System for supplying hydrogen gas to engine

a hydrogen gas and engine technology, applied in the direction of electrical control, speed sensing governor, container discharging method, etc., can solve the problems of large number of cylinders to be loaded, large amount of hydrogen required, unrealistic, etc., and achieve the effect of increasing the degree of freedom of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

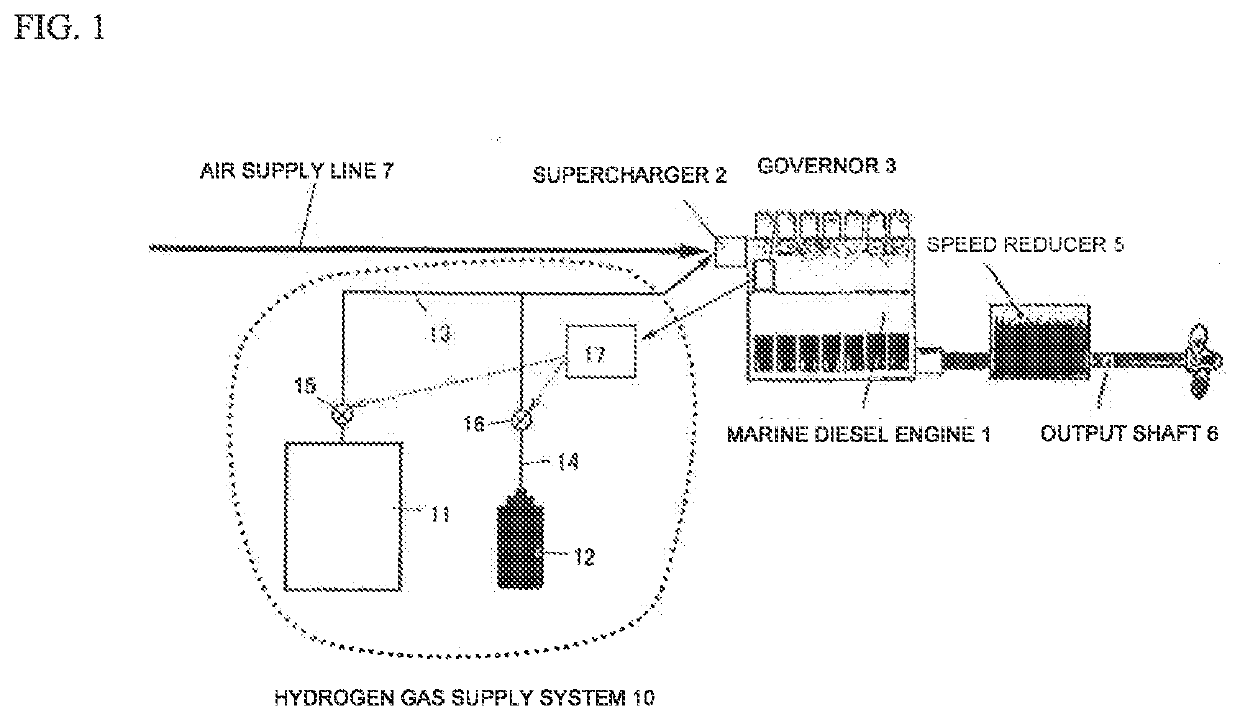

[0031]Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings. FIG. 1 shows an example in which a hydrogen gas supply system according to the first aspect of the present invention is applied to a marine diesel engine. The marine diesel engine 1 includes a supercharger 2, a governor 3 to maintain the engine rotation speed within a certain range even if the load fluctuates, a speed reducer 5 (not equipped in a low-speed engine) for decreasing the rotation of the engine, and a propeller shaft 6 (output shaft).

[0032]An air supply line (piping) 7 for taking in outside air into the engine has, at one end, the supercharger 2. To the air supply line 7 including the supercharger 2, a trace amount of hydrogen gas is sent via the hydrogen gas supply system 10. (In an engine having no supercharger, hydrogen is put into an air filter.)

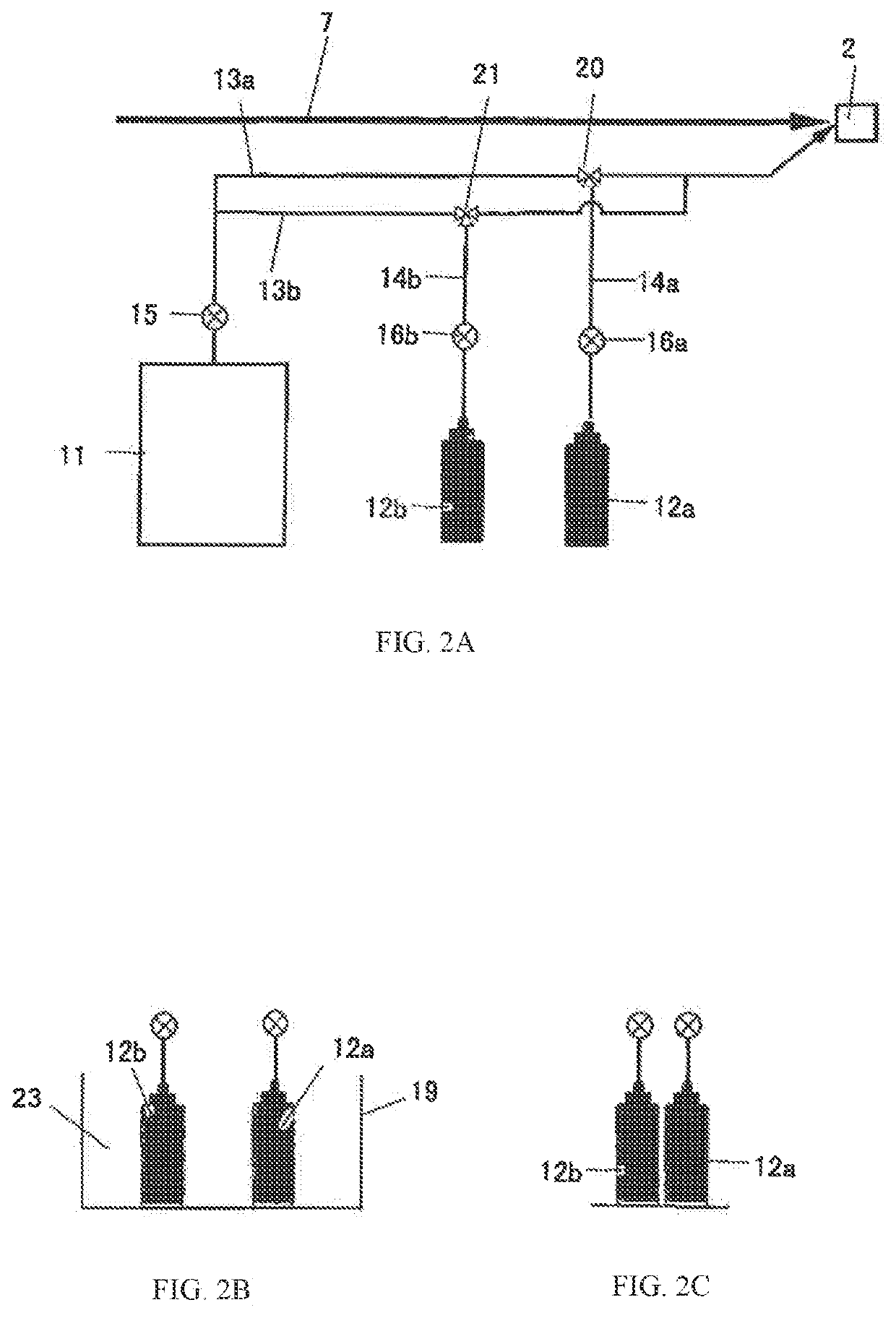

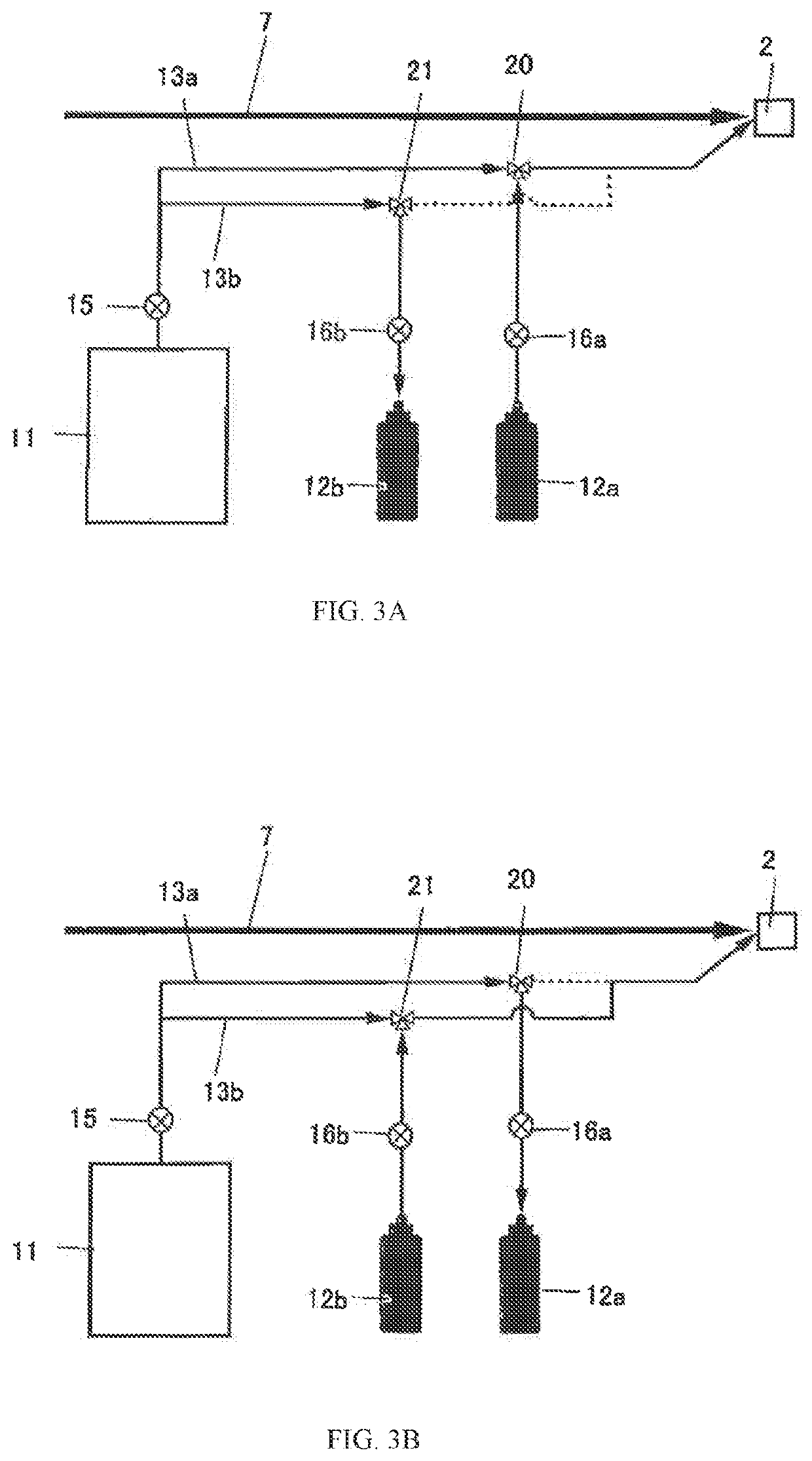

[0033]The hydrogen gas supply system 10 includes a hydrogen gas producer 11 for electrolyzing pure water to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com