Cosmetic compositions

a composition and composition technology, applied in the field of cosmetic compositions, can solve the problems of reducing the effect of perspiration, reducing or eliminating visible deposits, and unable to achieve the effect of controlling perspiration, reducing or eliminating visible deposits, and enhancing syneresis resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

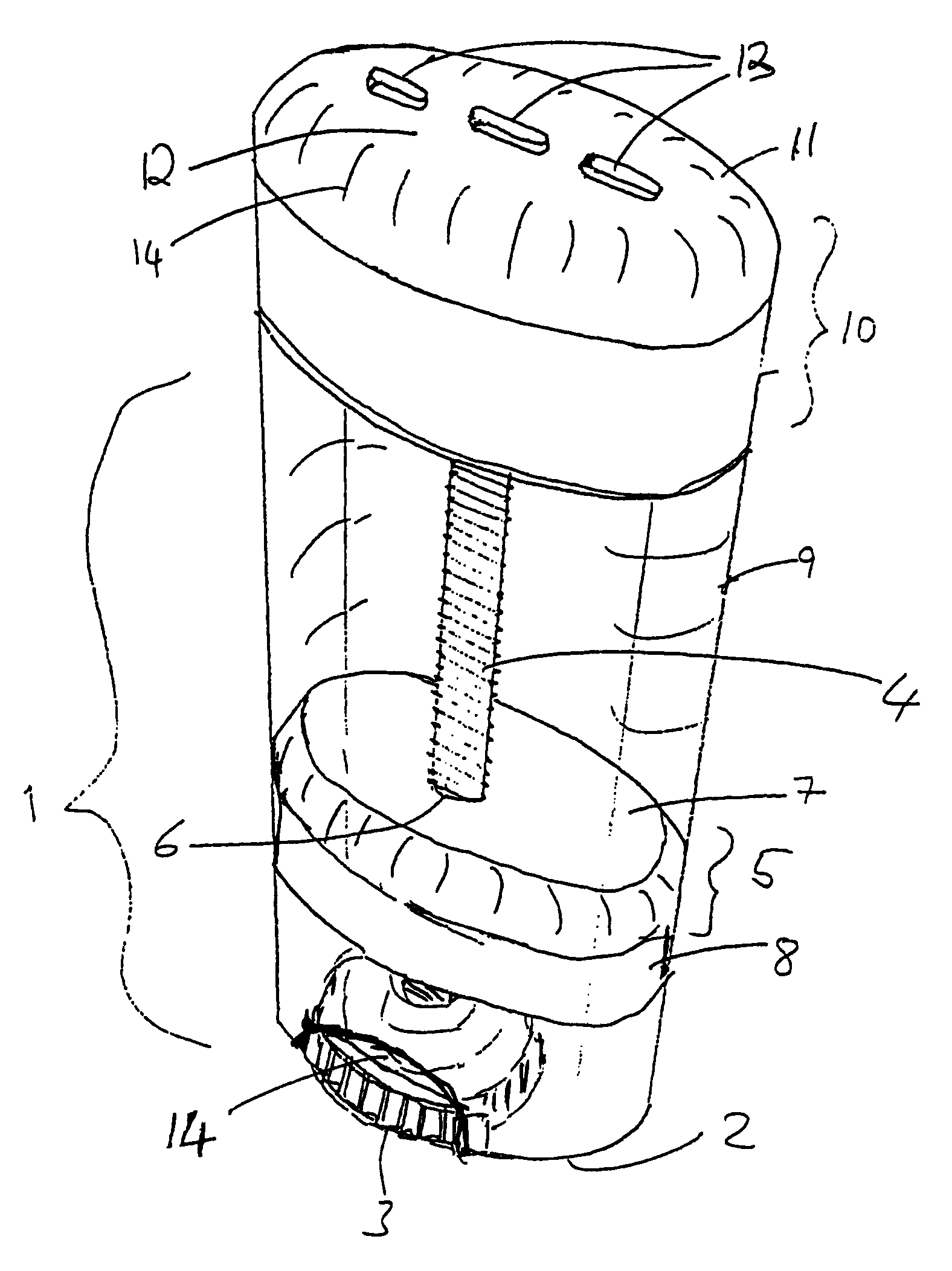

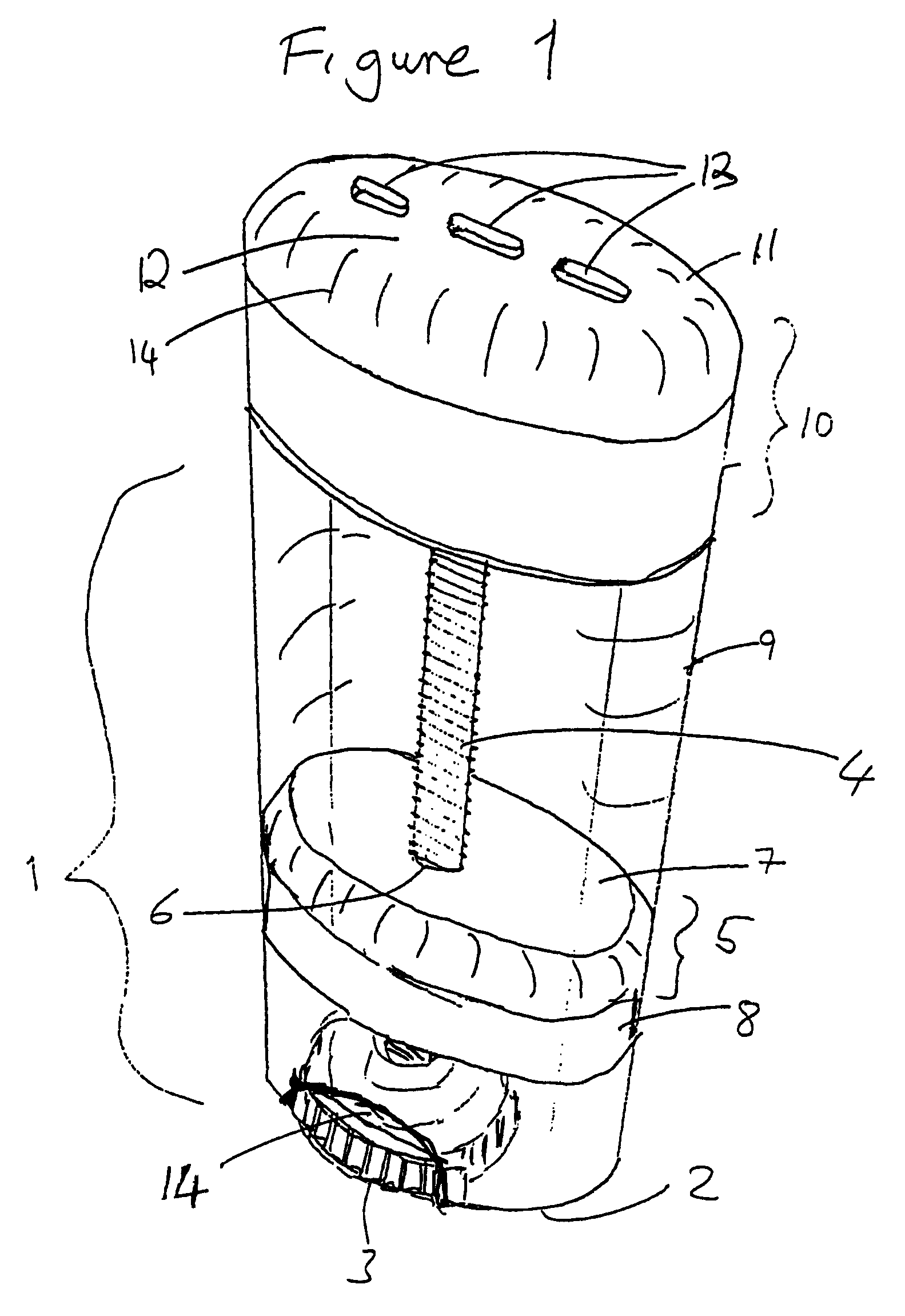

Image

Examples

formulation examples 1 to 15

AND COMPARISONS CP1 to CP12.

[0087]The following ingredients were employed in the below-mentioned Examples and Comparisons:—

[0088]

NoProduct descriptionTrade name and gradeProducer1volatile D5 siliconeDC245Dow Corningoil2non-volatile siliconeDC200 350cstDow Corningoil3Fumed silicaAerosil 200Degussa4microcrystalline waxMultiwax 180-MWitco5C18-36 acidSyncrowax HGLCCrodatriglyceride wax6gel -DimethiconeDC9040Dow Corningelastomer incyclomethicone7Aluminium zirconiumReach 908Reheistrichlorhydrex gly[AZAG]8Glyceryl tribehenateSyncrowax HRCCrodawax9non-volatile siliconeDC200 10cstDow Corningoil10dextrin palmitateRheopearl KLChiba FlourMilling11activated aluminiumAloxicoll LRGiulinichlorohydrate [AACH]12C12-15 alkylbenzoateFinsolv TNFinetexoil13Castor waxCastorwax MP80Caschem14C18-36 acid glycolSyncrowax ERLCCrodaester wax15gel - dimethicone / KSG 31Shin-etsucopolyol elastomer inmineral oil16gel - block copolymerTransgel 110Aiglonin hydrocarbon oil17Isoparaffin oilIsopar MExxon Chemicals18Isopa...

examples 1-15

[0115]

TABLE 2Example No123456Ingredients% by weightTransgel40.230.240.230.230.230.2110 (16)Benzoate26.818.426.818.418.418.4oil (12)Isoparaffin (17)18.4Isoparaffin (18)18.4Mineral18.4oil (19)Mineral18.4oil (20)Castor5.6255.6255.6255.6255.6255.625wax (13)glycol ester1.8751.8751.8751.8751.8751.875wax (14)AACH (11)25.525.5AZAG(7)25.525.525.525.5CharacterisationSyneresis ScoreN6CN6CN6CN6CN6CN6CEfficacypasspasspassPolymer49.23.32.93.92.9Viscosity Pa · sExample No789101112Ingredients% by weightTransgel35.2110 (16)Versagel40.235.2MD750 (21)Versagel40.2ME750 (22)Versagel40.2M750 (23)Polysynlane40.2Gel (24)Benzoate21.426.826.826.815.927.3oil (12)Isoparaffin (17)15.9Castor5.6255.6255.6255.6255.6259wax (13)glycol ester1.8751.8751.8751.8751.8753wax (14)AACH (11)25.525.525.5AZAG (7)25.525.525.5CharacterisationSyneresis ScoreN6CN6CN6CN6CN6CN6CEfficacypassPolymer24.414.810.1———Viscosity Pa · sExample No131415Ingredients% by weightTransgel 110 (16)40.427.540.2Benzoate oil (12)22.027.524.8Naphthalate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com