Submerged combustion melters and methods of feeding particulate material into such melters

a technology of melters and particulates, applied in the field of submerged combustion melters, can solve the problems of reducing melt quality, affecting the quality of melt, so as to minimize the entrainment of particulate feed materials, improve quality, and maximize mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

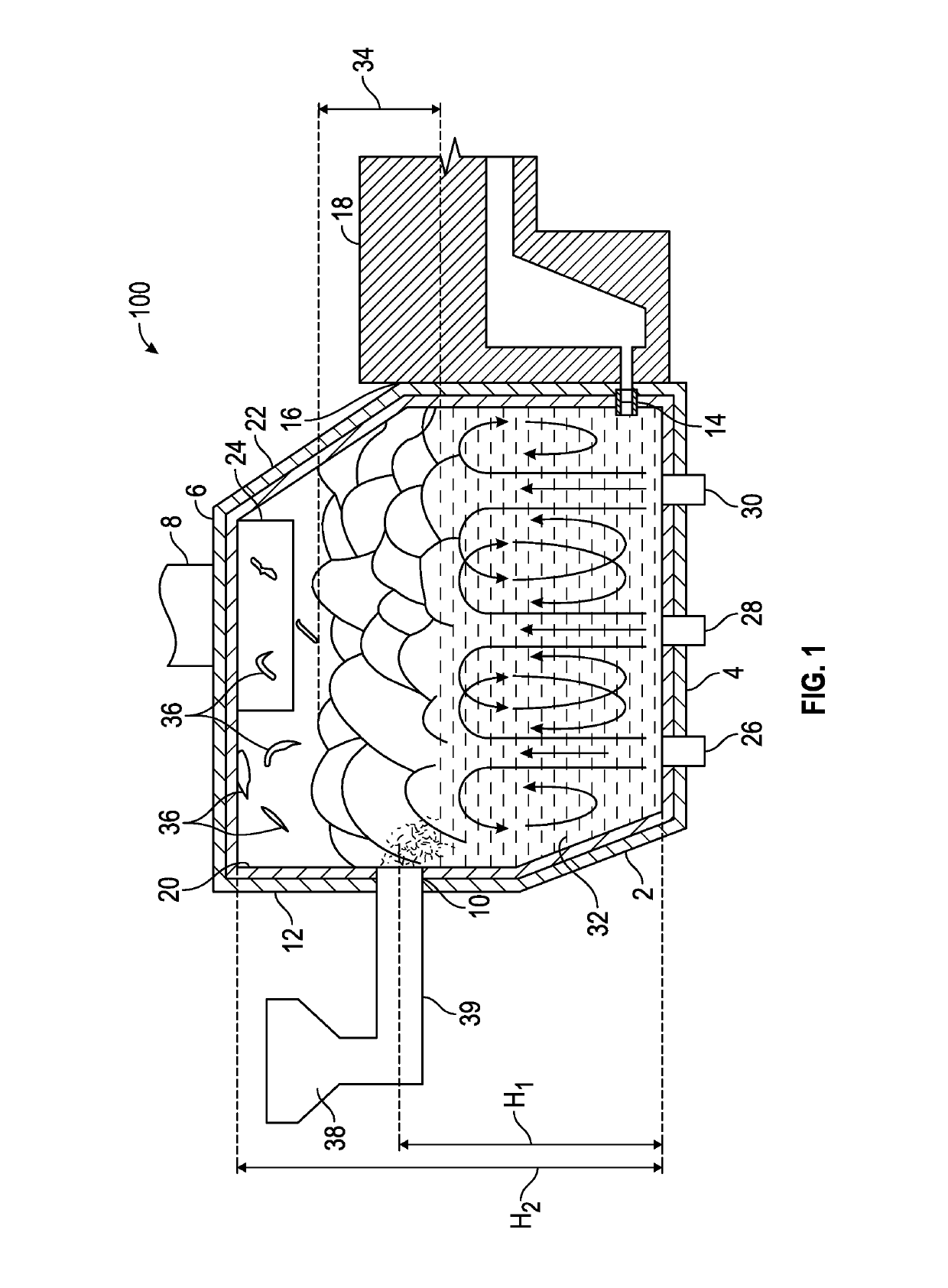

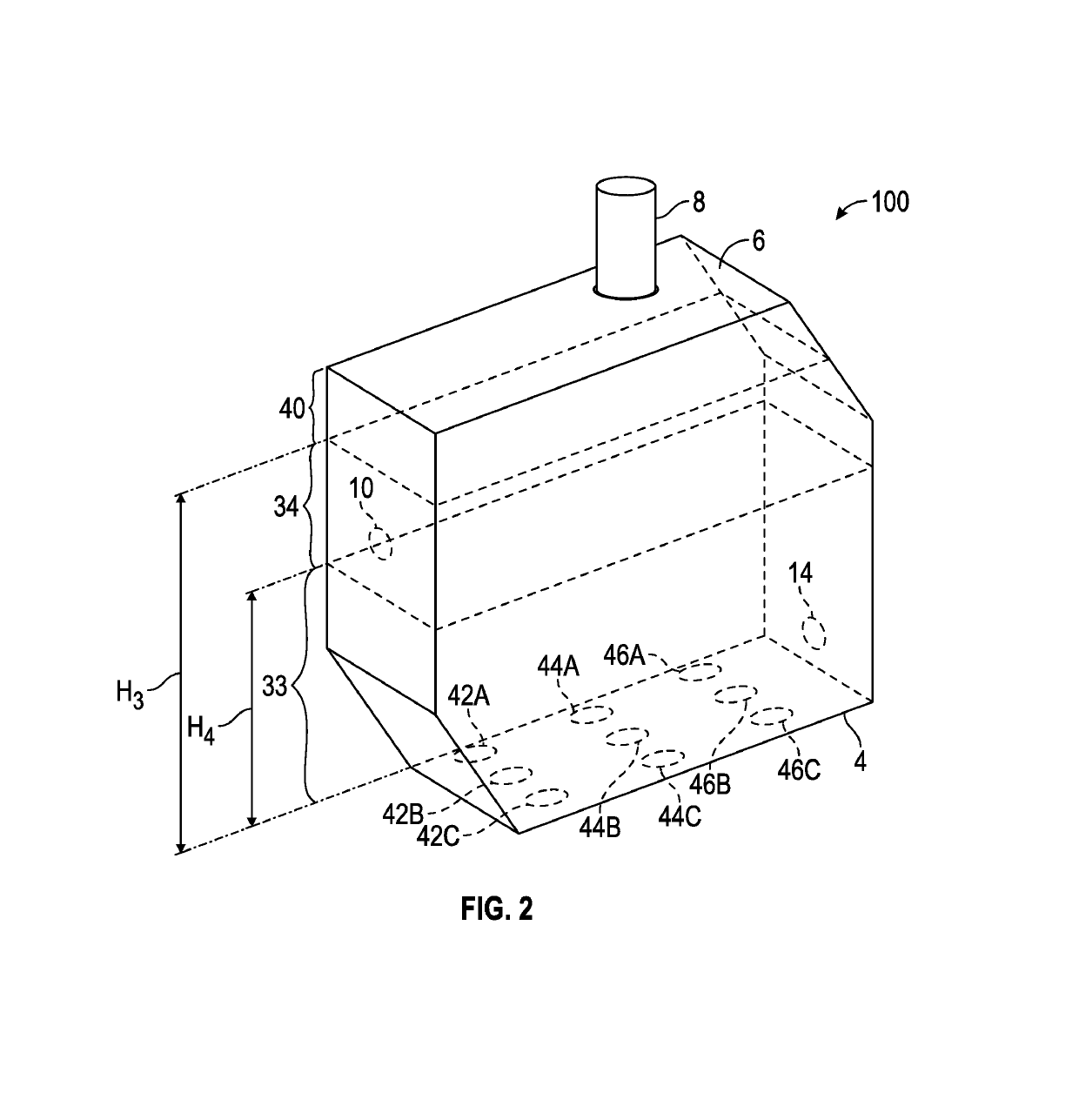

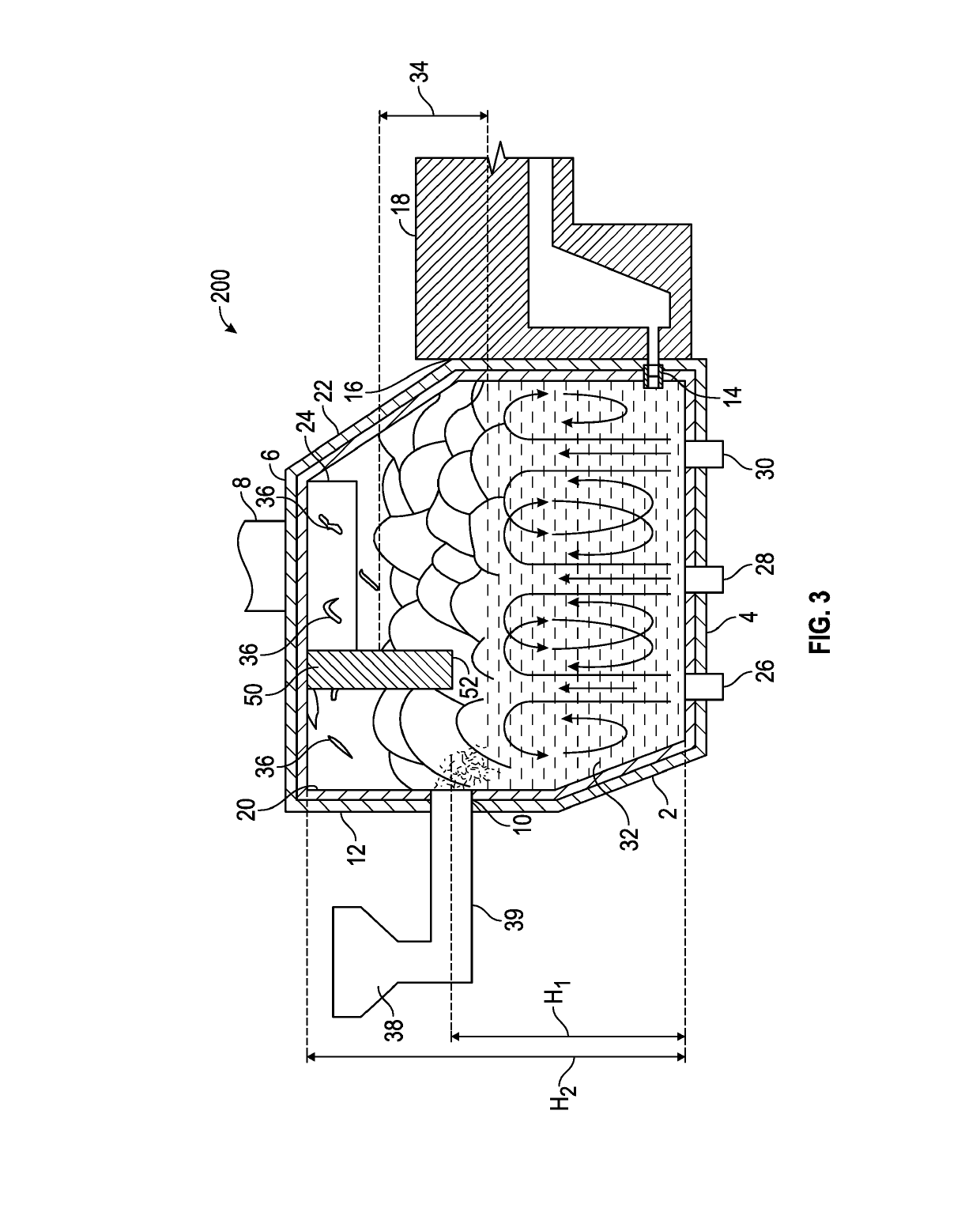

[0024]In the following description, numerous details are set forth to provide an understanding of the disclosed systems, apparatus, and methods. However, it will be understood by those skilled in the art that the systems, apparatus, and methods covered by the claims may be practiced without these details and that numerous variations or modifications from the specifically described embodiments may be possible and are deemed within the claims. For example, wherever the term “comprising” is used, embodiments and / or components where “consisting essentially of” and “consisting of” are explicitly disclosed herein and are part of this disclosure. An example of “consisting essentially” is with respect to the total feed to an SCM: a feed consisting essentially of particulate feedstock means there may be a minor portion of feed that is not particulate feedstock, such as rock used to make mineral wool. An example of “consisting of” may be a feedstock made up of only particulate feedstock, or o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com