Electromagnetic device

a technology of electromagnetic devices and magnetic fields, applied in the direction of inductances, windings, cores/yokes, etc., can solve the problems of non-uniformity, difficult sealing and monitoring leakage, and temperature differences across the machin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Rotating Electric Machine According to FIGS. 1 and 2

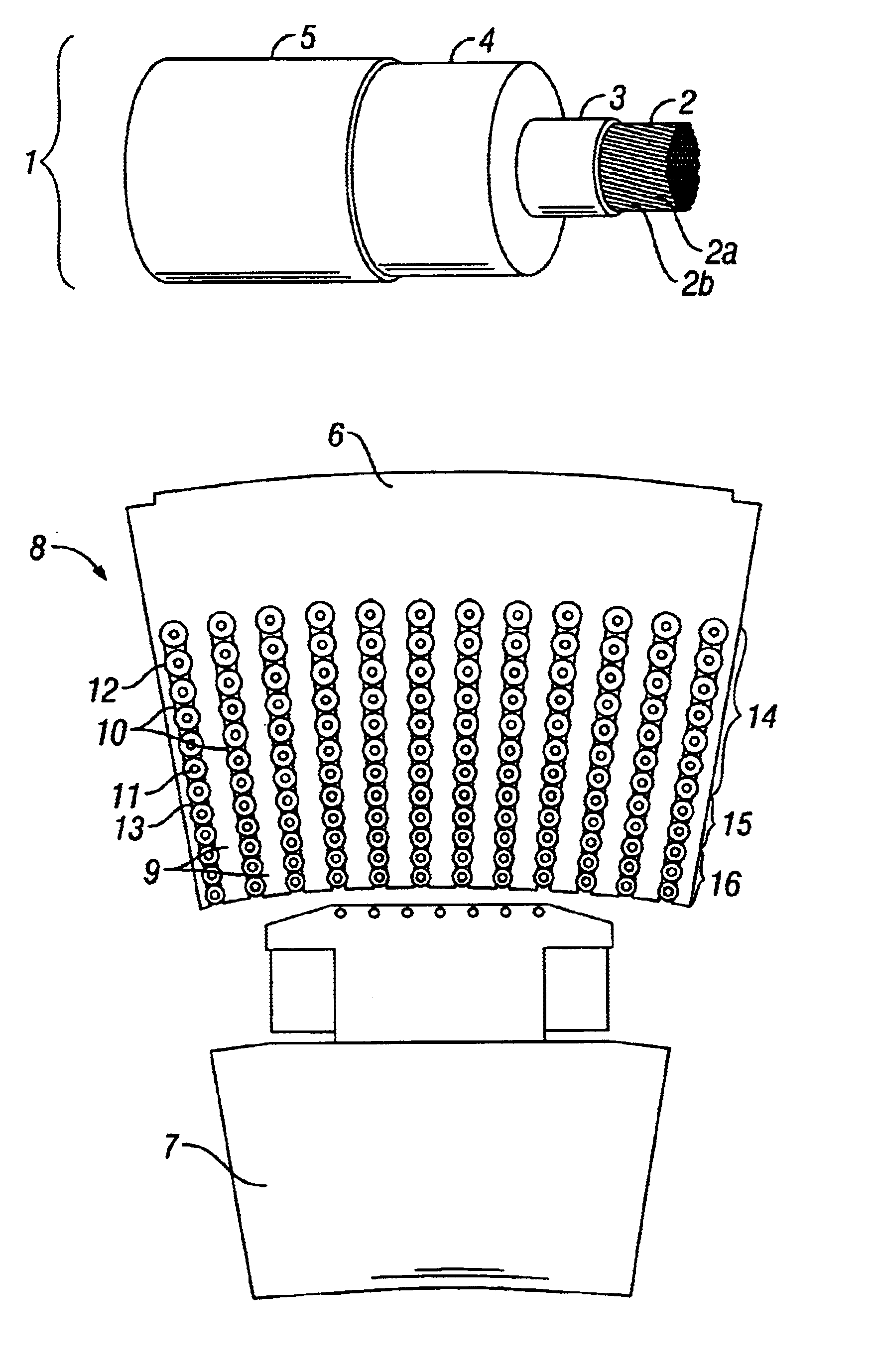

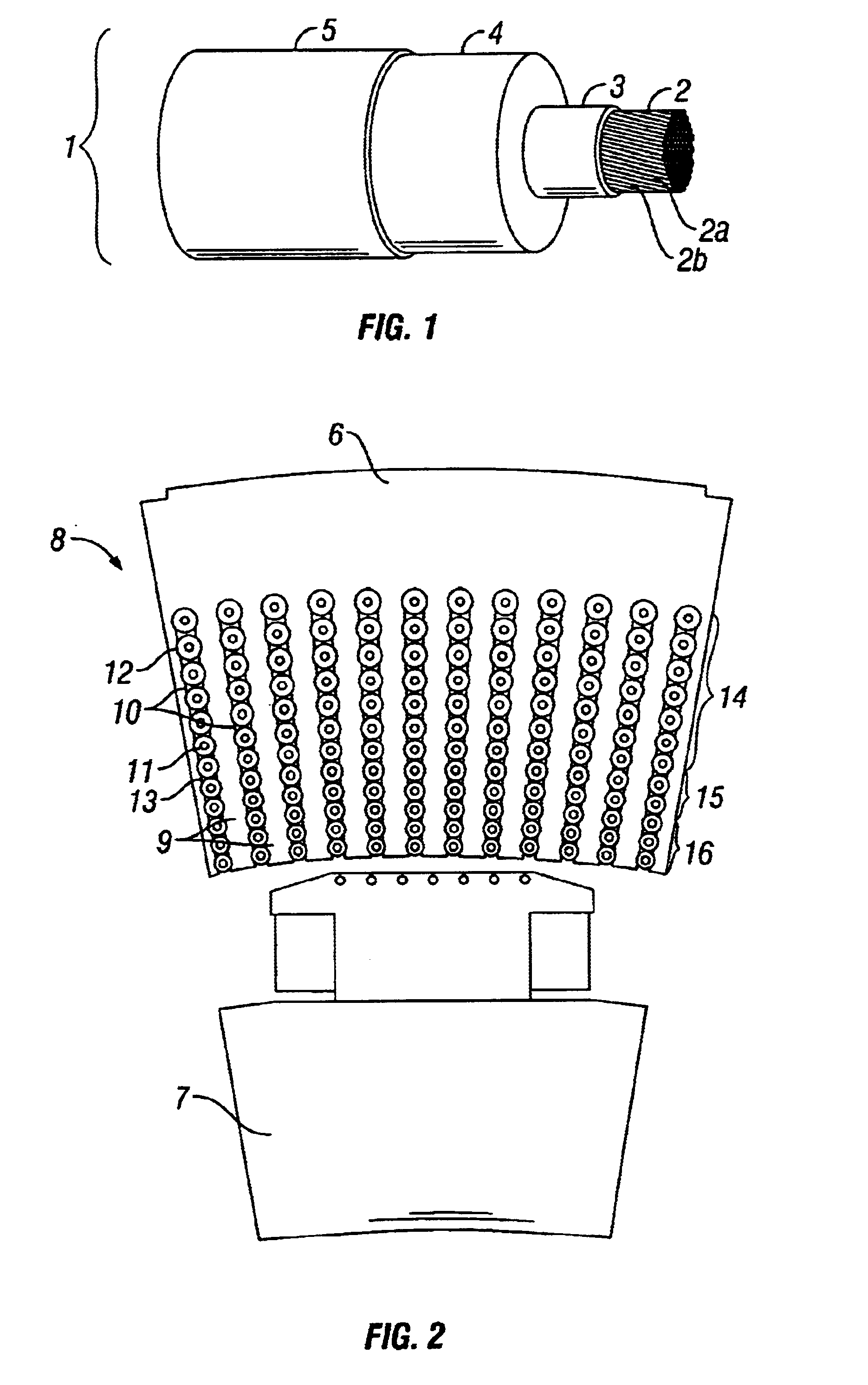

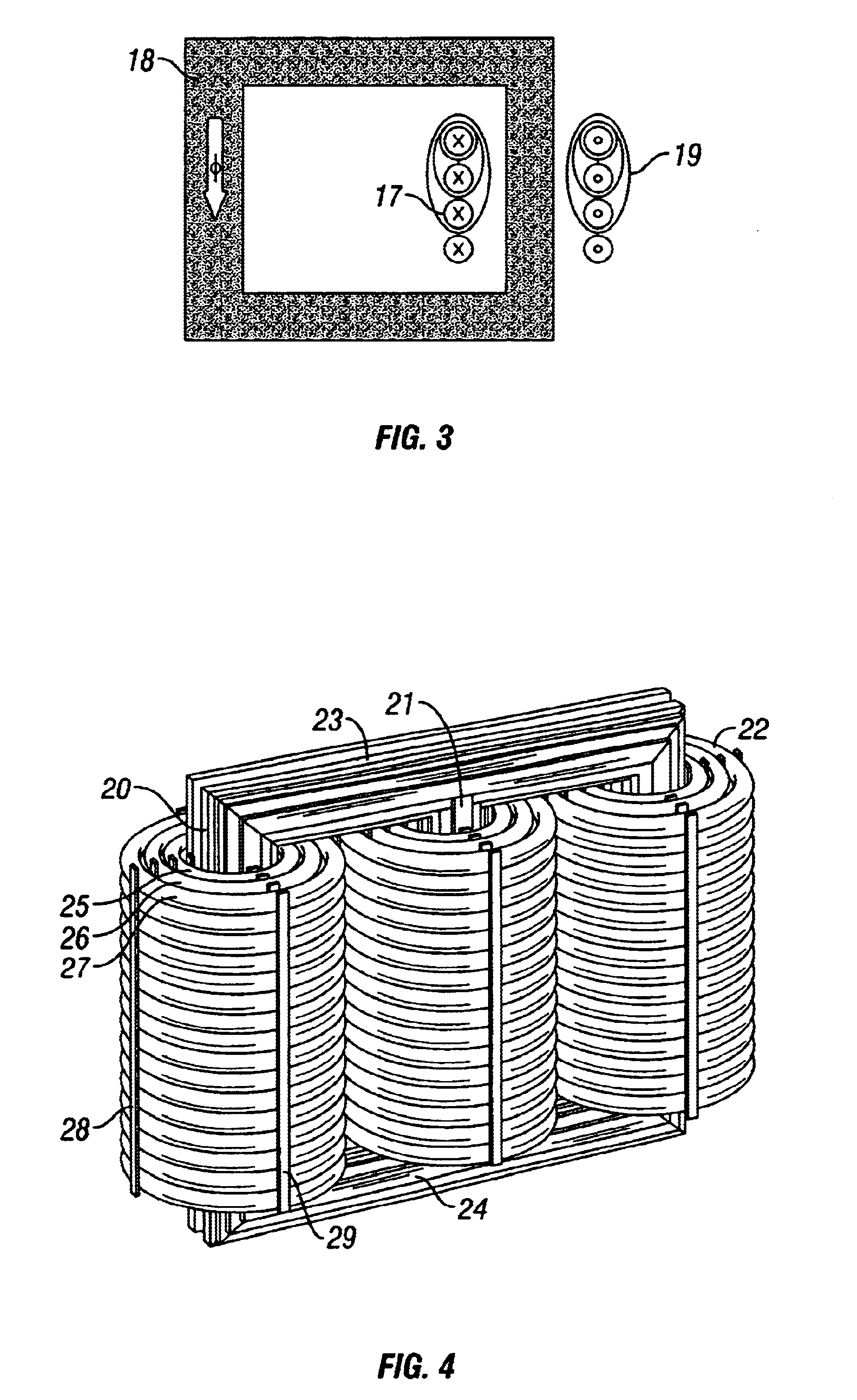

An important condition for being able to manufacture a magnetic circuit in accordance with the description of the invention, is to use for the winding a conductor cable with a solid electrical insulation with an inner semiconducting layer or casing between the insulation and one or more electrical conductors located inwardly therof and with an outer semiconducting layer or casing located outwardly of the insulation. Such cables are available as standard cables for other power engineering fields of use, namely power transmission. To be able to describe an embodiment, initially a short description of a standard cable will be made. The inner current-carrying conductor comprises a number of non-insulated strands. Around the strands there is a semiconducting inner layer. Around this semiconducting inner layer, there is an insulating layer of solid insulation. The solid insulation is formed by a polymeric material with low electrical los...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com