Method of manufacturing a 7xxx-series aluminium alloy plate product having improved fatigue failure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0077]Rolling ingots have been DC-cast of the aluminum alloy AA7055, with a composition as given in Table 1

TABLE 1LotSiFeCuMgZnZrA, B, C, D, E0.070.072.351.948.050.12

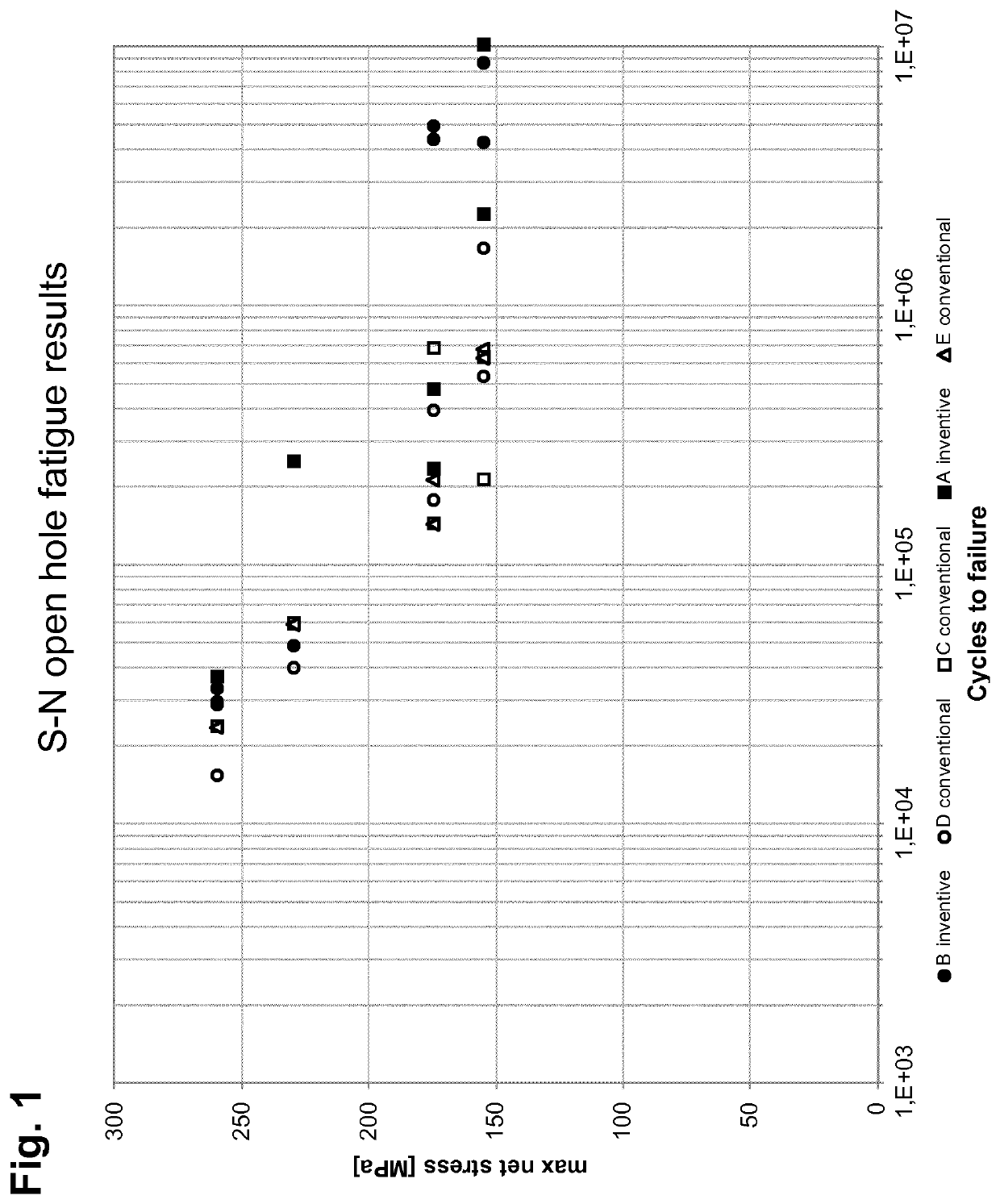

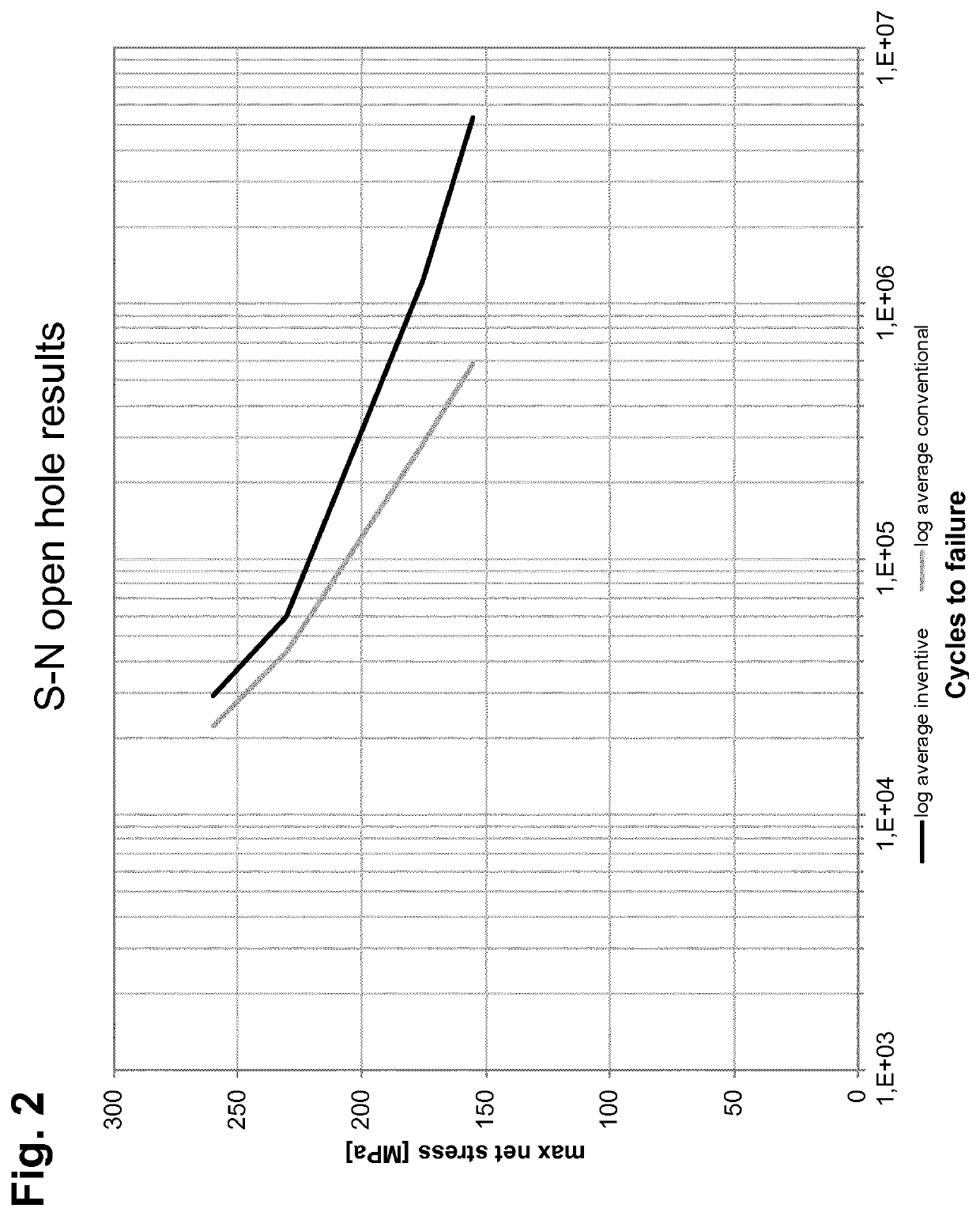

[0078]The rolling ingots had a thickness of about 400 mm. Homogenization of the ingots was carried out in a two-step homogenization procedure at 465° C. (first step) and 475° C. (second step) followed by cooling to ambient temperature. After scalping, the ingots were pre-heated to 410° C. for hot rolling. Hot rolling was carried out on a hot rolling mill having a work roll radius of about 575 mm. Lots A and B were processed in accordance with the invention, i.e. both lots receive a high reduction pass during the hot rolling process. During the high reduction rolling pass, lot A received a thickness reduction of about 30% (167 mm to 117 mm) and lot B received a thickness reduction of about 28% (165 mm to 118 mm). The rolling speed during this high reduction pass was about 25 m / min giving a deformation rate of about 0.53 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com