Laser projector having safety lens for audience scanning

a technology of audience scanning and laser projector, which is applied in the field of laser projectors, can solve the problems of scanning failure, retinal damage, and retinal damage, and achieve the effects of increasing safety, reducing the risk of damage, and increasing the diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

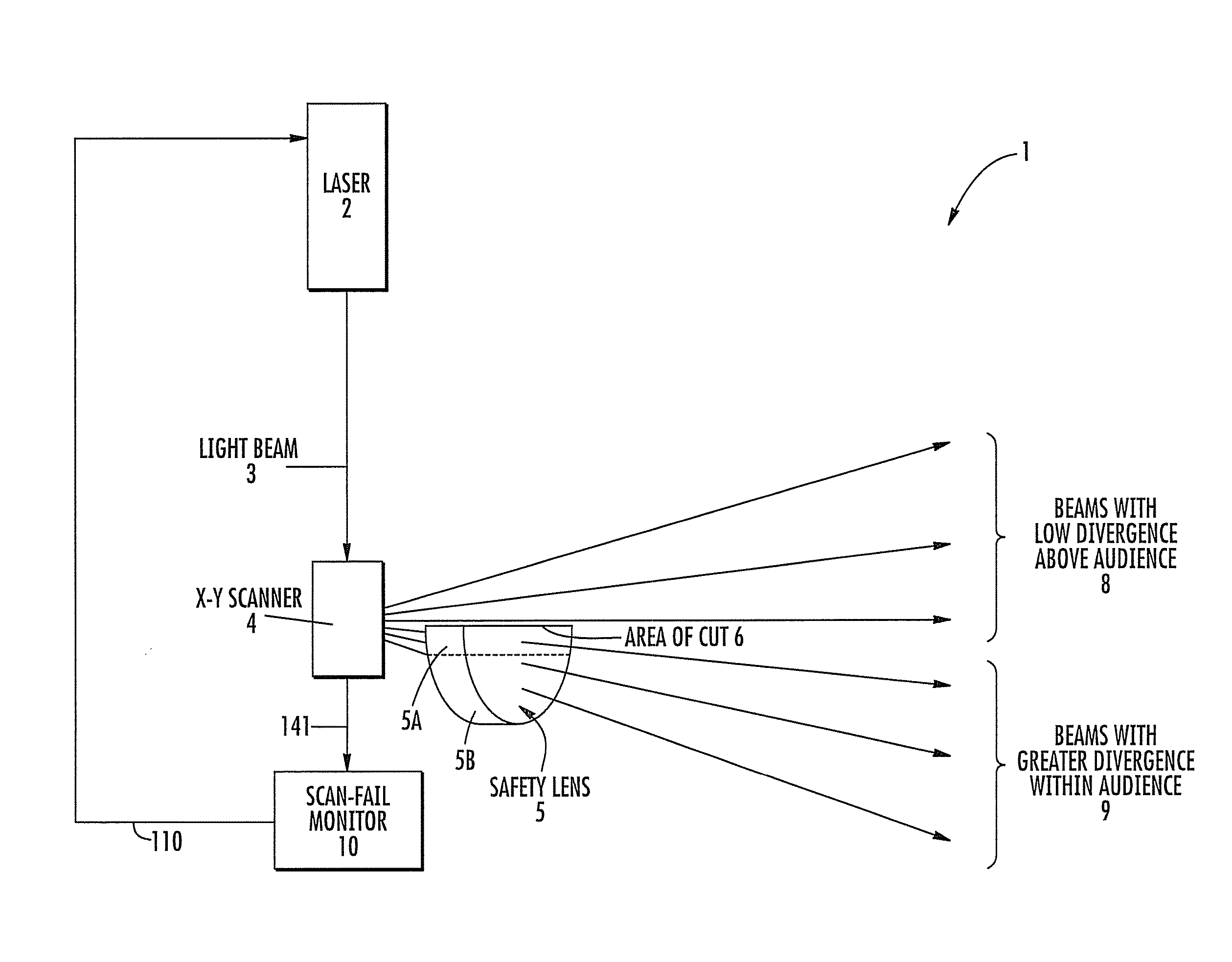

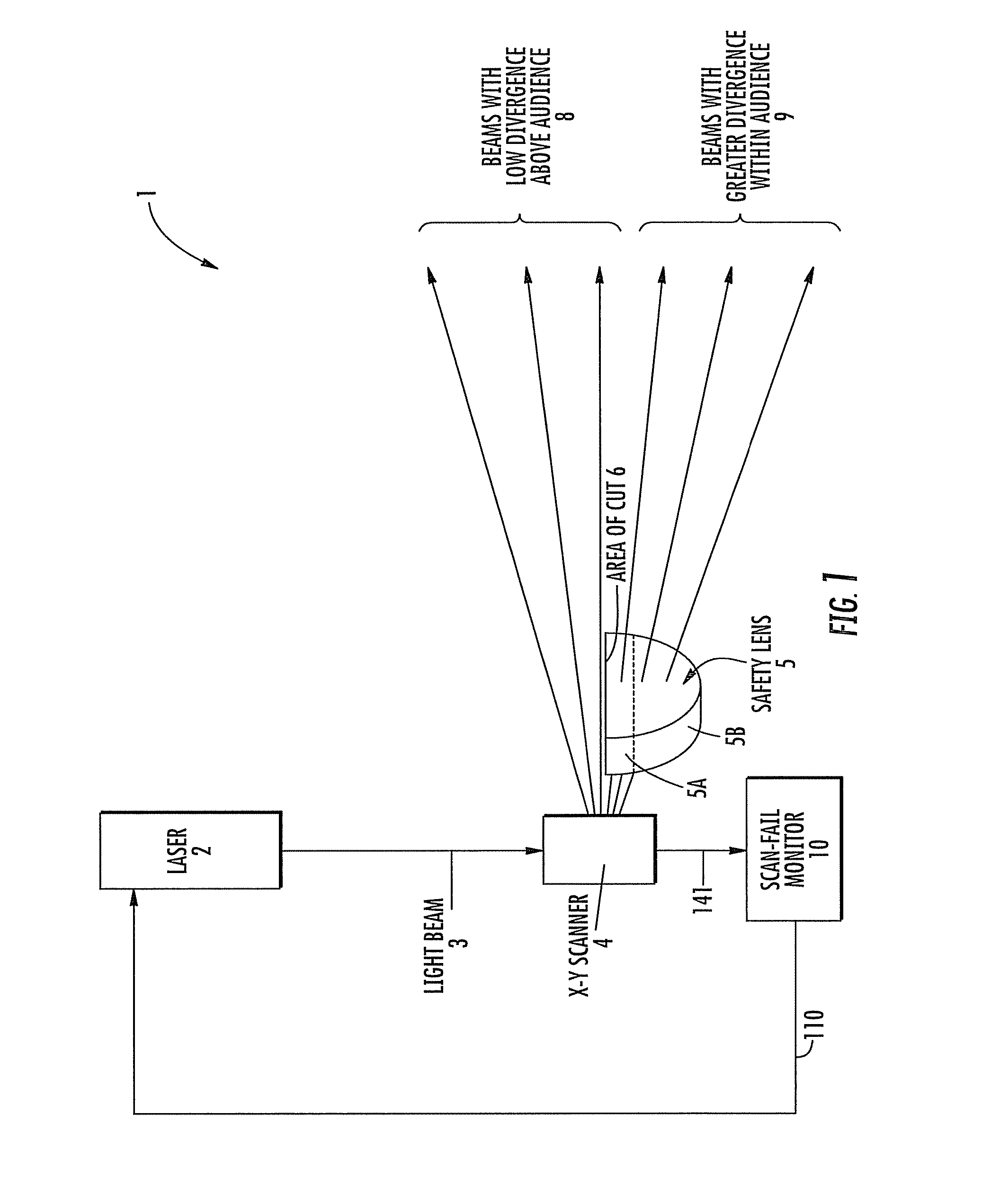

embodiment 11

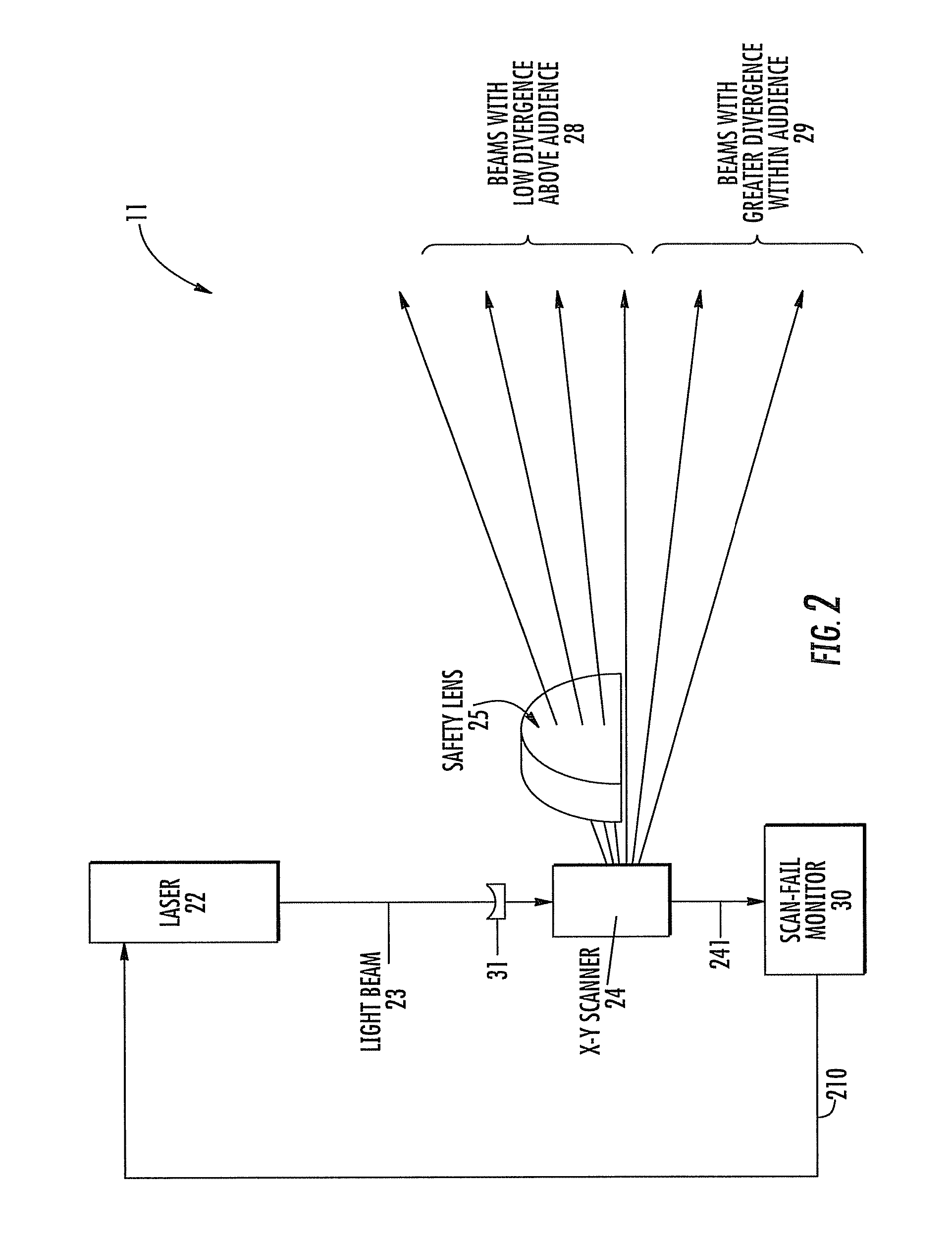

[0050]Up-collimators that comprise two lenses are known in the art, and are typically placed before the scanner. However, placing the single lens 31 before the scanner 24 and a second lens (the safety lens 25) after the scanner 24 provides a dual benefit. In this embodiment 11, the moving mirror on the scanner 24 does not have to be as big as would be the case with prior art up-collimator methods, and another benefit is provided by the fact that the safety lens 25 does not affect beams projected around where the audience resides 29.

[0051]Since the safety lens 25 is positioned in such a way as to only affect beams projected generally above the audience 28, the system will provide beams with higher divergence into the audience 29 because of the optical power of the lens 31.

[0052]Since it may be desirable for the safety lens 25 to be located externally to the projector and easily removable so that different optical powers may be used for different venues, it should be understood that t...

second embodiment

[0053]As noted above, within this second embodiment, illustrated with reference to FIG. 2 for the system 11, it is preferable to have the lens 31 configured to provide a negative optical power, and the safety lens 25 configured to have a positive optical power. However, it is possible for lens 31 to provide a positive optical power, and also possible to configure the safety lens 25 to provide negative optical power. Many lens and optical configurations are possible and still remain within the scope of this invention as long as the system places beams with lower divergence above the heads of the audience 28, and beams with greater divergence within the audience 29.

[0054]The safety lens 25 may additionally be coated with a multi-layer, reflection free coating optimized for transmittance in the visible wavelengths.

[0055]Embodiments of the present invention may be driven by a computer or other pattern generator, not shown in FIG. 1 or 2 because such is common and well known in the art.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com