Apparatus for treating storm water

a technology for storm water and apparatus, applied in water cleaning, multi-stage water/sewage treatment, separation processes, etc., can solve the problems of not being able to remove both floating and high flow that bypasses the low flow treatment chamber, and not being able to take into

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

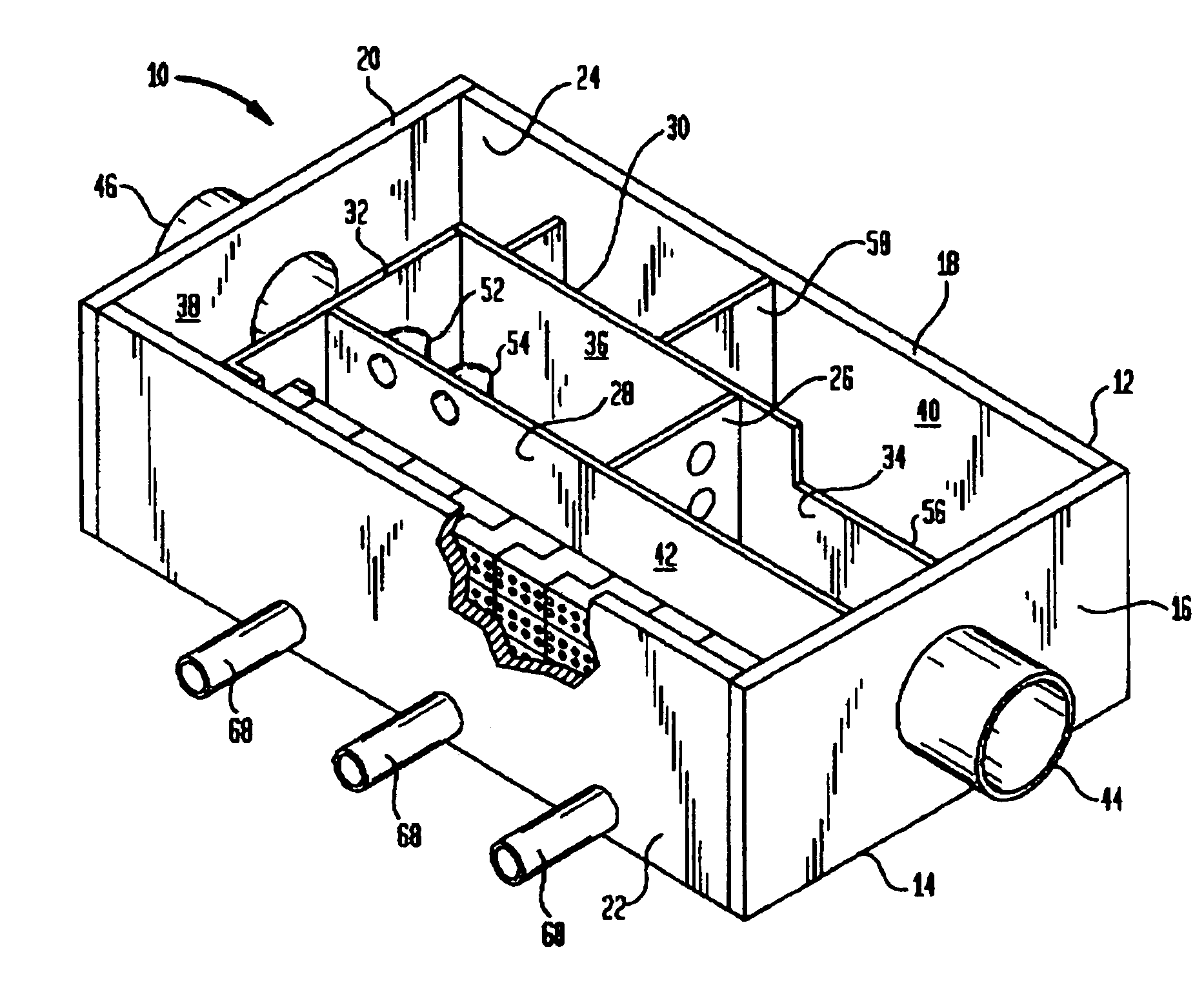

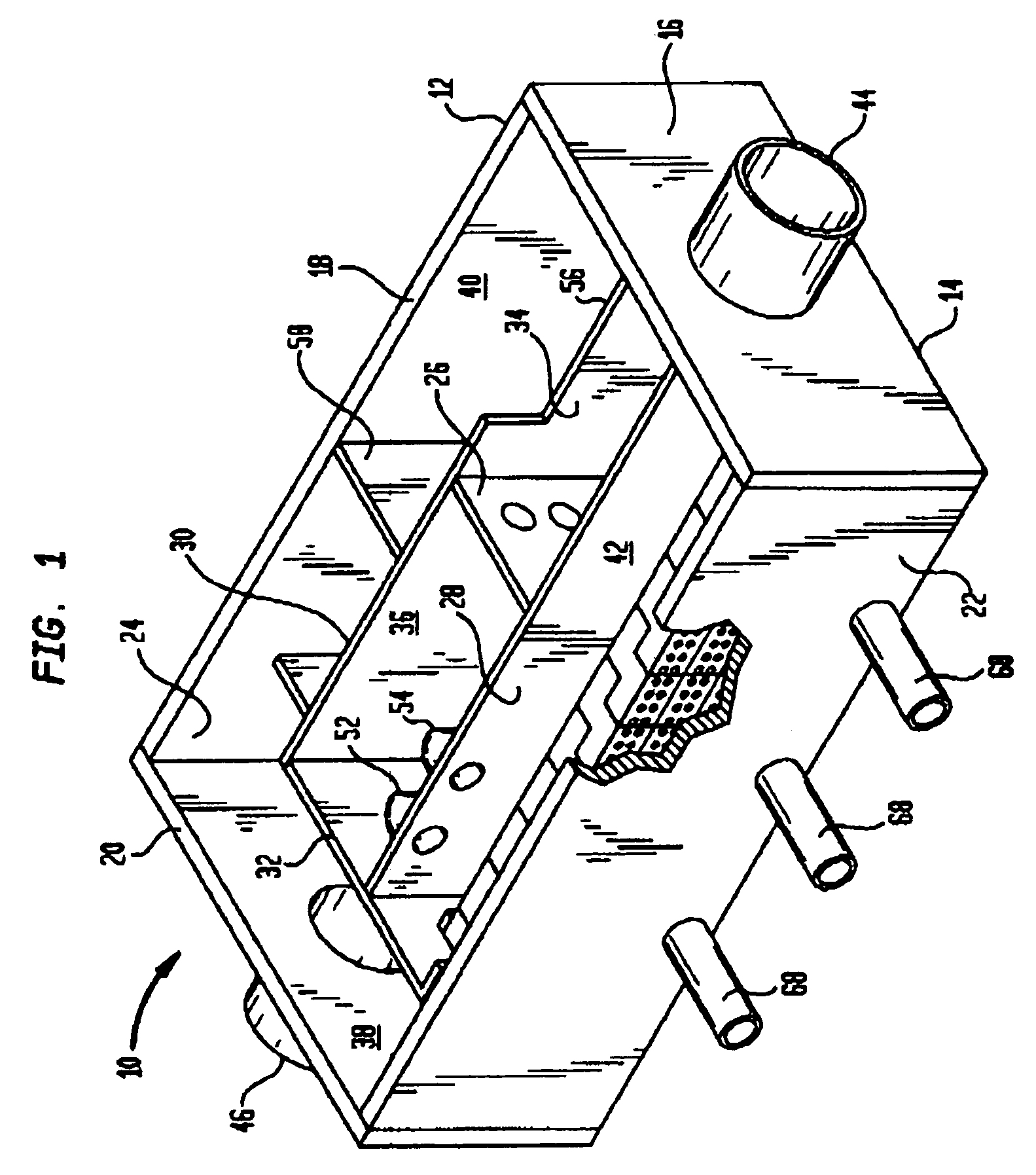

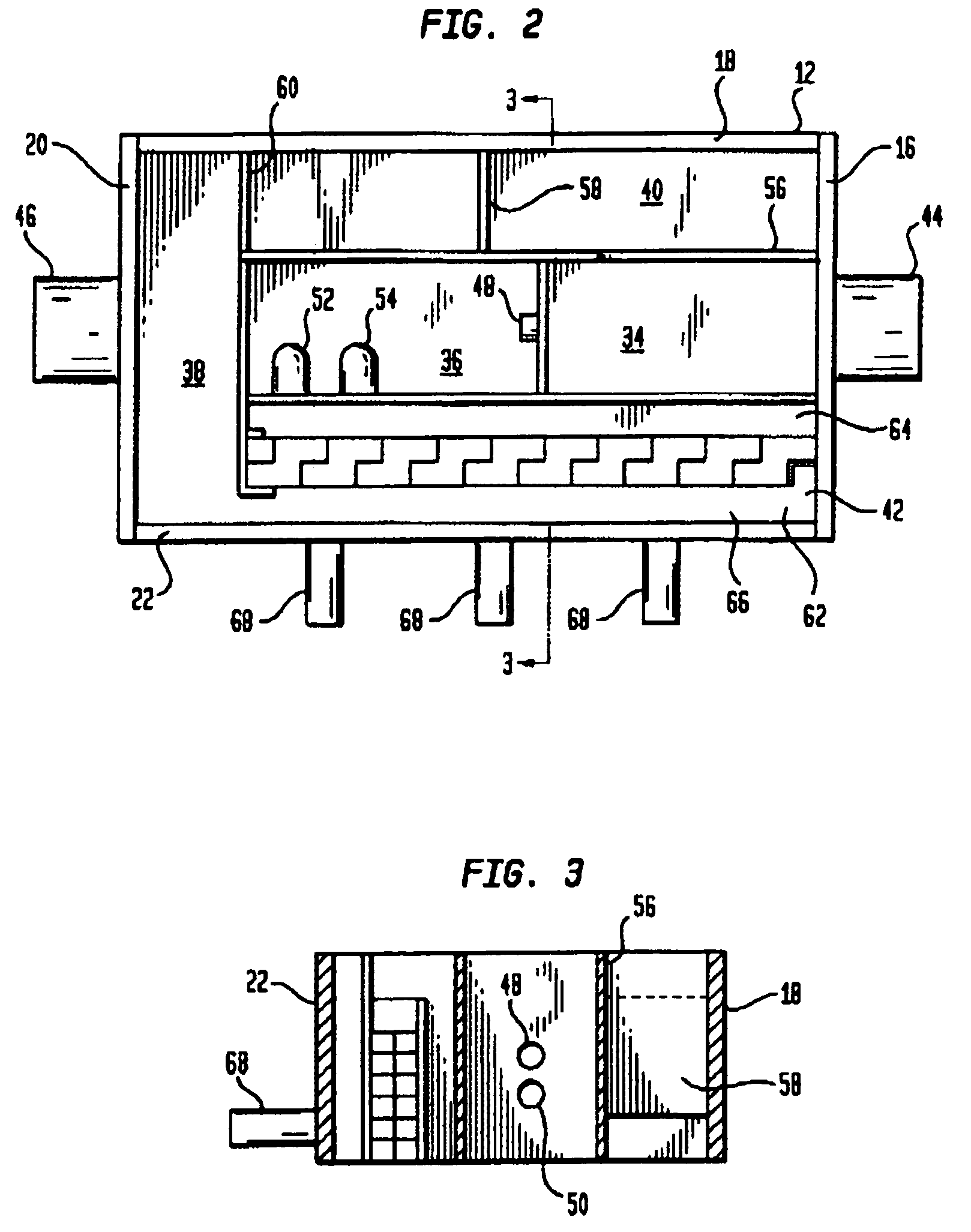

[0027]Referring now to FIG. 1, there is shown a separation tank 10 that comprises a container 12 having a bottom 14 and four side walls 16, 18, 20 and 22 that form a generally rectangular enclosure that also includes a cover 24 that is basically designed to cover that enclosure and is normally affixed to the upper ends of each of the side walls 16, 18, 20 and 22. The side walls 16, 18, 20, 22 bottom 14 and cover 24 can be constructed of a solid building material such as, but not limited to, concrete or metal.

[0028]Within that enclosure, there are located a plurality of partitions that divide the interior of the container 12 into a plurality of chambers and, as can be seen, those partitions are identified as a first partition 26, a second partition 28, a third partition 30 and a fourth partition 32.

[0029]Thus, the plurality of chambers that are formed by the partitions 26, 28, 30 and 32 are a first treatment chamber 34, a second treatment chamber 36, an outlet chamber 38, a high flow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| flow rate | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com