Fine cellulose fiber sheet

a technology of cellulose fiber and cellulose fiber, applied in the field of fine cellulose fiber sheet, can solve the problems of easy cleavage of hydrogen bonds, easy collapse of sheet structure, and extreme disadvantage of techniqu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0304]Linter pulp was immersed in water to a concentration of 10% by weight, subjected to heat treatment for 4 hours at 130° C. in an autoclave and the resulting resin pulp was rinsed several times with water to obtain a wet pulp immersed in water.

[0305]The resin pulp was dispersed in water (40 L) to a solid content of 1.5% by weight, and the 400 L of dispersion were subjected to beating treatment for 20 minutes using the Model SDR14 Lab Refiner (pressurized disk type) manufactured by Aikawa Iron Works Co., Ltd. for the disc refiner device at a clearance between disks of 1 mm. Continuing therefrom, beating treatment was continued under conditions of reducing the disk clearance to nearly zero. Samples were collected over time, and when CSF values were evaluated for the slurry samples according to the Canadian standard pulp freeness test method defined in JIS P 8121 (to be referred to as the CSF method), CSF values were confirmed to demonstrate a tendency by which they decreased over ...

example 2

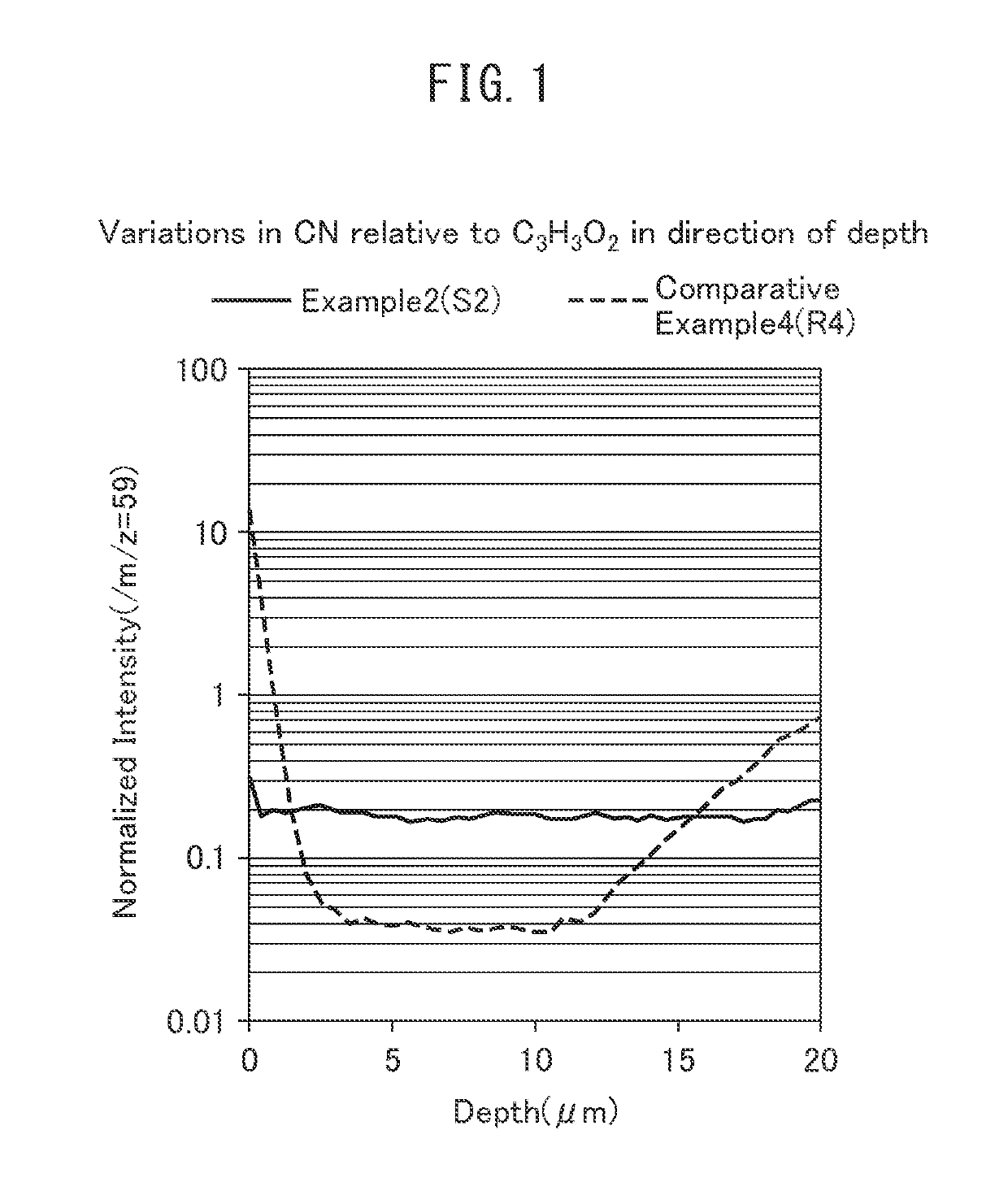

[0310]Diameter reduction, papermaking slurry preparation, papermaking, drying and heat treatment were carried out in the same manner as Example 1 with the exception of making the added amount of cationic blocked polyisocyanate to be 6.3 g (10% by weight based on the weight of the cellulose solid fraction to obtain S2. Papermaking ability, wet / dry strength ratio, wet / dry strength ratio after solvent immersion and block polyisocyanate distribution were all superior. In addition, a graph indicating the relationship of variations in C1 / C2 in the direction of depth for one of the four sample sites of S2 analyzed by TOF-SIMS is shown in FIG. 1. Although the C1 / C2 ratio was indicated to be large only on the uppermost surface of the upper portion of the sheet, it subsequently became stable and demonstrated a value of C1 / C2≈0.2. On the basis thereof, it can be said that, although blocked polyisocyanate is present in comparatively large amounts on the uppermost surface of the sheet, it is dis...

example 3

[0311]Diameter reduction, papermaking slurry preparation, papermaking, drying and heat treatment were carried out in the same manner as Example 1 with the exception of making the added amount of cationic blocked polyisocyanate to be 19 g (30% by weight based on the weight of the cellulose solid fraction) to obtain S3. Papermaking ability, wet / dry strength ratio, wet / dry strength ratio after solvent immersion and blocked polyisocyanate distribution were all superior.

PUM

| Property | Measurement | Unit |

|---|---|---|

| fiber diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com