Method of driving light emitting element array

a technology of light emitting elements and arrays, which is applied in the direction of process and machine control, optical radiation measurement, instruments, etc., can solve the problems of poor rise-up characteristics, long time for light emitting elements, poor stability, etc., and achieve excellent rise-up characteristics, high stability, and excellent response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

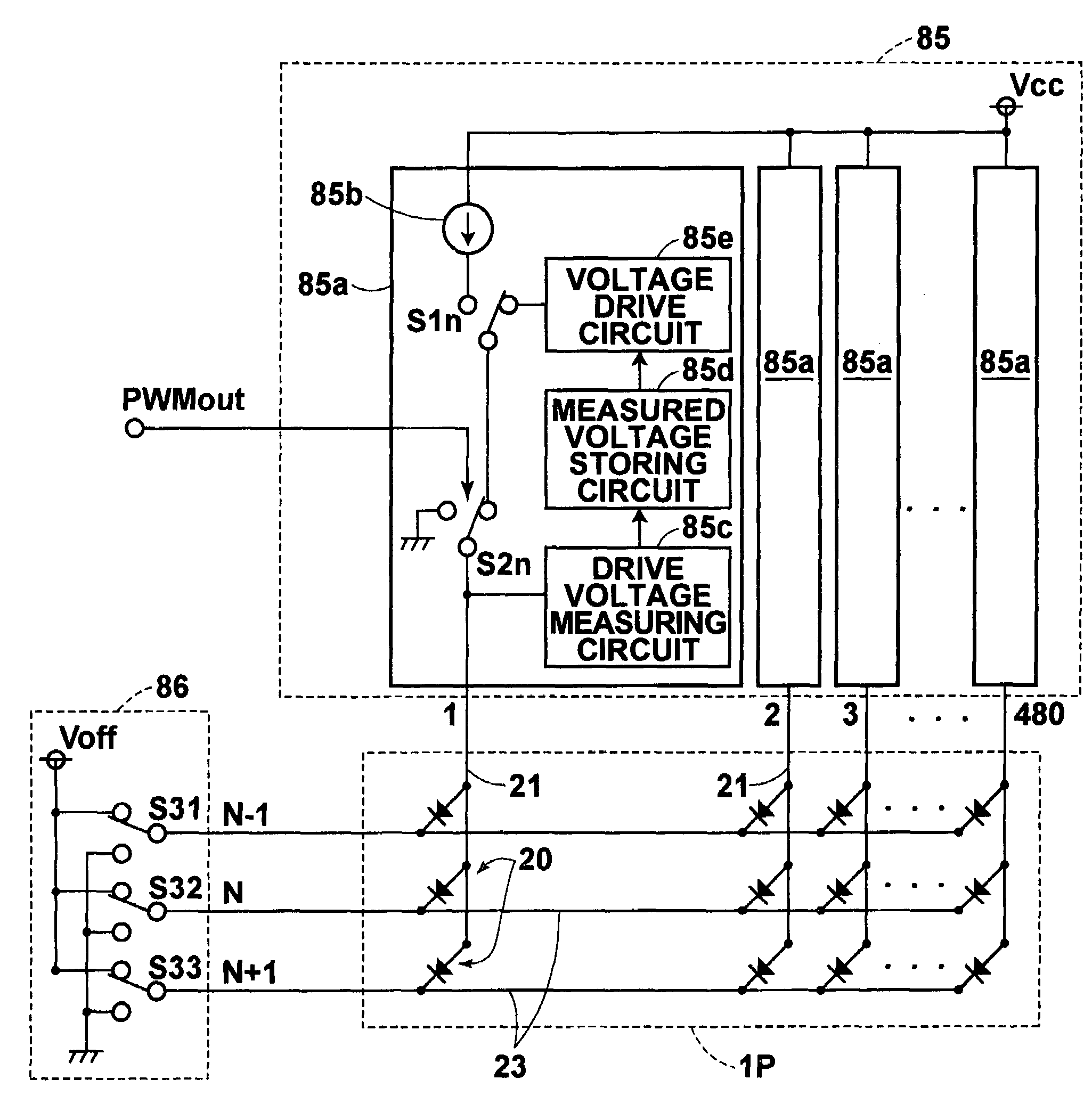

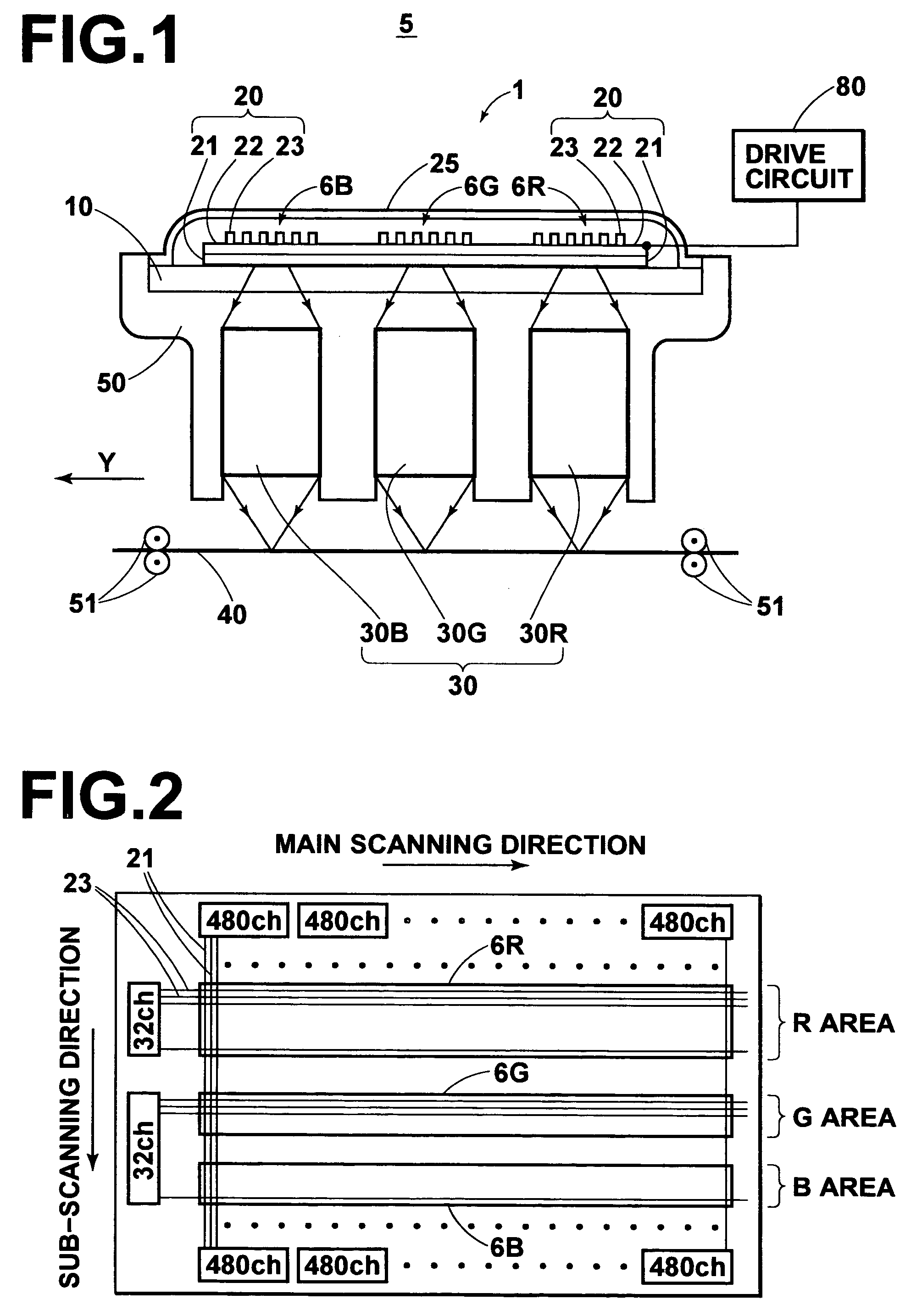

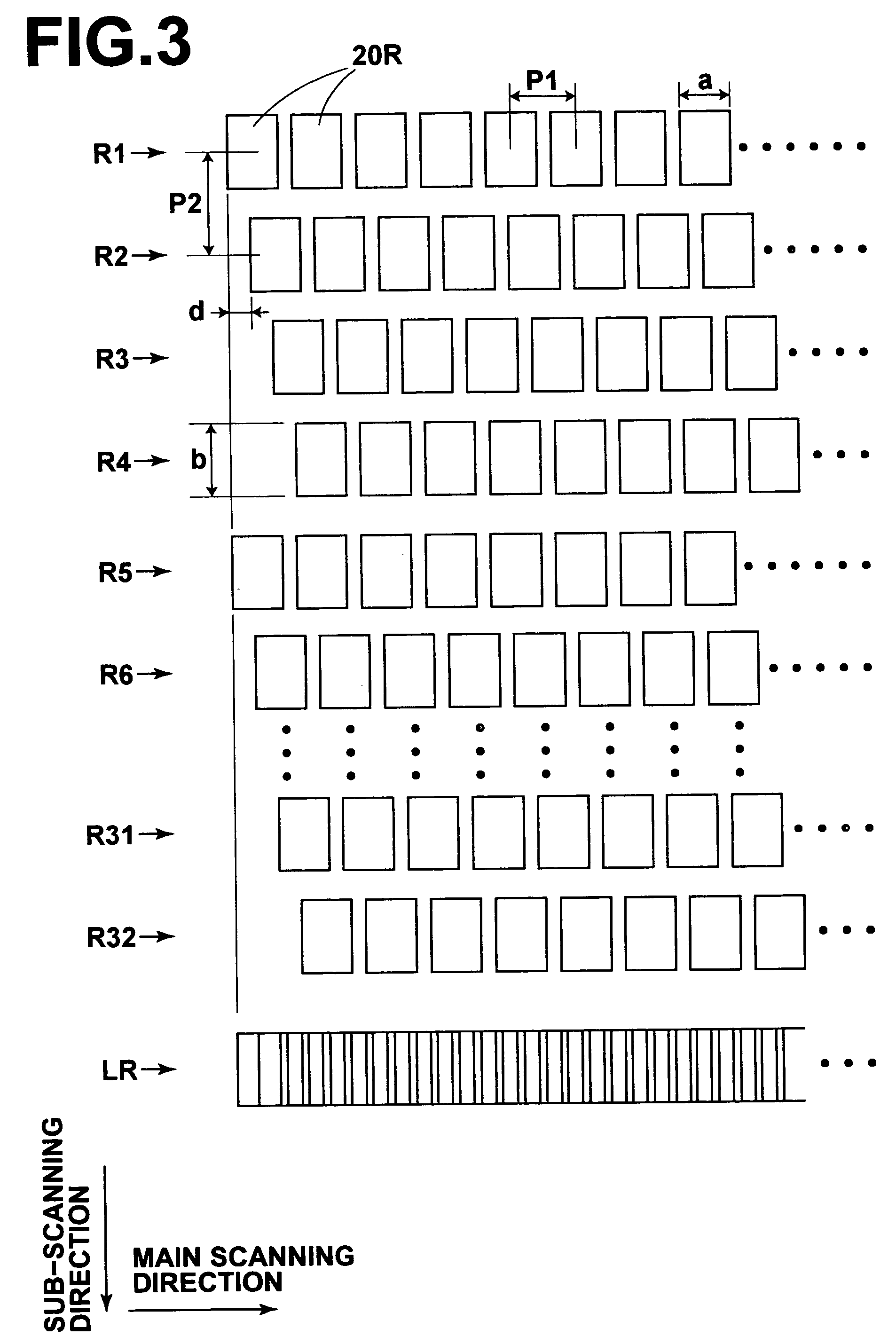

[0038]As shown in FIG. 1, an exposure system 5 in accordance with an embodiment of the present invention has an exposure head 1. The exposure head 1 comprises a transparent base 10, a number of organic EL elements 20 formed on the base 10 by deposition, a refractive index profile type lens array 30 (30R, 30G and 30B) which is a unit system for imaging on a color photosensitive sheet 40 an image generated by the light emitted from the organic EL elements 20, and a support 50 which supports the base 10 and the refractive index profile type lens array 30.

[0039]The exposure system 5 further comprises, in addition to the exposure head 1, a sub-scanning means 51 in the form of, for instance, a pair of nip rollers which conveys the color photosensitive sheet 40 at a constant speed in a direction of arrow Y.

[0040]The organic EL elements 20 comprises a transparent anode 21, an organic compound layer 22 including a light emitting layer and patterned for each pixel and a metal cathode 23 forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com