HIGH CURRENT LATERAL GaN TRANSISTORS WITH SCALABLE TOPOLOGY AND GATE DRIVE PHASE EQUALIZATION

a gallium nitride transistor, high current technology, applied in the direction of electronic switching, semiconductor/solid-state device details, pulse techniques, etc., can solve the problems of unstable operation, poor performance, and introduction of significant parasitic on-chip inductance, and achieve the effect of improving the gate drive phase equalization and high current handling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

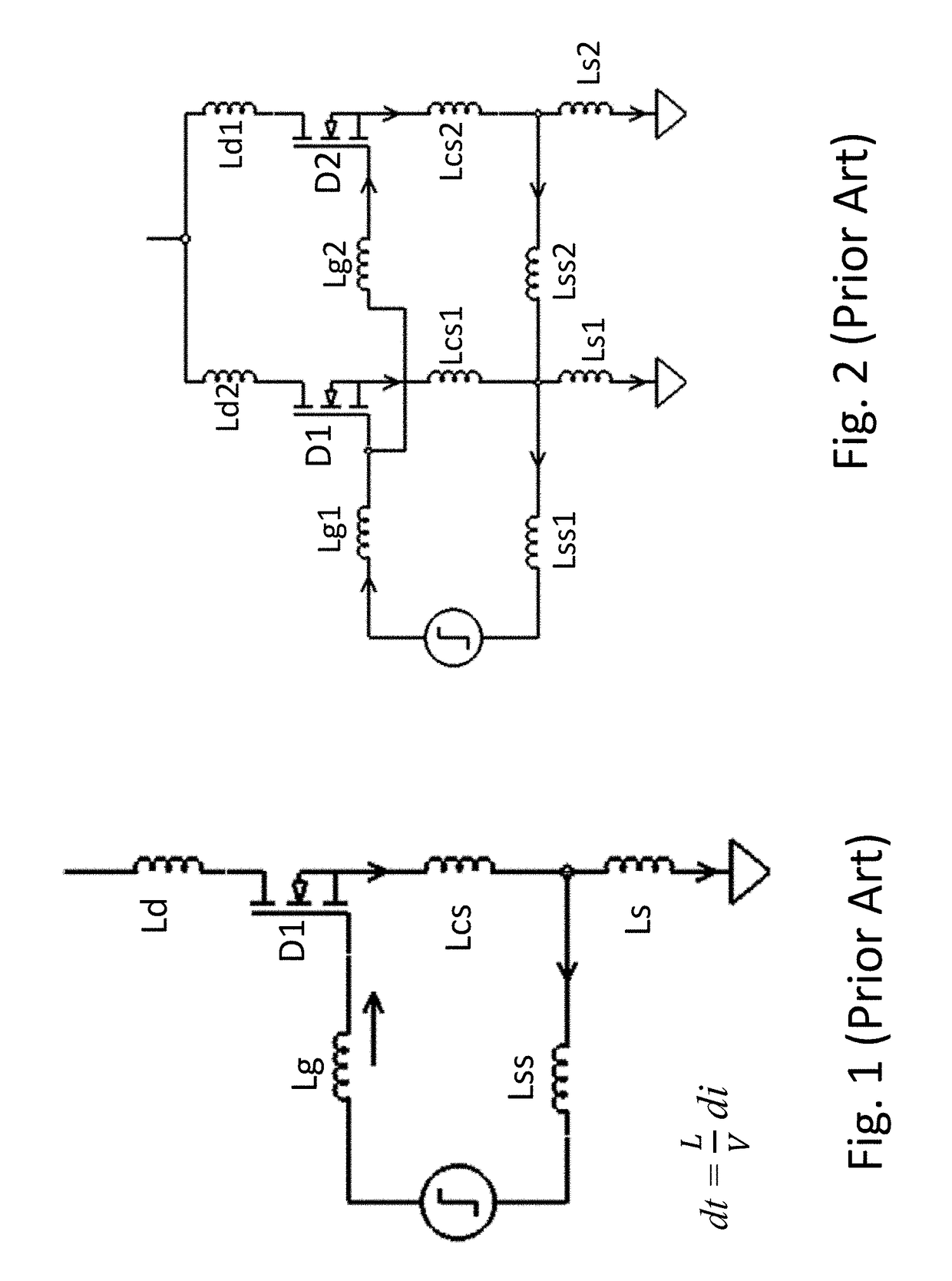

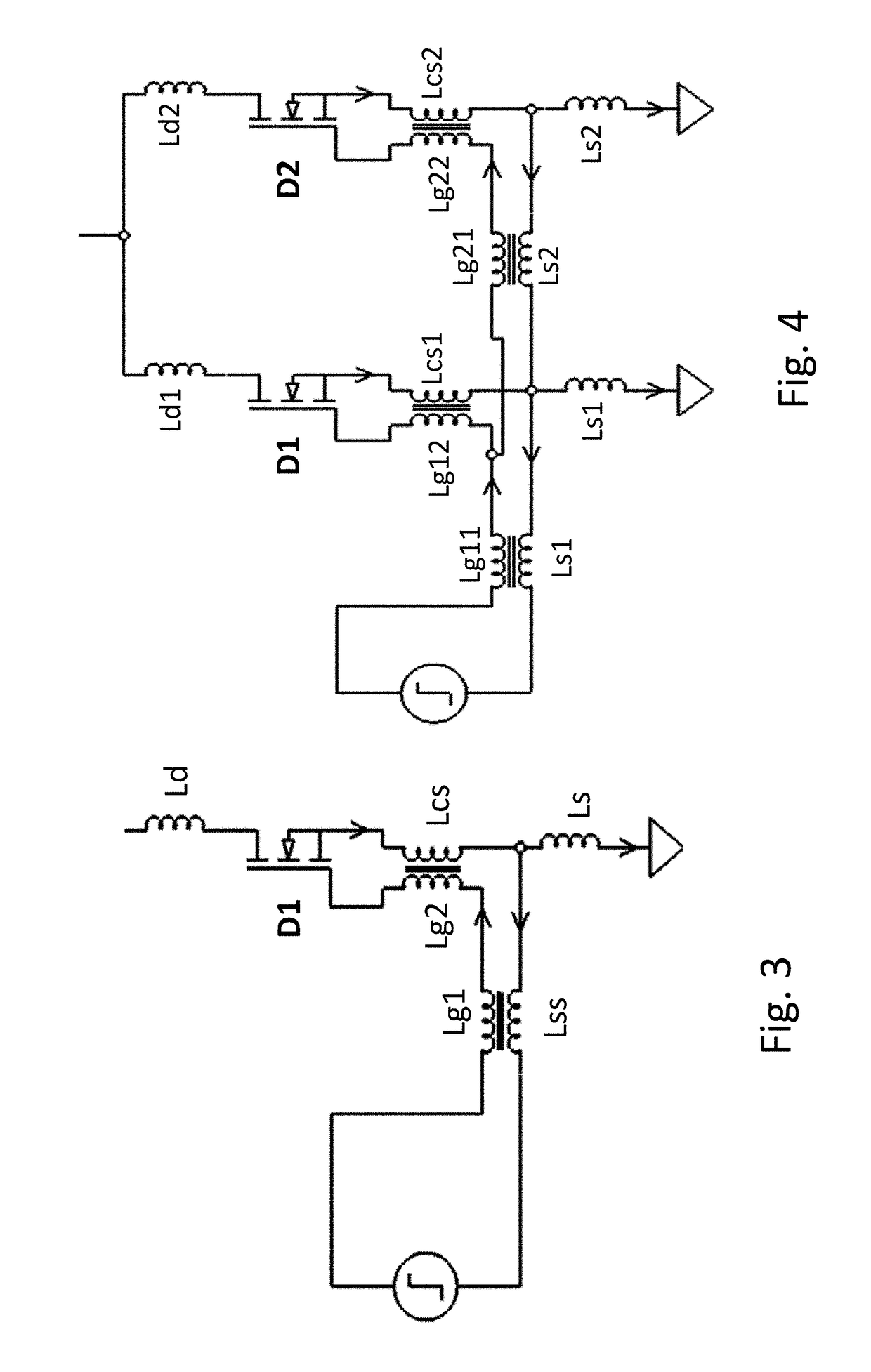

[0060]A circuit schematic of a lateral GaN transistor D1 connected to a gate drive supply voltage is shown in FIG. 1 (Prior Art) to illustrate parasitic inductances of the gate loop. That is, the gate delay is directly proportional to the total loop inductances dt=L / V di. The gate loop inductance includes the inductance of the gate drive path Lg, inductance of the gate return path Lss and the common source inductance Lcs. The drain inductance Ld and source inductance Ls in the power loop is also shown; the latter may include package interconnect inductances.

[0061]When two transistors are interconnected in parallel, for example as shown in the circuit schematic of FIG. 2 (Prior Art) comprising two a large area lateral GaN transistor elements D1 and D2 interconnected in parallel to a single gate drive supply voltage, it will be apparent that the difference in length of conductive tracks for each transistor element means that the gate loop inductance for the second transistor D2 (i.e. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com