High-performance textured coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

trength Testing

[0081]Powder compositions were prepared as shown in Table 1 and coated on to test specimens at the indicated film thickness. Pullout strength tests were performed according to ASTM A944-10. Results are shown in Table 1.

TABLE 1Pullout Strength% PulloutFilmParticle sizerelative tothicknessPullout perof powderTest SpecimenPullout Nmstandardmmmm (KN)(μm)Uncoated rebar (control)1677————Rebar with corrosion-718.642.90.28256662-70resistant coating (coatedbar)Single layer (textured138182.40.261529130-40coating)Single layer (textured100660.00.310324560-70coating)Single layer (textured1831109.20.3814806 90-100coating)Dual layer (corrosion-2026120.80.33026136 90-100resistant first coating +textured second coating)

example 2

Surface Roughness on Pullout Strength

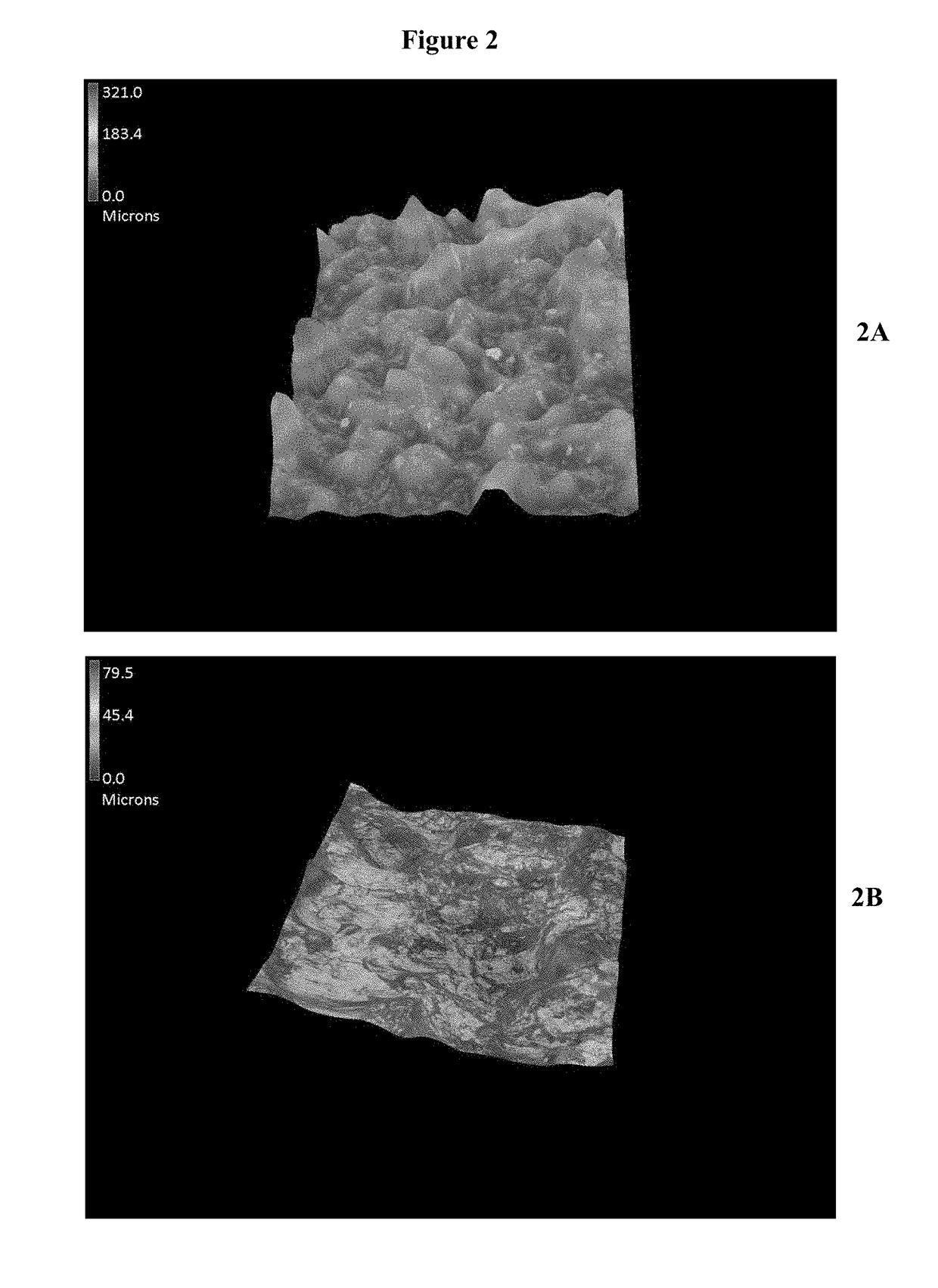

[0082]To determine the effect of surface roughness on pullout strength, metal test bars were coated with formulations #1 to #4 as shown in Table 2. For each test bar, the surface roughness was measured using a light microscope. The surface was imaged as shown in FIG. 2A, which depicts microscope images of a test bar surface with a textured coating applied thereon. FIG. 2B depicts a microscopic image from an uncoated surface.

[0083]For pullout strength testing, each test bar was potted in concrete for pullout testing. A tensile load was applied and each test bar was pulled out of the concrete at a fixed rate. The peak stress for each bar was measured, and results are reported in Table 2. A positive correlation is observed between surface roughness and peak stress.

TABLE 2Surface Roughness and Pullout StrengthSurfaceSampleroughnessPeak stressNo.Description(Sz; μm)(KPa)1Bare metal; blasted (control)79.515842Corrosion-resistant coating (smooth)166.9148...

example 3

Surface Roughness on Adhesion to Concrete

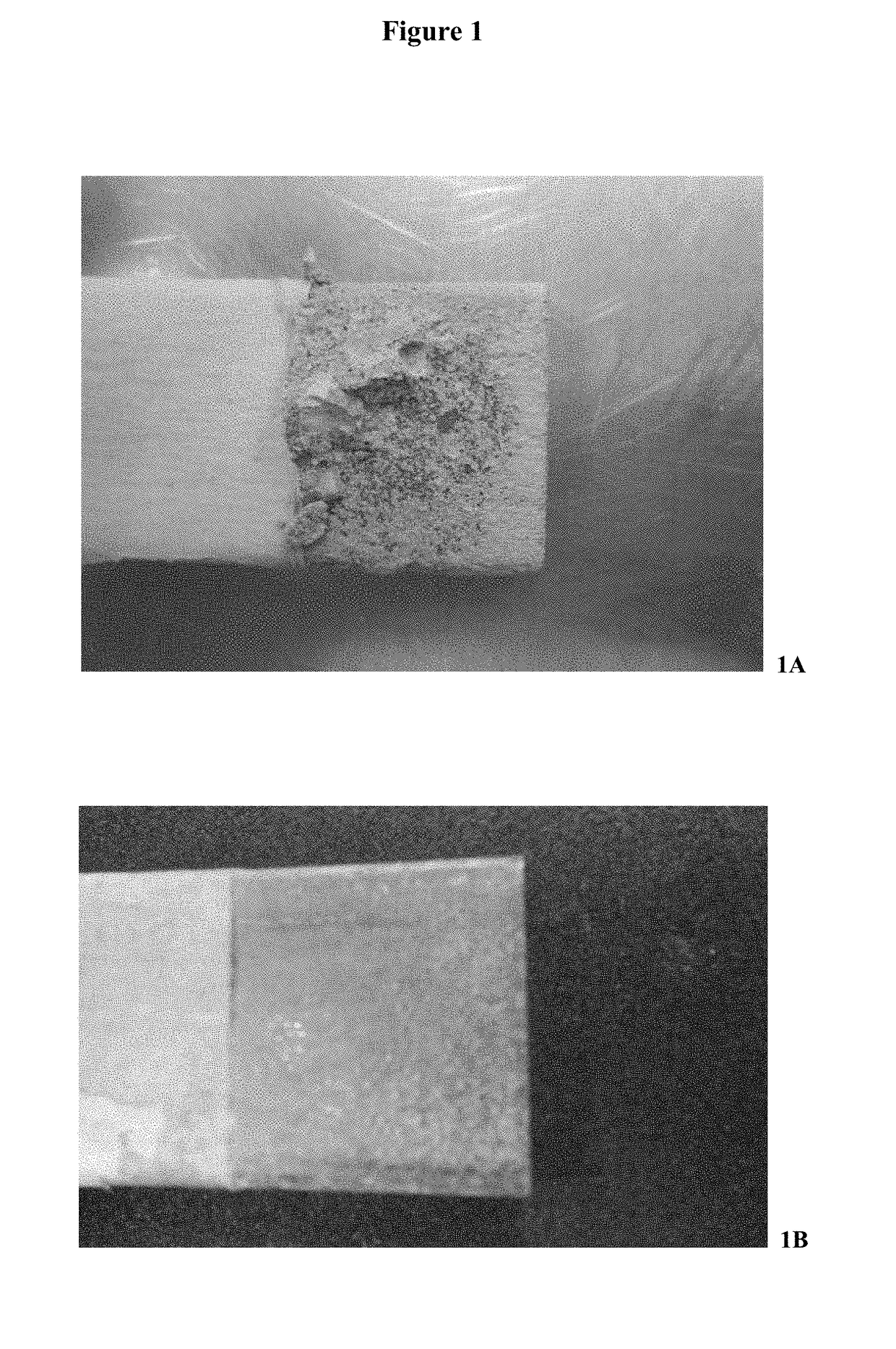

[0084]To demonstrate the effect of surface roughness on the adhesion of a coated metal bar to concrete, powder coating formulations #1 to #4 (as shown in Table 2) were applied to metal test bars and the bars where then potted in concrete. After potting and curing of the concrete, a tensile load was applied and the test bars were pulled out of the concrete at a fixed speed. FIG. 1A depicts a test bar coated with a textured coating and FIG. 1B depicts a test bar with a smooth surface. Concrete remains adhered to the textured coating on the test bar, whereas the test bar with the smooth surface pulls out cleanly from the concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com