Liquid crystal device, liquid crystal display panel and method for manufacturing the same

a liquid crystal display panel and liquid crystal technology, applied in non-linear optics, instruments, optics, etc., can solve problems such as leakage current, and achieve the effects of avoiding concave etching stoppers, precise alignment, and long tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

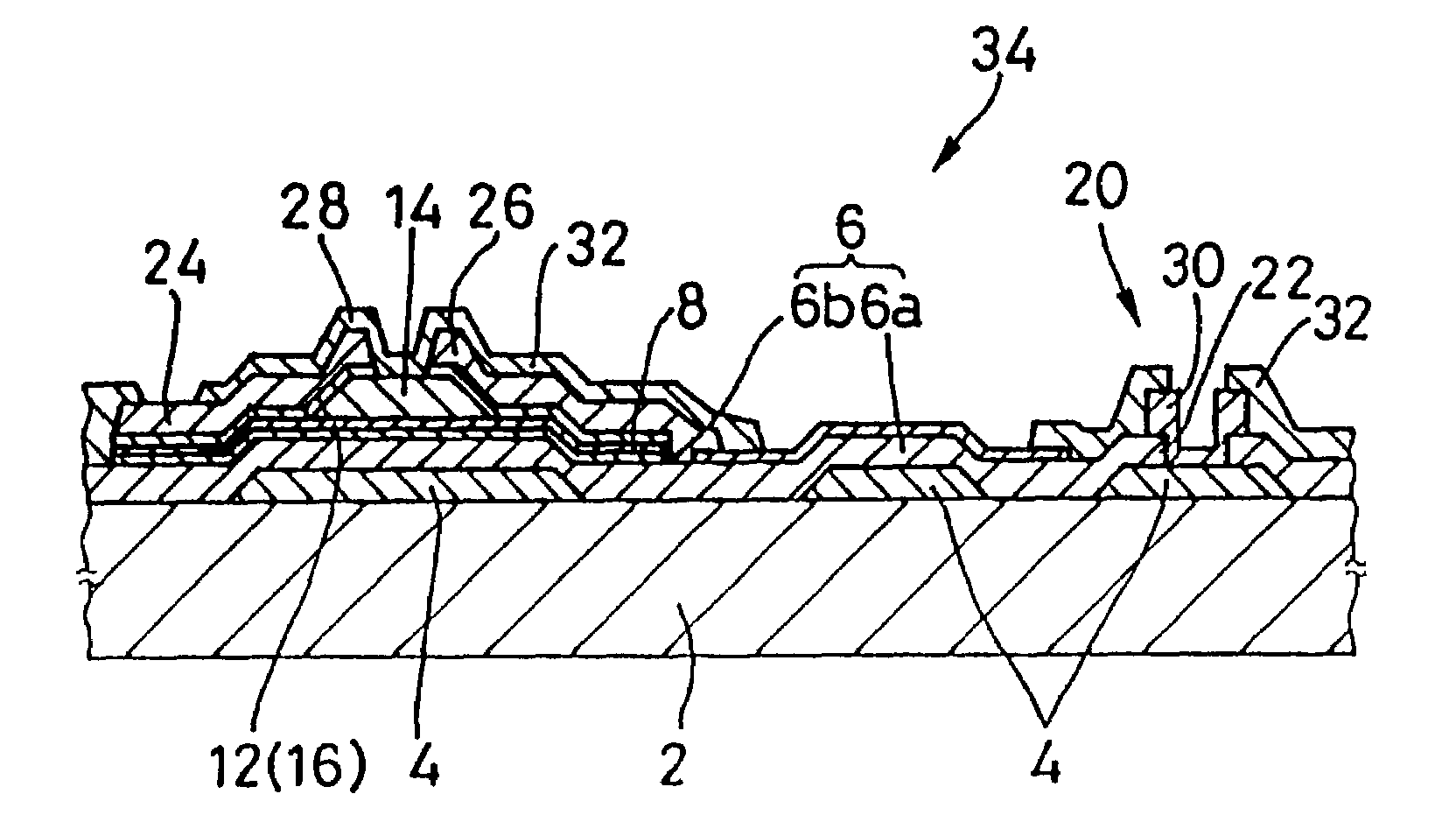

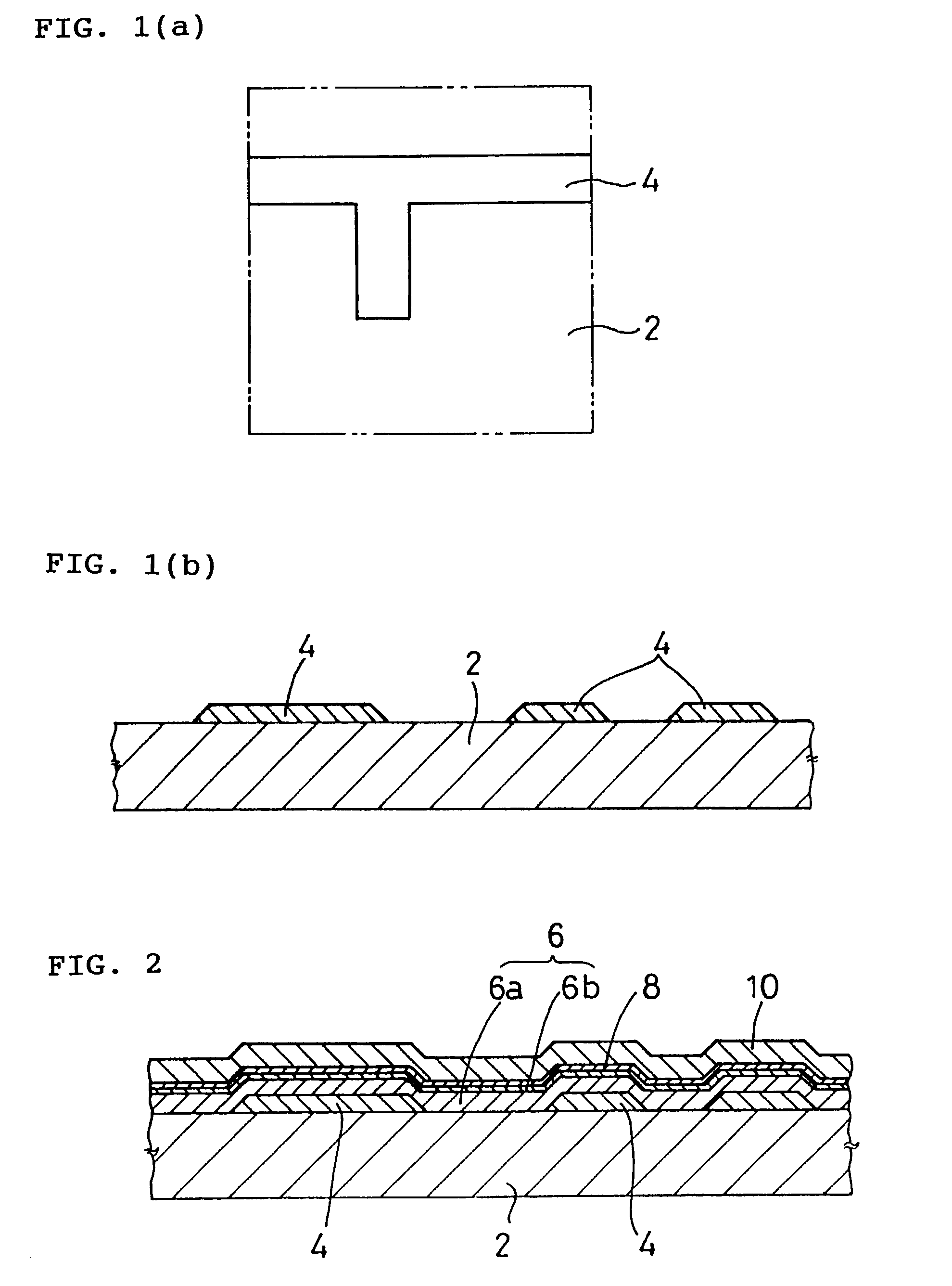

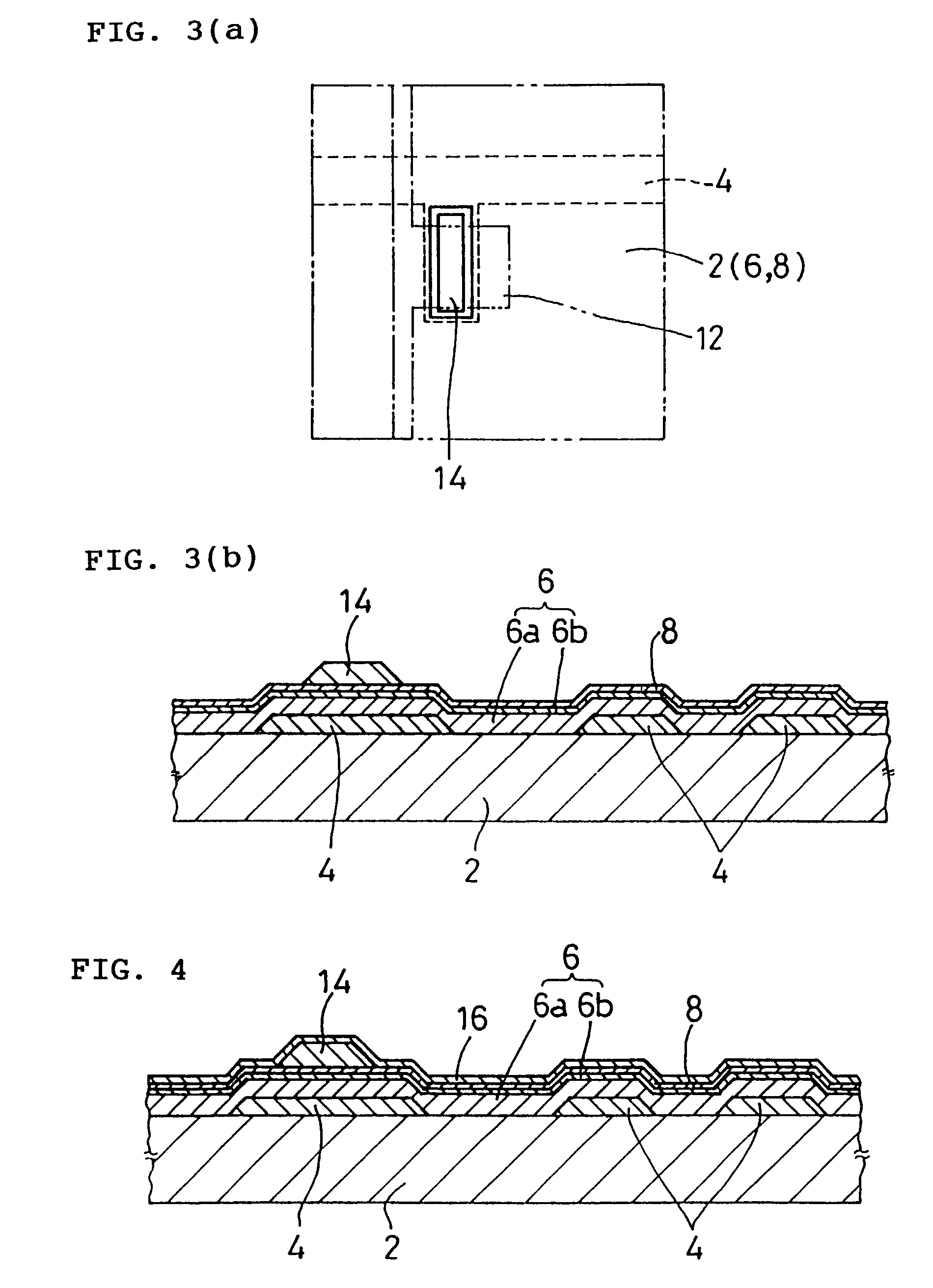

[0041]Now, a preferred embodiment of a liquid crystal device, a liquid crystal display panel and a method of manufacturing the device and the display panel will be described with reference to the accompanying drawings. It is noted that only a portion corresponding to one pixel is shown in the drawings for simplification. In addition, the sectional views illustrate, in principle, a TFT portion, a storage capacitance portion Cs and a pad portion for simplifying the description.

[0042]As shown in FIGS. 1(a) and 1(b), a gate electrode 4 (to be connected to a gate line in practice) is first formed on a transparent substrate 2. The most preferable transparent substrate 2 is a glass substrate, but can be a resin substrate or a flexible substrate as far as it is transparent and, in particular, good at heat resistance.

[0043]The gate electrode 4 consists of one or more layers of at least one element selected from the group consisting of MoW, Cr, Cu, Ni, Al, Mo, Ag and the like. Preferably, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

| shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com