Substrate structure and manufacturing method thereof

a technology of substrate structure and manufacturing method, which is applied in the direction of semiconductor devices, semiconductor/solid-state device details, electrical apparatus, etc., can solve the problems of difficult narrowing the aperture of blind holes and inability to achieve circuits with fine pitch, and achieve low-cost and high-electric effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]Reference will now be made to the drawings to describe various inventive embodiments of the present disclosure in detail, wherein like numerals refer to like elements throughout.

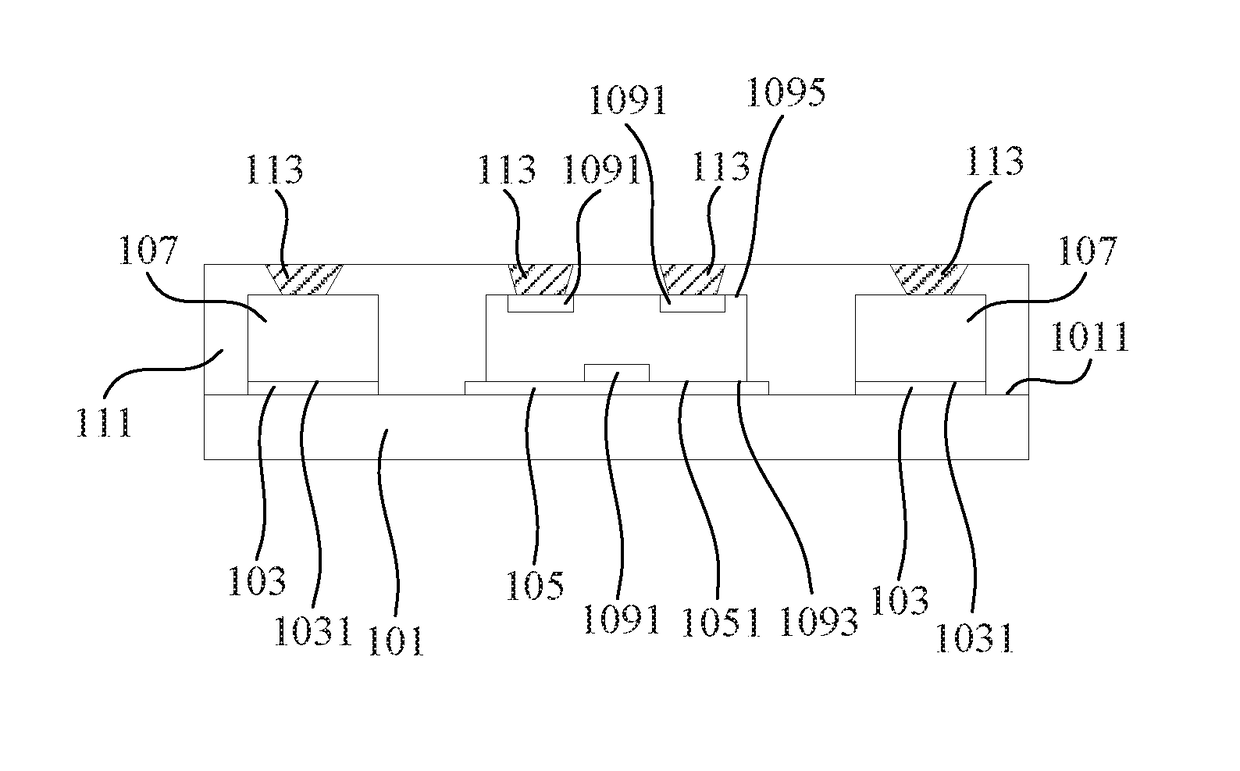

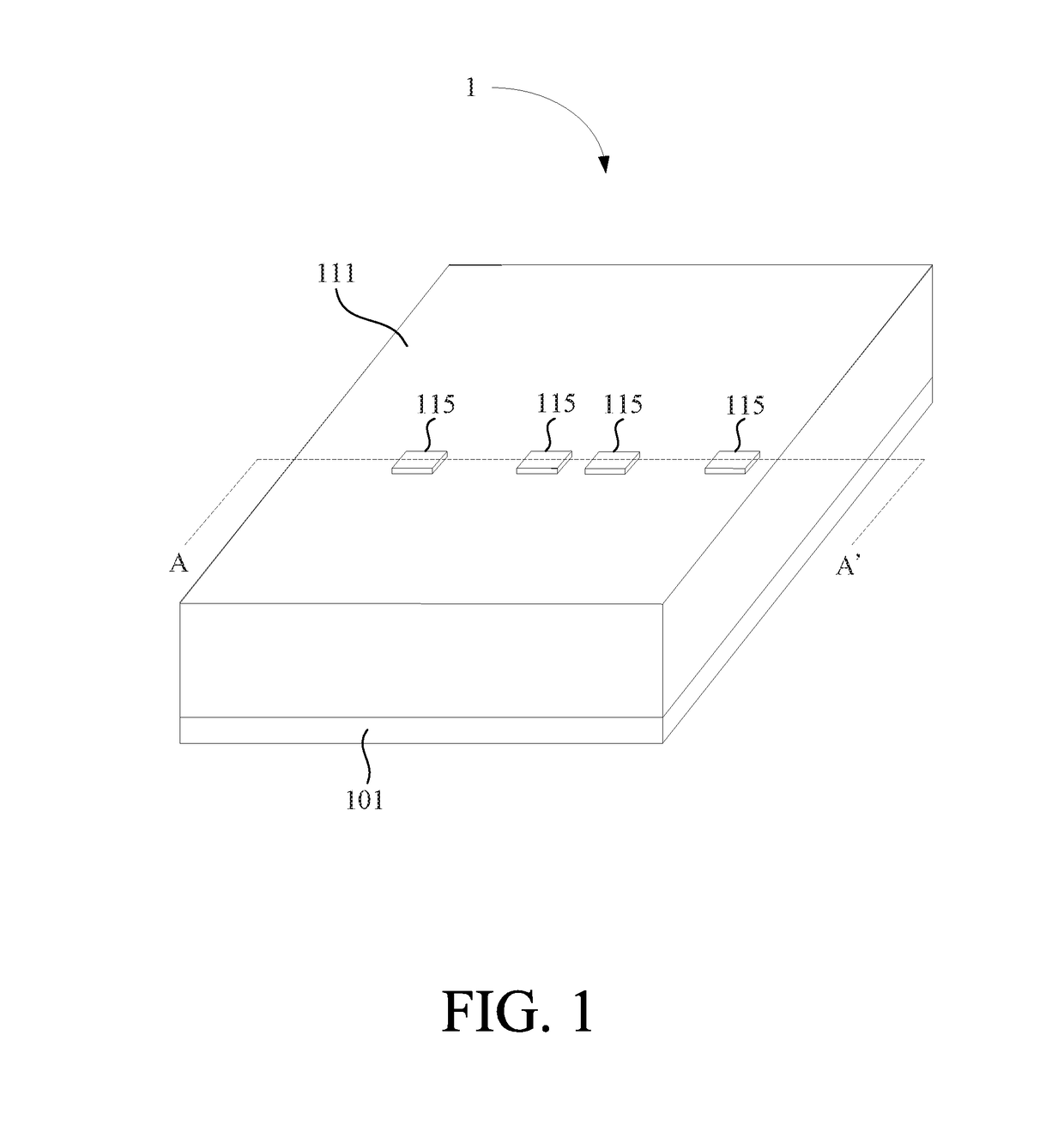

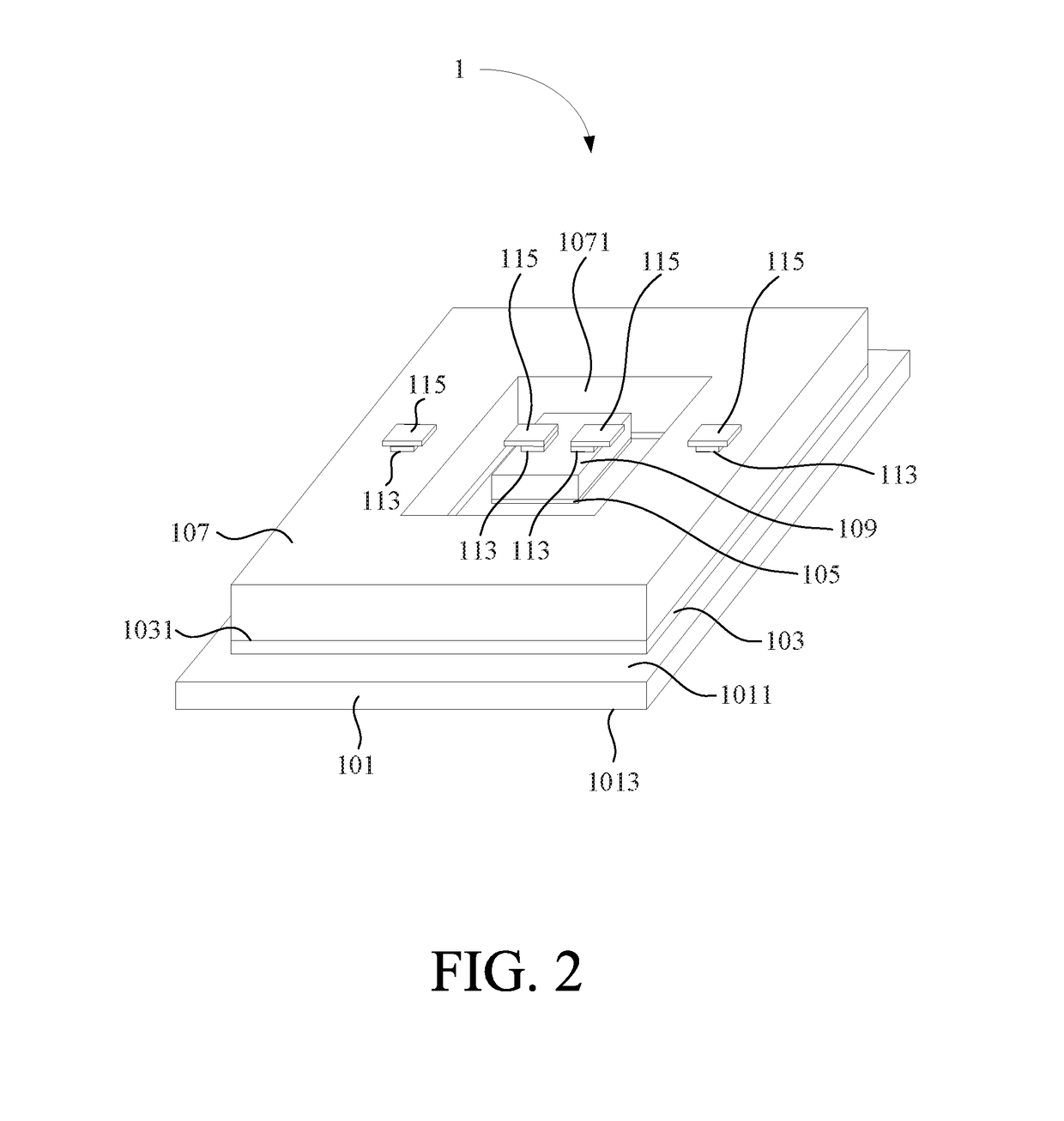

[0030]FIG. 1, FIG. 2 and FIG. 3 depict a first embodiment of the present invention. FIG. 1 is a schematic diagram of a substrate structure 1 andFIG. 2 is a schematic diagram of a part of substrate structure 1. FIG. 3 is a sectional diagram of A-A′ line of FIG. 1. The substrate structure 1 comprises a metal substrate 101, a first connection layer 103, a second connection layer 105, a metal core layer 107, an internal component 109, a dielectric material layer 111, a conductive pillar layer 113 and a conductive wiring layer 115. The metal substrate 101 has a first surface 1011 and a second surface 1013. The first connection layer 103 has a surface 1031. The second connection layer 105 has a surface 1051. The metal core layer 107 has an opening 1071. The internal component 109 has a plurality of electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com