Catalyst layer, membrane electrode assembly, and polyelectrolyte fuel cell

a fuel cell and membrane electrode technology, applied in the direction of fuel cells, cell components, electrical equipment, etc., to achieve the effect of high power generation performance and excellent substance transport properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0079]Examples and comparative examples will now be described.

[0080][Preparation of Membrane Electrode Assembly]

[0081]Membrane electrode assemblies according to Examples 1 to 5 and Comparative Examples 1 to 5 were prepared by the following method.

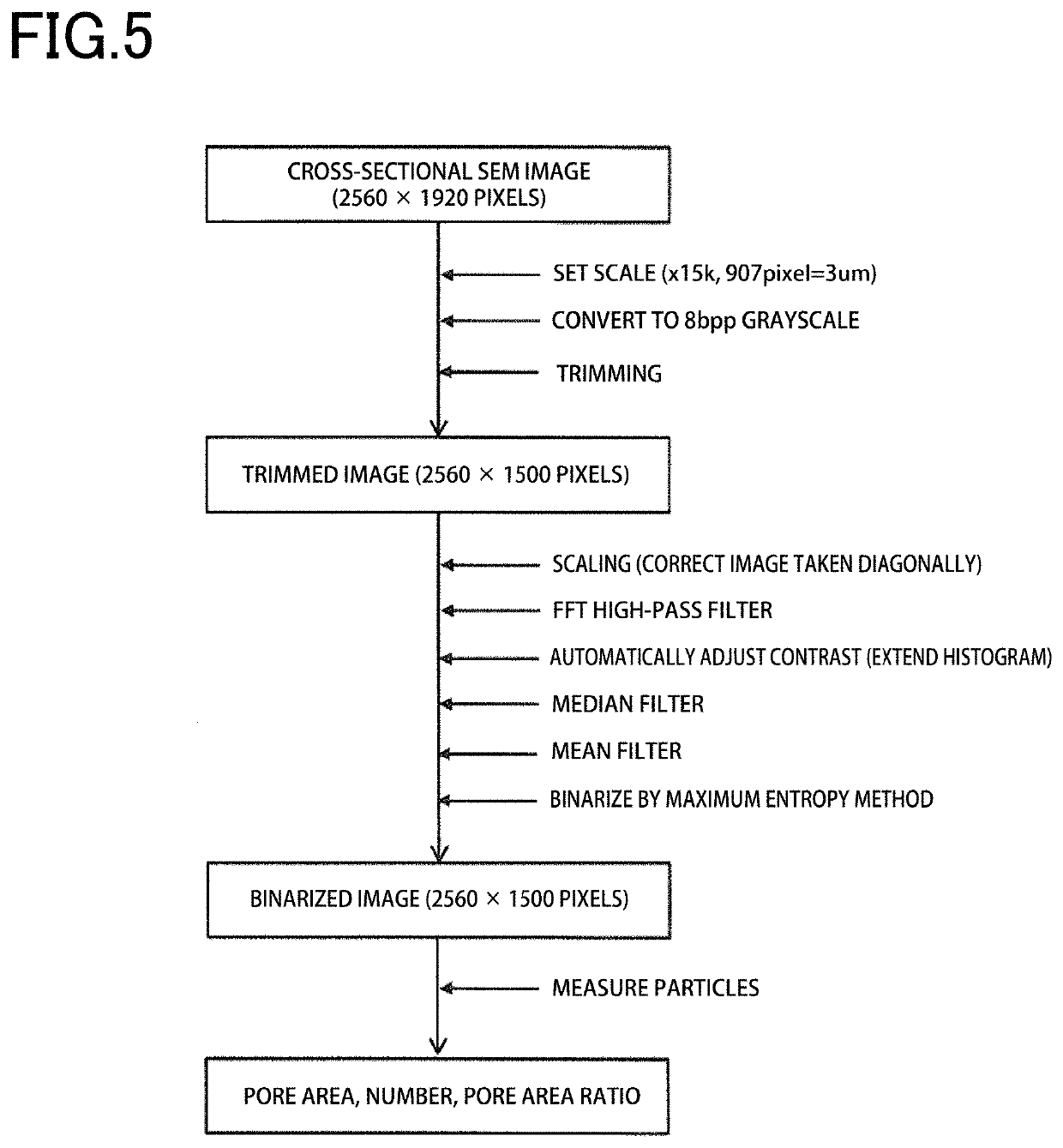

[0082]In Example 1, a platinum-on-carbon catalyst (TEC10E50E manufactured by Tanaka Kikinzoku Kogyo K.K.), water, 1-propanol, polyelectrolyte (Nafion (registered trademark) dispersed liquid manufactured by Wako Pure Chemical Industries, Ltd.), and carbon nanofibers (VGCF-H (registered trademark) manufactured by Showa Denko K.K.) were mixed. The platinum-on-carbon catalyst is a platinum catalyst supported on carbon particles. The blending ratio of the carbon particles to the polyelectrolyte was 1:1 by mass ratio. The mixture was dispersed in a planetary ball mill at 300 rpm for 60 minutes to prepare a catalyst ink. At this time, zirconia balls having a diameter of 5 mm were added to the mixture. The amount of the zirconia balls added was abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com