Radiation patterning tools, and methods of forming radiation patterning tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

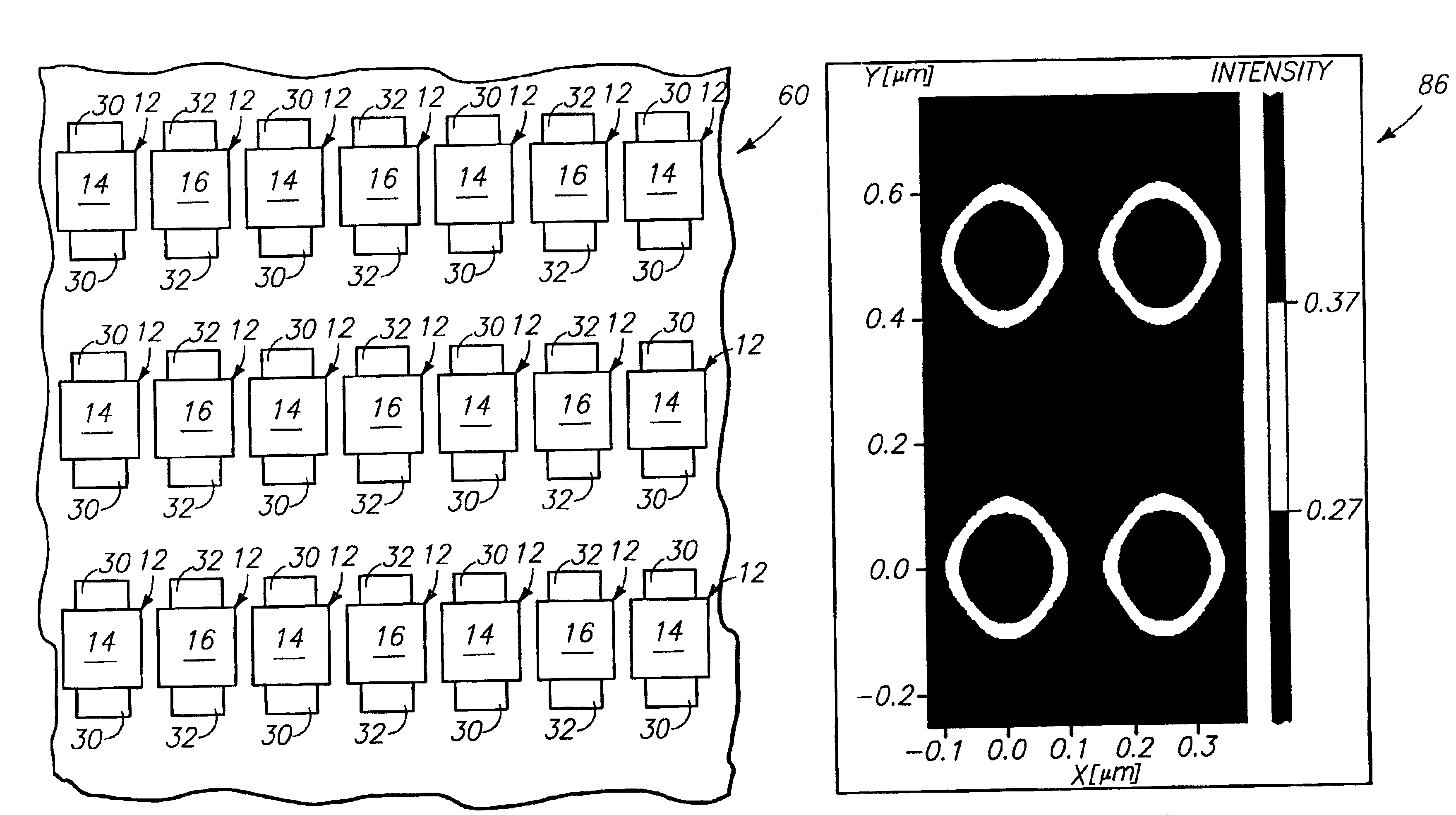

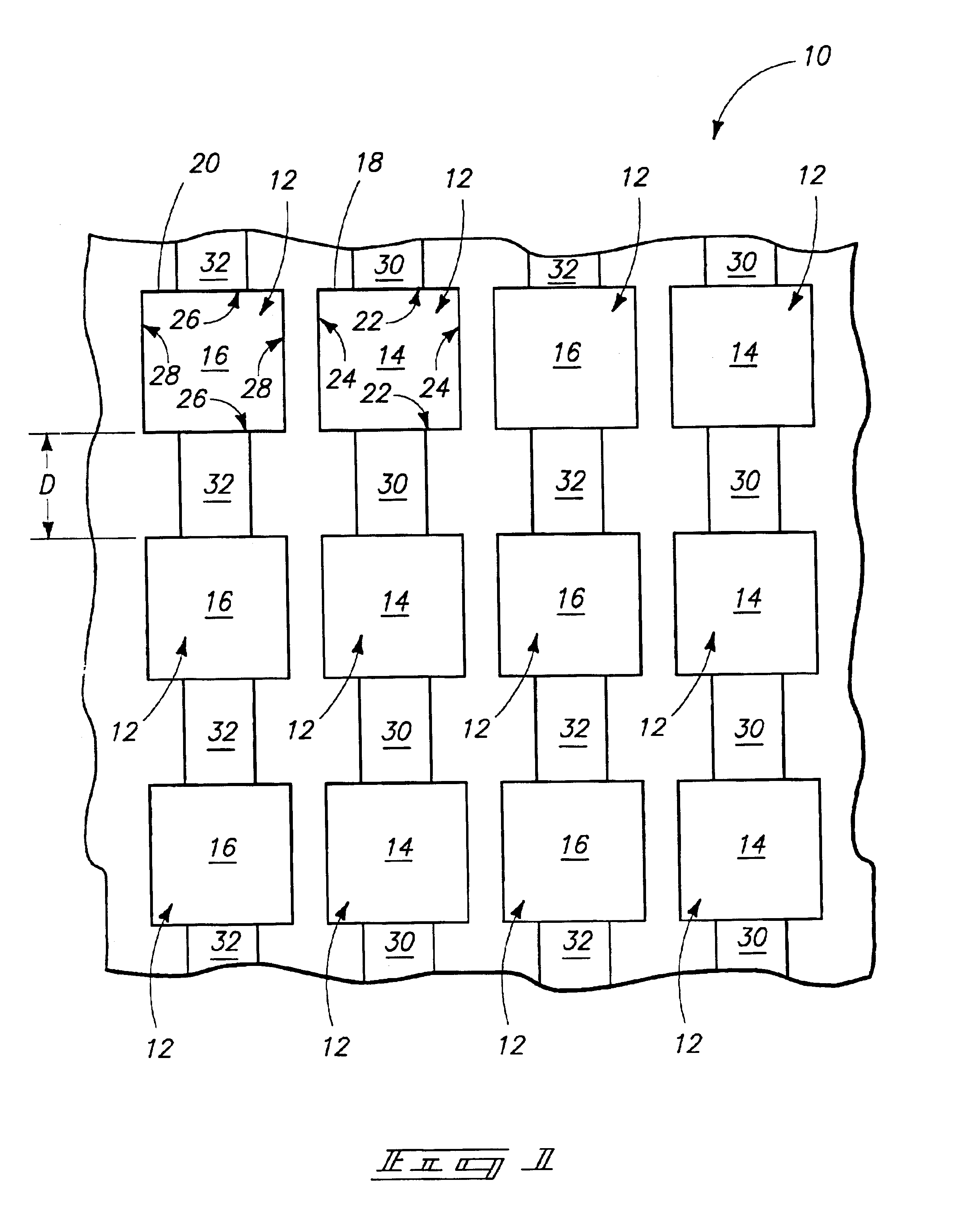

Referring initially to FIG. 1, a first embodiment radiation patterning tool construction 10 comprises an array of feature patterns 12 arranged in vertically-extending columns and horizontally-extending rows. The feature patterns 12 are divided between a pair of defined types. Specifically, some of the feature patterns 12 are a first type 14 (also referred to herein as first feature patterns) and others are a second type 16 (also referred to herein as second feature patterns). The first type of feature pattern rotates a phase of a wavelength of light to a first orientation as the wavelength passes through it; and the second type of feature pattern rotates the phase of the wavelength of light to a second orientation as the wavelength passes through it. The second orientation can be from about 170° to about 190° relative to the first orientation, can be about 180° relative to the first orientation, and can be exactly 180° relative to the first orientation. The light passing through fea...

second embodiment

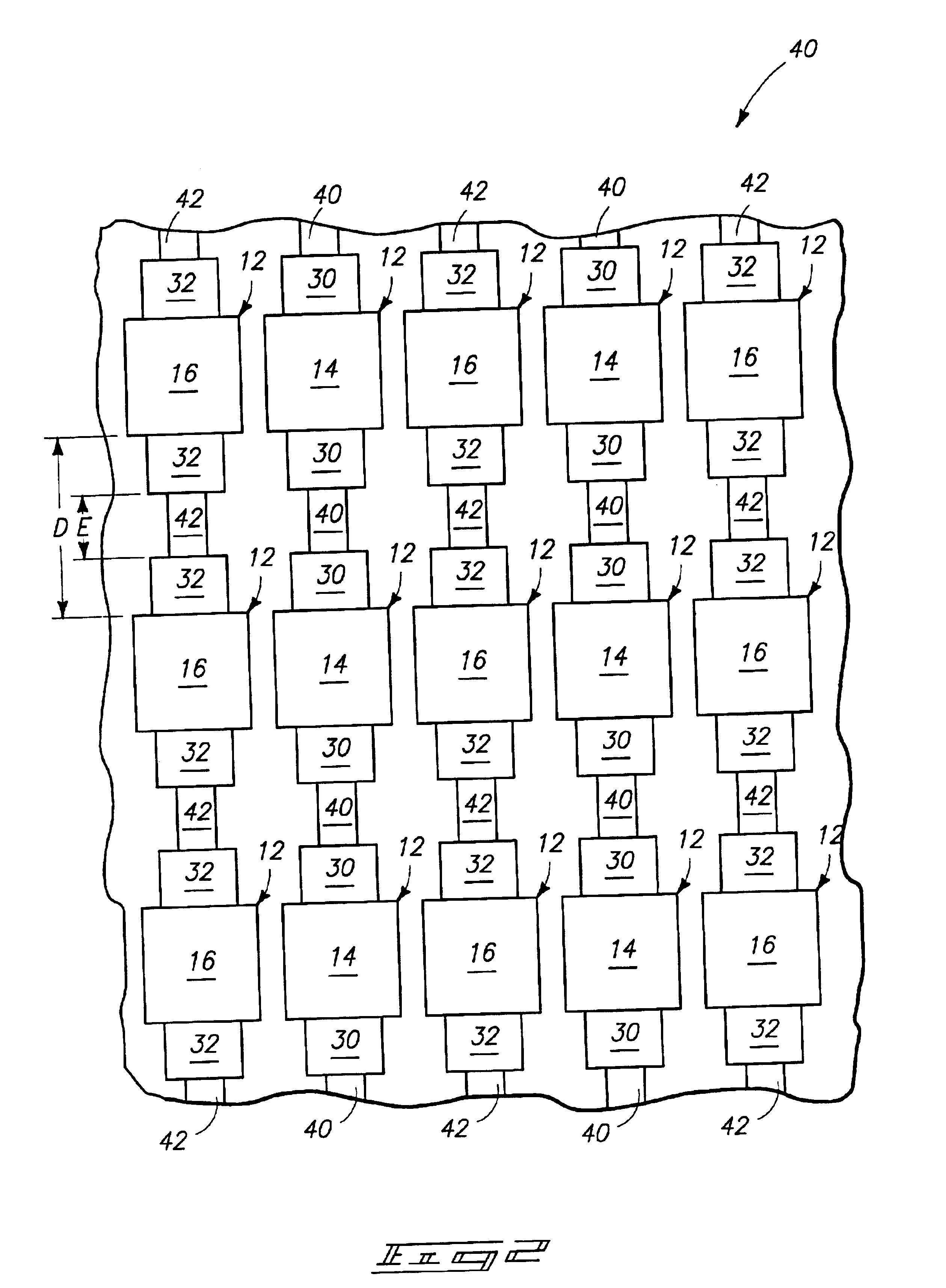

Referring to FIG. 2, a second embodiment radiation patterning tool 40 is illustrated. Similar numbering is utilized for describing the tool 40 as is utilized above in describing the tool 10 of FIG. 1, where appropriate. Accordingly, tool 40 comprises first feature patterns 14, second feature patterns 16, first rims 30 and second rims 32. Also, the feature patterns are arranged in an array having columns and rows, and there is a distance “D” between adjacent feature patterns along the columns of the array. The distance “D” of the tool 40 can be the same or different than the distance “D” of the tool 10 of FIG. 1, and in typical embodiments the distance “D” of tool 40 will be larger than that of tool 10. In either tool 10 of FIG. 1 or tool 40 of FIG. 2, distance “D” can be about the size of feature pattern which is ultimately to be formed with the tool.

The rims 30 and 32 do not extend an entirety of the distance between adjacent feature patterns along columns of the array, but rather ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com