Thermoelectric dehumidifying device

a dehumidifying device and thermoelectric technology, applied in space heating and ventilation, lighting and heating apparatus, heating types, etc., can solve the problems of inability to further cool the cold surface, inability to meet the needs of cramped use environments, and bulky dehumidifiers, so as to improve the dehumidification effect of the airflow entering the dehumidifying device, the effect of dehumidification capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

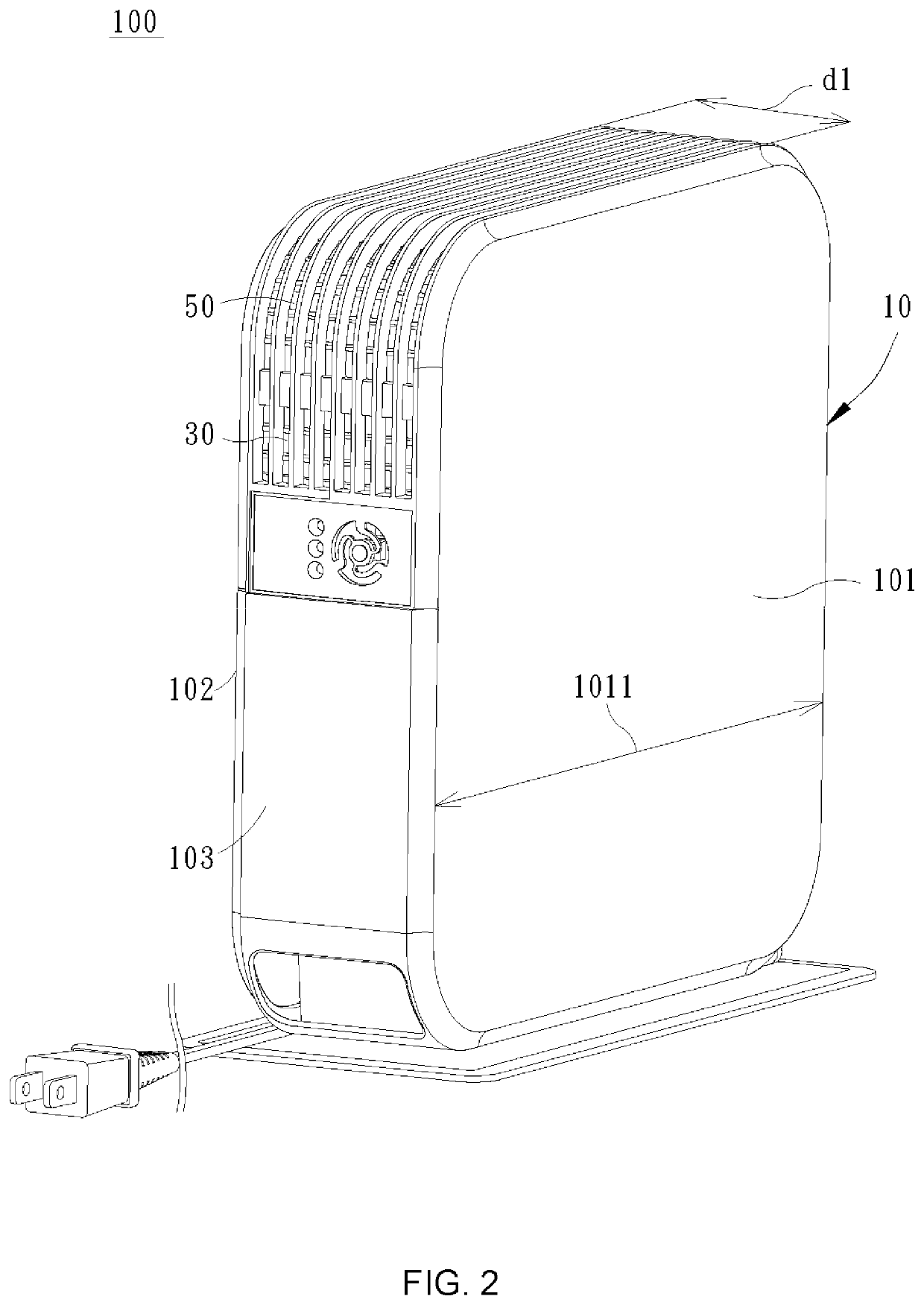

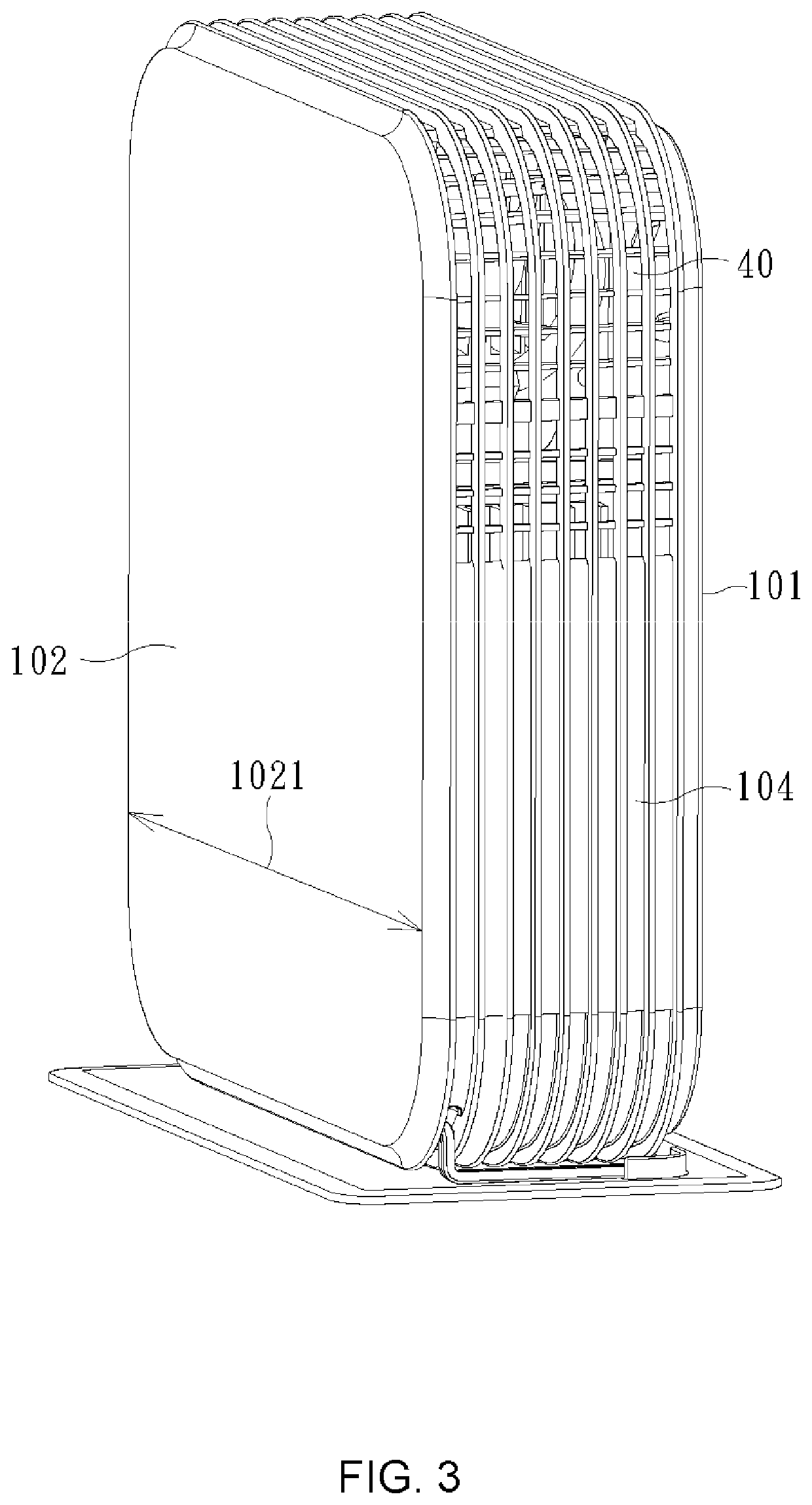

[0022]As shown in FIG. 2 toFIG. 8, a thermoelectric dehumidifying device 100 of the present invention includes a case 10, a thermoelectric element 20, a first air inlet 30, a second air inlet 40, an air outlet 50, a condenser 60, a heatsink 70, and a fan 80, wherein the first air inlet 30, the second air inlet 40, and the air outlet 50 are provided on the case 10, while the thermoelectric element 20, the condenser 60, the heatsink 70, and the fan 80 are provided in the case 10.

[0023]The case 10 includes a first lateral surface 101, a second lateral surface 102, a third lateral surface 103, and a fourth lateral surface 104, wherein the first lateral surface 101 and the second lateral surface 102 are separated by a first spacing d1. A horizontal length 1011 of the first lateral surface 101 and a horizontal length 1021 of the second lateral surface 102 are both greater than the first spacing d1. The third lateral surface 103 and the fourth lateral surface 104 are provided between the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com