Firearm noise and flash suppressor having ratcheted collet locking mechanism

a technology of collet locking mechanism and suppressor, which is applied in the field of firearms, can solve the problems of affecting the sound and flash of the flash, the noise of the collet being ratcheted, and the threaded connection becoming difficult to separate, so as to reduce the propellant gas pressure, improve the attenuation of the sound and flash, and reduce the noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

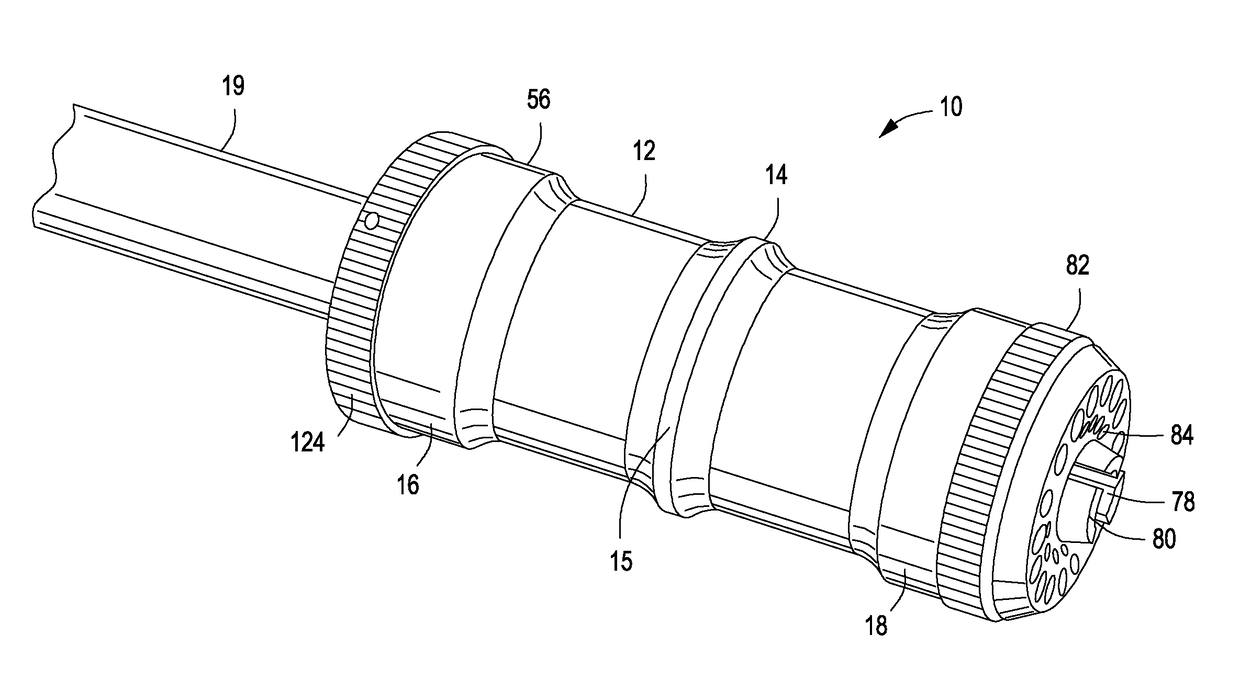

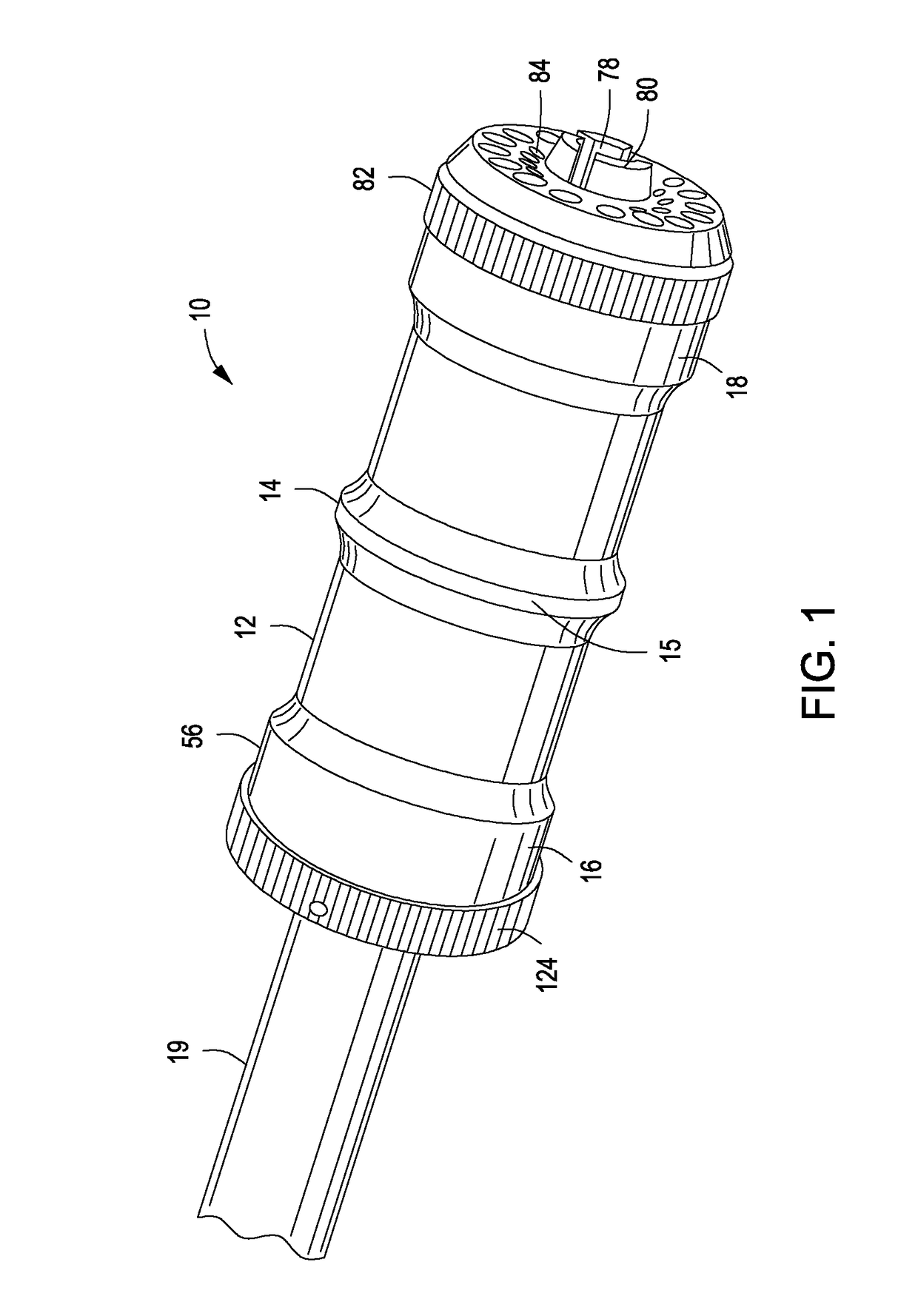

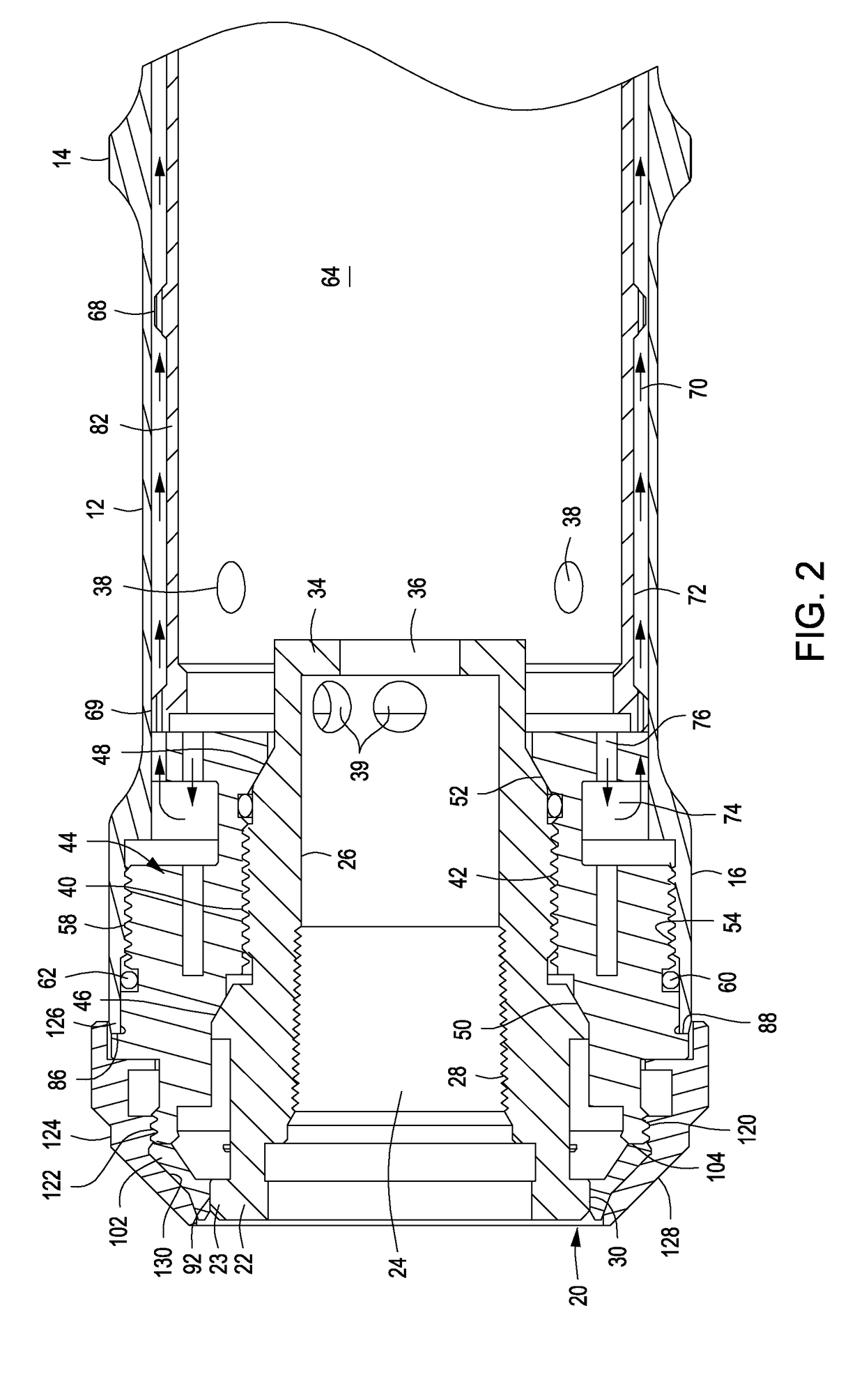

[0033]Referring now to the drawings and first to FIG. 1, a sound and flash suppressor embodying the principles of the present invention is shown generally at 10 and includes a generally cylindrical housing 12 having at least one annular intermediate structural ridge 14 to enable the housing to withstand the internal pressure that occurs when a firearm cartridge is discharged. The structural ridge and other external enlargements of the suppressor housing are knurled as shown at 15 to facilitate ease of rotational assembly as the suppressor is threaded onto a suppressor adapter of a firearm barrel. The housing is also strengthened against damage by cartridge gas pressure by structurally sound annular enlarged end sections 16 and 18 which are also externally knurled. The sound and flash suppressor 10 is shown in FIG. 1 to me mounted to the forward or muzzle end of a gun barrel 19 to which a suppressor mounting adapter 20 is secured.

[0034]Within the suppressor housing 12 there is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com