Additional liquid natural gas plant and method of operating thereof

a liquid natural gas and plant technology, applied in the direction of liquidification, lighting and heating equipment, solidification, etc., can solve the problem of energy-consuming process in the liquefaction of natural gas, and achieve the effect of more efficient lng plants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050]The following examples of certain aspects of some embodiments are given to facilitate a better understanding of the present invention. In no way should these examples be read to limit, or define, the scope of the invention.

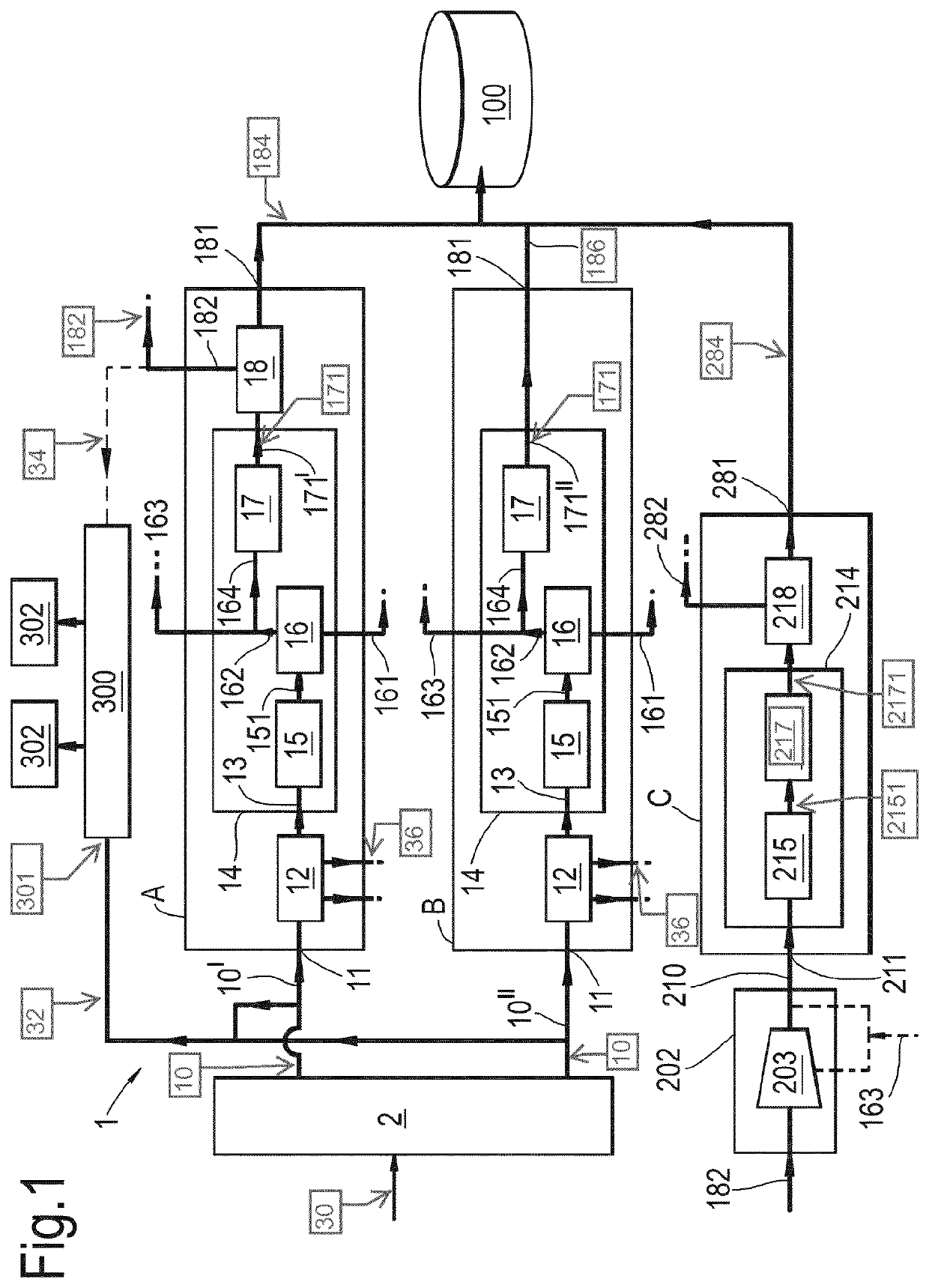

[0051]There is provided a liquid natural gas plant comprising a plurality of liquefaction trains, of which at least one train, referred to as an additional liquefaction train, liquefies gas streams received from the other trains (referred to as treating and liquefaction trains). The additional liquefaction train is preferably added to an existing plant as retrofit.

[0052]In existing plant designs, i.e. plants not comprising an additional liquefaction train as described here, typically fuel is obtained from gas streams obtained from the treatment and liquefaction trains, such as portions of the end flash gas and the overhead of the scrub column used for NGL-extraction, which are relatively lean and clean.

[0053]Now provided is a liquid natural gas plant in whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com