Defect inspection apparatus

a technology of defect inspection and inspection apparatus, which is applied in the direction of measurement devices, instruments, color/spectral properties measurements, etc., can solve the problems of reducing the yield rate, requiring a large development cost, and a long development period, so as to reduce the yield rate, the inspection speed of the defect inspection apparatus is raised, and the development cost is not high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

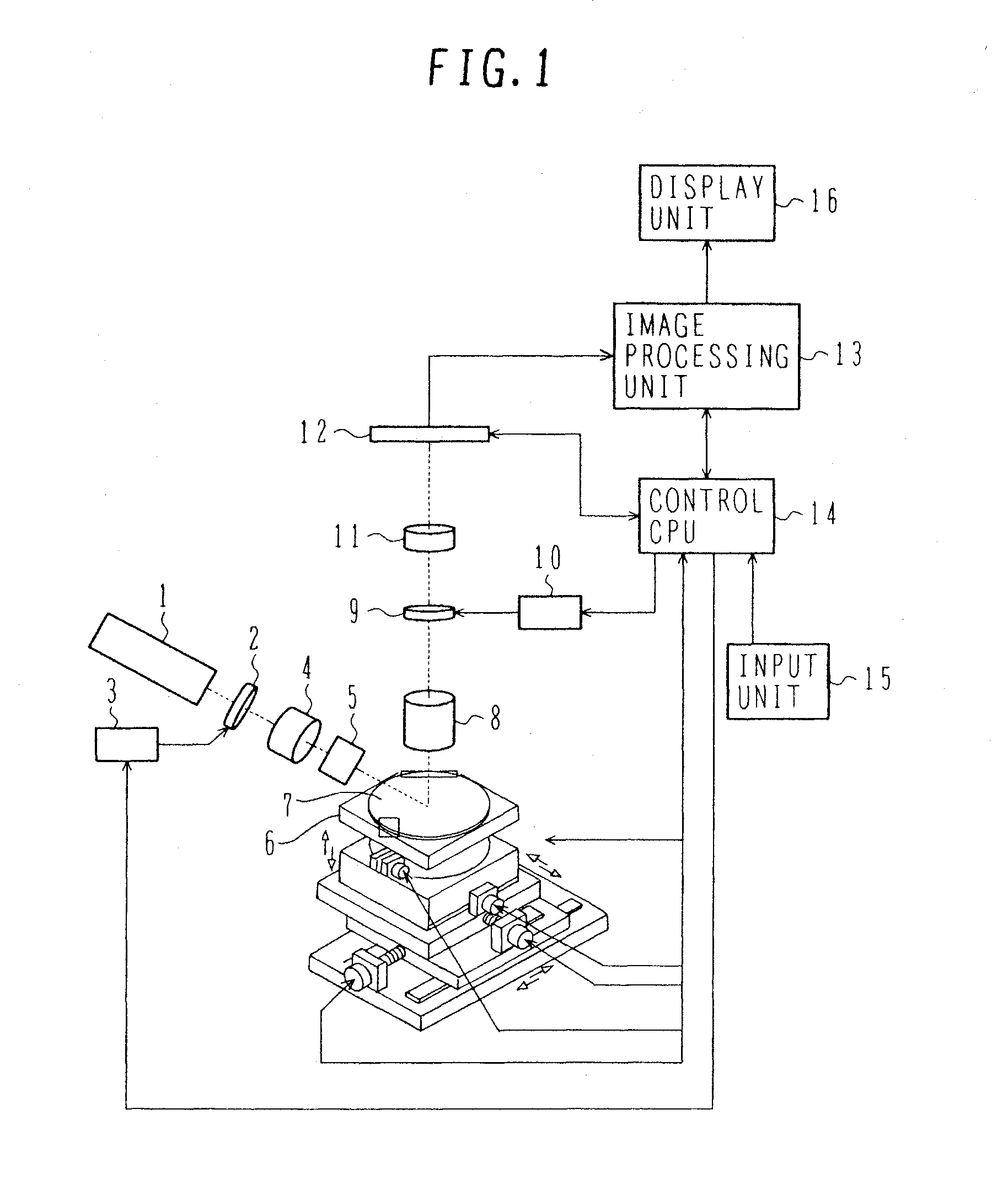

[0018]Embodiments of the present invention will now be described with reference to the accompanying drawings.

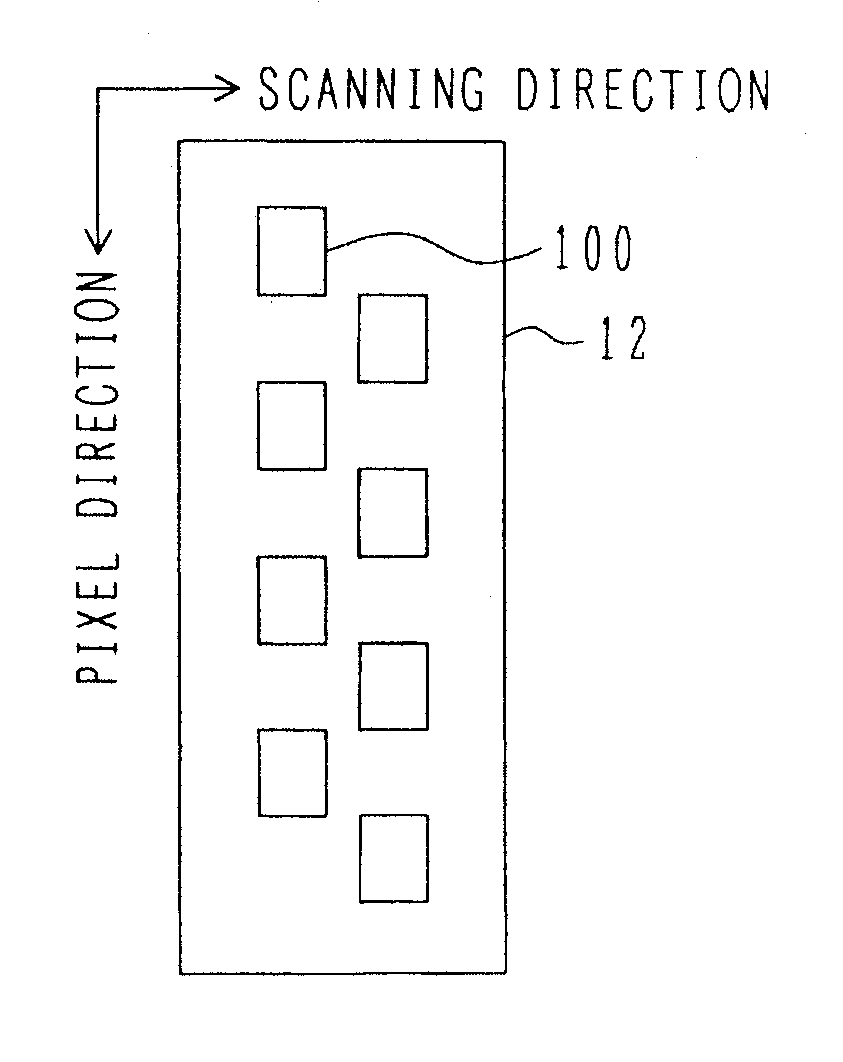

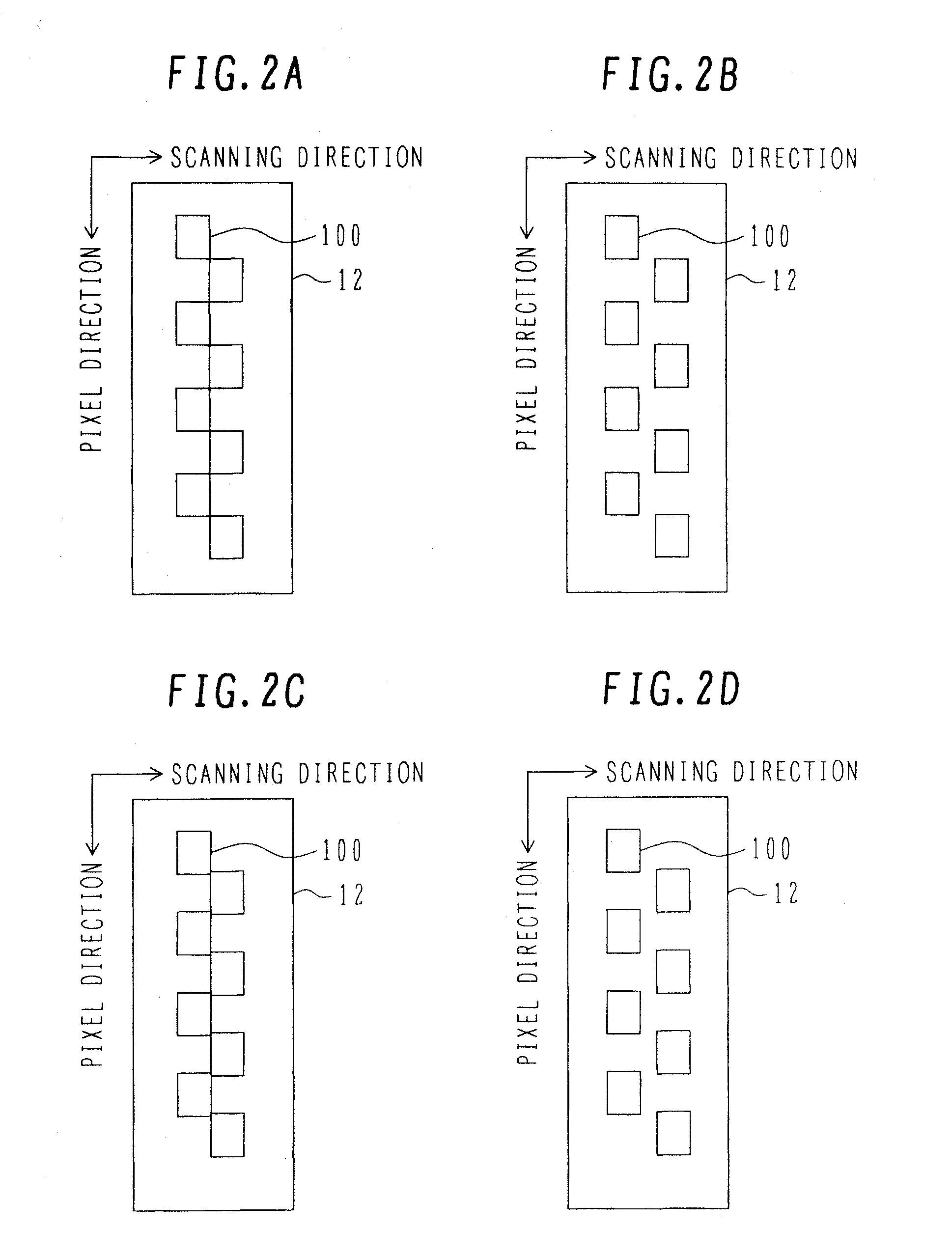

[0019]FIG. 1 is a schematic diagram illustrating the configuration of a defect inspection apparatus to which the present invention is applied. Referring to FIG. 1, a stage includes X, Y, Z, and θ (rotation) stages. A semiconductor wafer (specimen) 7, which is a typical inspection target pattern, is to be mounted on the stage 6. An illumination light source 1 is made of an ultraviolet or far-ultraviolet laser light source having a wavelength of 266 nm or 355 nm and used to illuminate the specimen 7.

[0020]The ultraviolet laser light source includes a device that uses a nonlinear optical crystal or the like, subjects a solid YAG laser to wavelength conversion, and generates a third harmonic (355 nm) or fourth harmonic (266 nm) of a fundamental wave. Alternatively, a laser light source having a wavelength of 193 nm, 195 nm, or 248 nm may be used. Another alternative is to use a l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com