Transportable breakwater construction block factory contained within an iso-shipping container transportable along shorelines where marine construction sites extend

a technology of iso-shipping container and construction block, which is applied in the direction of climate change adaptation, marine site engineering, construction, etc., can solve the problems of high production cost of units, long casting operation time, and difficult to meet the requirements of construction sites, so as to reduce surface erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

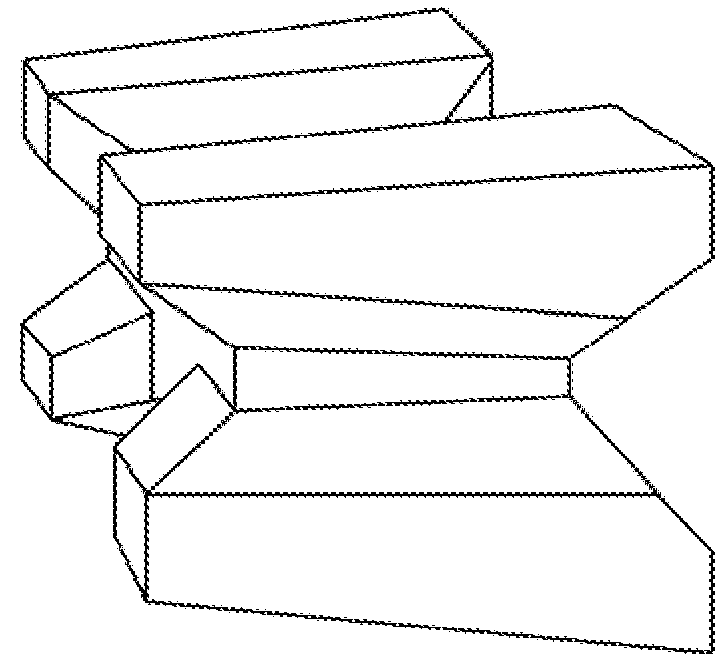

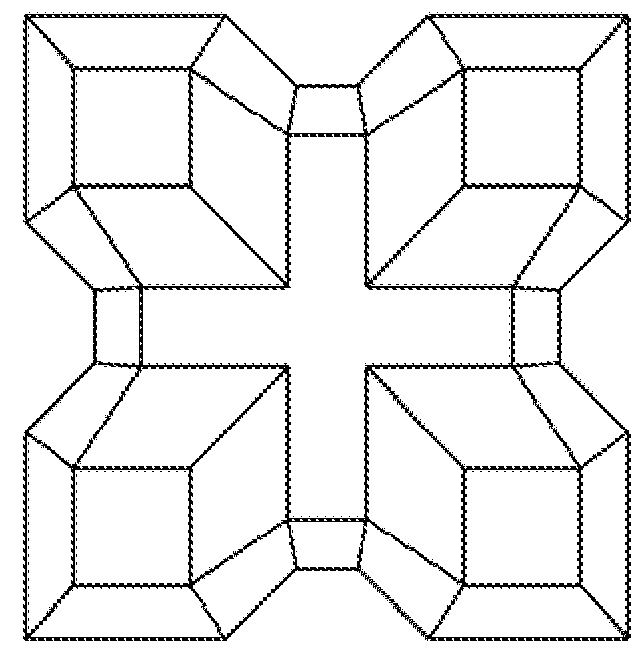

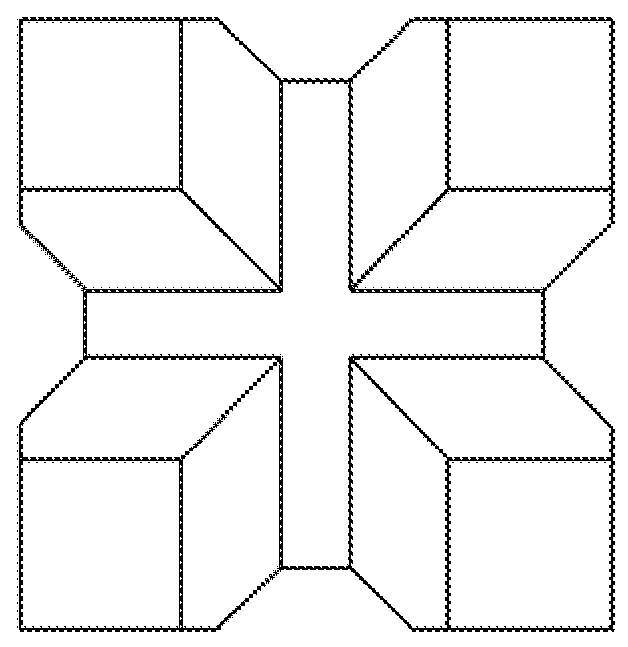

[0317]FIG. 40B shows the multi-tiered seawall erosion-protection system 260′ depicted in FIG. 40, installed upon a bed or crushed rock or stone 263 on the inclined surface of the coastal region, constructed from multiple continuous rows of 2-ton flat-top breakwater construction blocks 1F shown in FIGS. 14A through 14E with truncated leg portions tailored to the incline surface, and interconnected by interlocking shear key blocks 10A shown in FIGS. 28A through 28D, the purpose of which is to protect against erosion (i.e. scouring) of shoreline along which the multi-tiered seawall subsystem is installed.

third embodiment

[0318]FIG. 40C is a side view of the multi-tiered seawall erosion-protection system 260″ depicted in FIG. 40, comprising (i) a seawall subsystem 261 installed at the top elevation of a coastal incline upon a bed of crushed rock and / or stone 263 and constructed from a continuous row of breakwater construction blocks 1B shown in FIGS. 10B1A through 10B4 arranged leg portion to leg portion and connected together by interlocking shear key blocks 10A shown in FIGS. 28A and 28B having a height substantially equal to the height of the breakwater construction block (e.g. 5′ or so), and (ii) a scour-protection subsystem 262′ installed upon a bed or crushed rock or stone on the inclined surface 263 of the coastal region, disposed in front of the seawall subsystem 261, and constructed from multiple continuous rows of 2-ton flat-top breakwater construction blocks 1F shown in FIGS. 14A through 14E with truncated leg portions tailored to the incline surface, and interconnected by interlocking she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com