Chamber pump and method for operating a chamber pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

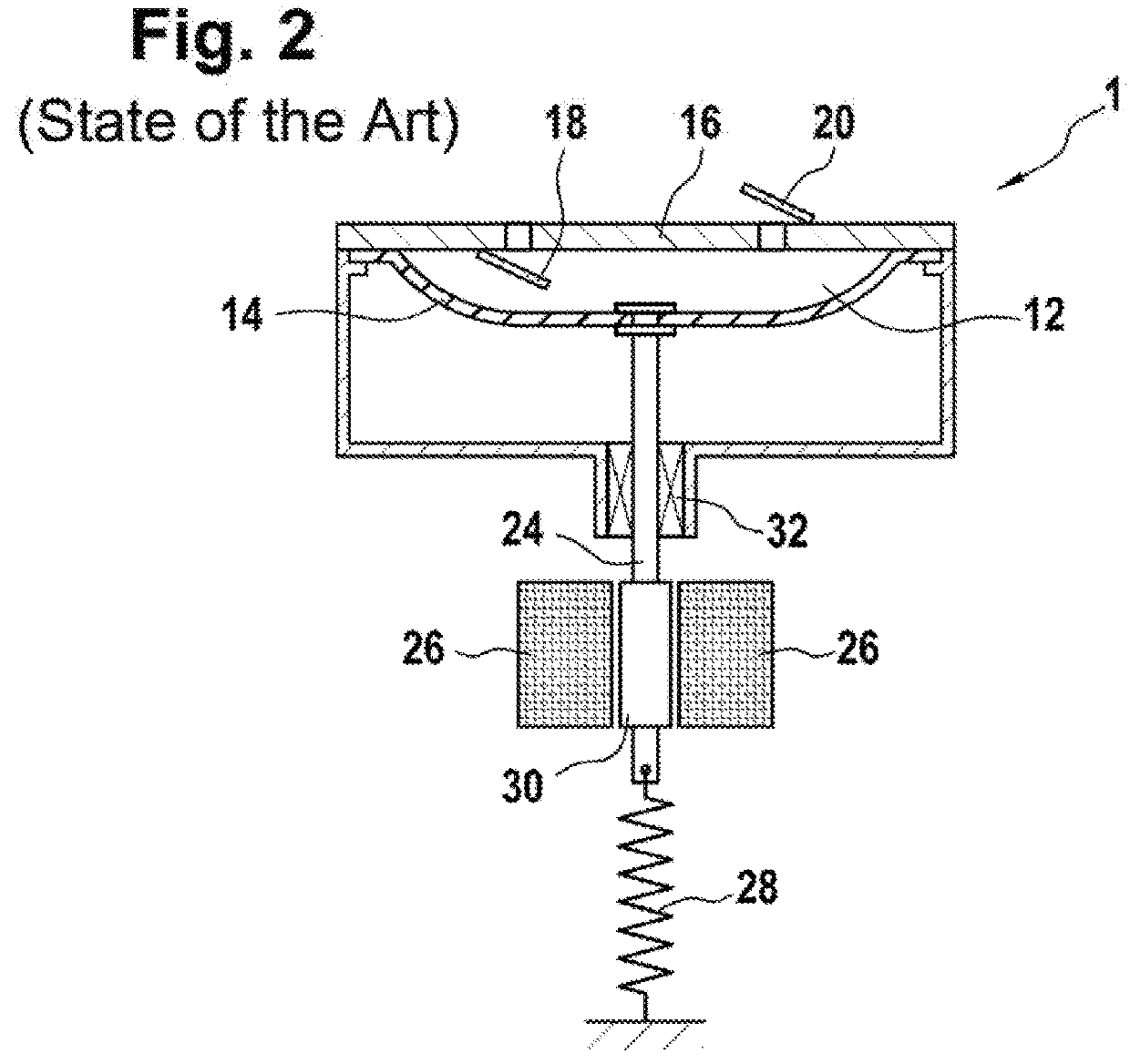

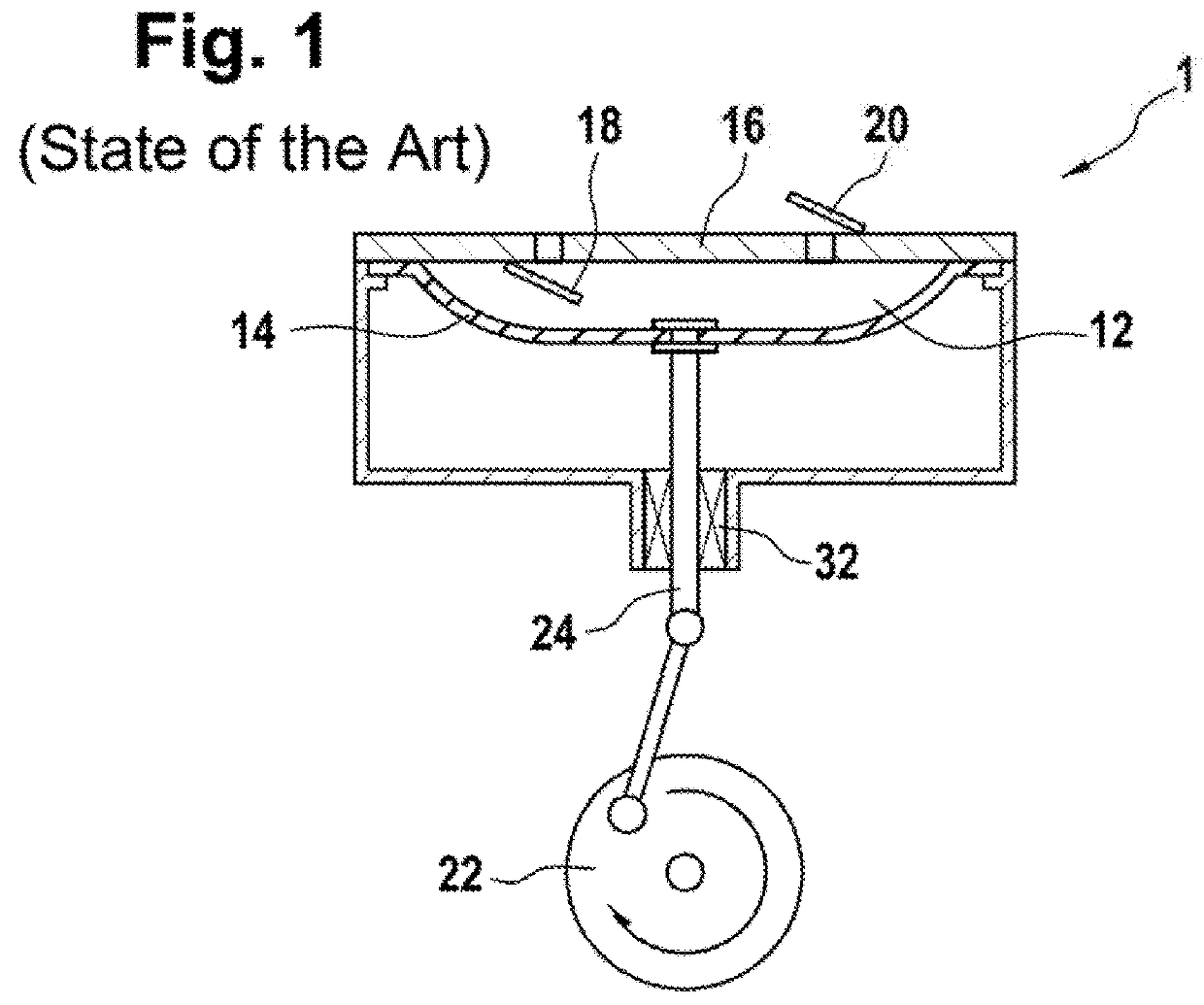

[0041]Referring to the drawings, the views in FIG. 1 and FIG. 2 show in a schematically simplified manner two embodiments of a chamber pump 1, which will hereinafter sometimes also be called pump 1 for short, which embodiments are basically known per se. Each pump 1 has a pump chamber 12, which is defined by an elastic diaphragm 14, on the one hand, and by a housing part 16 of a pump housing, on the other hand, with at least one respective inflow opening and outflow opening formed therein. The diaphragm 14 hereinafter called chamber diaphragm 14 for distinction is connected on the side to the housing part 16. A respective valve 18, 20, which releases or closes the inflow opening or outflow opening synchronously with the pump cycle, is associated with the inflow opening or each inflow opening as well as with the outflow opening or each outflow opening.

[0042]The pump cycle is obtained during the operation of the pump 1 on the basis of a respective drive of the pump 1. A rotating drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com