Variable-capacity compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

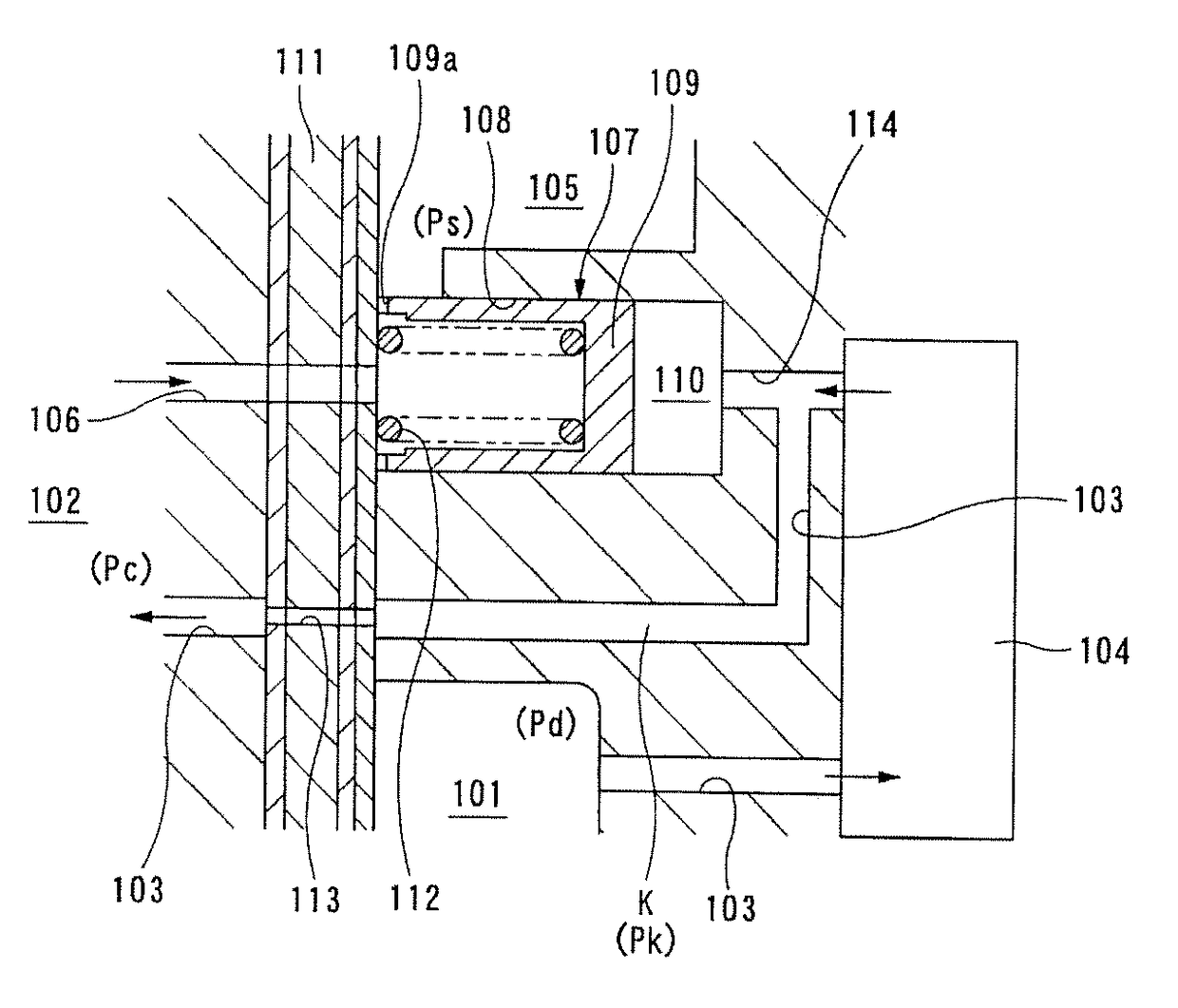

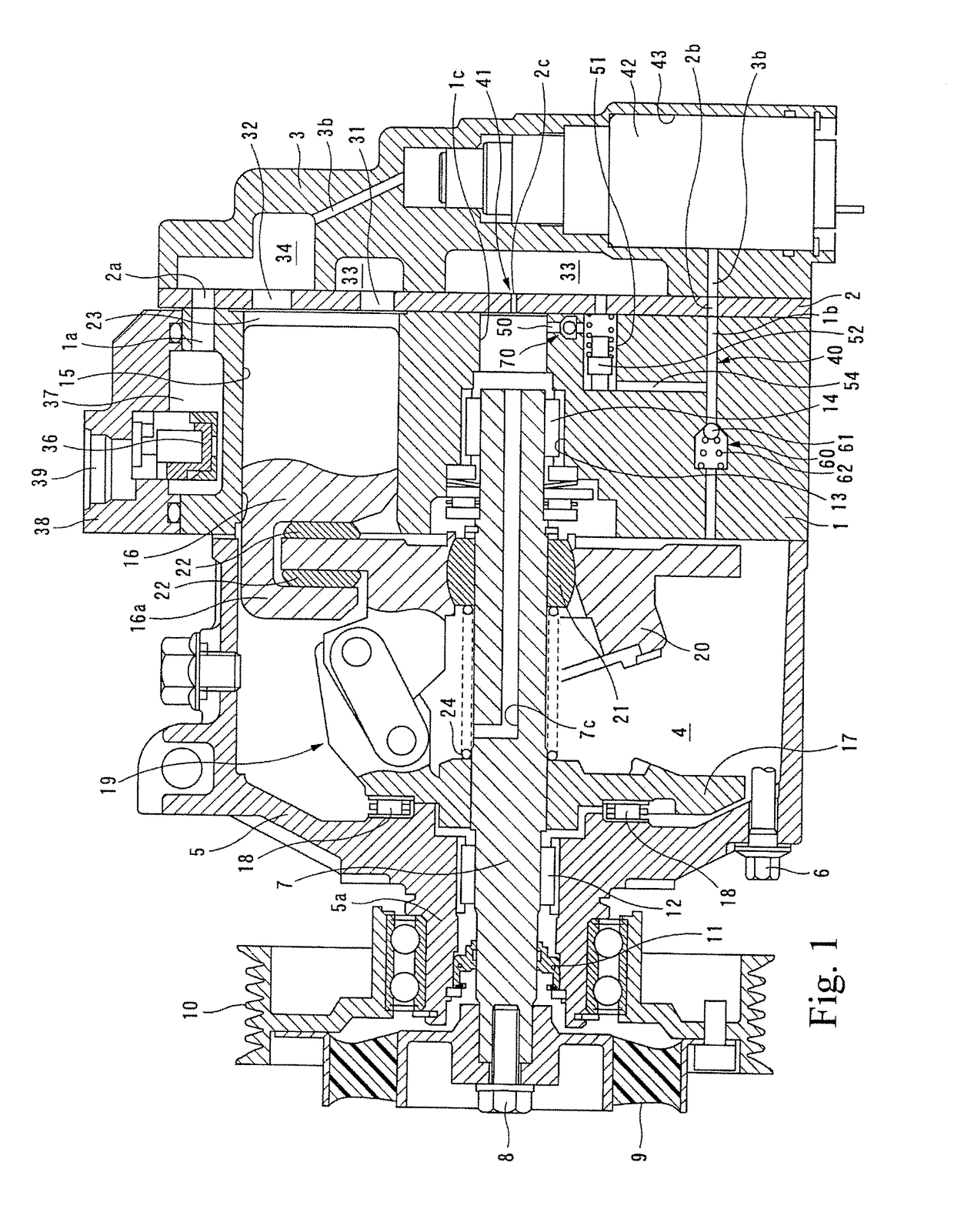

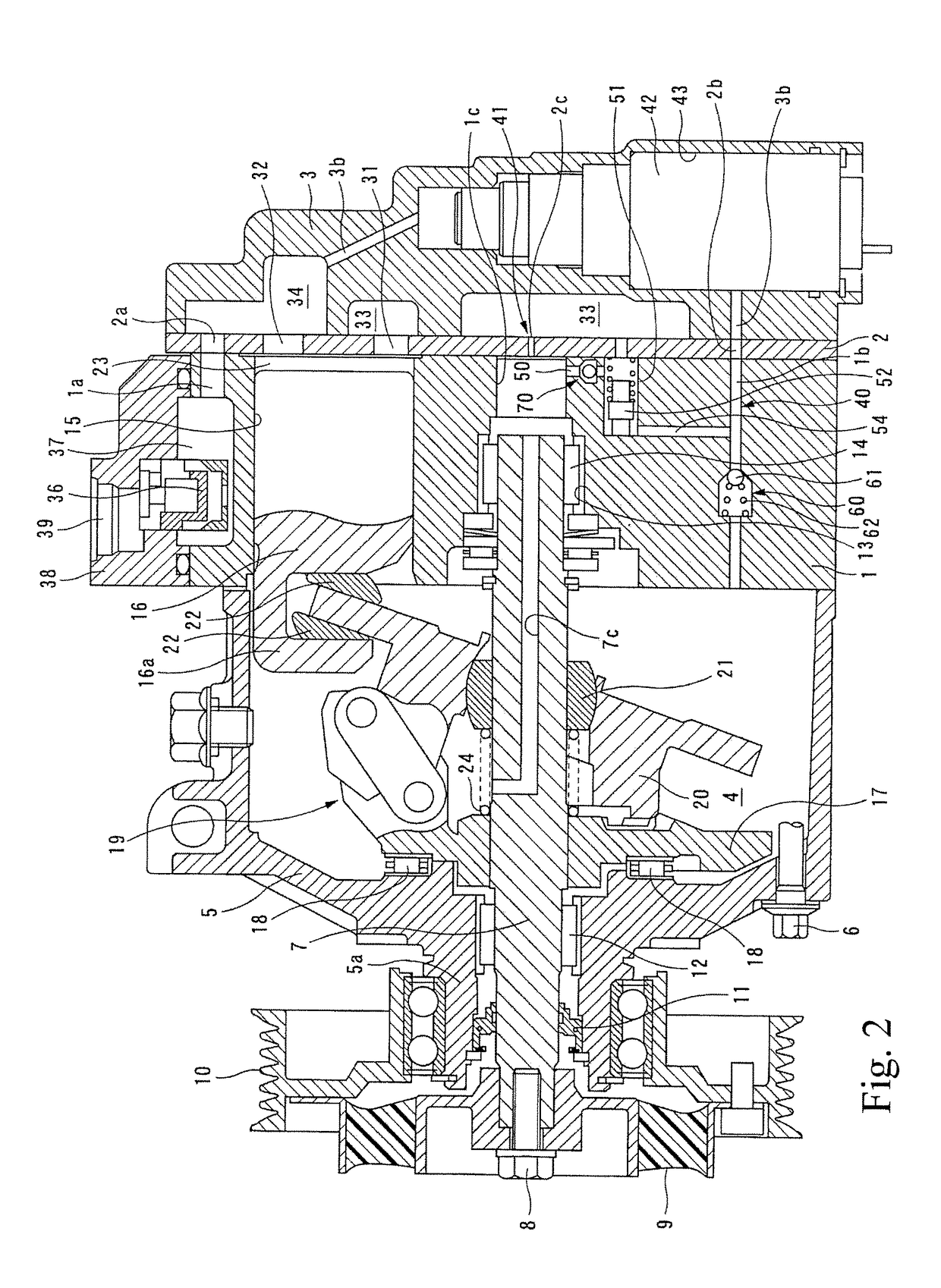

[0044]Hereinafter, an embodiment of the present invention will be explained with reference to attached drawings.

[0045]In FIG. 1 to FIG. 3, a clutchless-type variable-capacity compressor that is belt-driven by a power source such as an engine. The variable-capacity compressor includes a cylinder block 1, a rear head 3 assembled to a rear side (right side in the drawing) of the cylinder block 1 through a valve plate 2 and a front head 5 assembled so as to block a front side (left side in the drawing) of the cylinder block 1 to demarcate a control pressure chamber 4, and these front head 5, the cylinder block 1, the valve plate 2 and the rear head 3 are fastened in an axial direction by a fastening bolt 6 to form a housing of the compressor.

[0046]A drive shaft 7 one end of which protrudes from the front head 5 penetrates the control pressure chamber (also referred to as a crank chamber) 4 demarcated by the front head 5 and the cylinder block 1. A drive pulley 10 fitted onto a boss port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com