Stackable differential mobility analyzer for aerosol measurement

a technology of differential mobility analysis and aerosol measurement, which is applied in the direction of material analysis, instruments, etc., can solve the problems of dma axial alignment and gas leakage, become increasingly difficult to perform accurate measurement/classification for particles less than 10 nm, and can only classify one particle at a time as the conventional dma, so as to achieve higher resolution sizing measurements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0047]The present invention is further illustrated by the following specific Examples, which should not be construed as limiting the scope or content of the invention in any way.

Calibration of Central Electrode Voltage

[0048]Theoretical central voltage (Vt) was calculated by equation (1) based on Knutson and Whitby:

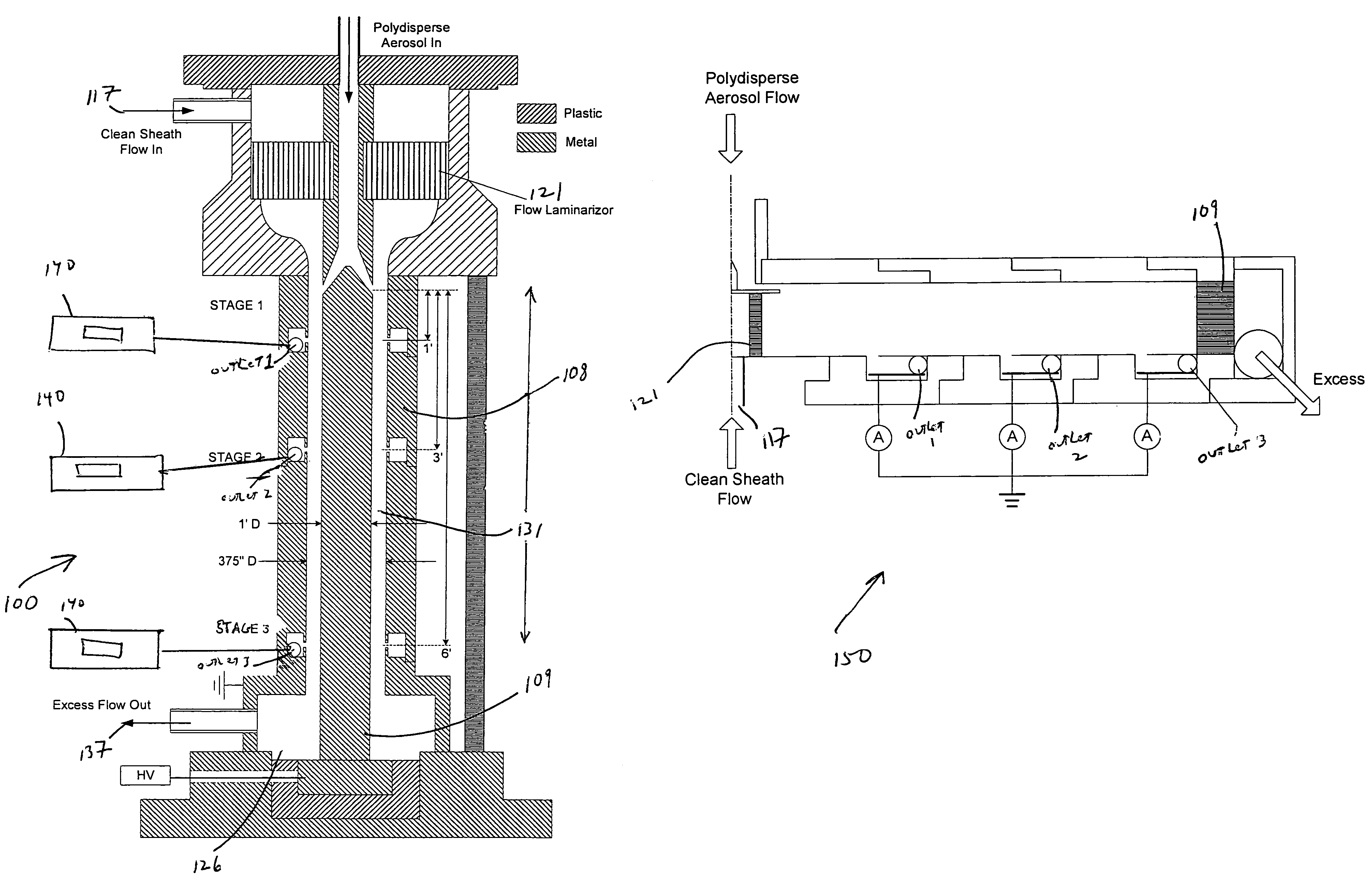

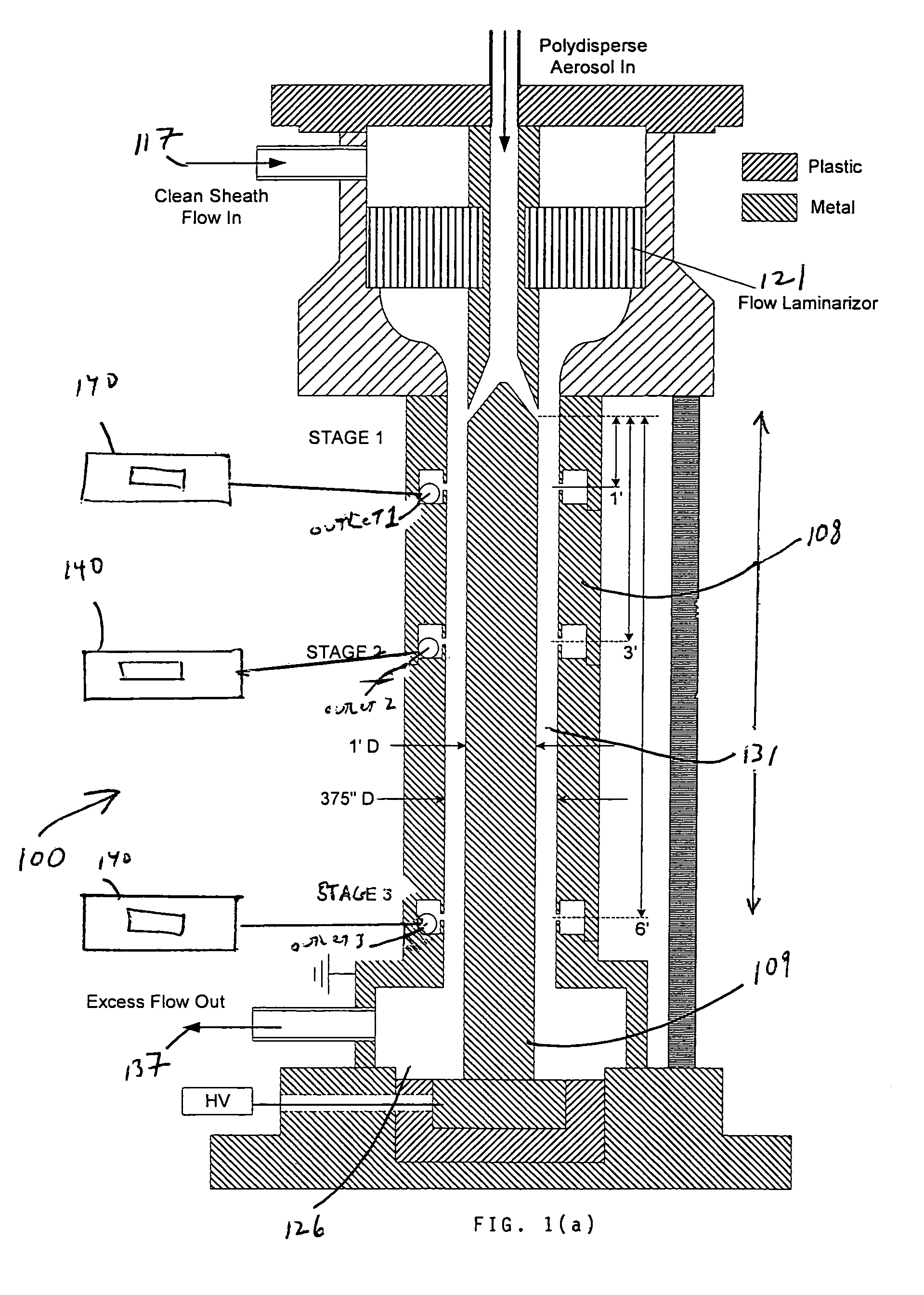

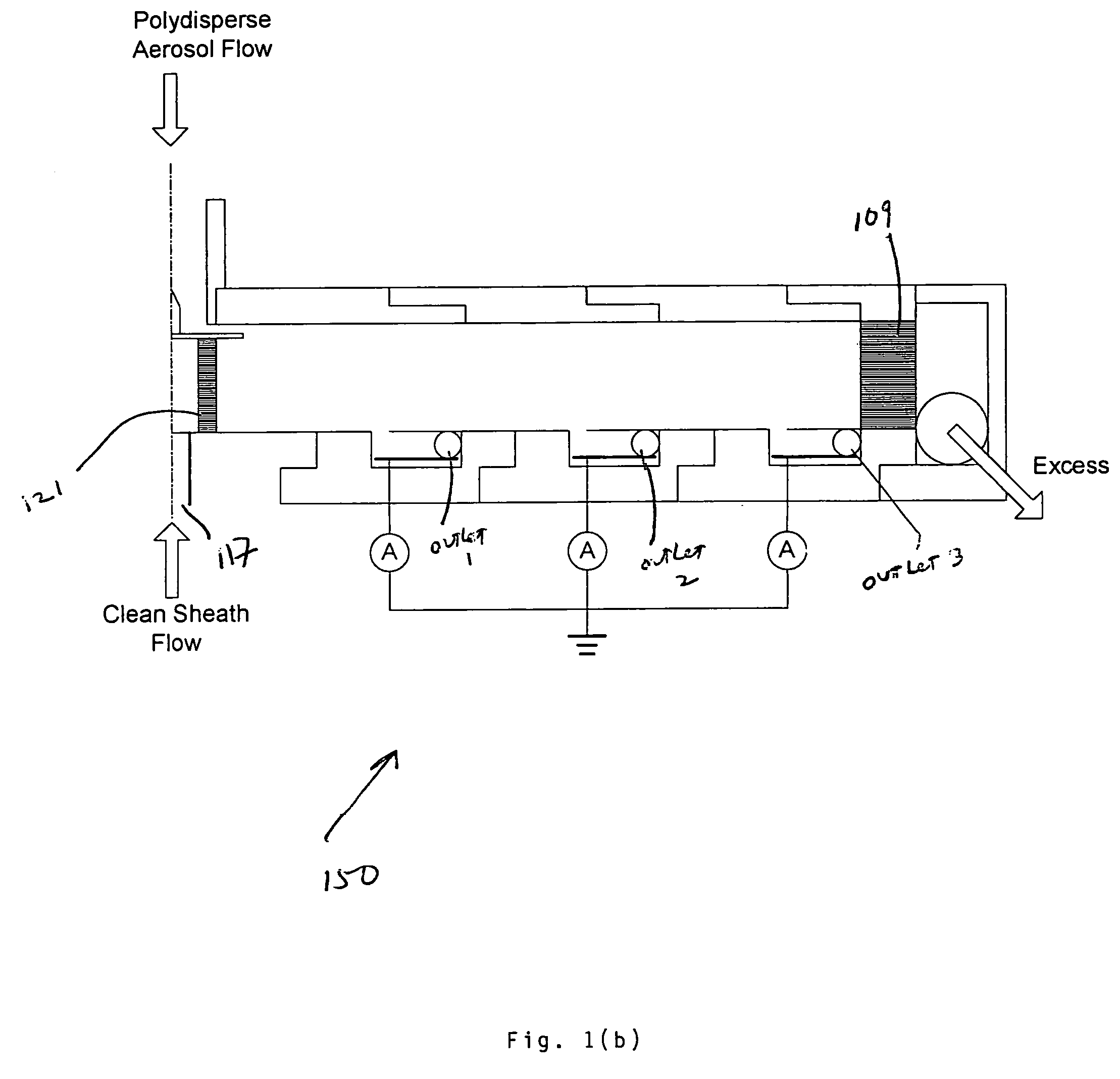

[0049]Vt=(qc+qm)ln(R2 / R1)4πLZp*(1)

where qc is the sheath flow rate, qm is the excess flow rate, R1 is the outer radius of the center rod (1.27 cm), R2 is the inner radius of the MDMA (1.746 cm), L is the classification length for each stage, and Z*p is the central mobility of first DMA. Since sampling flow is extracted from each stage in MDMAs 100 and 150, the flowrate ratio of polydisperse aerosol and sheath flows are different for each of the three stages. A method is described herein calculate the sheath flow at each stage. The sheath flow at first stage is the clean air introduced into MDMA. The sheath flow subtracting sampling flow at the first stage is equal to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particles sizes | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com