Yarn formed from recycled cotton and recycled para-aramid, and fabrics made therefrom

a technology of para-aramid and yarn, which is applied in the direction of weaving, yarn, protective fabrics, etc., can solve the problems of compromising the strength and softness of yarns and fabrics, and the manufacturing of cotton fibers is harmful to the environmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

rics Made of Recycled Cotton and Recycled Para-Aramid

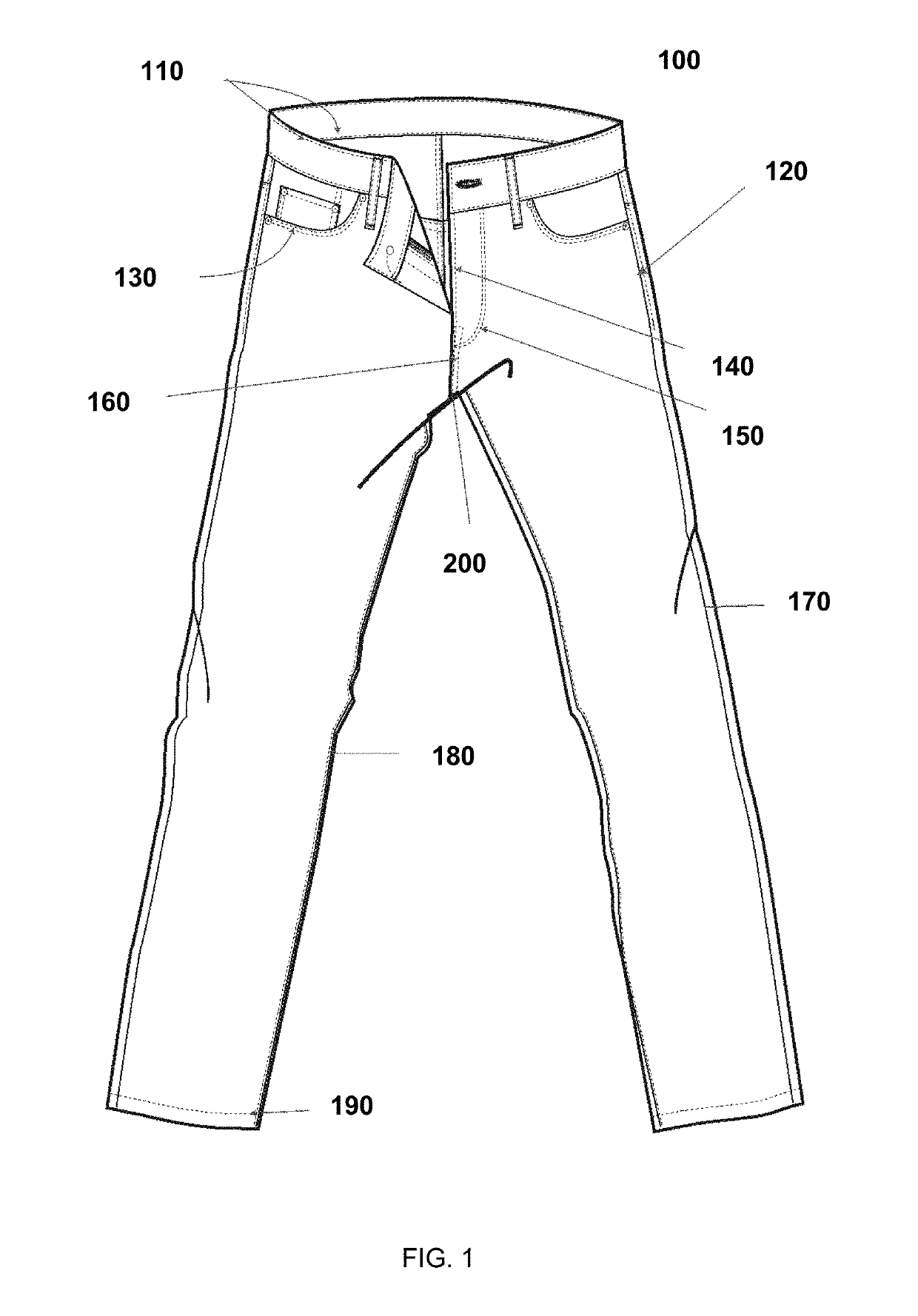

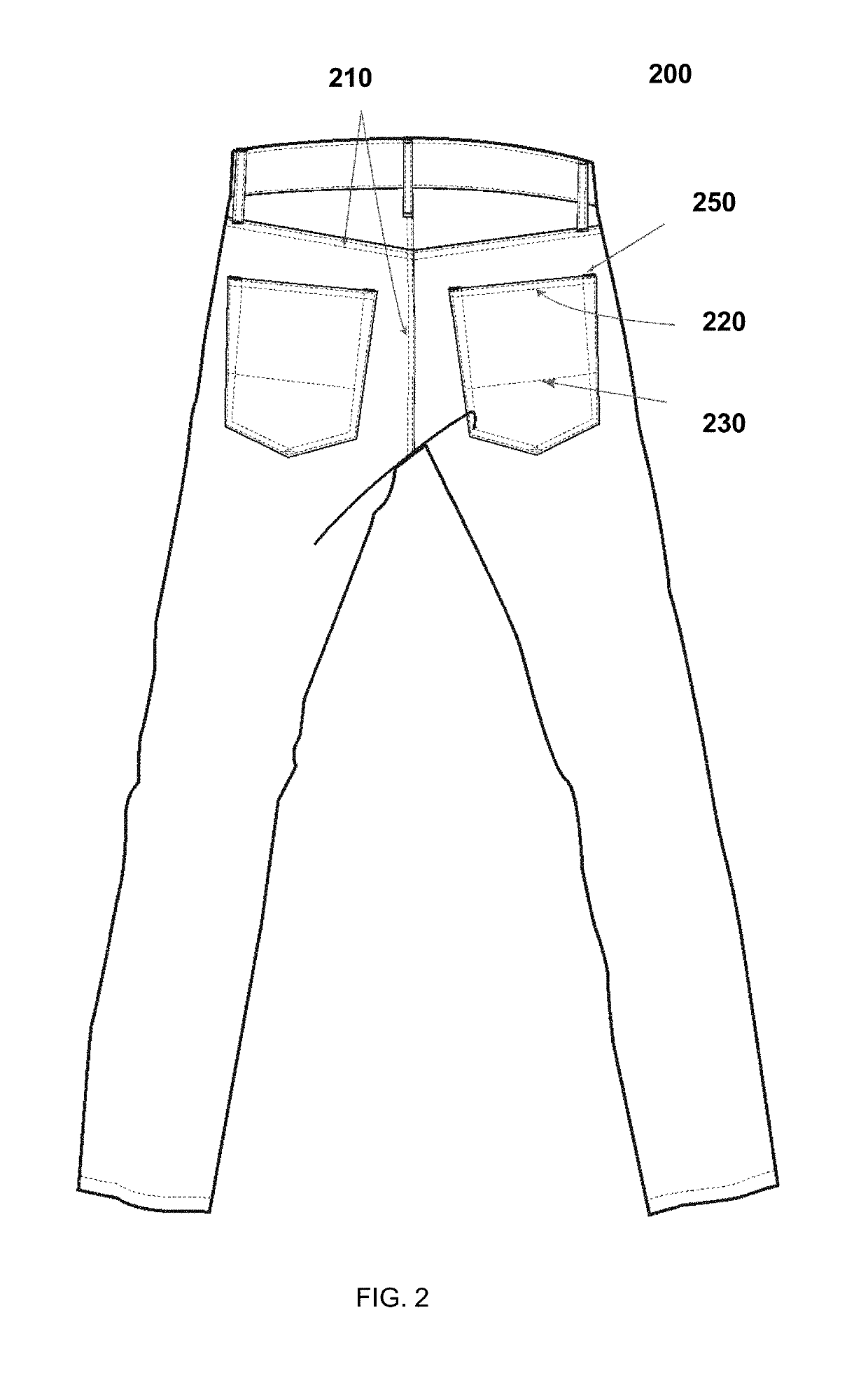

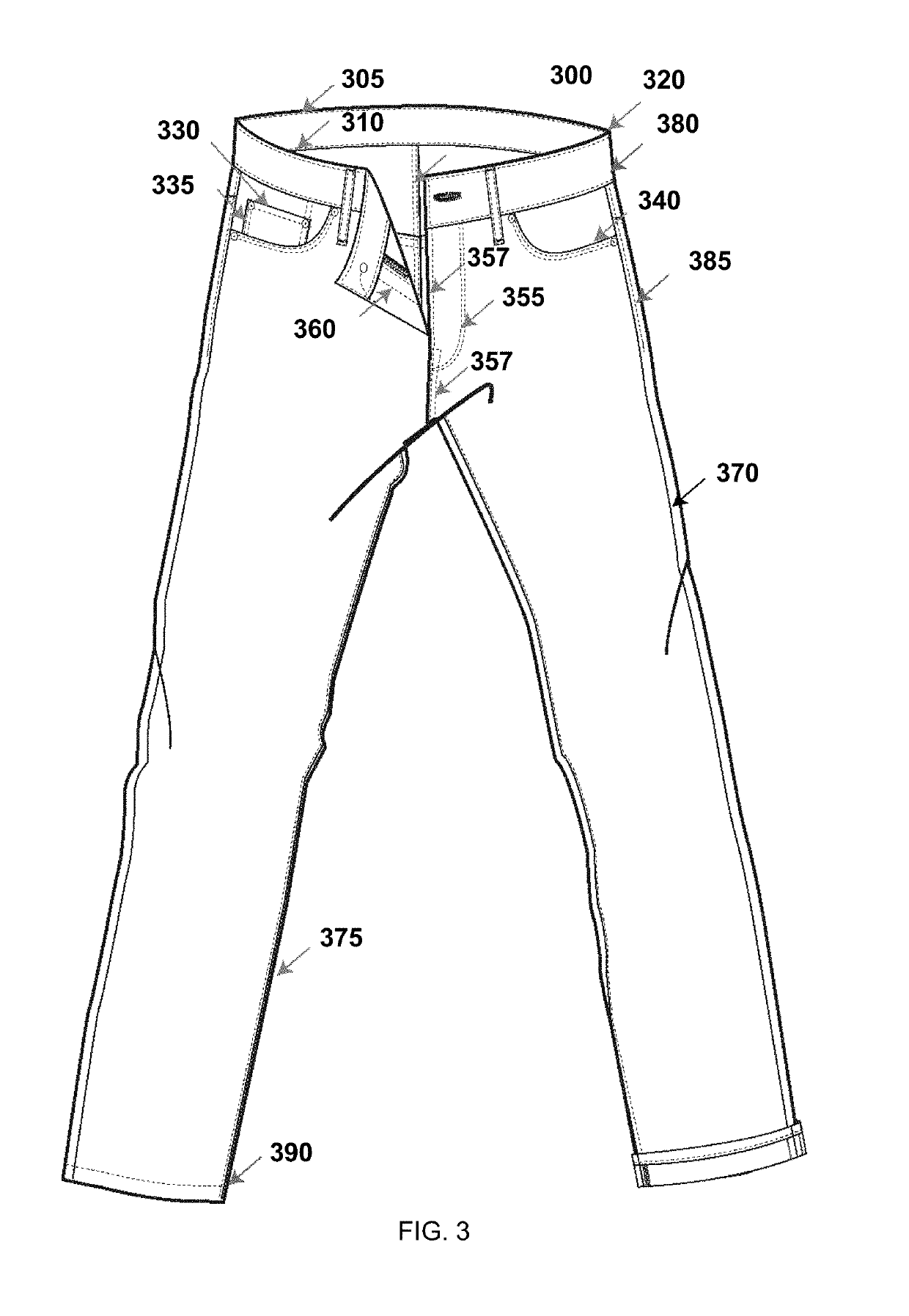

[0201]This example illustrates that denim fabrics containing recycled cotton and 3% recycled para-aramid have increased breaking strength, tear strength, and abrasion resistance compared to denim fabric containing 100 wt % virgin cotton.

[0202]In the study, the breaking strength and tear strength of denim samples were tested. The denim samples were treated using one of the following conditions: (A) rinse wash; (B) edge damage (delicate)+bioenzyme treatment for 20 minutes; (C) whiskering and shaving+bioenzyme treatment for 40 minutes; and (D) whiskering and shaving+bioenzyme treatment for 60 minutes+chlorine bleach treatment.

[0203]Breaking strength was evaluated using a standard test method (ASTM D 5034) for determining breaking strength of textile fabrics (grab method). Briefly, a rectangular shaped fabric is loaded into the clamps or grips of the standard test equipment with the longer dimension parallel to the direction to be tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wt % | aaaaa | aaaaa |

| wt % | aaaaa | aaaaa |

| wt % | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com