Crumpled Transition Metal Dichalcogenide Sheets

a technology of transition metal dichalcogenide and sheet metal, which is applied in the direction of electrodes, electrolysis components, electrodes with substrates, etc., can solve the problems of poor stability against nanoparticle coarsening and agglomeration, impose practical limitations, and the functional performance of pt remains inferior, so as to achieve electrochemical stability, reduce the series resistance (rs), and obtain high-efficiency her catalysts. , the effect of high throughpu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

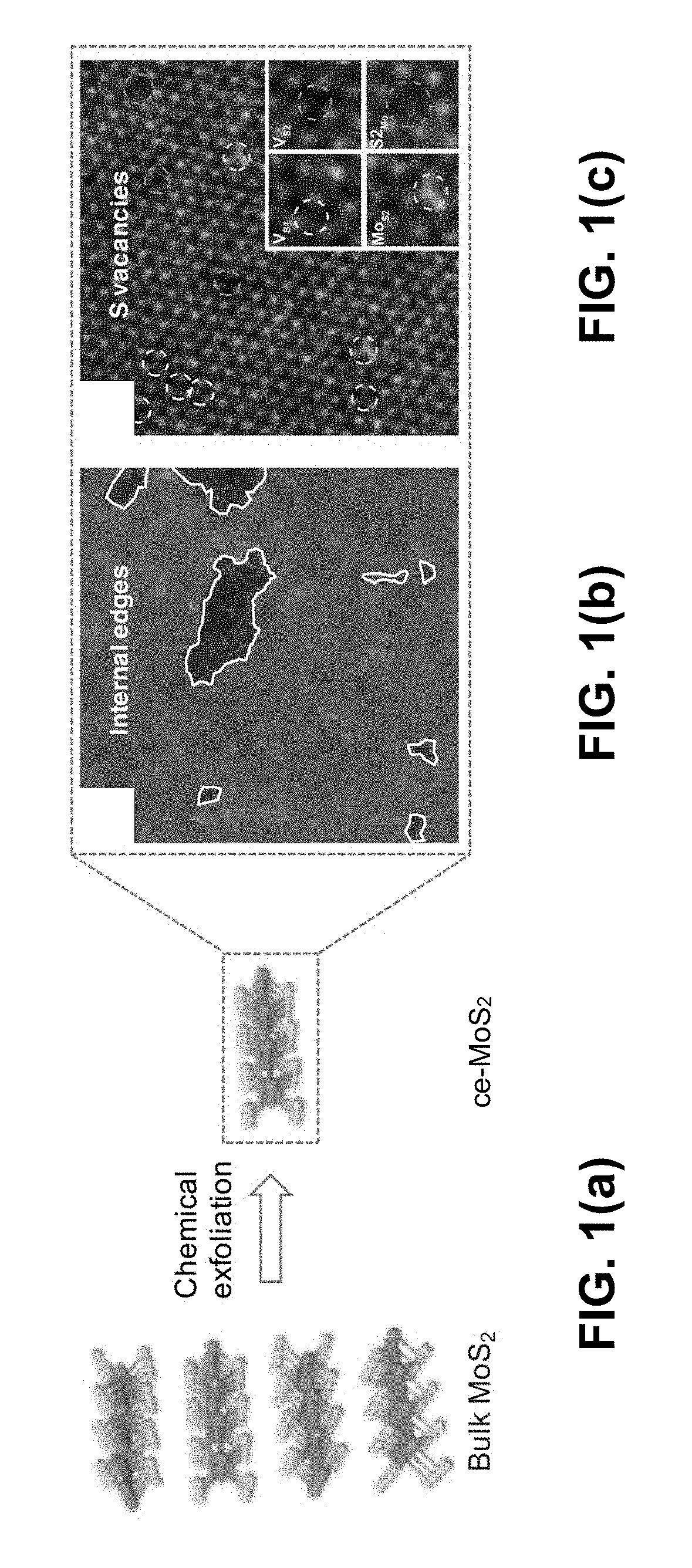

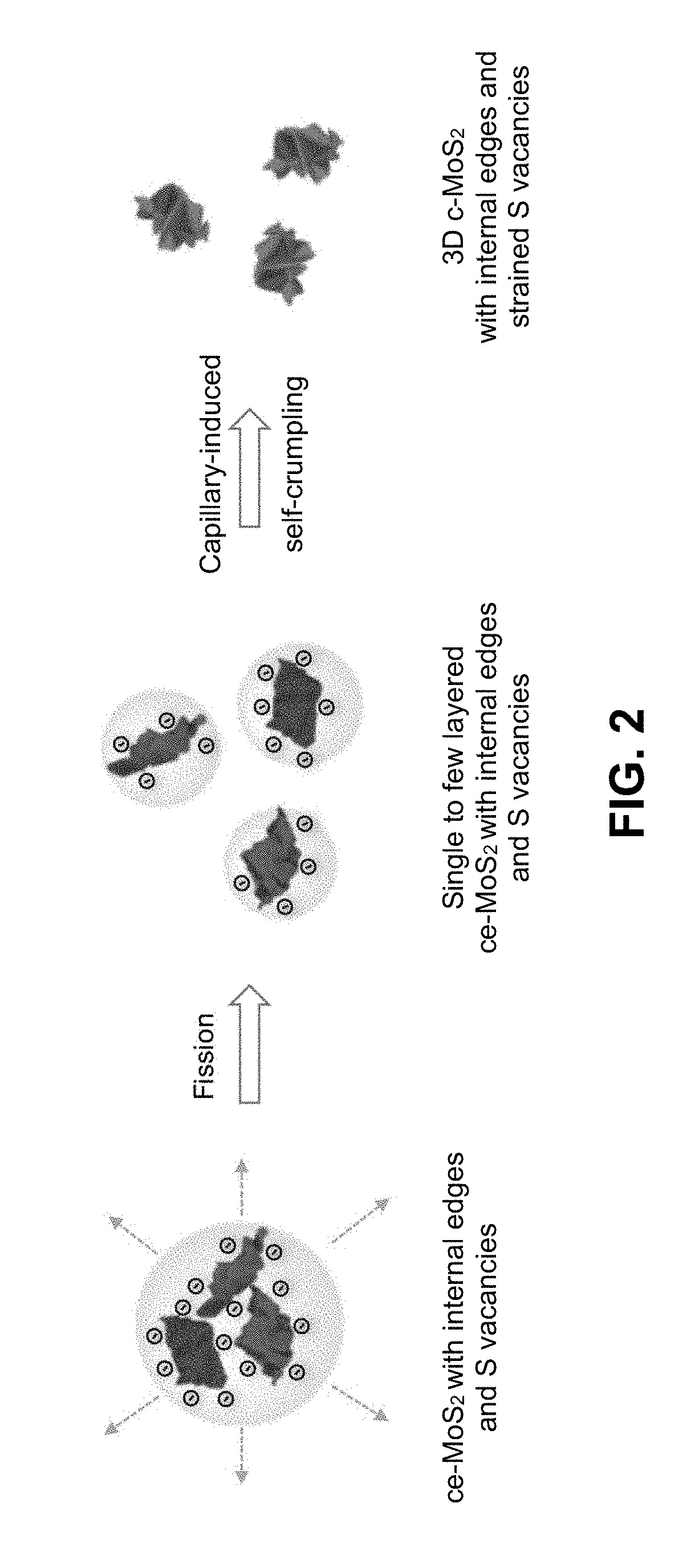

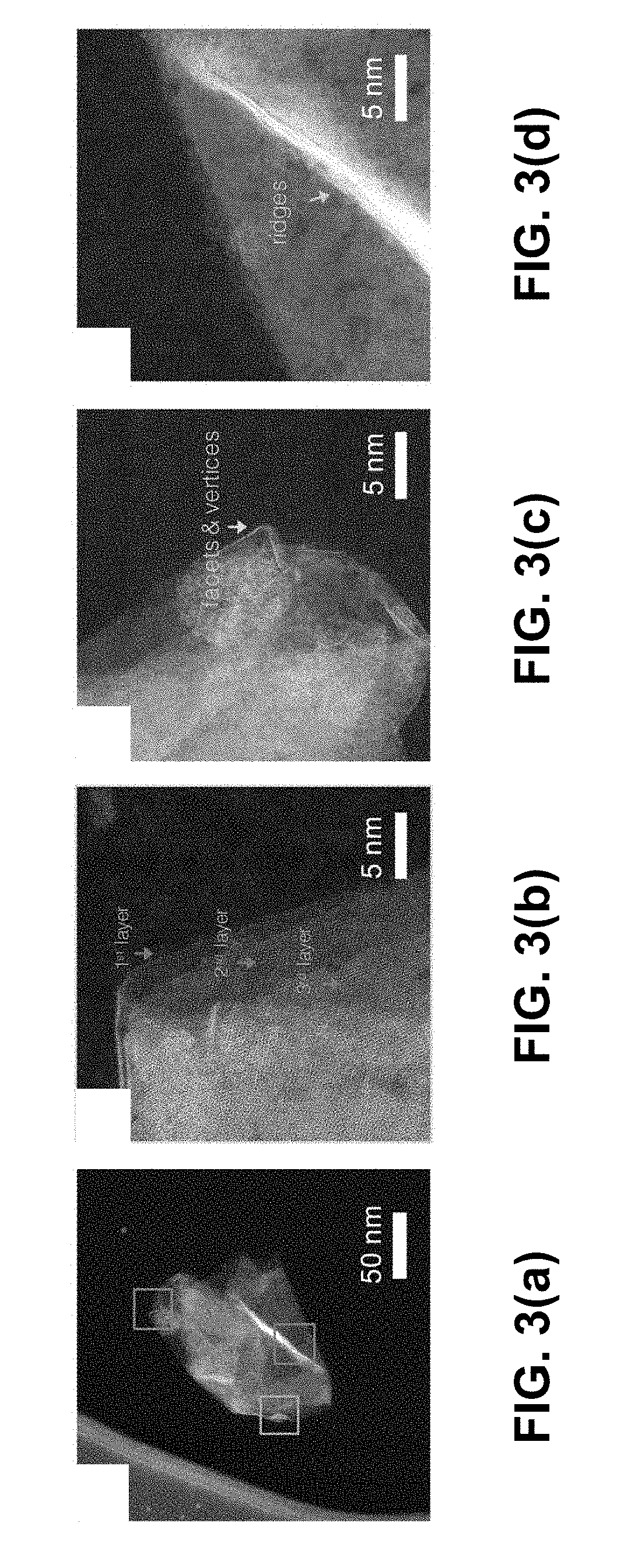

Lithium Intercalation and Exfoliation and MoS2 Crumpling by EHD

[0022]As an example of the invention, Li-intercalation was accomplished by immersing 2 g of MoS2 powder in 15 mL of 0.8 m n-butyl lithium in hexane. The mixture was stirred vigorously in an Ar-filled glovebox for 96 h. Next, the intercalated compound was transferred to DI-H2O and sonicated to yield exfoliated monolayers. Upon contact with the DI-H2O, copious gas evolved at the interlayer interfaces, thus yielding high concentrations of monolayers and forming a black, opaque solution. After ultrasonication, the compound was washed over Whatman filter paper with 500 mL of hexane. 200 mL of DI-H2O was then added to the mixture. With the filter paper removed, the mixture was then sonicated for 90 min. The resulting solution was then aliquoted into 45 mL centrifuge tubes with solution depths of 2-3 cm and centrifuged at 5200 rcf for 12 h, decanted, and then resuspended in 100 mL of DI-H2O. After resuspension, the centrifugati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com