Apparatus and method for depositing superior Ta (N) copper thin films for barrier and seed applications in semiconductor processing

a technology of semiconductor processing and barrier film, applied in the direction of semiconductor/solid-state device manufacturing, electrical equipment, basic electric elements, etc., can solve the problem of insufficient high-density plasma, insufficient ipvd source, and insufficient step coverage of high-aspect ratio structure, etc. problem, to achieve the effect of enhancing the subsequent deposition of copper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

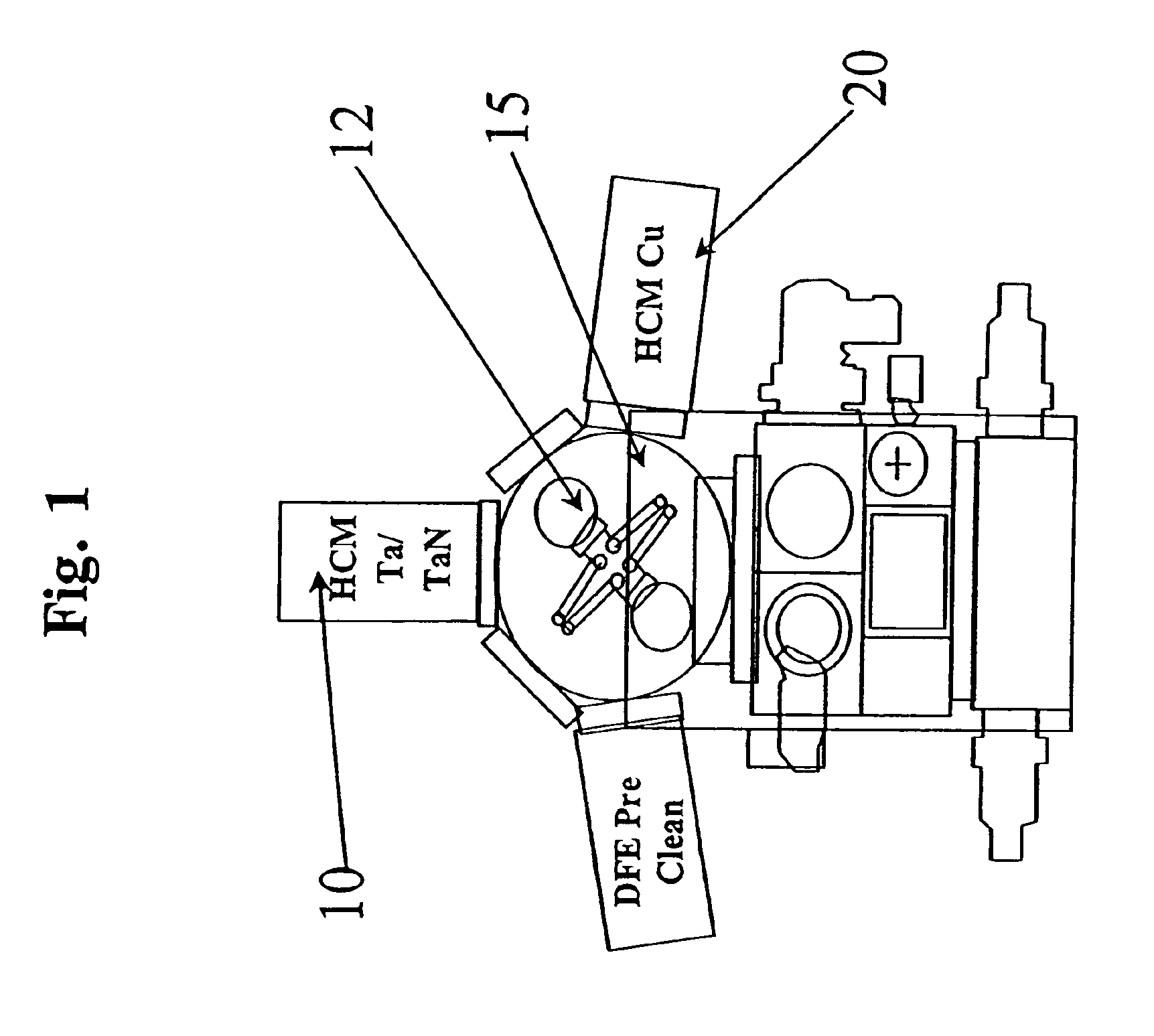

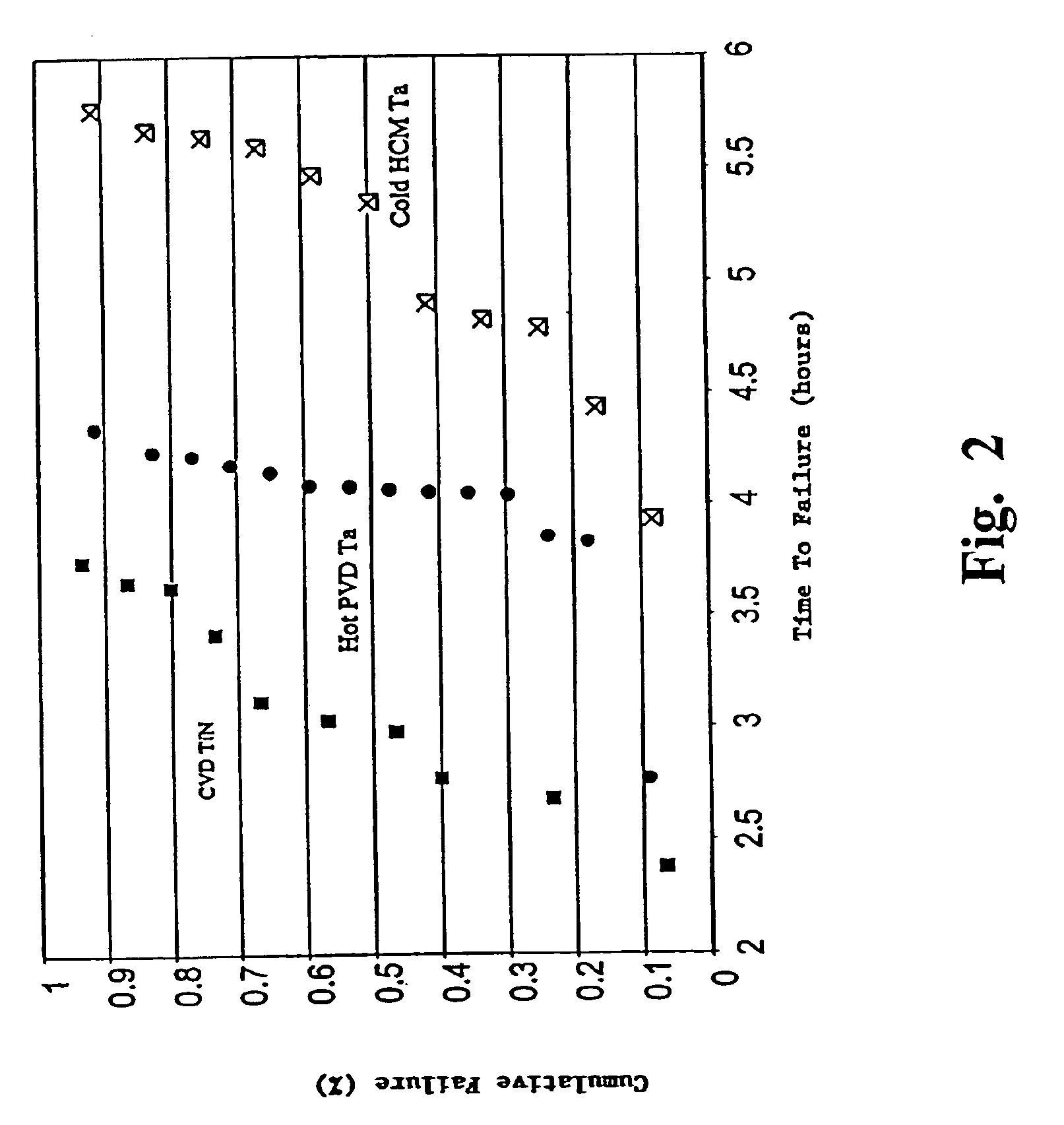

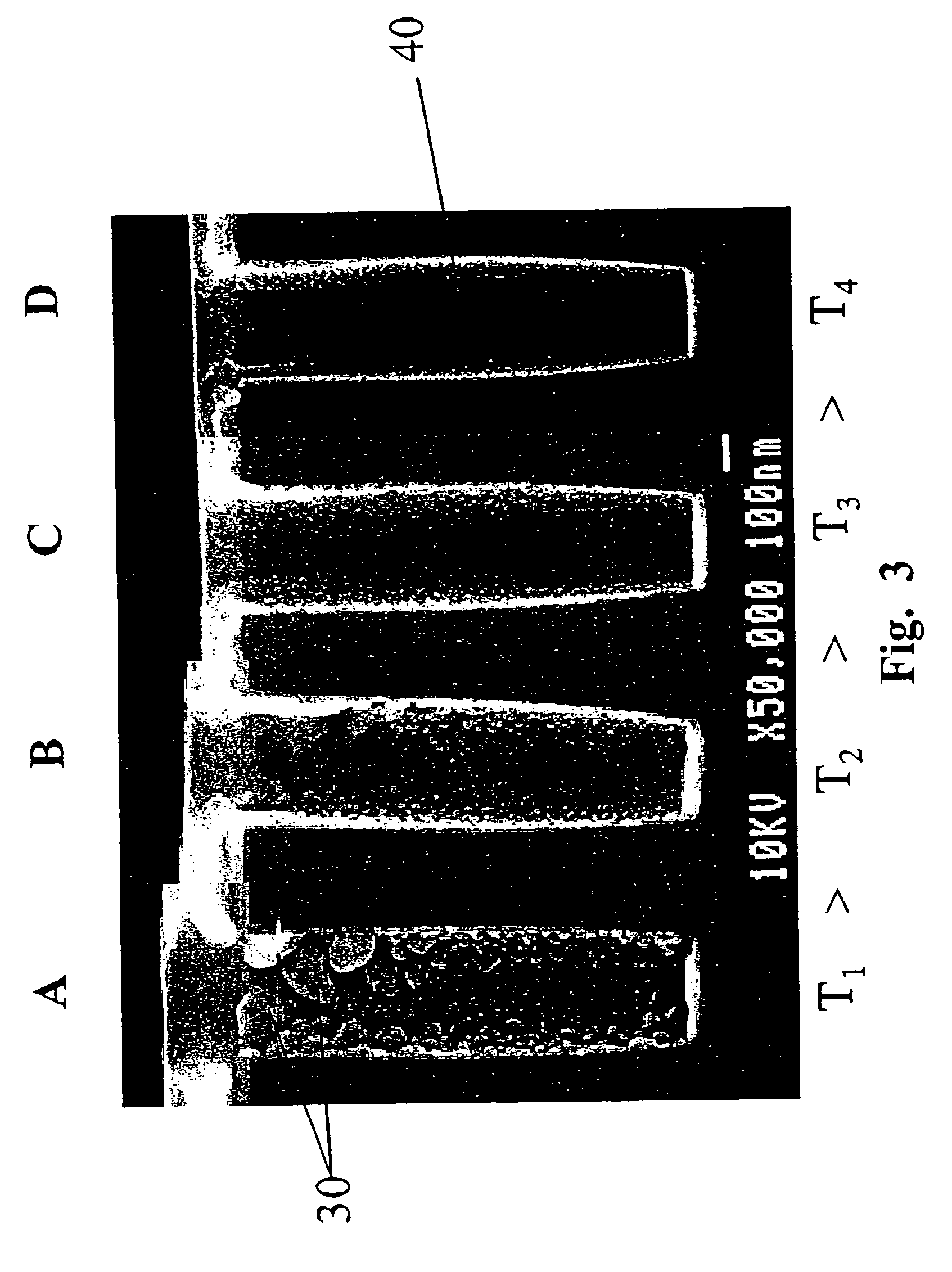

[0035]In describing the preferred embodiment of the present invention, reference will be made herein to FIGS. 1-5 of the drawings in which like numerals refer to like features of the invention. Features of the invention are not necessarily shown to scale in the drawings.

[0036]The present invention is directed to a method of depositing barrier films comprising tantalum, tantalum nitride and tantalum / tantalum nitride, and copper seed layers in high aspect ratio openings such as vias, contacts or trenches under low temperature conditions. The barrier films and seed layers of the present invention are deposited at extremely low temperatures wherein the wafer stage temperature of the sputter source is about −70° C. to about 0° C., preferably about −50° C., and the wafer is cooled to a temperature of about 20° C. to about −10° C. The resulting tantalum / tantalum nitride barrier films and copper seed layers are superior in surface smoothness, grain size and uniformity such that subsequent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com