Vacuum cleaner

a vacuum cleaner and vacuum cleaner technology, applied in the field of vacuum cleaners, can solve the problems of inconvenient storage, moving or carrying the vacuum cleaner, the connecting components of the entire vacuum cleaner are difficult to gather, and cannot be stored into the main body portion so as to ensure the performance of the vacuum cleaner, reduce the space occupied by the suction pipe unit, and minimize the distance between the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

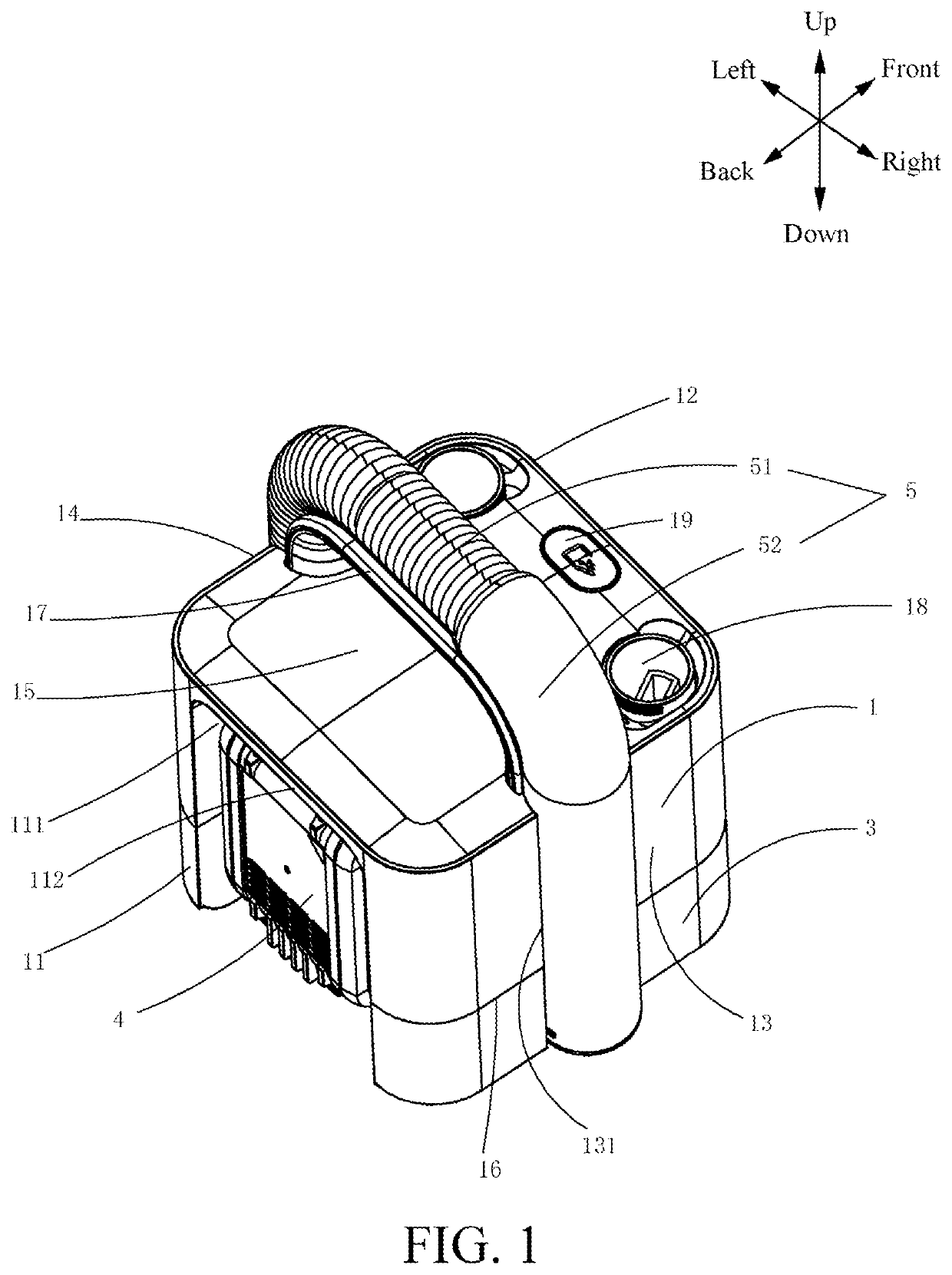

[0380]The present embodiments provide a vacuum cleaner, which is flexible to operate and has a long single cleaning time.

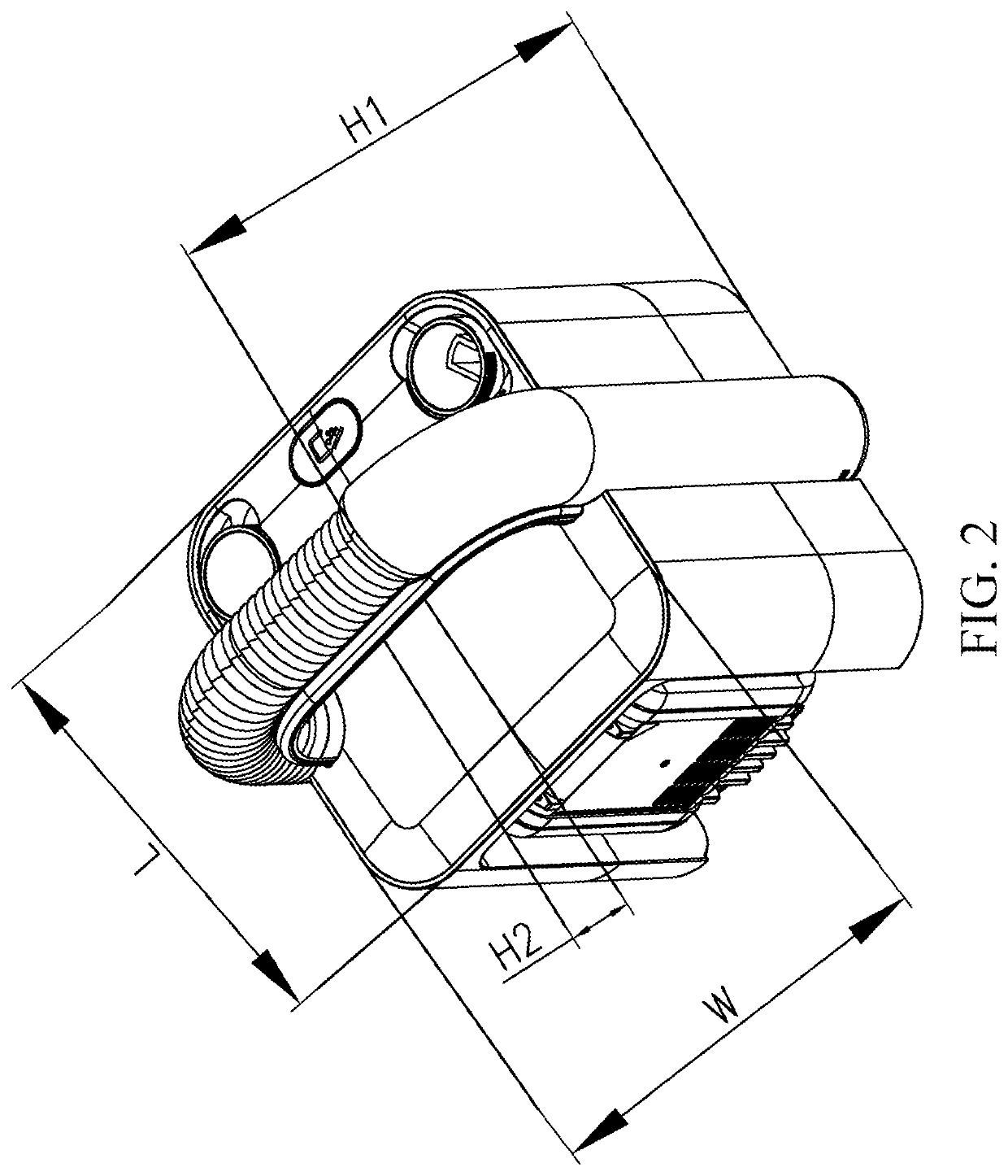

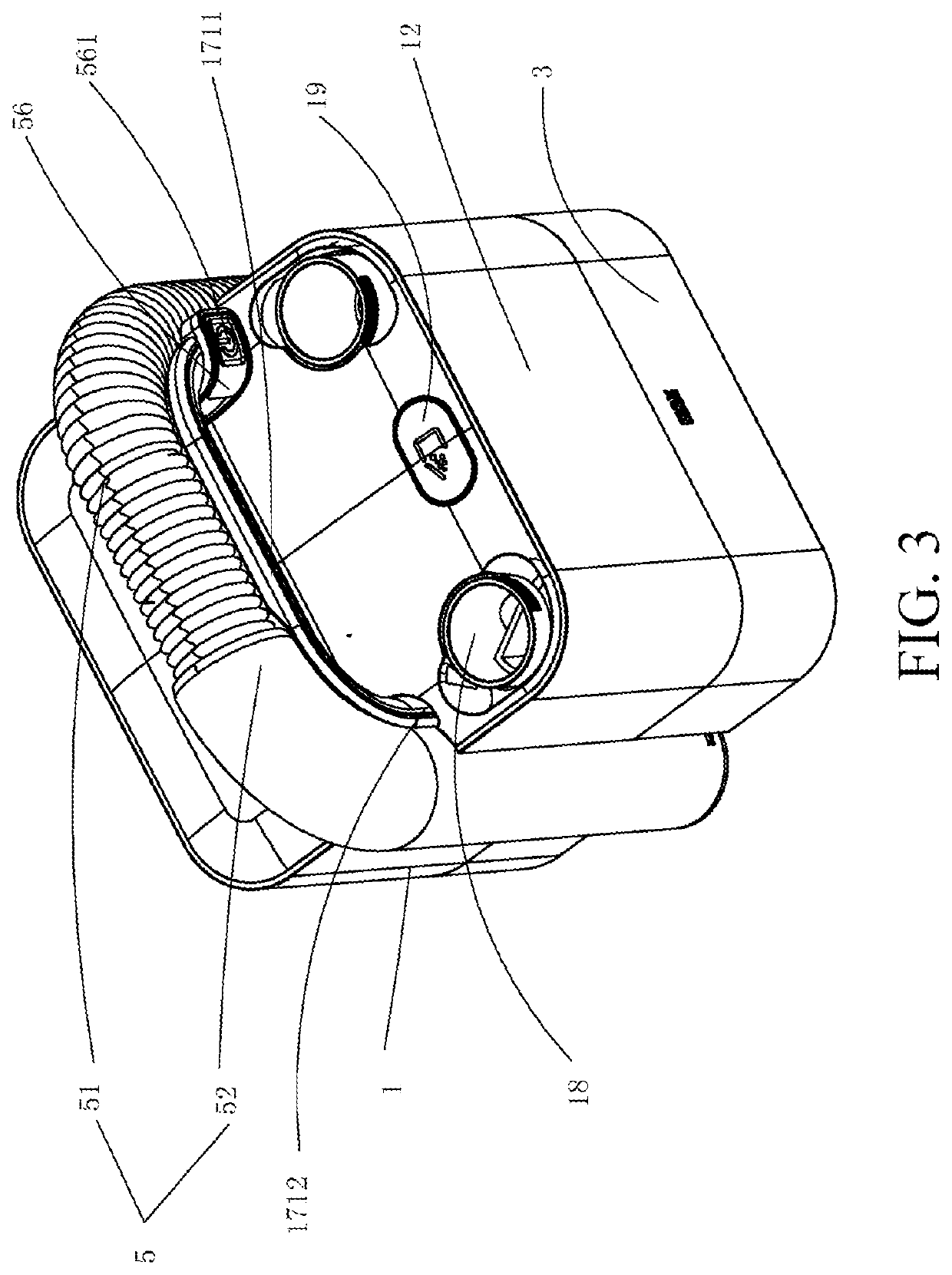

[0381]Exemplary implementations of the present invention are described below in detail with reference to the accompanying drawings. It should be understood that the detailed descriptions are merely used for teaching a person skilled in the art to implement the present embodiments, but are not used to exhaust all manners of the present embodiments and are not used for limiting the scope of the present embodiments.

[0382]It should be noted that, when a component is referred to as “being fixed to” another component, the component may be directly on the other component, or an intervening component may be present. When a component is considered to be “connected to” another component, the component may be directly connected to the another component, or an intervening component may also be present. In contrast, when a component is referred to as being “directly on” or “di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com