Structural panel intended to form part of a cold box of a separation device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

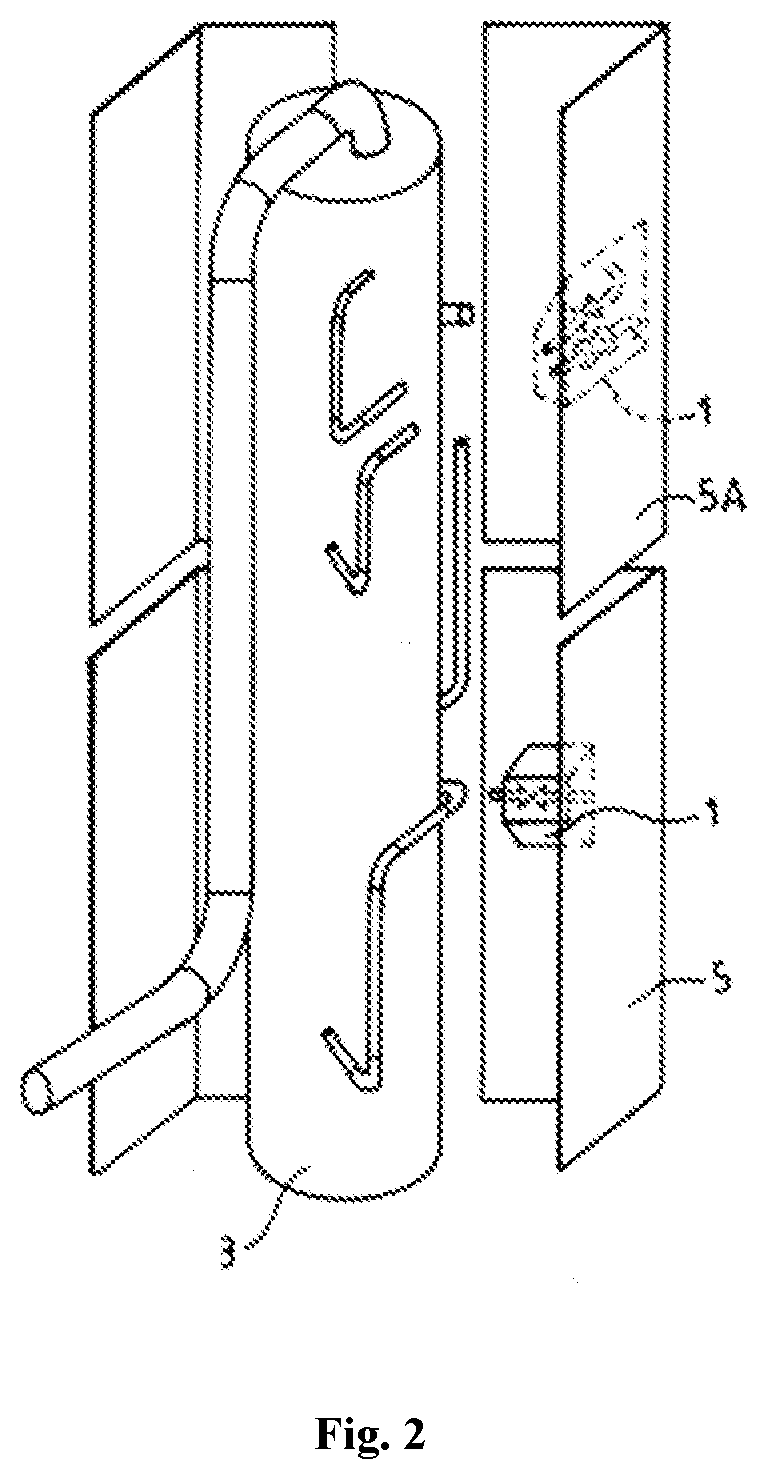

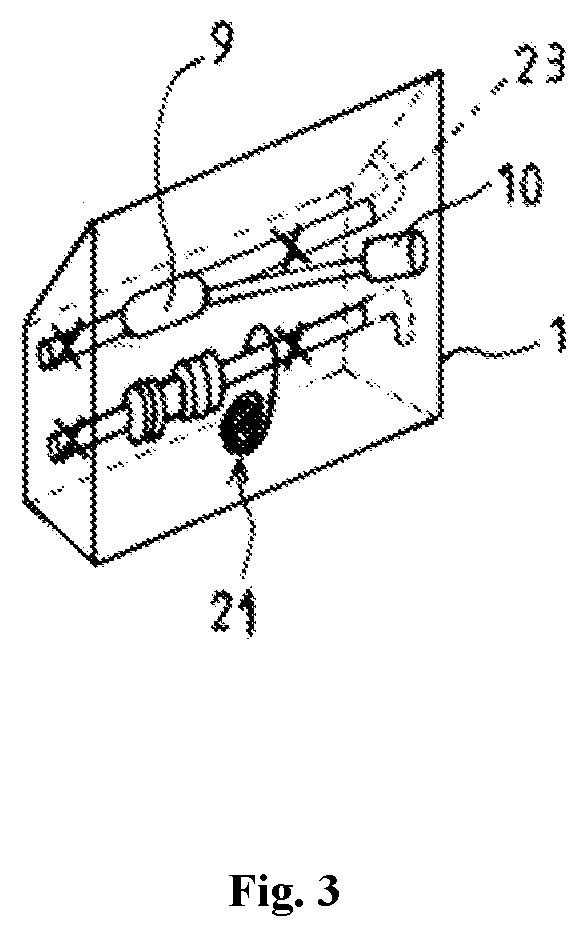

[0043]FIG. 1 illustrates a panel 5 of a cold box of a distillation air separation device; the cold box can contain a column and / or a heat exchanger. An element 3 to be insulated is illustrated as being surrounded with perlite 15. Fastened to the inner face of the panel 5 is a chamber 1 made from carbon steel or chrome and nickel alloy steel (stainless steel). It has a roof at an angle of 60° relative to a vertical plane, which is the plane of the panel 5. The bottom is sloped at 45° relative to the panel. Other angles between 45° and 60° are possible.

[0044]This serves to prevent the perlite 15 surrounding it from banking. The chamber 1 has one open face, the open face being positioned on the inner face of the structural panel 5. Inside the chamber 1 is at least one accessory 9 that can be a manual valve, an automatic valve, a flow meter, a valve shutter or a sensor. The accessory is connected, if necessary, to the outside of the cold box through the panel 5 and a boot 8 to its actua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com