Toroidal Plasma Channel with Varying Cross-Section Areas Along the Channel

a technology of toroidal plasma and channel, which is applied in the direction of nuclear reactors, greenhouse gas reduction, etc., can solve the problems of limited plasma device performance, undesirable or uncontrolled gas flow pattern and plasma profile, and plasma device not optimized in the entire plasma channel, so as to reduce the erosion of toroidal plasma channel, increase the dissociation rate of reactive gases, and prolong the effect of product li

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

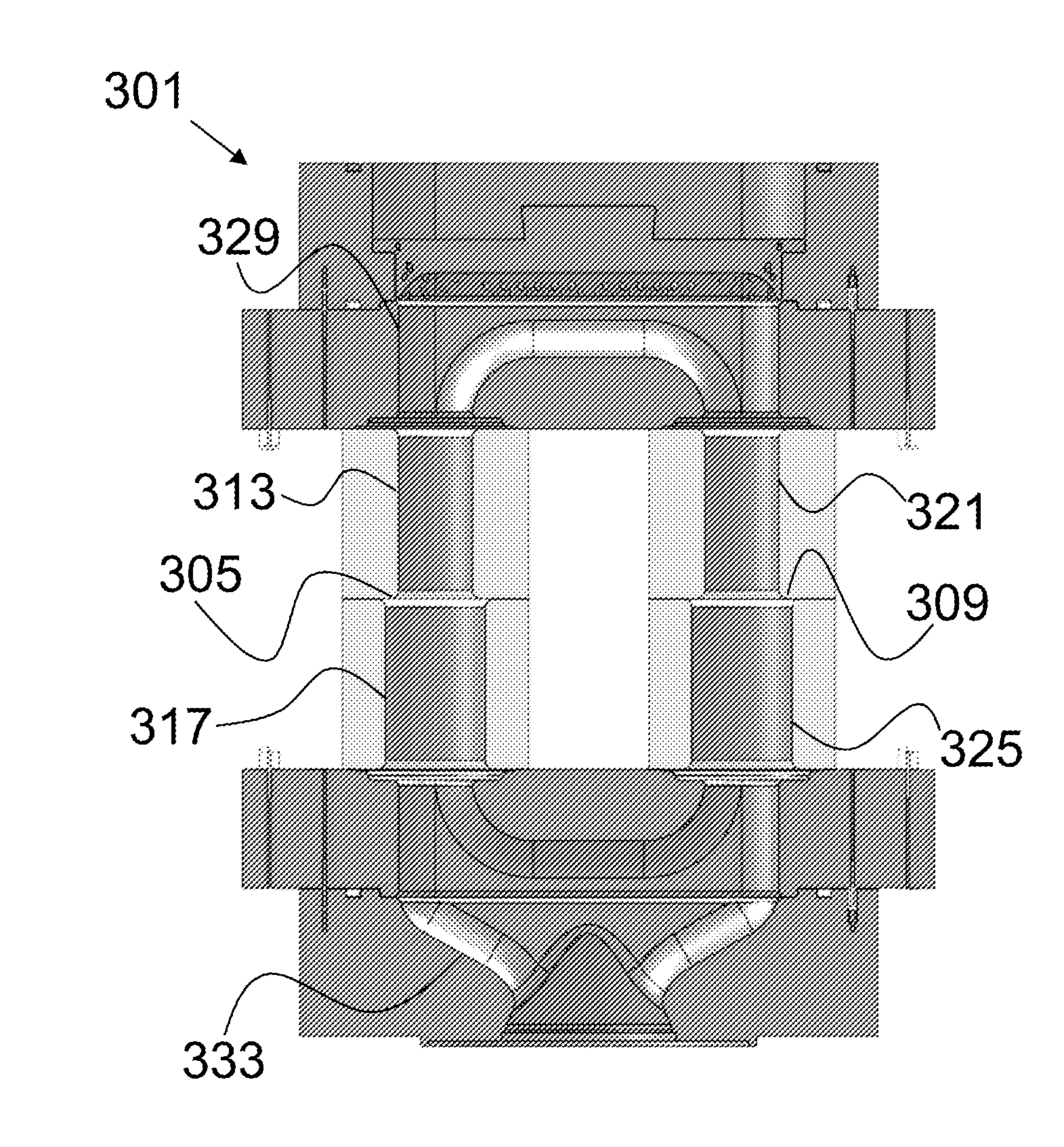

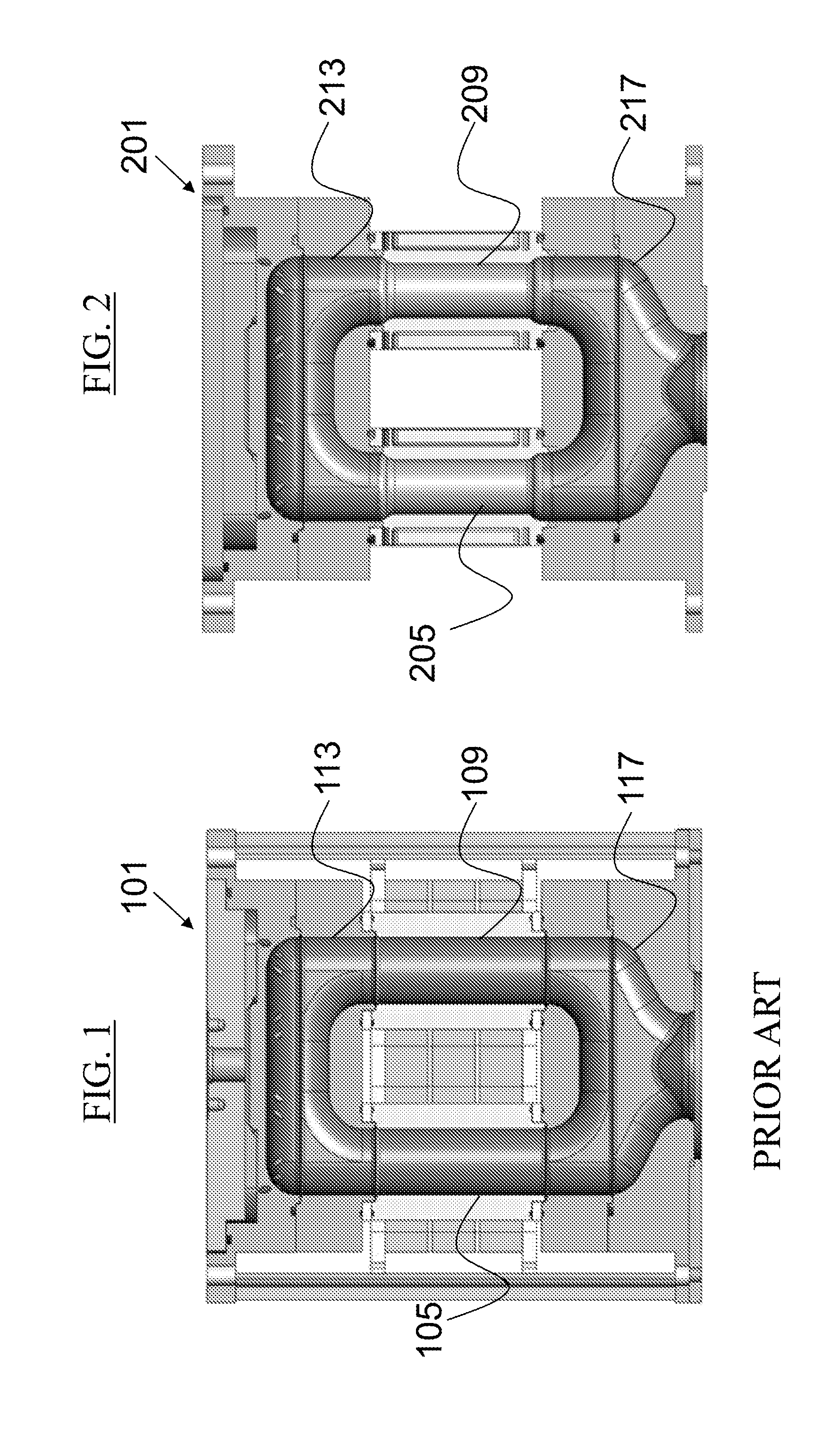

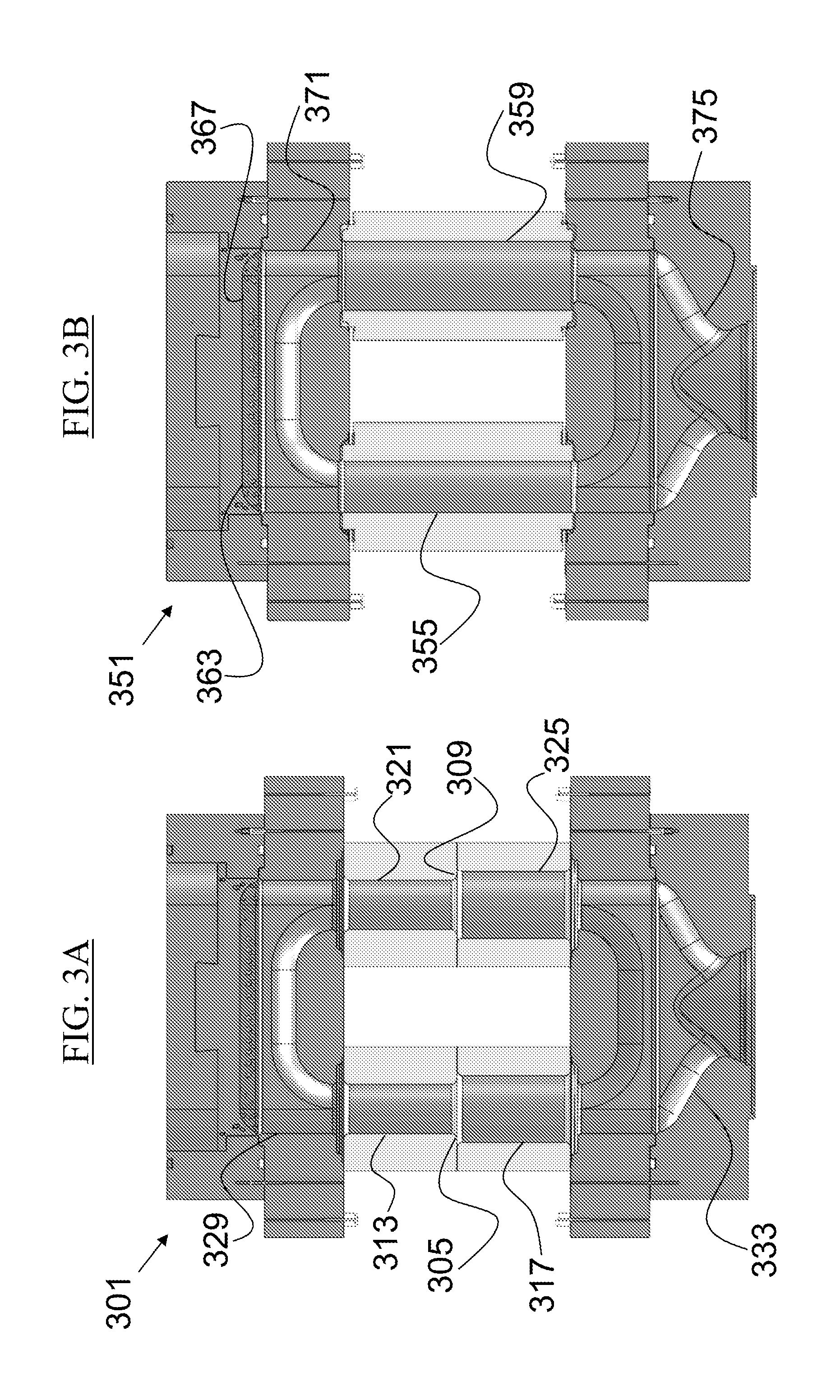

[0030]The present invention provides assemblies, kits, and methods for using toroidal plasma devices to adjust gas flow patterns and gas-plasma interactions. In general, toroidal plasma devices have a toroidal plasma chamber. p FIG. 1 shows a prior art embodiment of a toroidal plasma chamber 101. The toroidal plasma chamber 101 has a first side member 105 and a second side member 109. The toroidal plasma chamber 101 also has an injection member 113 and an output member 117. The injection member 113 is a point of entry where gas is introduced into the toroidal plasma chamber 101. The output member 117 is a point of exit where gas is permitted to exit the toroidal plasma chamber 101. A flow of gas will pass through both the first side member 105 and the second side member 109, encircling a channel inside the toroidal plasma chamber 101.

[0031]In existing toroidal plasma devices, the plasma channels have nearly-uniform cross-section areas. The first side member 105 has a substantially ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com