Spectacle lens and manufacturing method therefor

a technology of spectacles and lenses, applied in the field of spectacle lenses, can solve problems such as not addressing the overall wearing conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

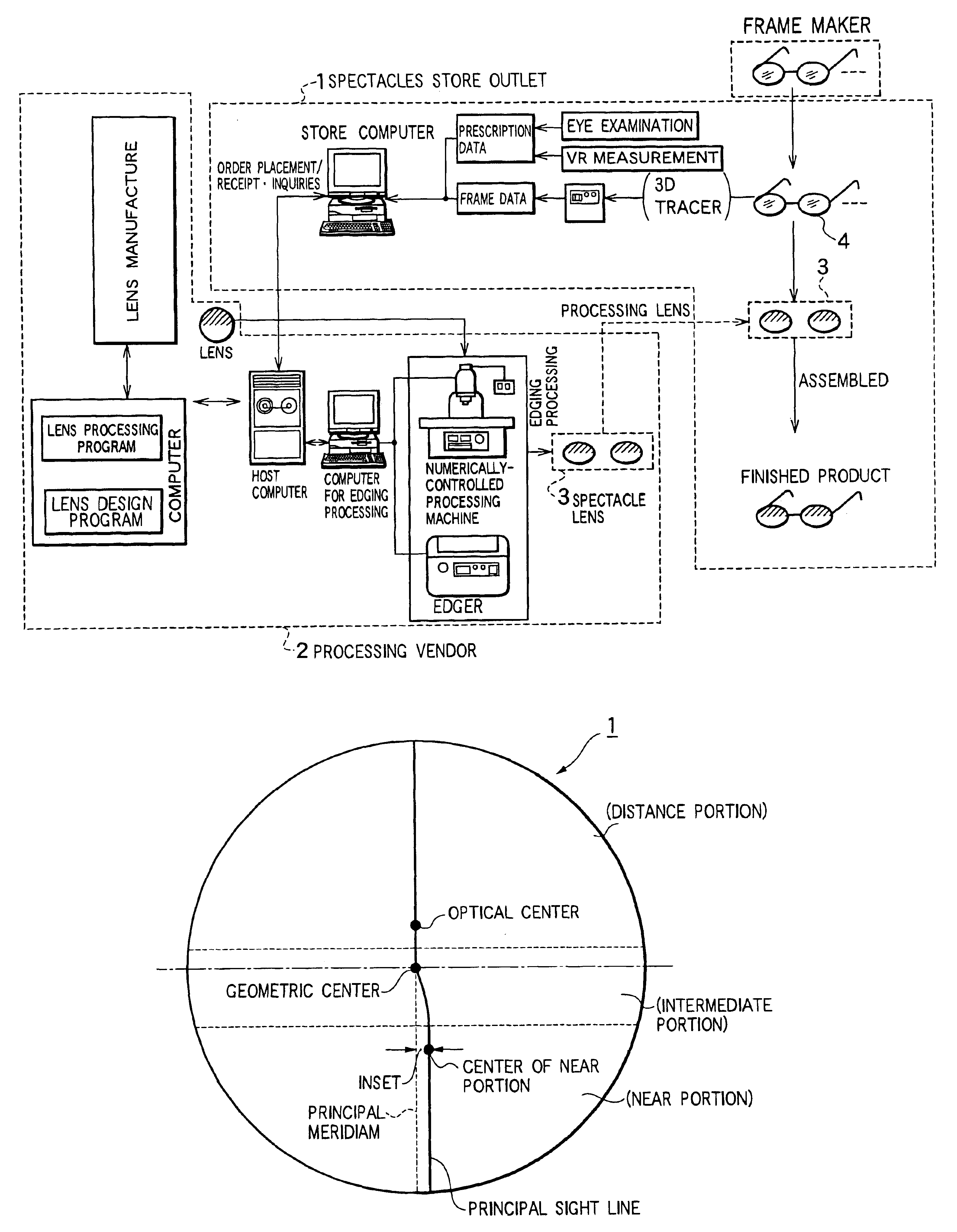

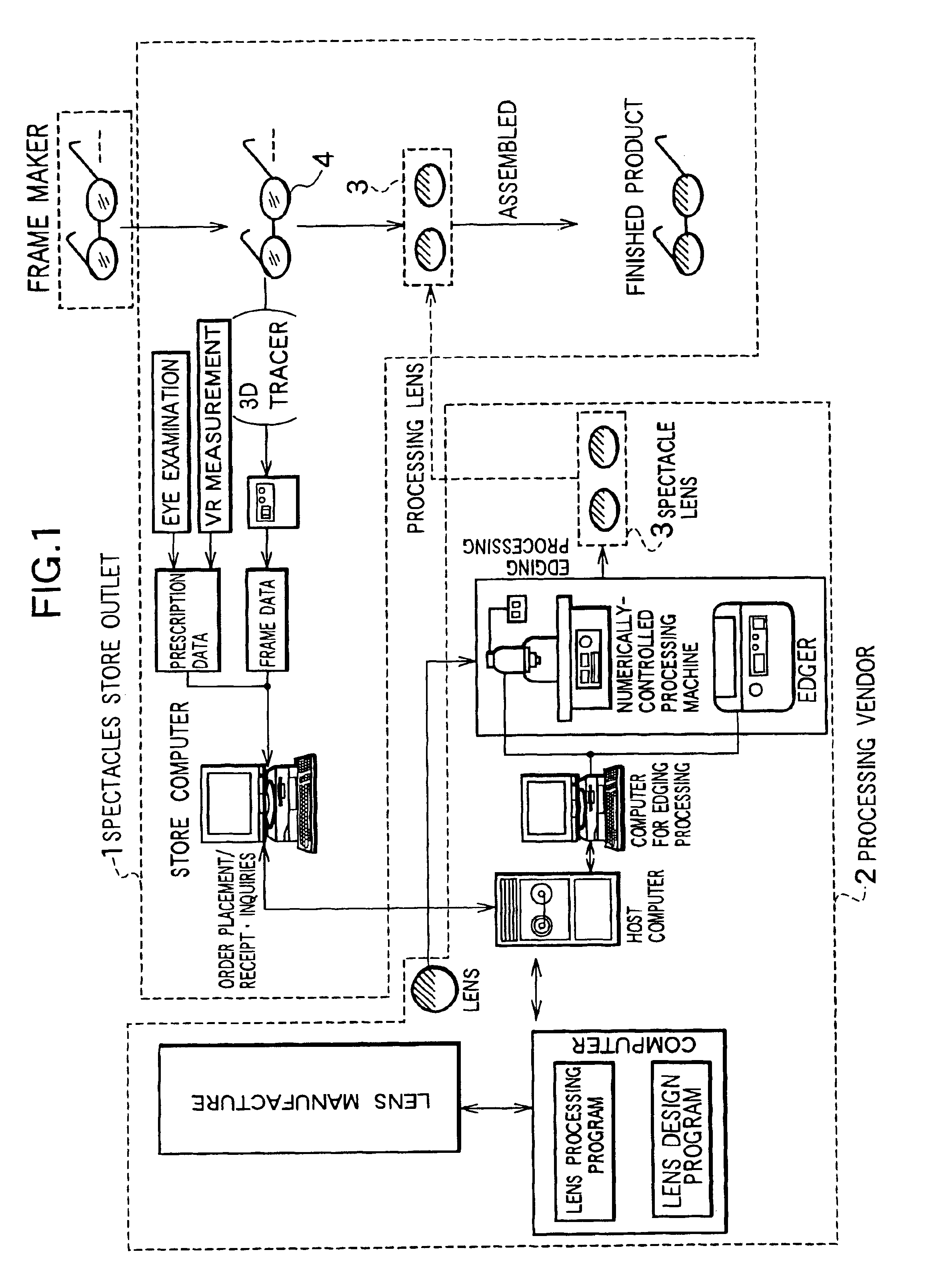

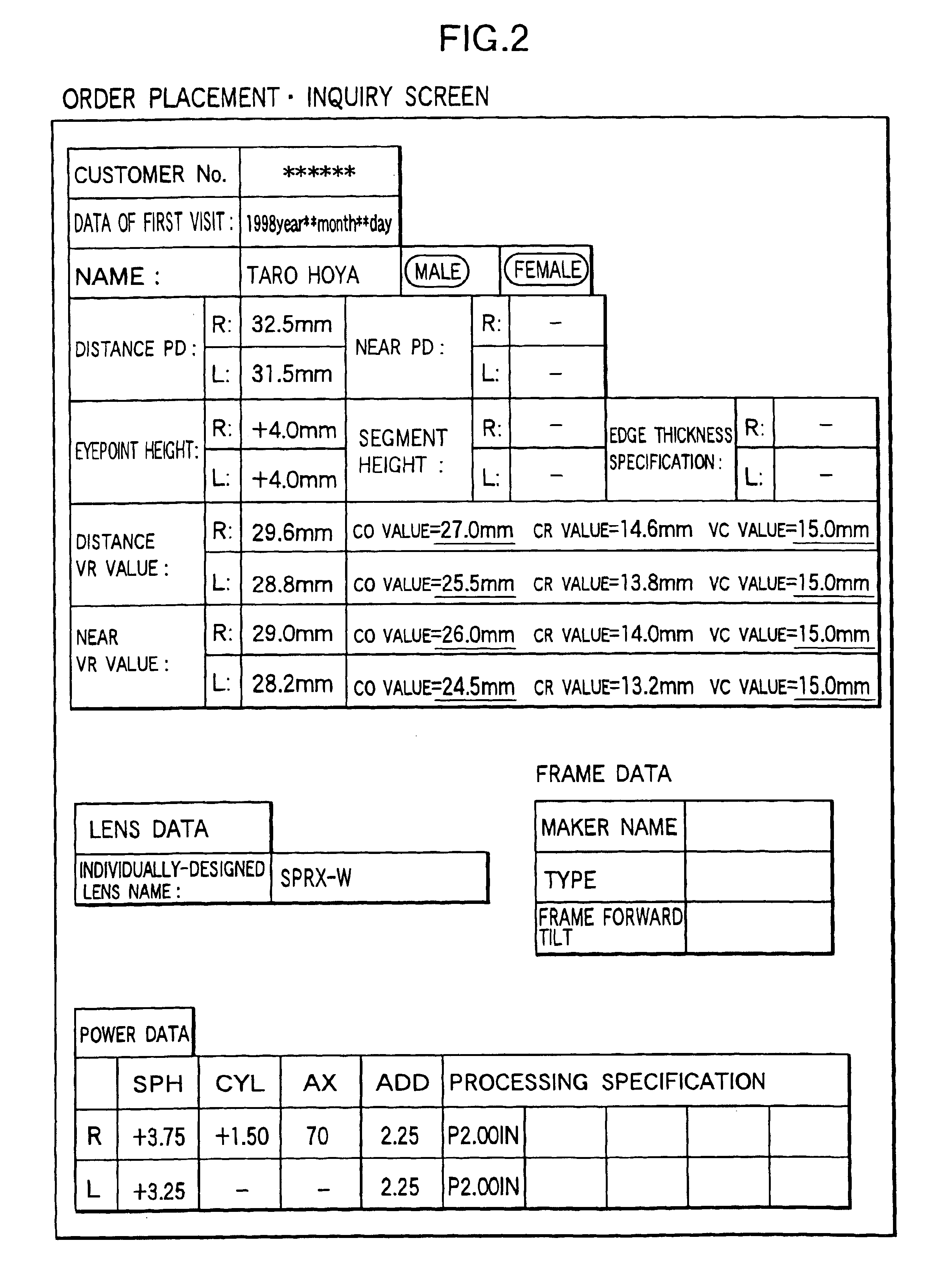

Aspects of the embodiment of the present invention will be explained hereinbelow based on the figures. FIG. 1 is a schematic diagram of a manufacturing method of a spectacle lens related to an aspect of the embodiment of the present invention, FIG. 2 is a schematic diagram of an ordering screen, FIG. 3 is a flowchart of a manufacturing process of a spectacle lens, and FIG. 4 is a schematic diagram of an optical model of spectacles wearing.

In FIG. 1. Reference Numeral 1 is a spectacles store (ordering party), and Reference Numeral 2 is a spectacles processor (processing party). The spectacle lens manufacturing method of this aspect of the embodiment is such that a spectacle lens 3 is designed and manufactured based on information sent via a terminal apparatus installed at the spectacles store (ordering party) 1 to an information processing system installed at the processor (processing party) 2.

That is, via the above-mentioned terminal apparatus there is sent to the above-mentioned in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com