Flux-enhanced energy harvesting from current-carrying conductors

a current-carrying conductor and current-enhanced technology, which is applied in the direction of inductance, power distribution line transmission, transportation and packaging, etc., can solve the problems of short-term power sources, inability to provide the ongoing power required for most devices, and limited life of batteries, so as to increase the output voltage and power of the coil. , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

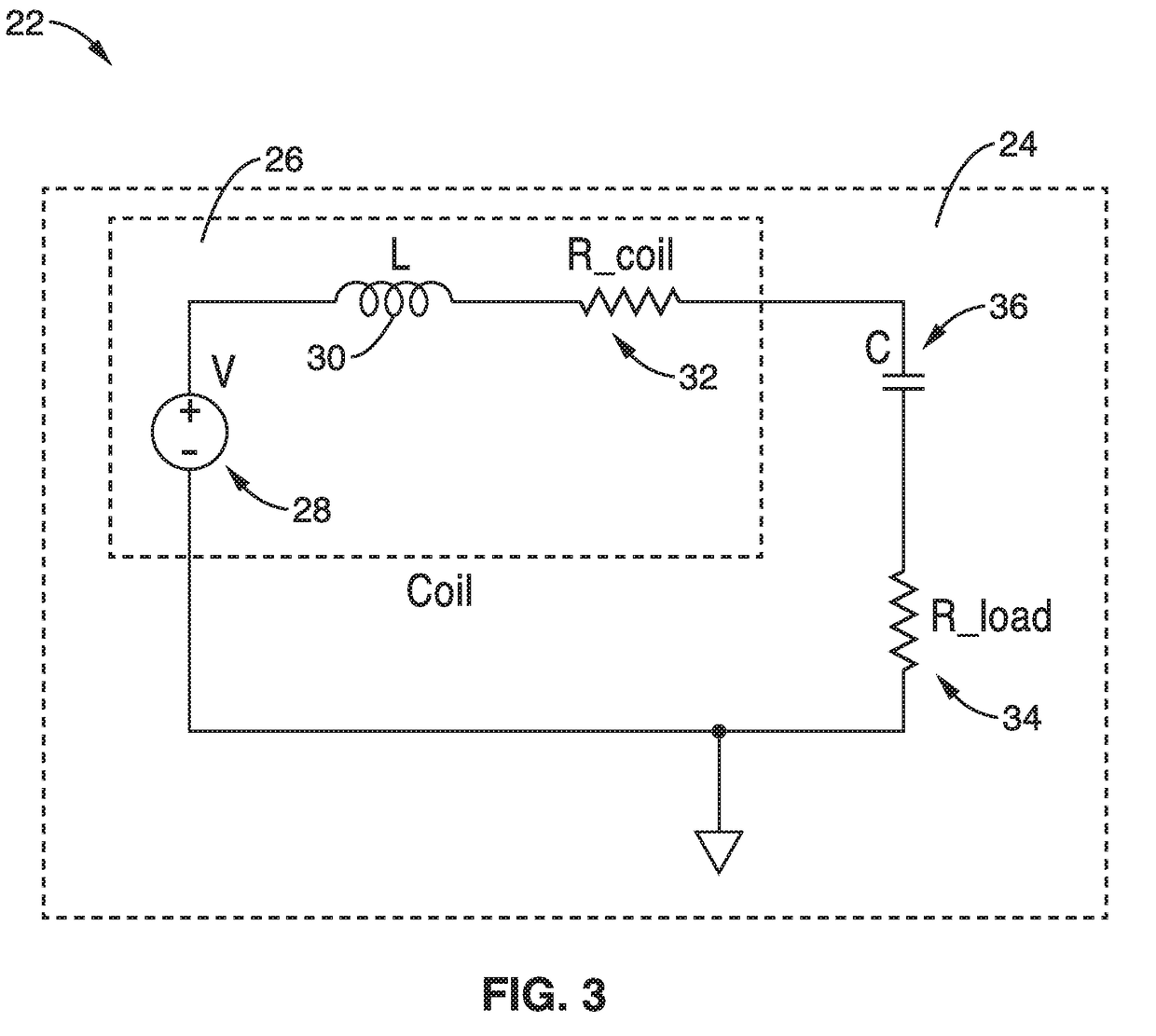

[0047]In order to demonstrate the operational principles of the apparatus and system, an energy harvester with a circuit shown generally in FIG. 4 with coils configured as shown generally in FIG. 2 was fabricated for testing.

[0048]One can model coils (e.g., with COMSOL) to find designs that maximize their open-circuit voltage, or that maximize their power output when the coil is loaded. Because flux condensers are coupled magnetically to the coil the coil's measured inductance will change, and therefore the optimum capacitance will change. The changing coil inductance that is observed upon testing can provide some indication of the effectiveness of a given flux condenser.

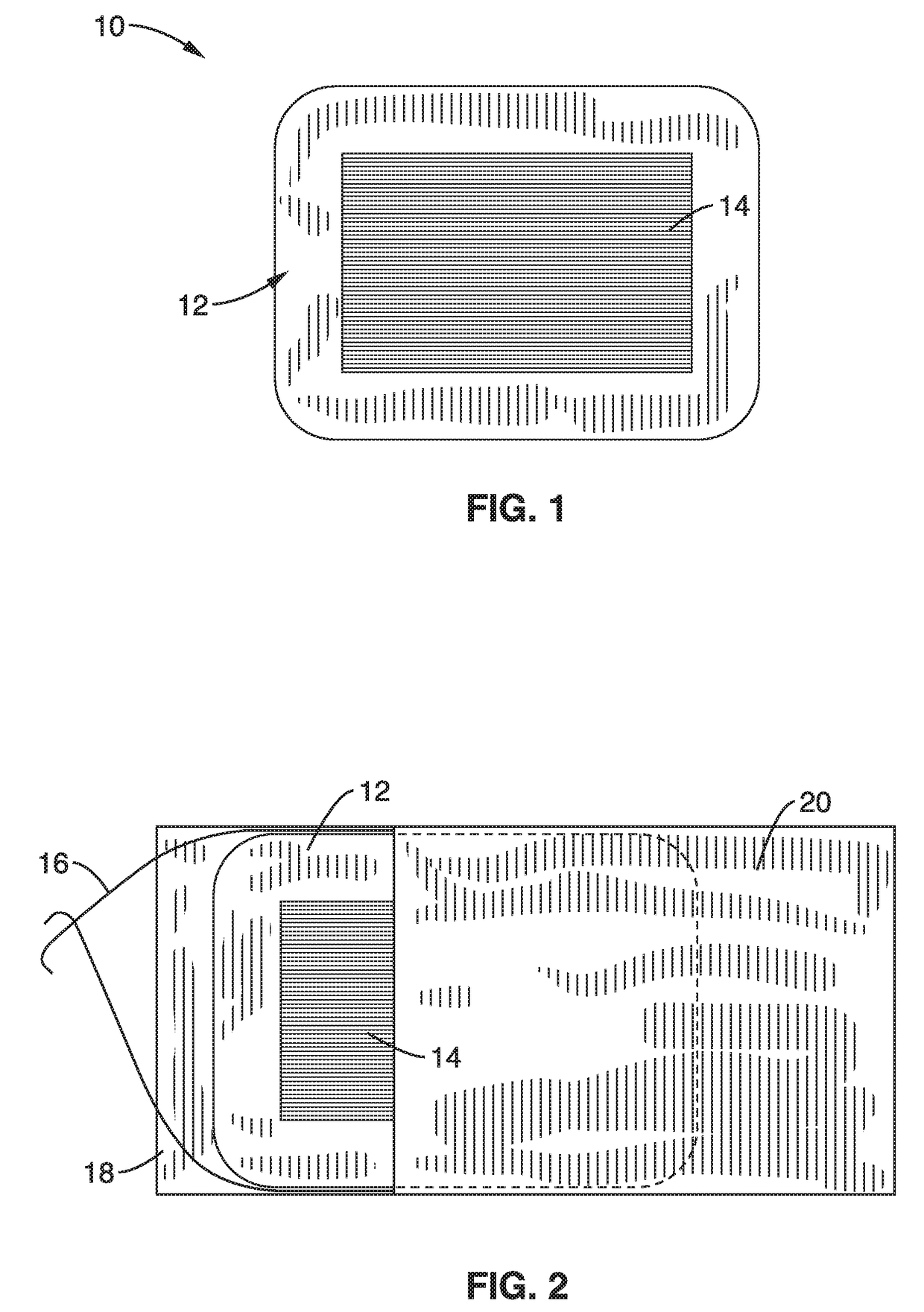

[0049]The coil that couples to the magnetic field produced by the powerline current (which, according to the Right-Hand Rule, encircles the current-carrying powerline conductor) can be made in three different ways. The first coil design was made by winding the wire of the coil on a non-magnetic form, producing an ai...

example 2

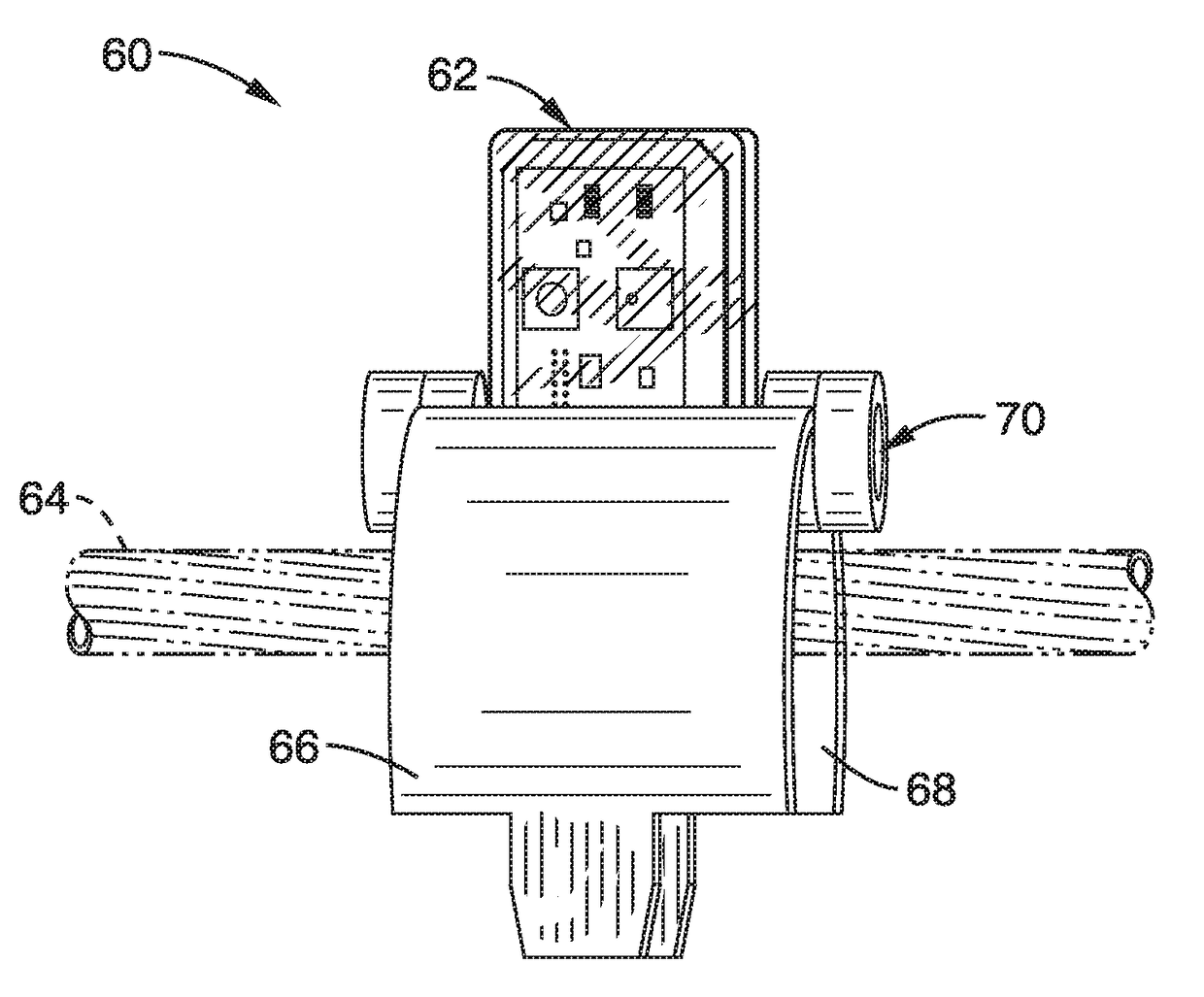

[0057]To further illustrate the apparatus and system, a printed circuit board with two commercial chemical vapor sensors along with a small radio chip to receive control signals and to transmit measured data. The harvester / sensor / radio embodiment is shown attached with conventional cable ties to a jacketed power distribution cable used for underground power distribution systems in FIG. 7 or to a typical bare aluminum overhead distribution power-line conductor in FIG. 8.

[0058]Since the harvester operates by coupling to the magnetic field near a current-carrying conductor, no ohmic contact need be made between the harvester and the conductor. Thus, the coil-based energy harvester, and sensors and communication devices associated with the harvester, could conveniently be contained in a weatherproof non-magnetic enclosure mounted near the conductor. As seen in the embodiment of FIG. 7 and FIG. 8, an inexpensive commercial plastic box was used to contain a harvester coil with a printed-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com