Apparatus for automatically managing ballast water of ship, and operation method thereof

a technology for automatic management and ballast water, which is applied in the direction of propulsive elements, vessel construction, marine propulsion, etc., can solve the problems of high insurance premium of the ship, inability to navigate, and risk of oil spillage from the ship, so as to prevent the disturbance of the ecosystem, increase the profit of the ship, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Technical Problem to be Solved

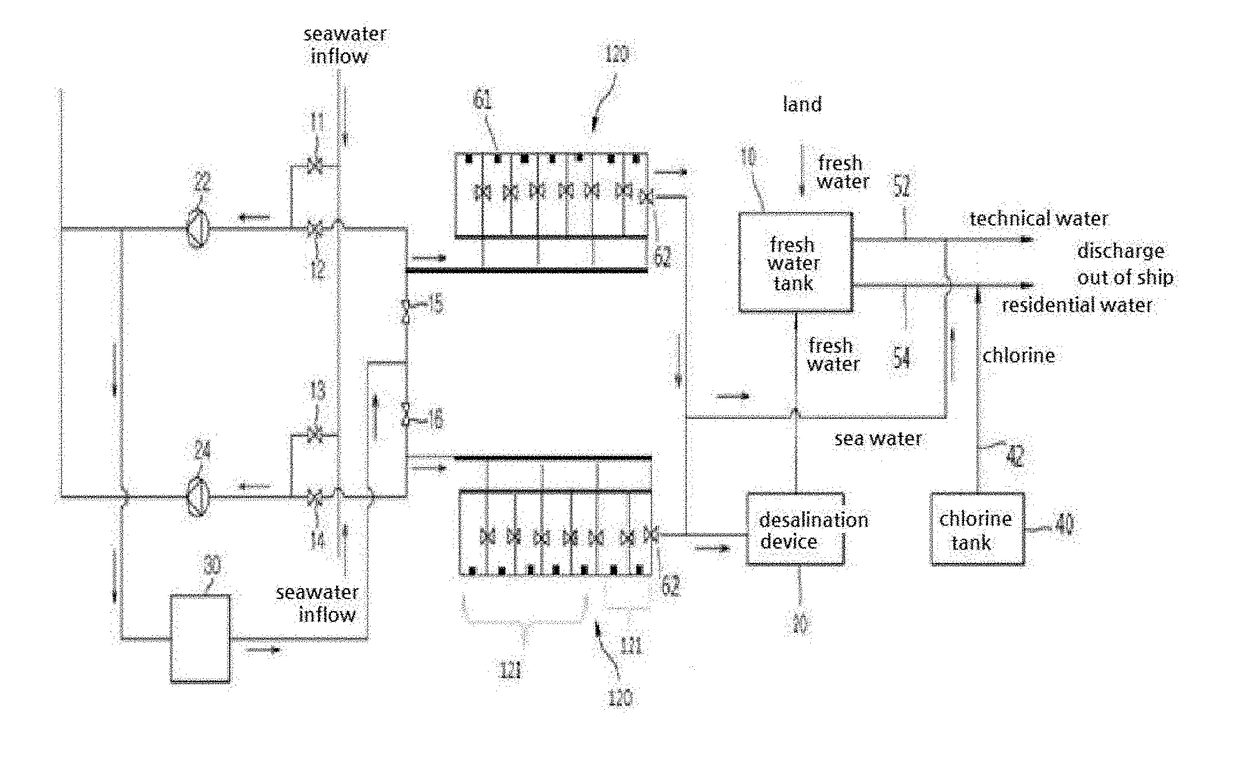

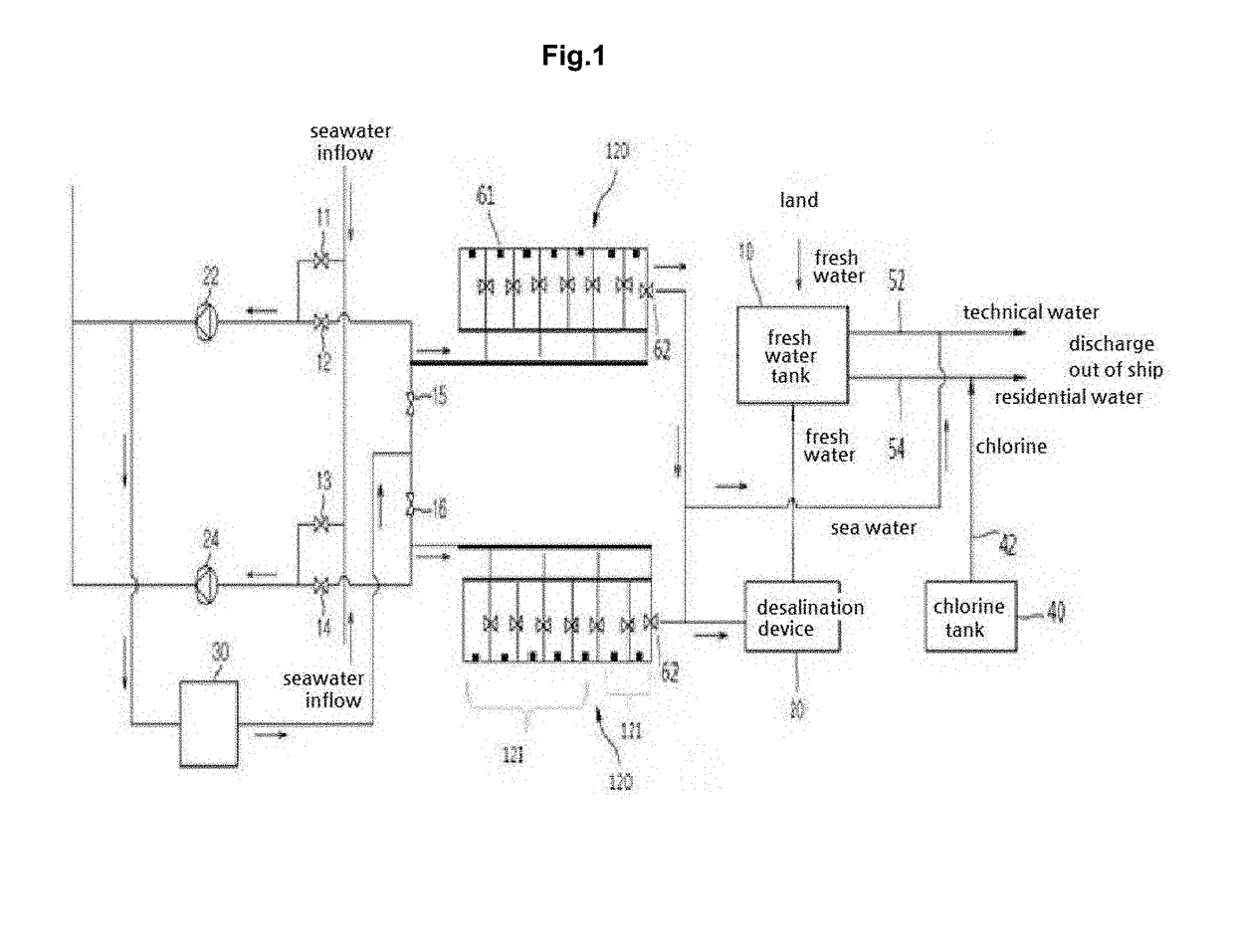

[0023]The present invention is devised for improving the drawbacks of the prior art. The conventional ballast water management system is composed as follows.

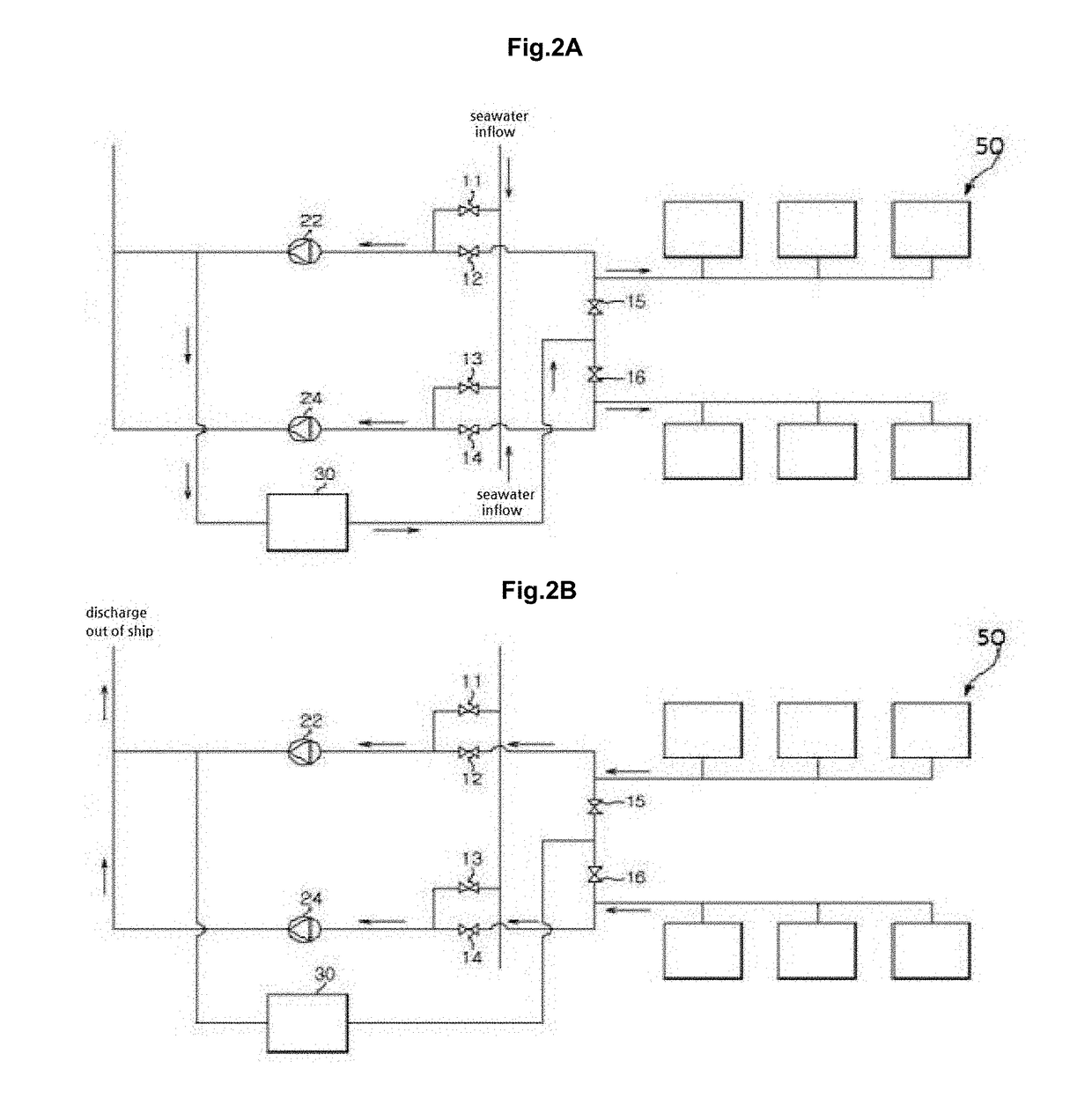

[0024]In ships, seawater is used for various purposes during sailing. In order to use seawater, there is an inlet device (which is called Seachest) for introducing seawater on the bottom or side of the engine room. It is equipped with an open-close unit (valve). When the open-close unit is closed, the watertight structure is formed to prevent the seawater from entering the room. When the open-close unit at the bottom is opened, seawater is introduced by natural pressure, and seawater flows into the ballast water line by the weight of the ship.

[0025]Pumps are installed in the machine room or the pump room to cause the flow of seawater. Generally, electrically operated pumps are used. Through the piping (piping and piping accessories) connected to these pumps and the seawater inlet open-close unit, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com