Semiconductor Strain Gauge and Method for Manufacturing Same

a technology of micro-semiconductor and strain gauge, which is applied in the direction of instruments, device details, and piezoelectric/electrostrictive device details, etc., can solve the problems of high yield loss and cost, poor uniform thickness across the wafer, and complicated post-fabrication and packaging steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

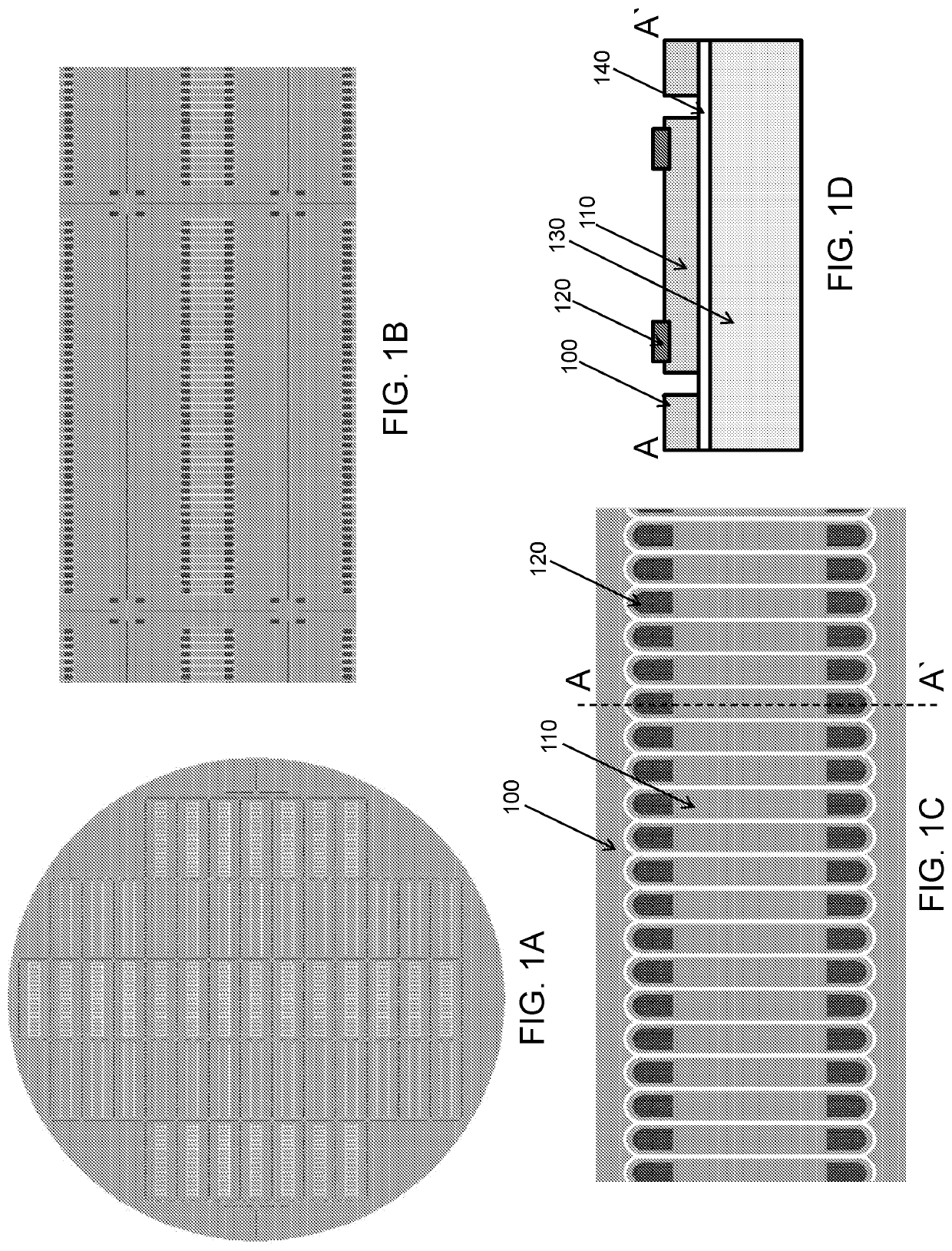

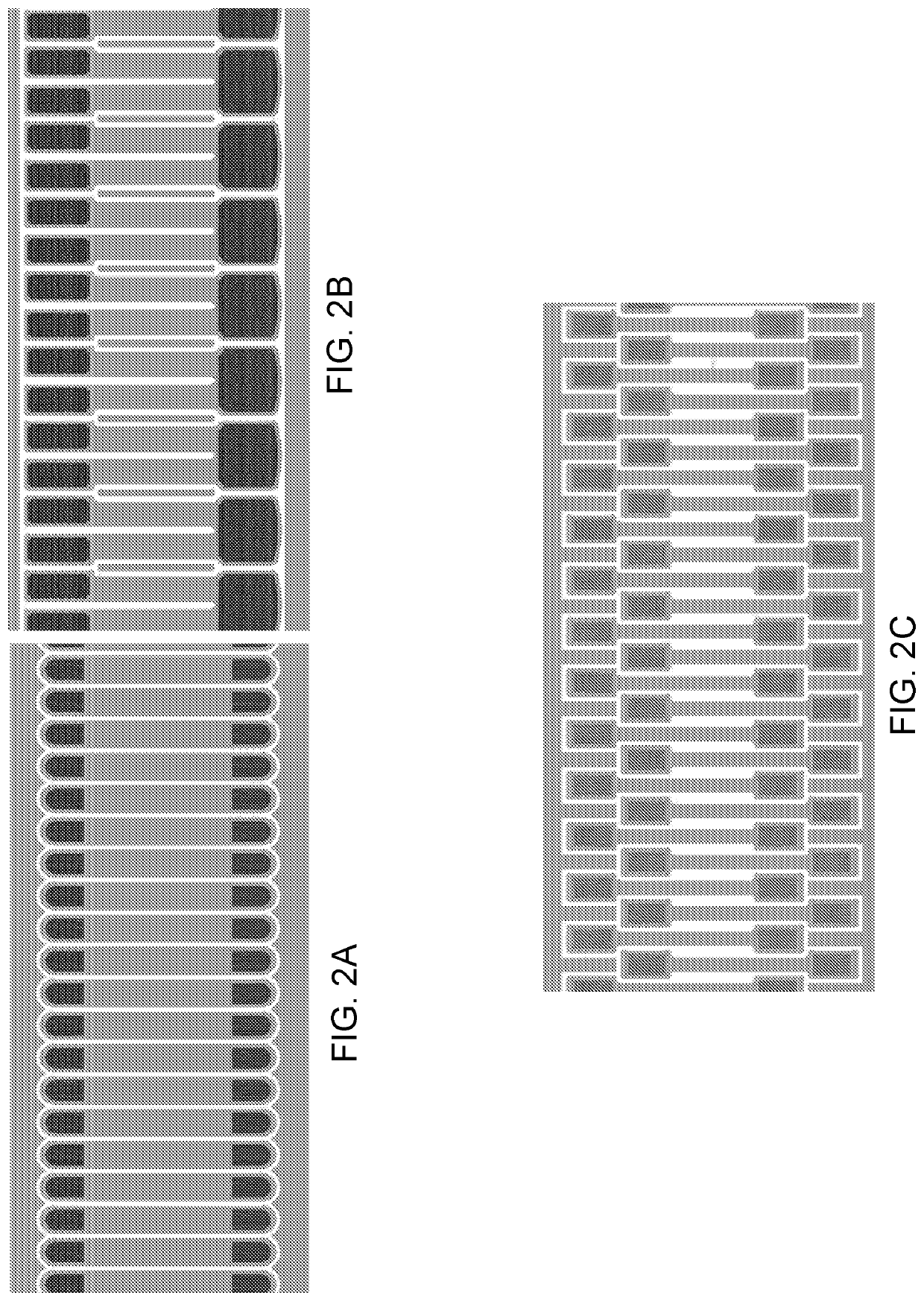

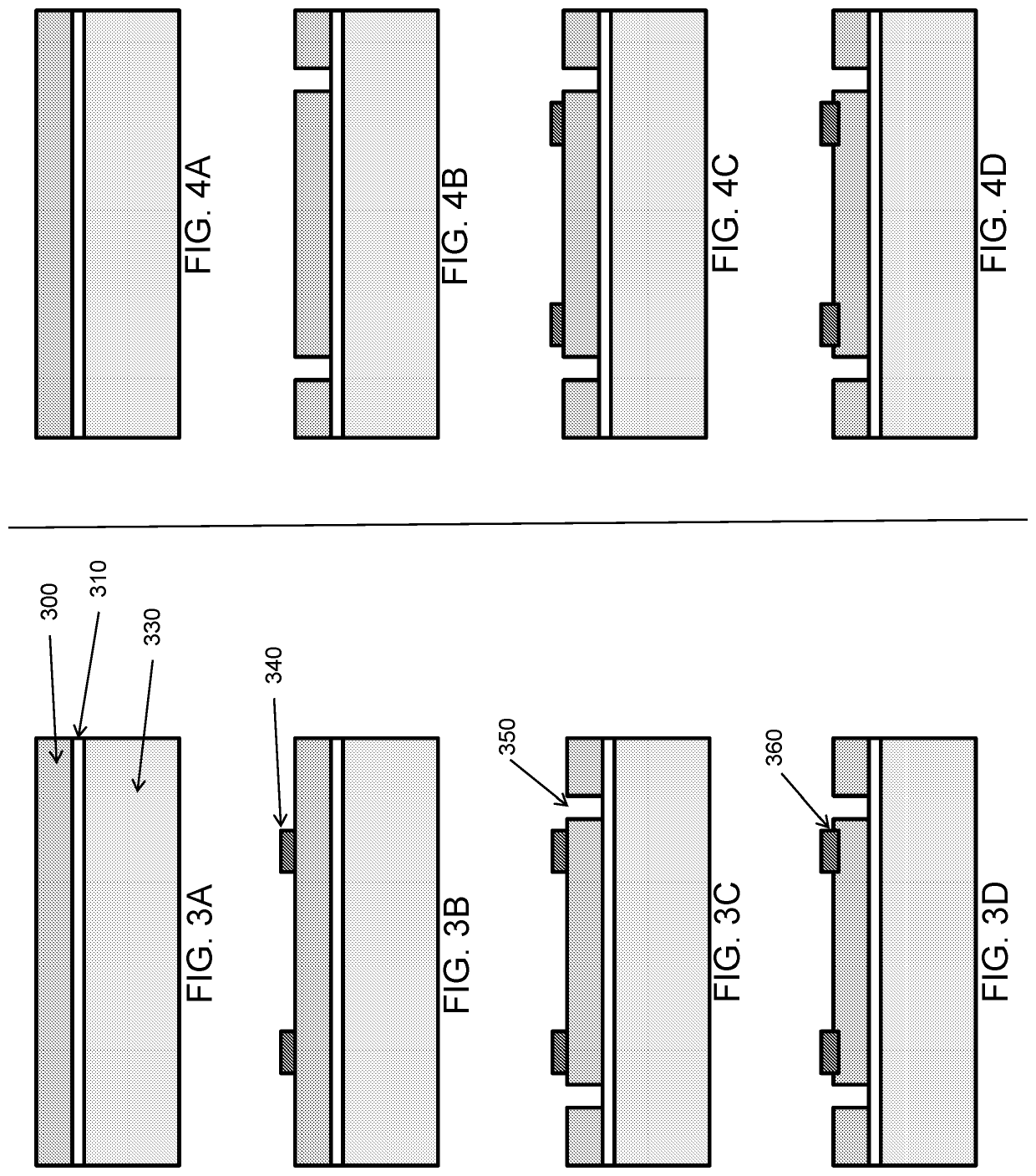

[0023]The current invention is now described with reference to the figures. Components appearing in more than one figure bear the same reference numerals.

[0024]Preferred embodiments of the present invention are described herein. Other variations of the present invention may also be performed and are claimed in the present patent, as referenced herein. The invention is described in combination with particular embodiments, but it is not the intention to limit the invention to the described embodiments. Rather, it is intended to encompass alternatives, equivalents and modifications as described by the scope of the presented claims.

[0025]Typically, when fabricating semiconductor devices, many devices are fabricated on one wafer. As devices become smaller, and thus typically cheaper, it becomes more difficult to free the devices from the wafer in a clean and high yielding way once the fabrication is finished. This invention describes a method of making high yielding semiconductor strain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| resistance | aaaaa | aaaaa |

| piezo resistance effect | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com