Photo-electric converting device and its driving method, and its manufacturing method, solid-state image pickup device and its driving method and its manufacturing method

a technology of photoelectric converting and driving method, which is applied in the direction of radio frequency controlled devices, television system scanning details, etc., can solve the problems of reducing the amount of light incident on unable to obtain sufficient sensitivity of the photo-electric converting portion b>53/b>, etc., and achieve suppression of an increase of dark current and high sensitivity characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058]The present invention will be described below with reference to the drawings.

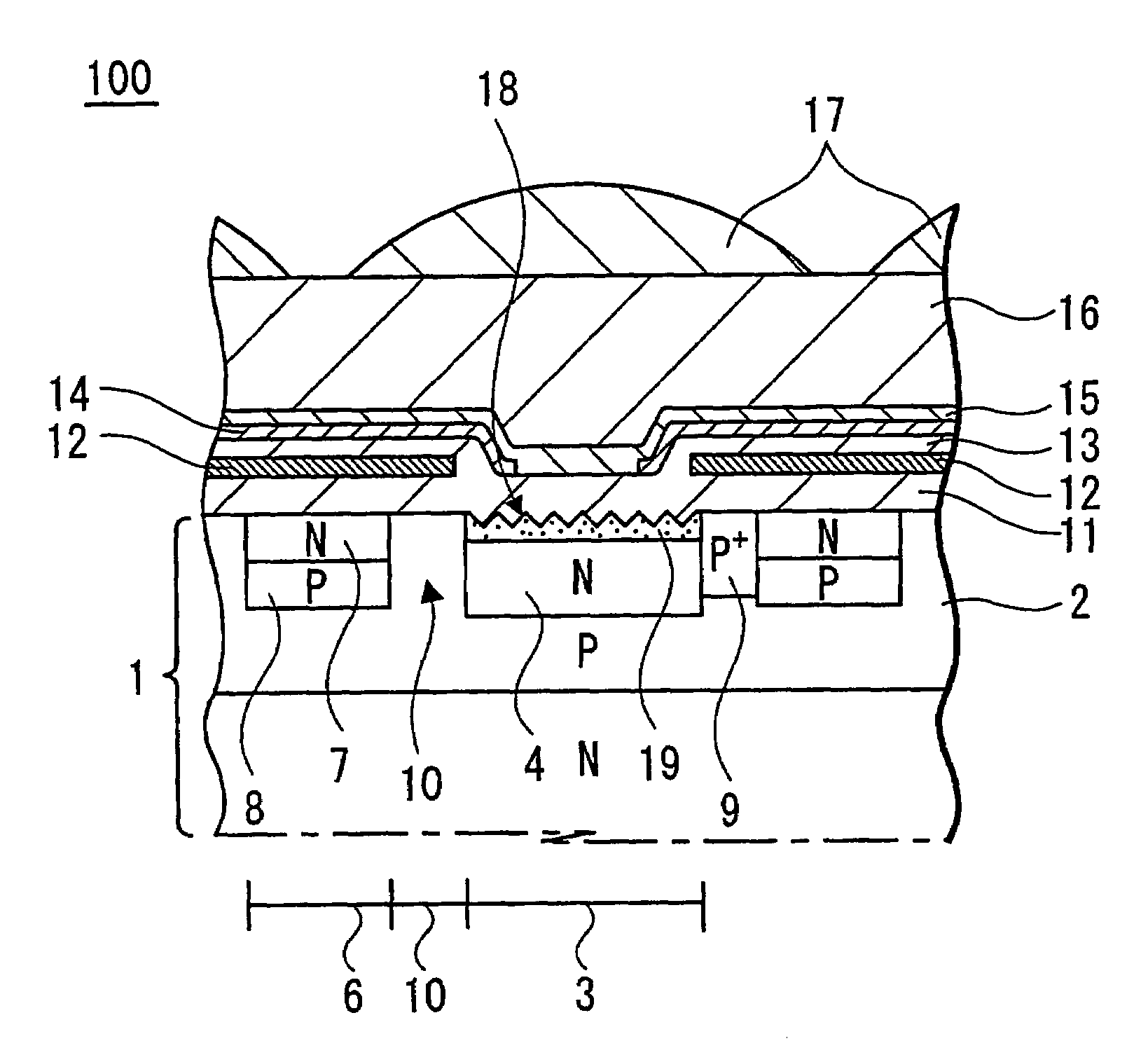

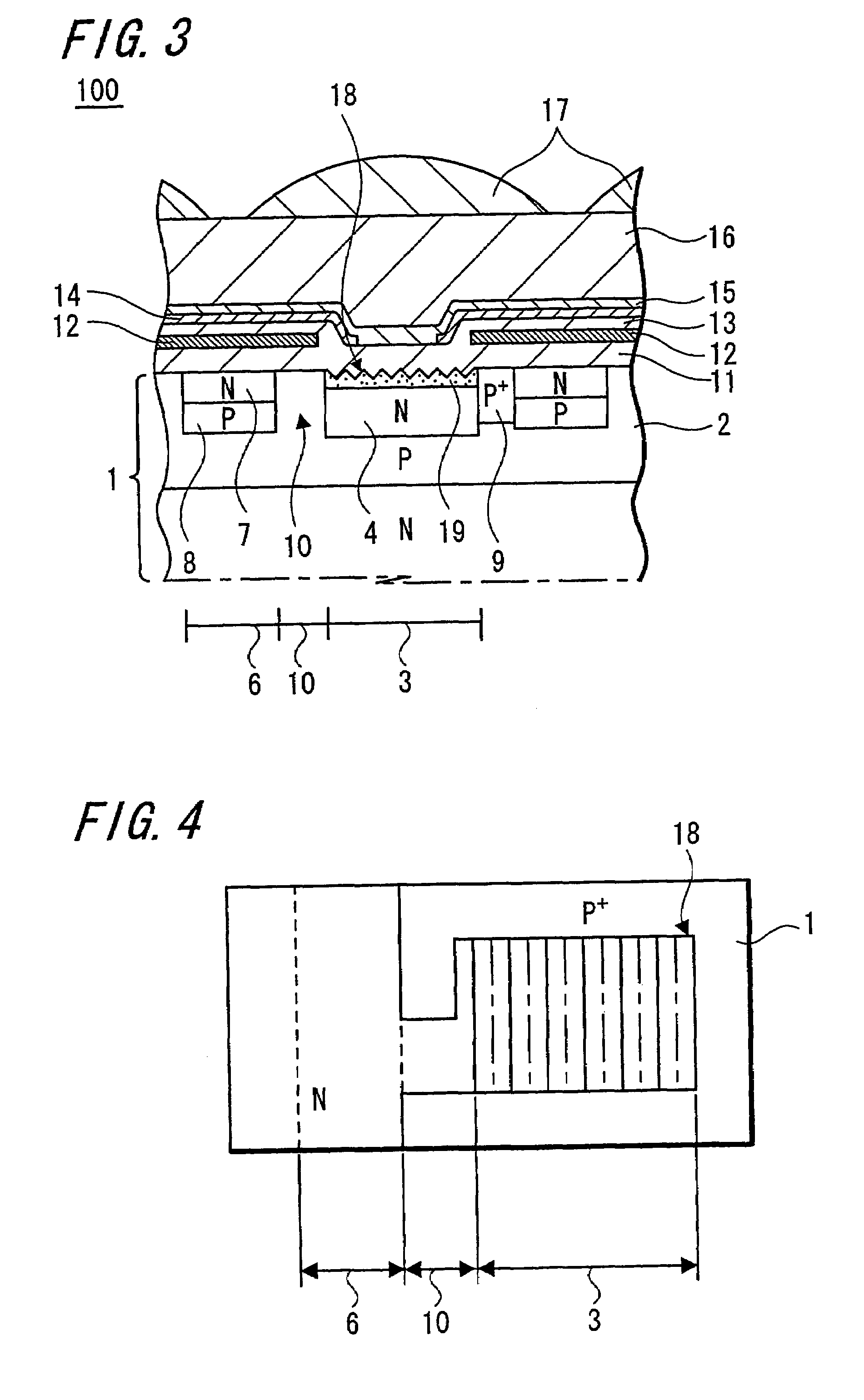

[0059]First, a solid-state image pickup device according to an embodiment of the present invention will be described with reference to FIG. 3 which is an enlarged cross-sectional view.

[0060]As shown in FIG. 3, a solid-state image pickup device 100 according to this embodiment includes an N-type silicon semiconductor substrate 1 which is mainly made of high-purity single crystal silicon (Si) in which a P-type first semiconductor well layer 2 is formed. A photo-diode formed of an N-type semiconductor region (so-called electric charge accumulating region) 4, for example, comprising a photo-electric converting portion 3 is formed on the surface side of the semiconductor substrate 1.

[0061]An N-type transfer channel region 7 comprising a vertical CCD portion 6 is formed on one side of the row of the photo-electric converting portion 3, and a P-type second semiconductor well region 8 is formed under the N-ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com