Method and system for cooling a motor during motor startup

a technology of compressor motor and startup sequence, which is applied in the direction of mechanical equipment, refrigeration components, light and heating equipment, etc., can solve the problems of complex systems and increase costs, and achieve the effect of increasing the pressure of liquid coolan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

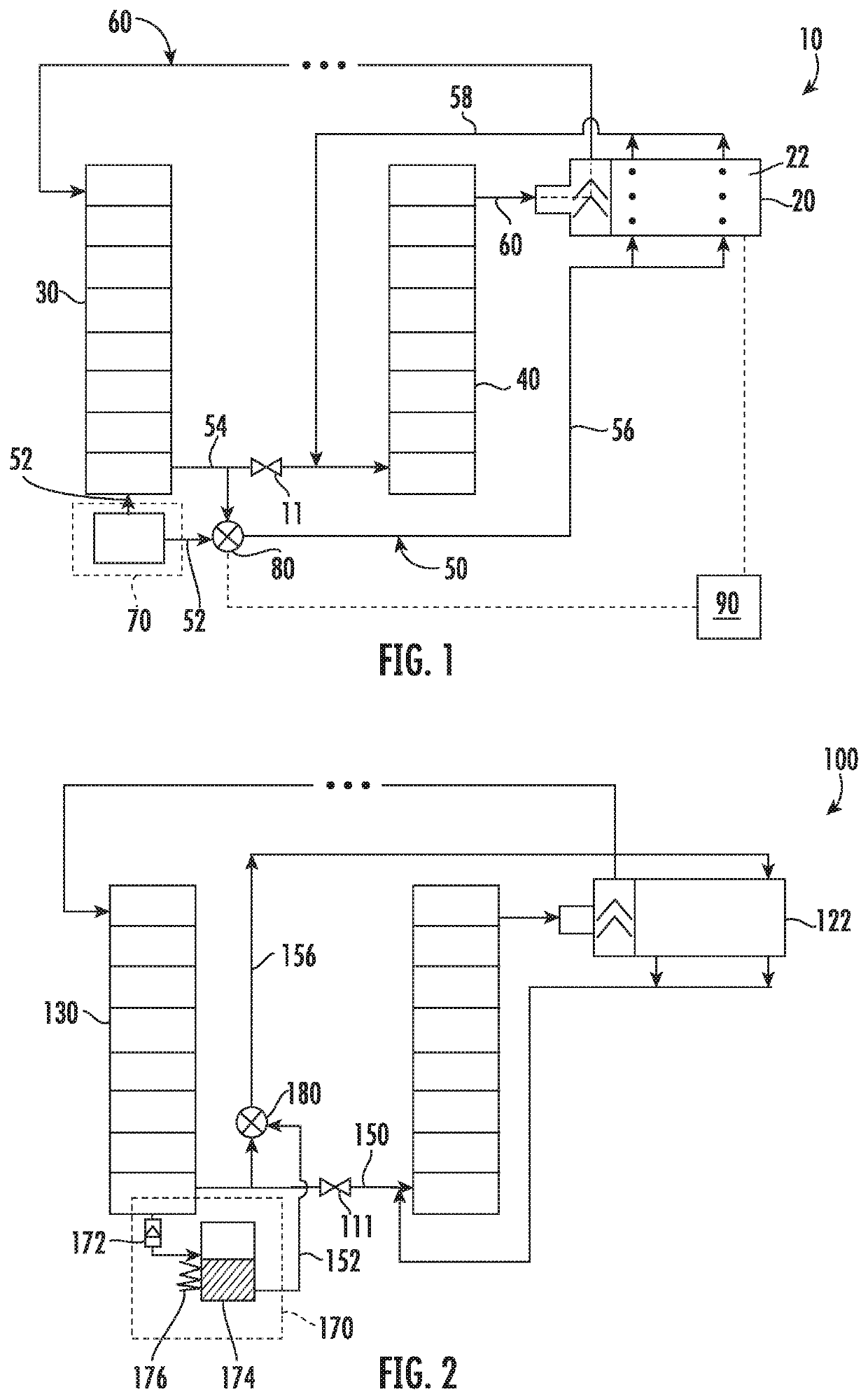

[0031]FIG. 1 schematically illustrates a vapor compression system with a compressor motor cooling subsystem 10 for a compressor 20 driven by a high speed motor 22 for HVAC applications. In one non-limiting example, the high speed motor 20 is a motor for a mini-centrifugal compressor. The system includes a condenser 30, an evaporator 40, and an expansion device 11 in fluid communication with the compressor 20. In order to provide cooling and lubrication to a high speed motor 22, a pressure rise generated by the compressor 20 provides liquid coolant from the condenser 30 to the motor 22 along a fluid flowpath 50 during full speed operations of the compressor 20. In the embodiment of FIG. 1, the liquid coolant cools and lubricates the motor 22, and is then provided to the evaporator 40 via the flowpath 58. Once in the evaporator 40, the coolant is evaporated, and provided to the compressor 20 in a vapor form along a vapor flowpath 60. The vapor flowpath 60 provides the evaporated coola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com