Electrolytic cell cathode with zero polar spacing

a technology of electrolysis cell and cathode, which is applied in the field of electrolysis cell, can solve the problems of unfavorable elastic change, unfavorable elastic change, and high cell voltage, and achieve the effect of preventing elastic change, and reducing the shaking of the ionic membran

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]The zero polar spacing technology for cathode is adopted in the electrolytic cells in order to solve the disadvantages of common higher voltage of the electrolytic cell, the reduced life of ionic membrane due to the pulling damage caused by extrusion force. In view of the above problems, this new invention proposes a zero polar spacing technology, aiming at improving electrolytic production efficiency and effectively reducing energy consumption. The specific technical scheme is as follows:

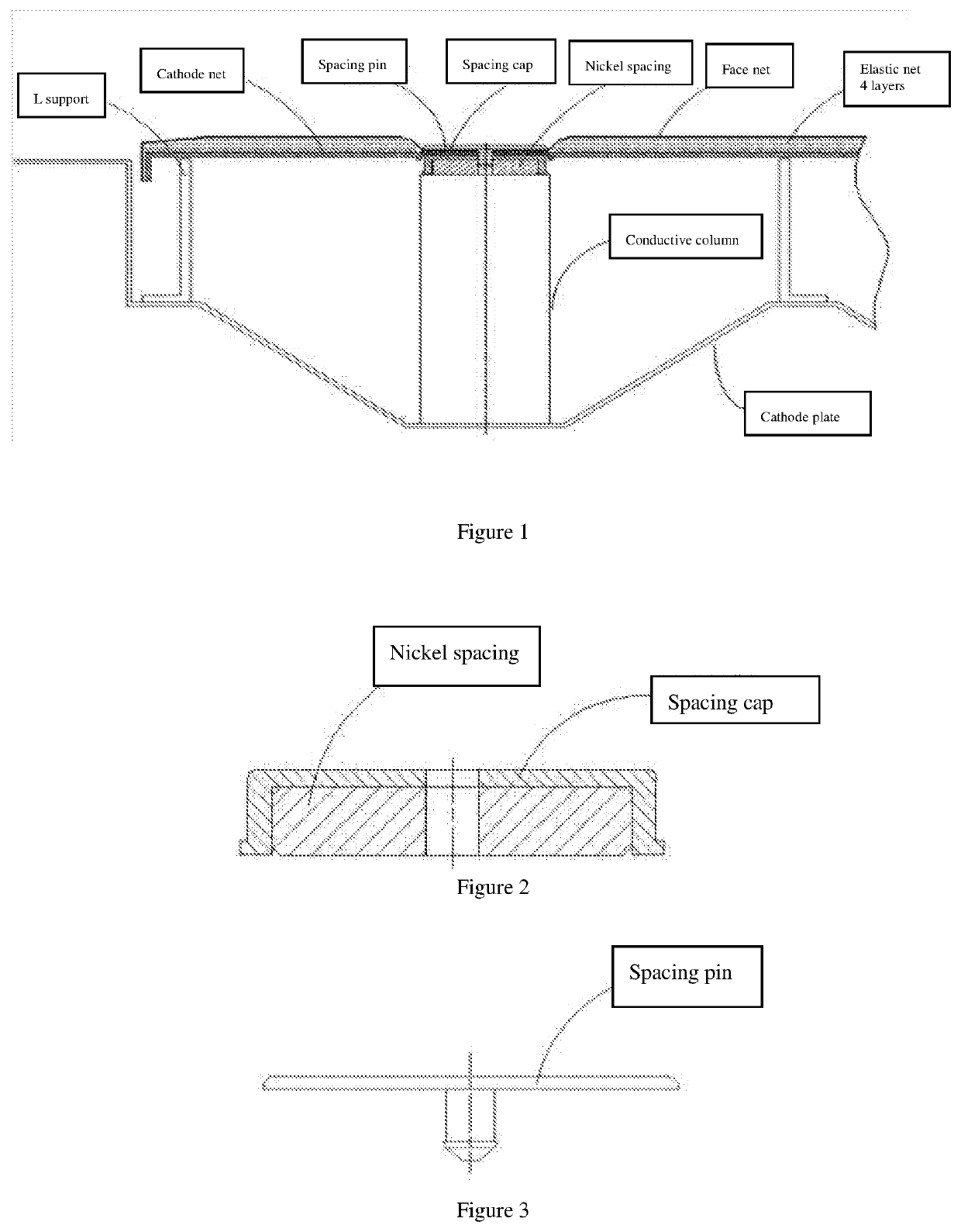

[0019]Referring to FIG. 1, in one embodiment of the present invention, the cathode of the electrolytic cell with zero polar spacing comprises a conductive column, a cathode net, an elastic net, a surface net, and a fastening part; wherein the cathode net is connected with the conductive column, the elastic net is covered on the cathode net, the surface net is covered on the elastic net, and a fastening part penetrating through the surface net, the cathode net and the elastic net and is fixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| zero polar spacing | aaaaa | aaaaa |

| temperature resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com