Semiconductor device and method for manufacturing same

a semiconductor and semiconductor technology, applied in the direction of semiconductor devices, basic electric elements, electrical appliances, etc., can solve the problems of deteriorating switching characteristics, increasing the recovery time, and affecting the recombination rate of minority carriers accumulated in the gap region, so as to reduce the recovery time and enhance the recombination rate of minority carriers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0032

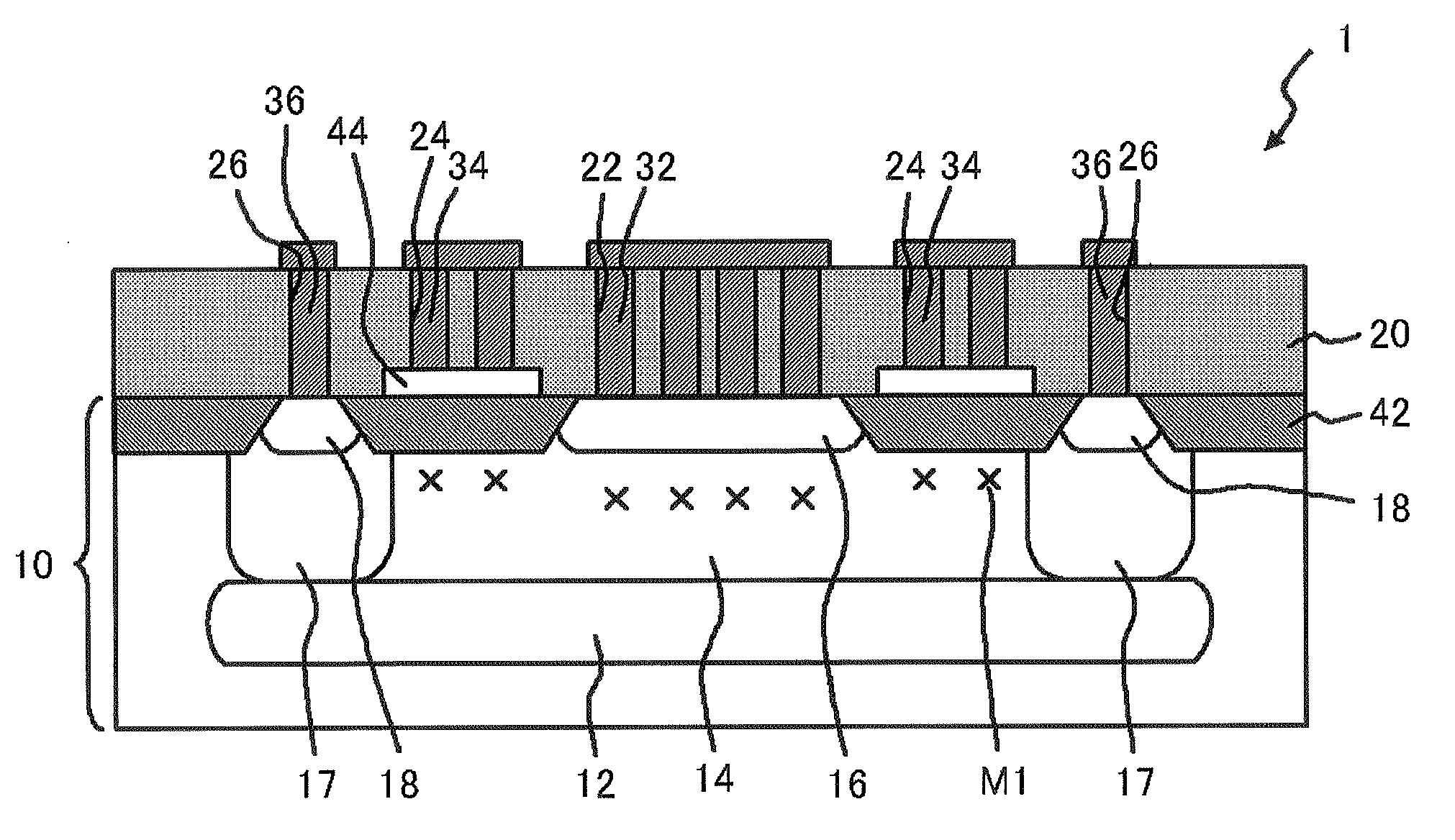

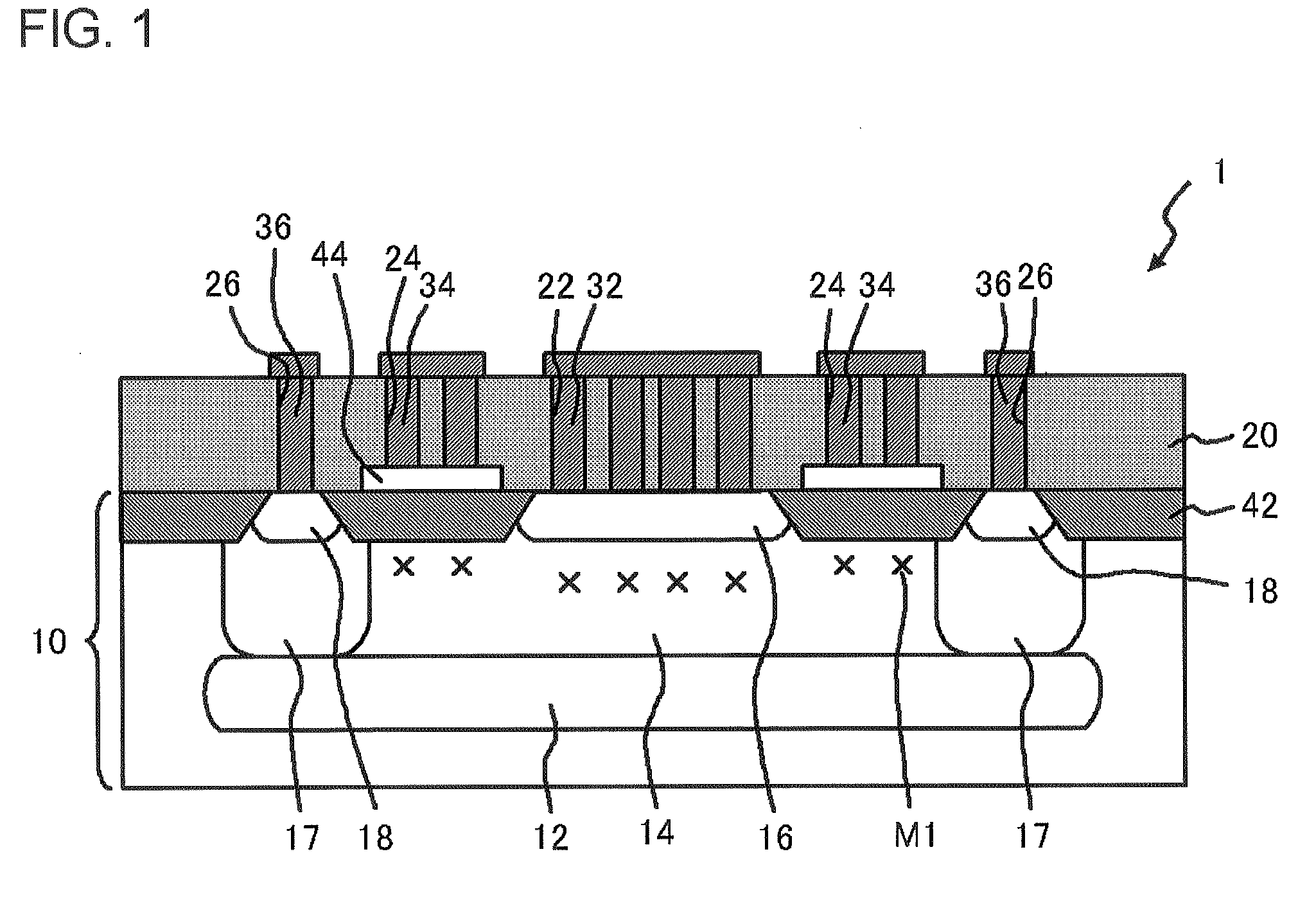

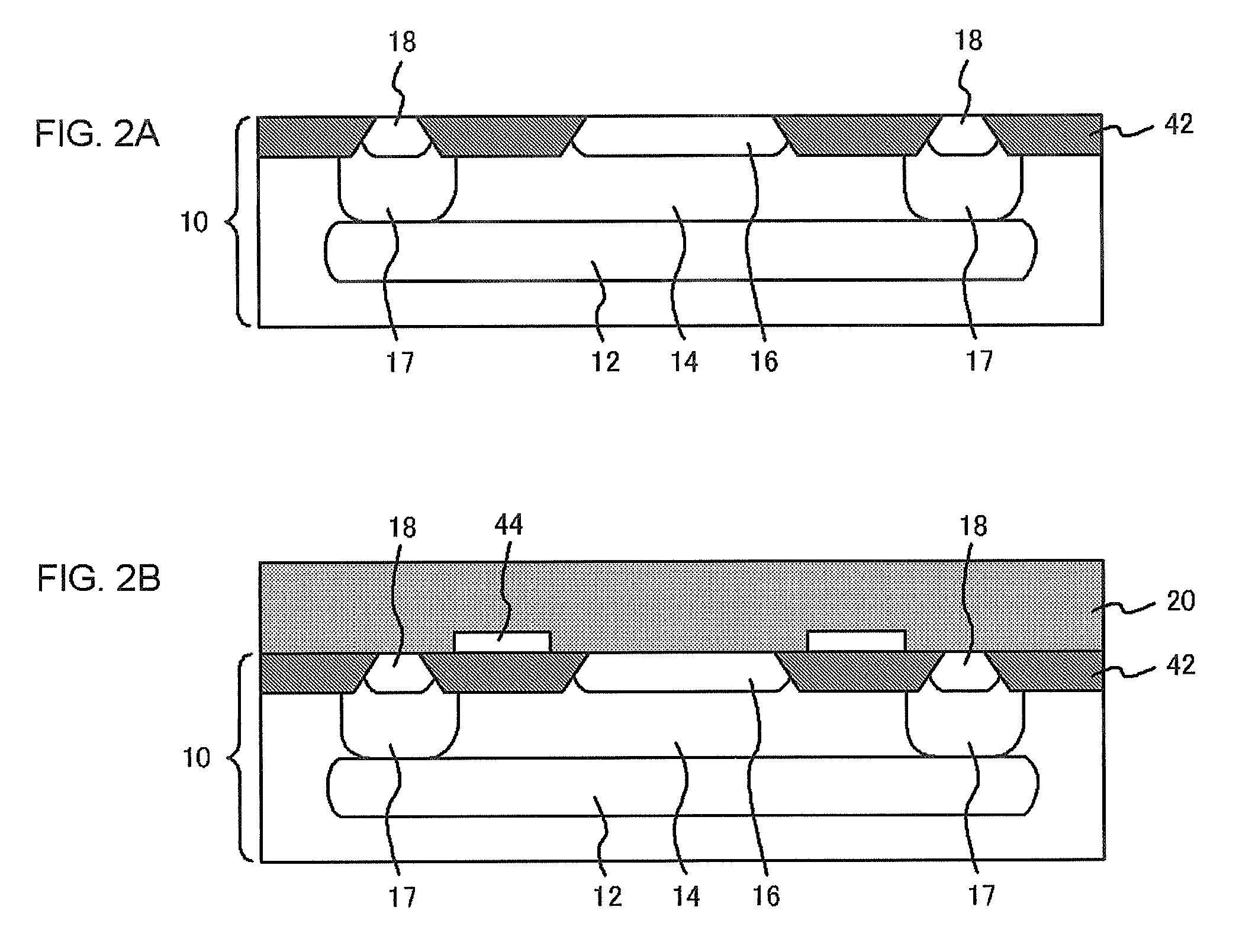

[0033]FIG. 1 is a cross-sectional view, illustrating first embodiment of a semiconductor device according to the present invention. A semiconductor device 1 includes a semiconductor substrate 10, a contact plug 32 (first electroconducting plug) and a contact plug 34 (second electroconducting plug). In the present embodiment, the semiconductor substrate 10 is a p-type silicon substrate. An n+ type buried region 12 is formed in the semiconductor substrate 10. An n-type region 14 is formed on the n+ type buried region 12, and a p-type diffusion layer 16 is formed in a surface layer of the n-type region 14. The n-type region 14 and the p-type diffusion layer 16 constitute a diode. Further, an n+ type region 17 extending from the surface of the semiconductor substrate 10 is formed so as to reach the n+ type buried region 12. An n-type diffusion layer 18 is formed in a surface layer of the n+ type region 17. Such n-type diffusion layer 18 functions as a contact layer of the n-type re...

second embodiment

[0050

[0051]FIG. 7 is a cross-sectional view, illustrating second embodiment of a semiconductor device according to the present invention. While first embodiment illustrates the exemplary implementation of applying the configuration of the present invention to the diode, the present embodiment is an exemplary implementation of applying the present invention to bipolar transistors. A semiconductor device 2 includes a p-type region 52 serving as a base of a bipolar transistor, formed in an n-type region 14 of a semiconductor substrate 10. The n-type region 14 functions as a collector of the bipolar transistor. A p+ type diffusion layer 54 (first impurity-diffusing layer) and an n+ type diffusion layer 56 (second impurity-diffusing layer) are formed in the surface layer of the p-type region 52. The p+ type diffusion layer 54 functions as a contact layer of the p-type region 52, and the n+ type diffusion layer 56 functions as an emitter of the above-described bipolar transistor.

[0052]An ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com