Emergency bulk liquid cargo spill prevention system

a technology for liquid cargo and spill prevention, applied in the field of pollution prevention, can solve the problems of significant increase in ship construction costs, serious affecting the stability of ships, and limitations of each of these methods and designs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

of the Figures

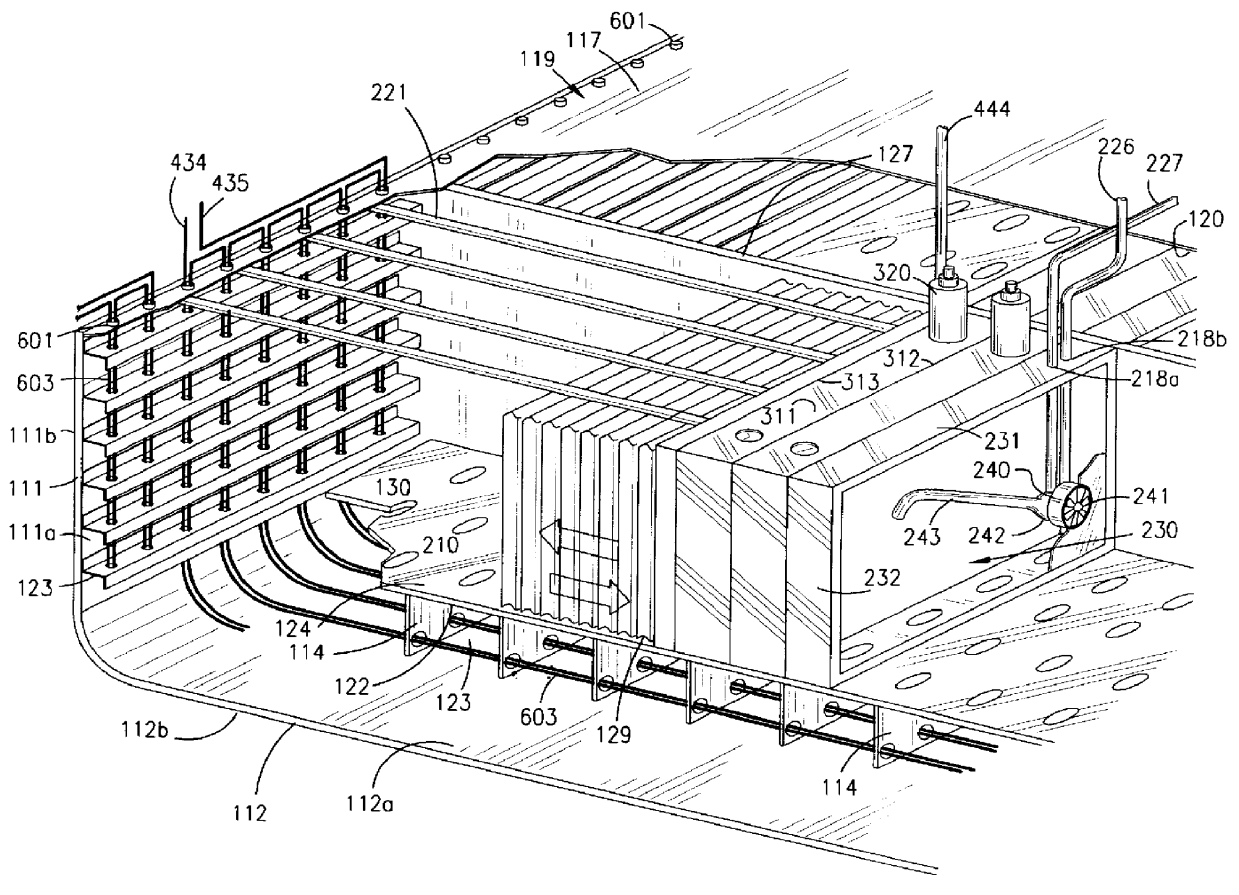

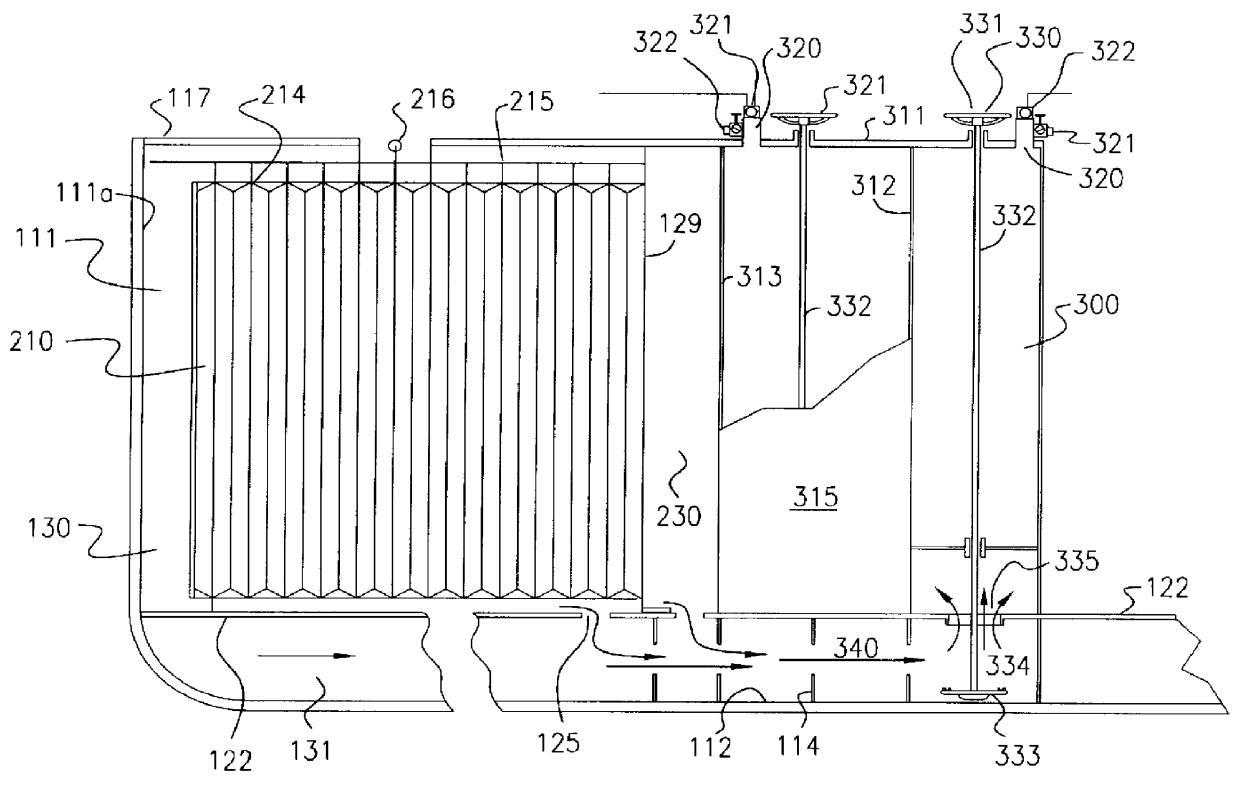

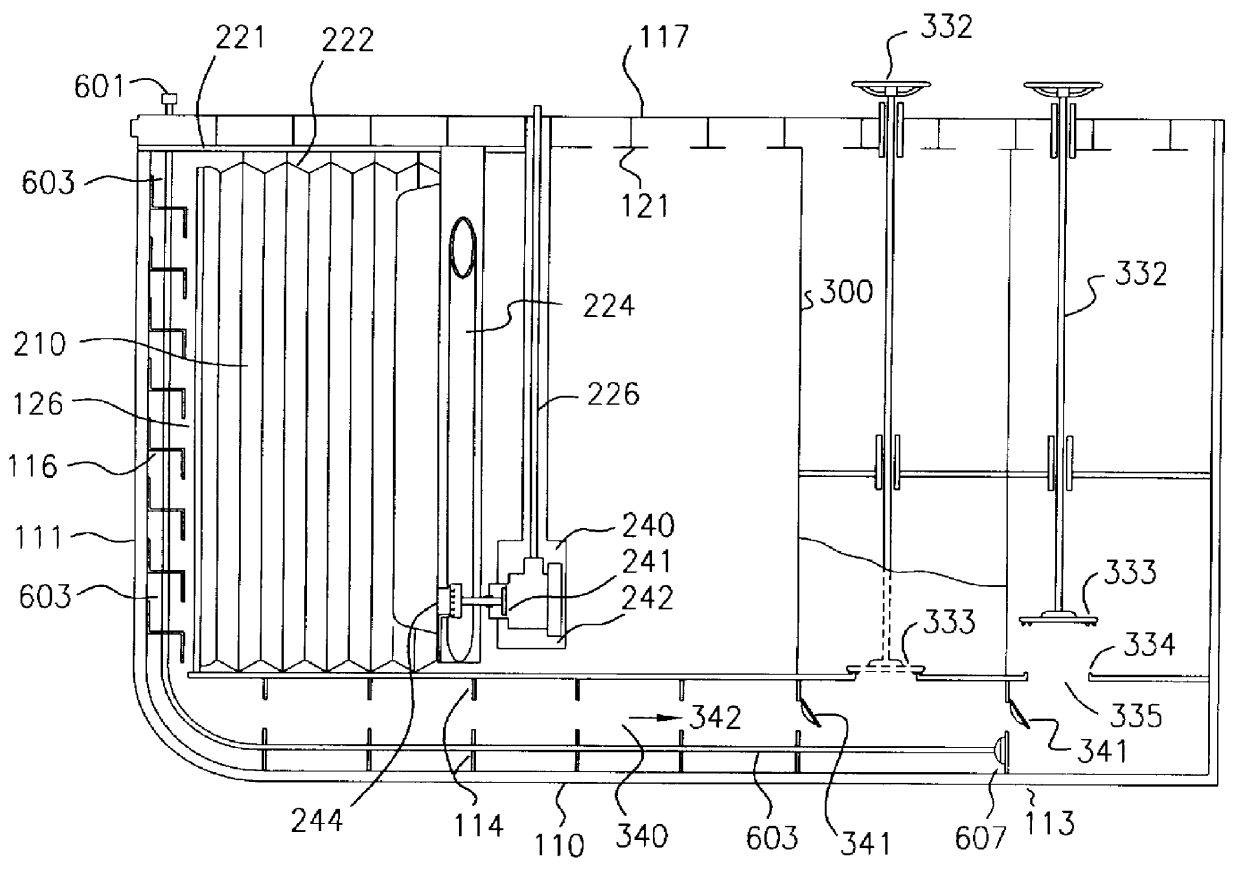

Referring now to FIG. 1, shown is an Emergency Expandable Bladder Assembly 200 for the containment of liquid cargo comprised of a liquid tight Expandable Bladder 210 having an interior volume for receiving liquid cargo from a ruptured liquid cargo tank. Said Expandable Bladder 210 is fixedly attached to an Inboard Sidewall 129 of an otherwise conventional Liquid Cargo Tank 126 . A bulk liquid cargo Tanker 100 would typically have a plurality of such Liquid Cargo Tanks 126 located from fore to aft in the cargo hold and port and starboard of the Tanker 100 Keel 113 comingled with conventional ballast tanks in such a configuration as to optimize Tanker 100 stability and buoyancy.

The Bulk Liquid Cargo Tank 126 of FIG. 1 is one from a plurality of such tanks and is typical of such tanks throughout Tanker 100. The Bulk Liquid Cargo Tank 126 shown is the aft-most port side located tank of such tanks. In an alternate embodiment, such tanks may even be stacked one above the oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com