System and method for resource allocation of semiconductor testing industry

a technology for semiconductor testing and resource allocation, applied in the field of system and method for resource allocation in the semiconductor testing industry, can solve the problems of time-consuming planning and capacity allocation, conflict, delay and waste of resources, etc., and achieve the effect of efficient resource planning and capacity allocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

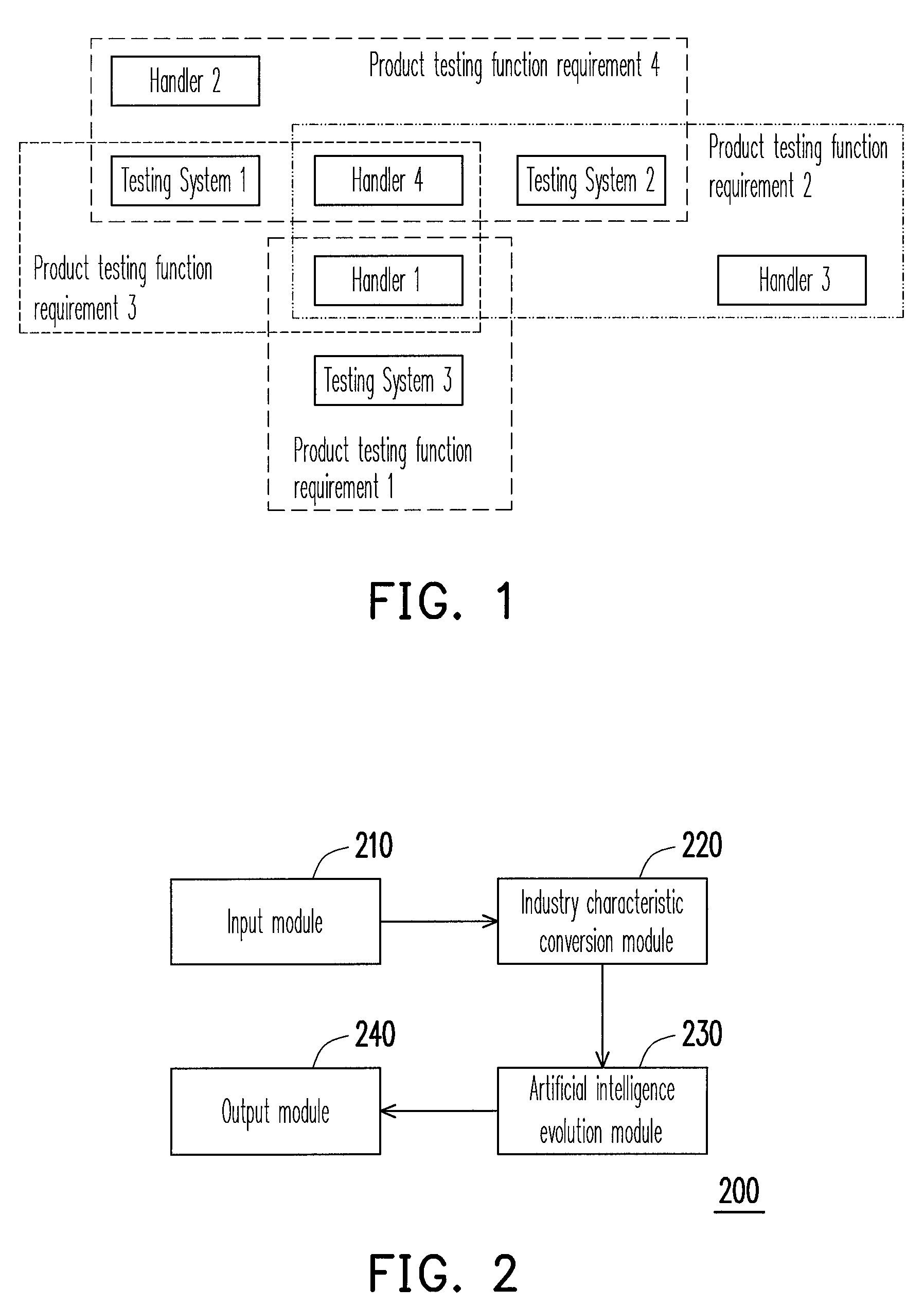

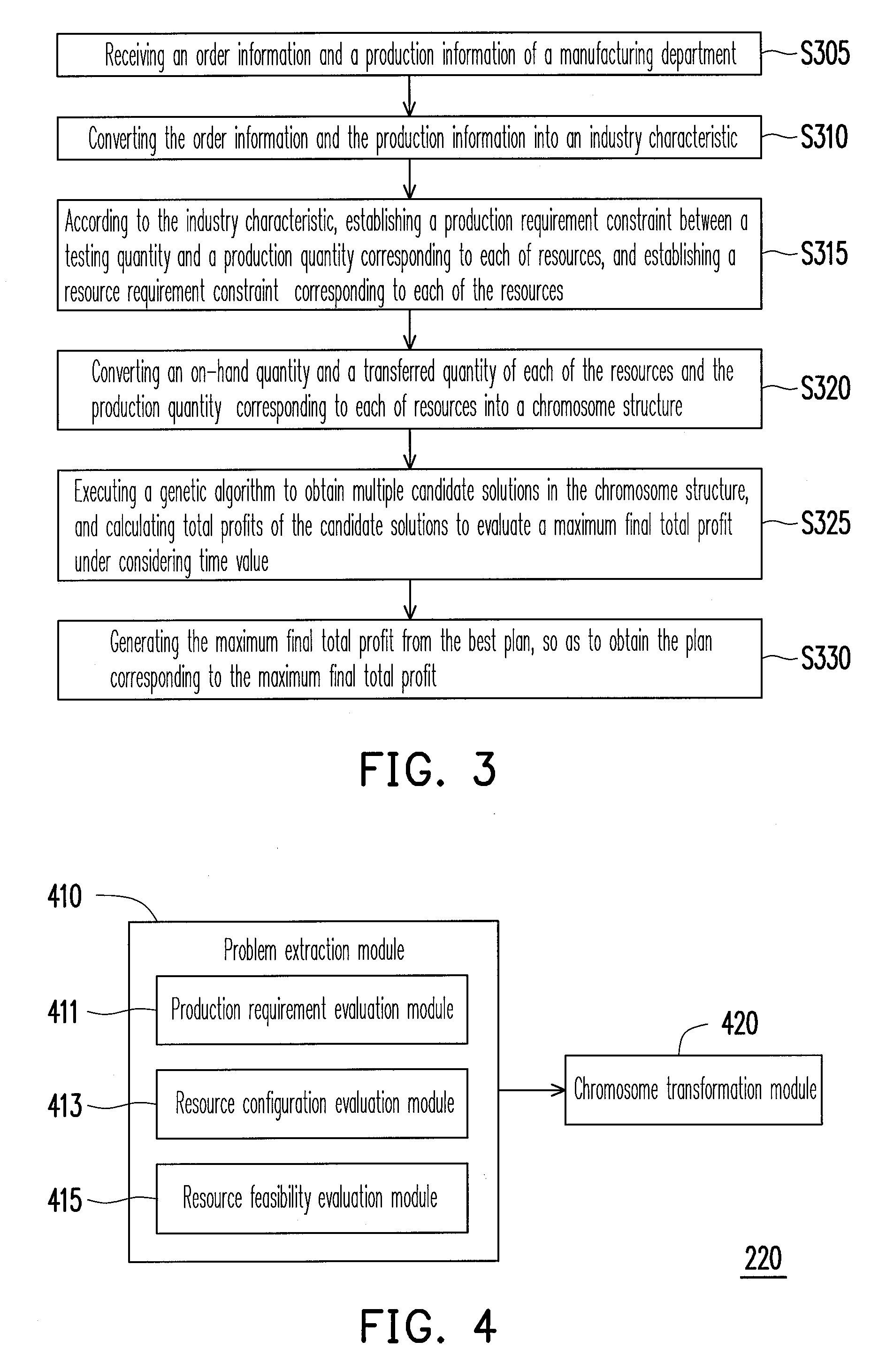

[0020]The semiconductor testing industry is a capital intensive industry. In order to effectively use costly resources of such industry (e.g. machinery equipment and human resources), the present invention provides a method and system for resource allocation in the semiconductor testing industry, so that obtainment of and configuration of the resources are well planned under multiple resource planning constraints. In order to make the present invention more comprehensible, embodiments are described below as the examples to prove that the present invention can be embodied.

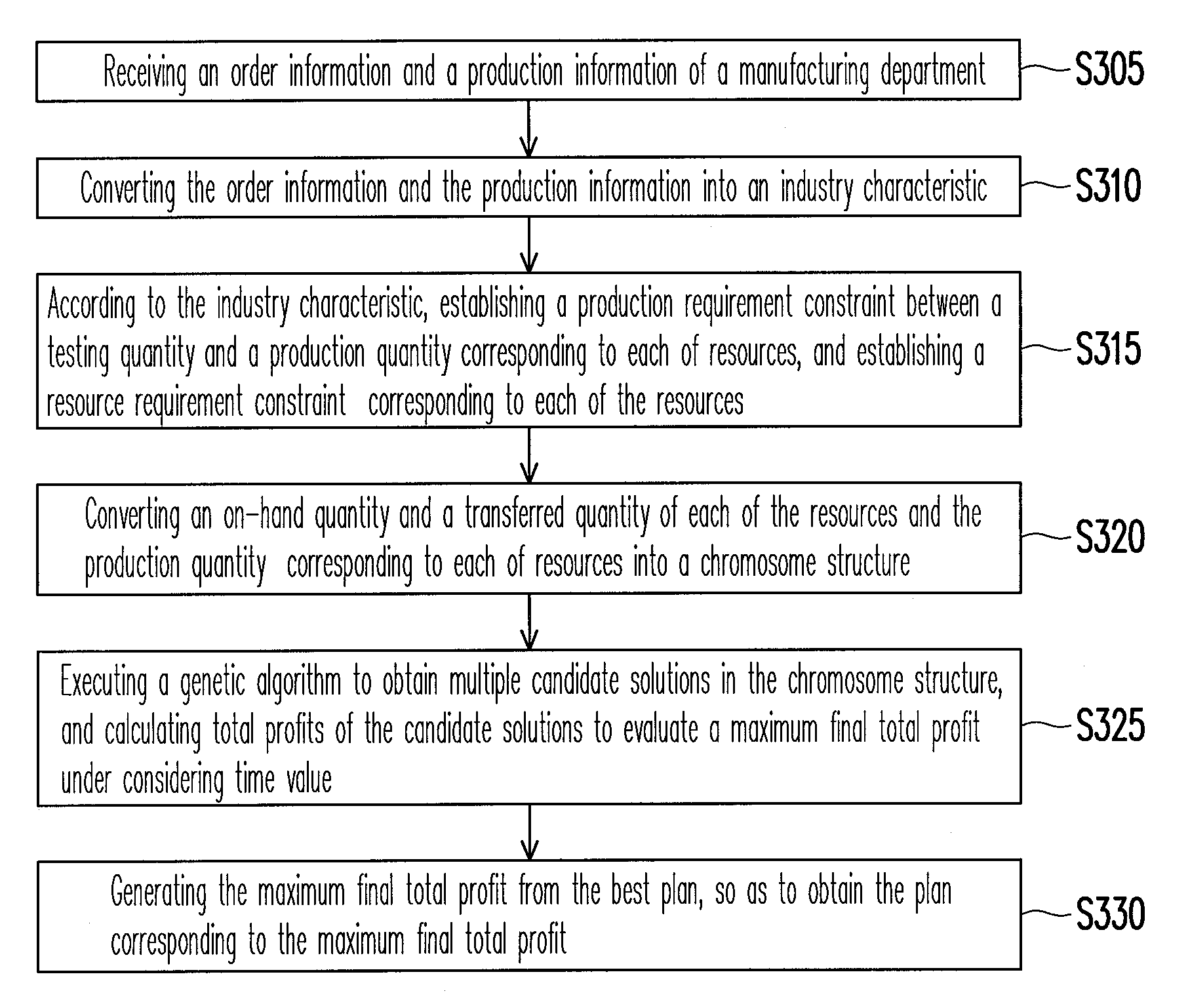

[0021]FIG. 1 is a schematic diagram showing a multiple resource environment in a semiconductor testing factory according to an embodiment of the present invention. Referring to FIG. 1, according to the present embodiment, the resources in the semiconductor testing factory include testing systems 1 to 3 and handlers 1 to 4. Here, product testing function requirements 1 to 4 are given by the customers. As shown in FIG...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com