Vision inspection system and method of inspecting parts

a technology of inspection system and inspection method, applied in the field of vision inspection system, can solve the problems of low detection accuracy, poor product consistency, laborious and high cost of manual inspection system, etc., and achieve the effect of improving image contrast, enhancing images, and improving image contras

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

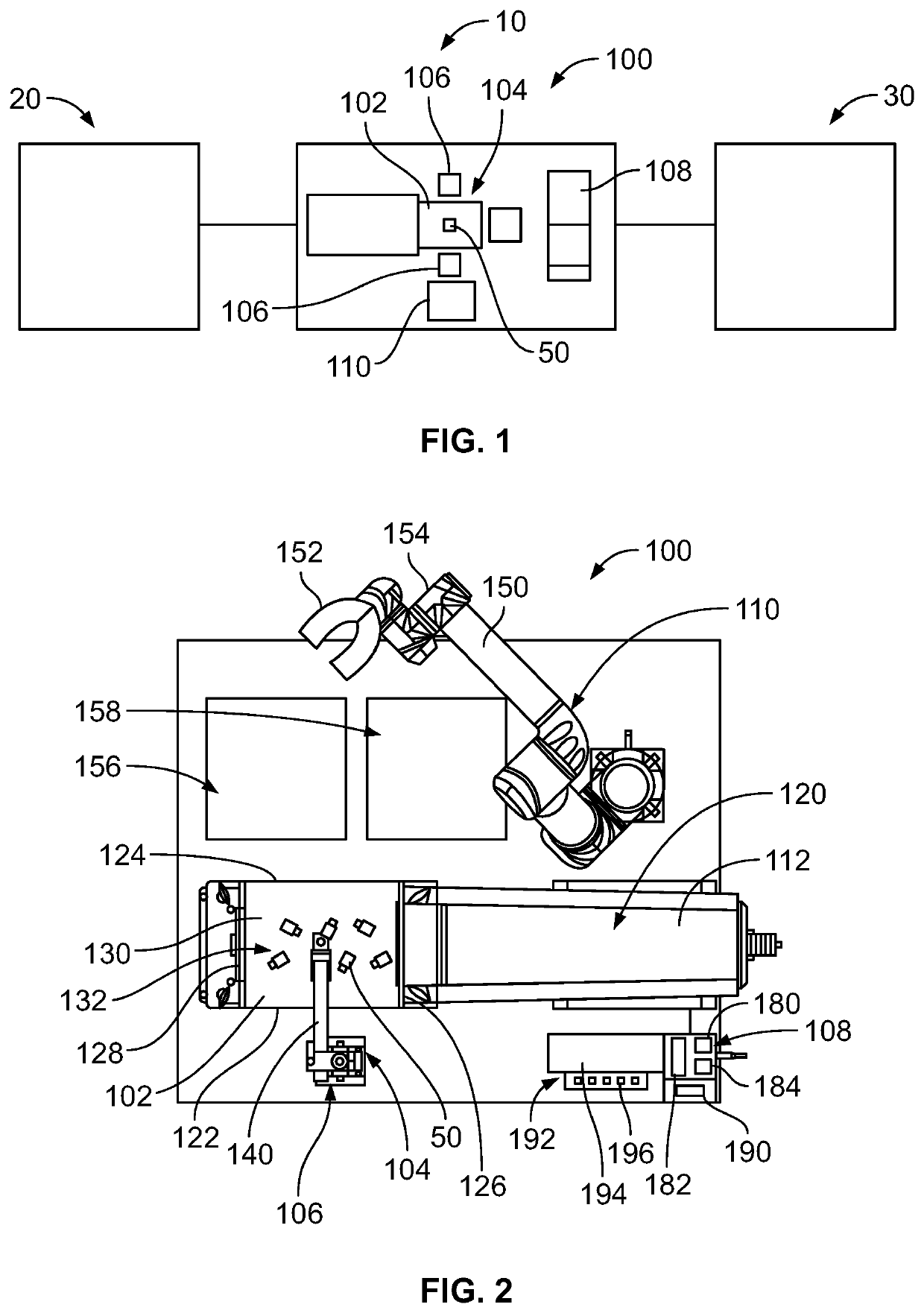

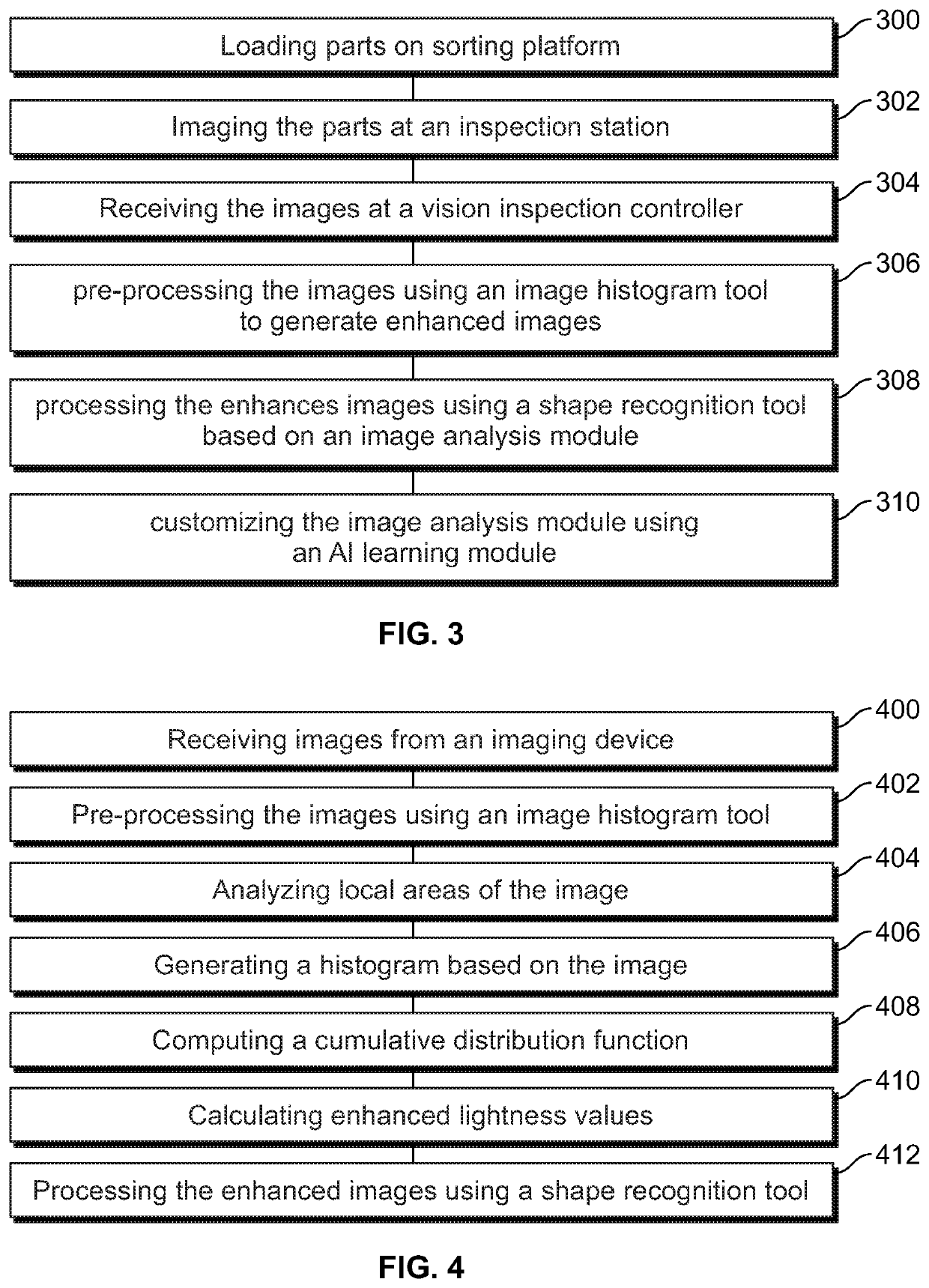

[0016]FIG. 1 is a schematic illustration of a machine 10 for manufacturing parts 50, such as parts used in electrical connectors. For example, the parts 50 may be contacts, housings, circuit boards, or other types of parts. The machine 10 may be used for manufacturing parts used in other industries. The machine 10 includes one or more forming machines 20 used to form various parts 50. For example, the forming machines 20 may include a molding machine, a press, a lathe, and the like. The machine 10 includes a vision inspection system 100 used to inspect the various parts 50. The machine 10 includes one or more processing machines 30 used for processing the various parts 50. For example, the processing machines 30 may include assembly machines, packaging machines, and the like. For example, in various embodiments, the parts 50 may be assembled, such as at an assembly station, prior to packaging, such as at a packing station. The parts 50 are transported between the forming machines 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| brightness | aaaaa | aaaaa |

| field of view | aaaaa | aaaaa |

| shapes | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com