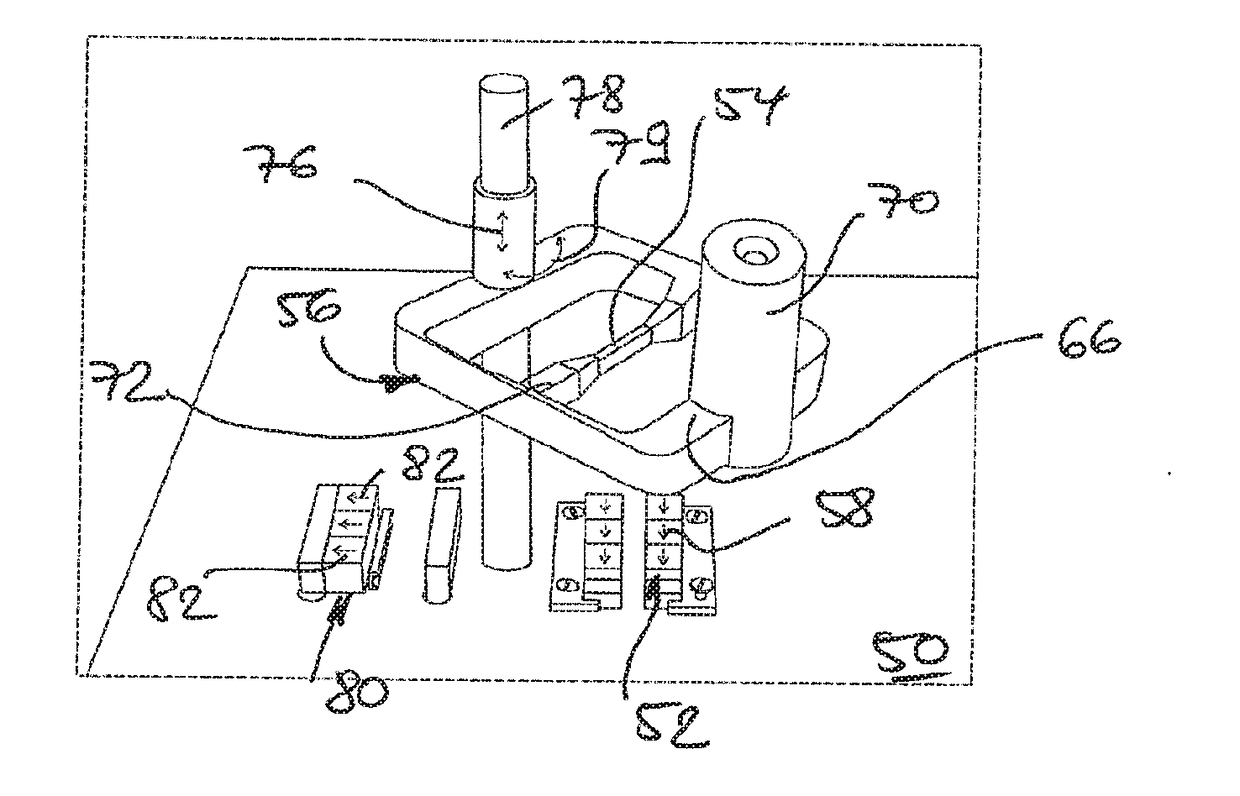

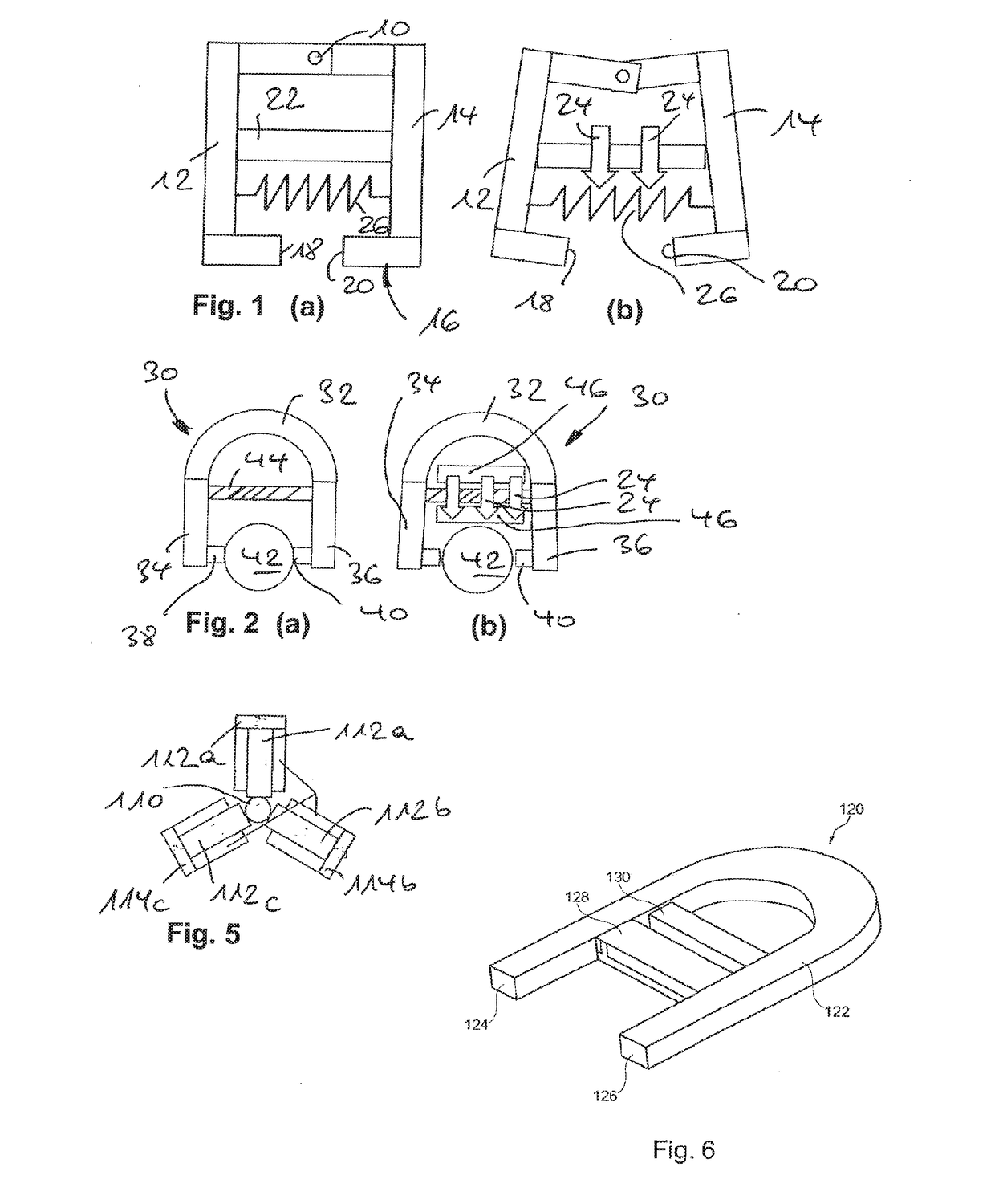

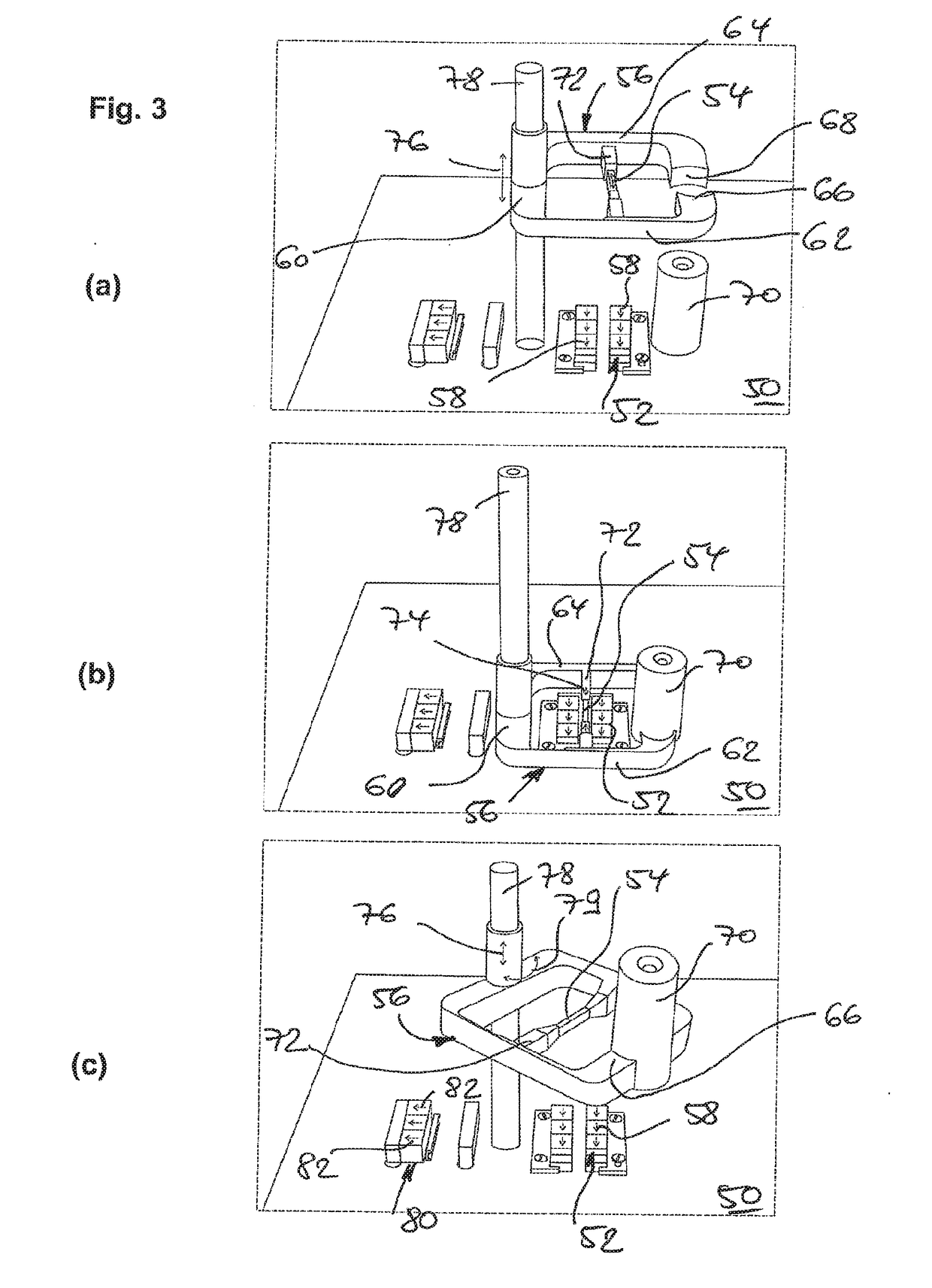

[0027]Possible basic configurations of the present invention (not exhaustive with regard to the breadth of variants) are explained with the aid of FIGS. 1 and 2. Thus, a gripper device schematically shown in the first example of embodiment of FIG. 1 has a gripper 16 formed by two gripping arms 12, 14, which are connected to one another such that they can pivot about a joint 10, and which by means of a pair of jaw sections 18 and 20 formed on the free ends of the arms 12, 14 have contact sections for purposes of interaction with a workpiece (not shown in FIG. 1).

[0028]An MSM crystal body 22, which is designed in the elongated manner as shown from an NiMnGa alloy exhibiting a magnetic shape-memory behaviour, connects the arms 12, 14 such that a magnetic field (arrows 24 in FIG. 1(b)) that is introduced transversely to the direction of extension of the actuator element 22 effects an expansion of the MSM crystal along the direction of extension. In the manner shown, this variation in le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com