Method for optimising the life cycle of measurement data based on the retroaction during assembling processes whilst being produced

a technology of assembling process and measurement data, which is applied in the direction of adaptive control, process and machine control, instruments, etc., can solve the problems of increasing assembly cost, affecting productivity and quality, and requiring a lot of space, so as to improve the joining process, shorten production times, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

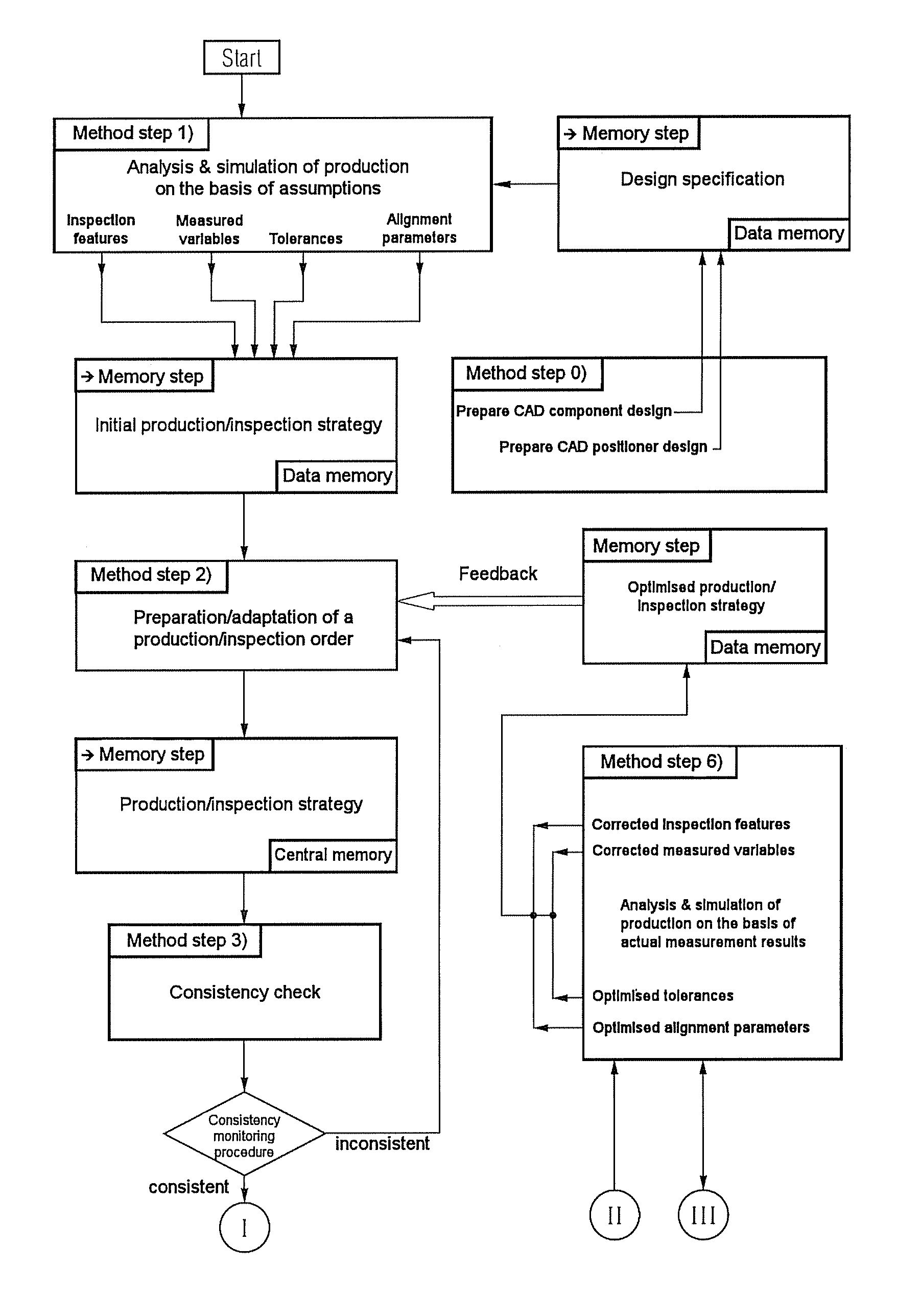

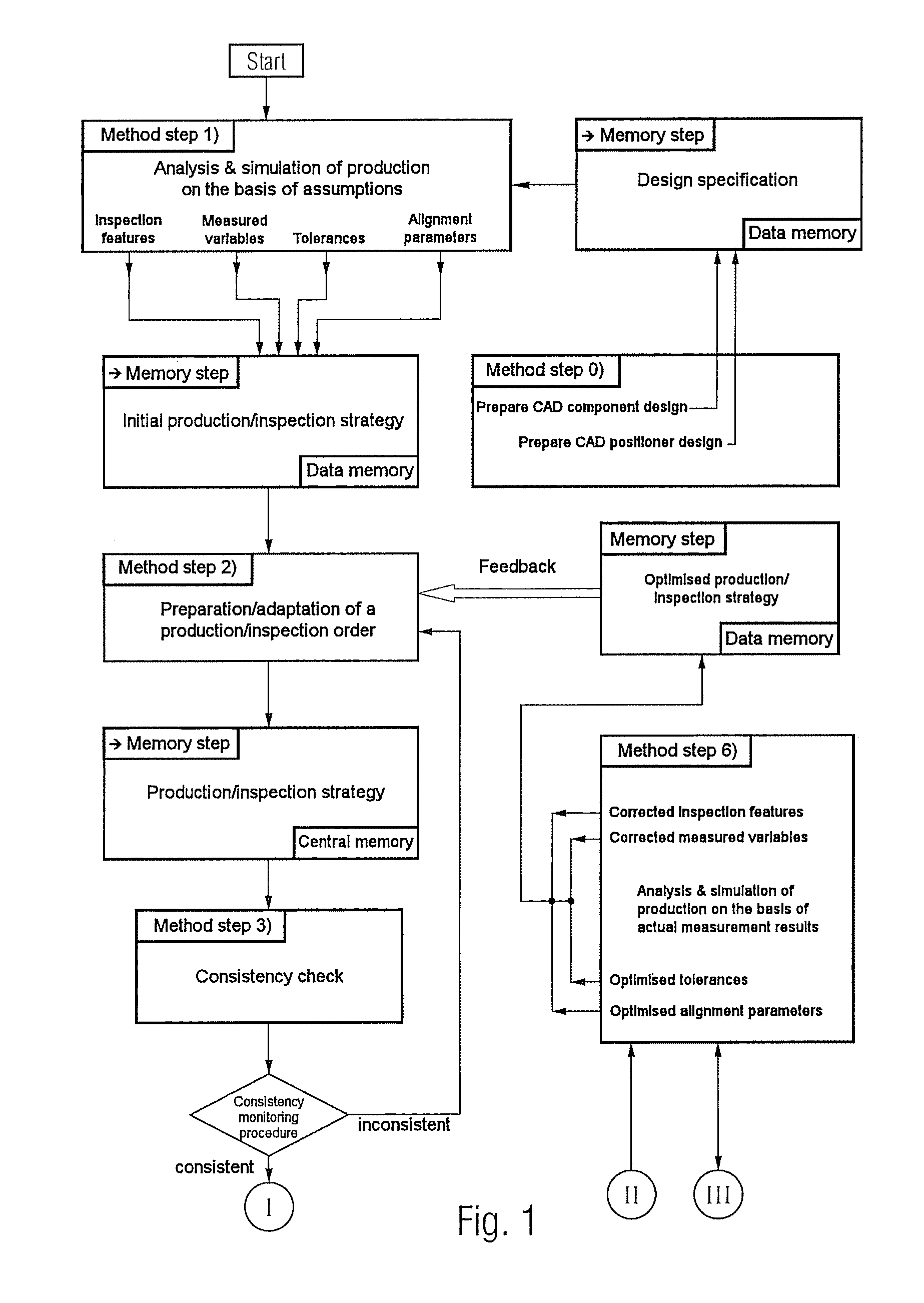

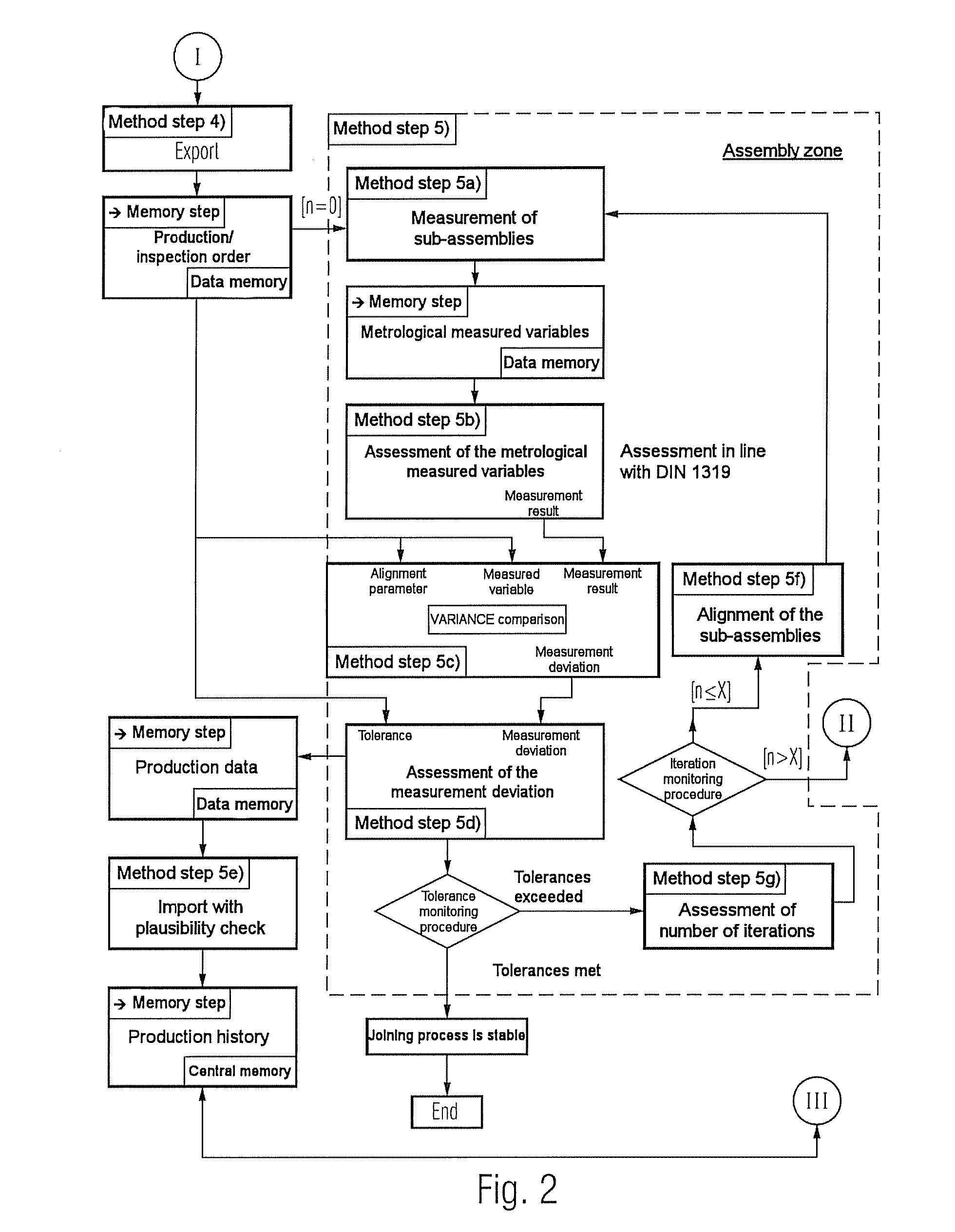

[0039]The sequence of the method according to the invention for feedback-based optimisation of the measurement data life cycle during joining processes in production will now be described in further detail with reference to both FIG. 1 and FIG. 2, into which the flow diagram has been divided in order to improve the clarity of the drawings. First, a component design and a positioner design are prepared using known CAD systems in a method step 0) which precedes the method. The component design comprises, for example, geometrical data of the sub-assemblies to be joined together to form a component, while the positioner design comprises, inter alia, geometrical data of the positioning devices used for the joining process in an assembly zone. Accordingly, geometrical data from the joining devices present in the assembly zone can also be stored. The design specification resulting therefrom is stored in a data memory.

[0040]The actual method begins in method step 1) with the analysis and si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com