Power transmission belt method for production thereof

a transmission belt and transmission belt technology, applied in the field of transmission belts, can solve the problems of increasing the cost of assembling the elements to the stacked ring, the process of applying residual compressive stress to the ring materials typically increases the cost, and the endless sheet metals of the inner layers (especially the innermost layer) tend to degrade, so as to suppress the increase in compressive stress, increase the strength of the ring materials of the first to mth layers, and reduce the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]An embodiment of the present invention will be described below with reference to the accompanying drawings.

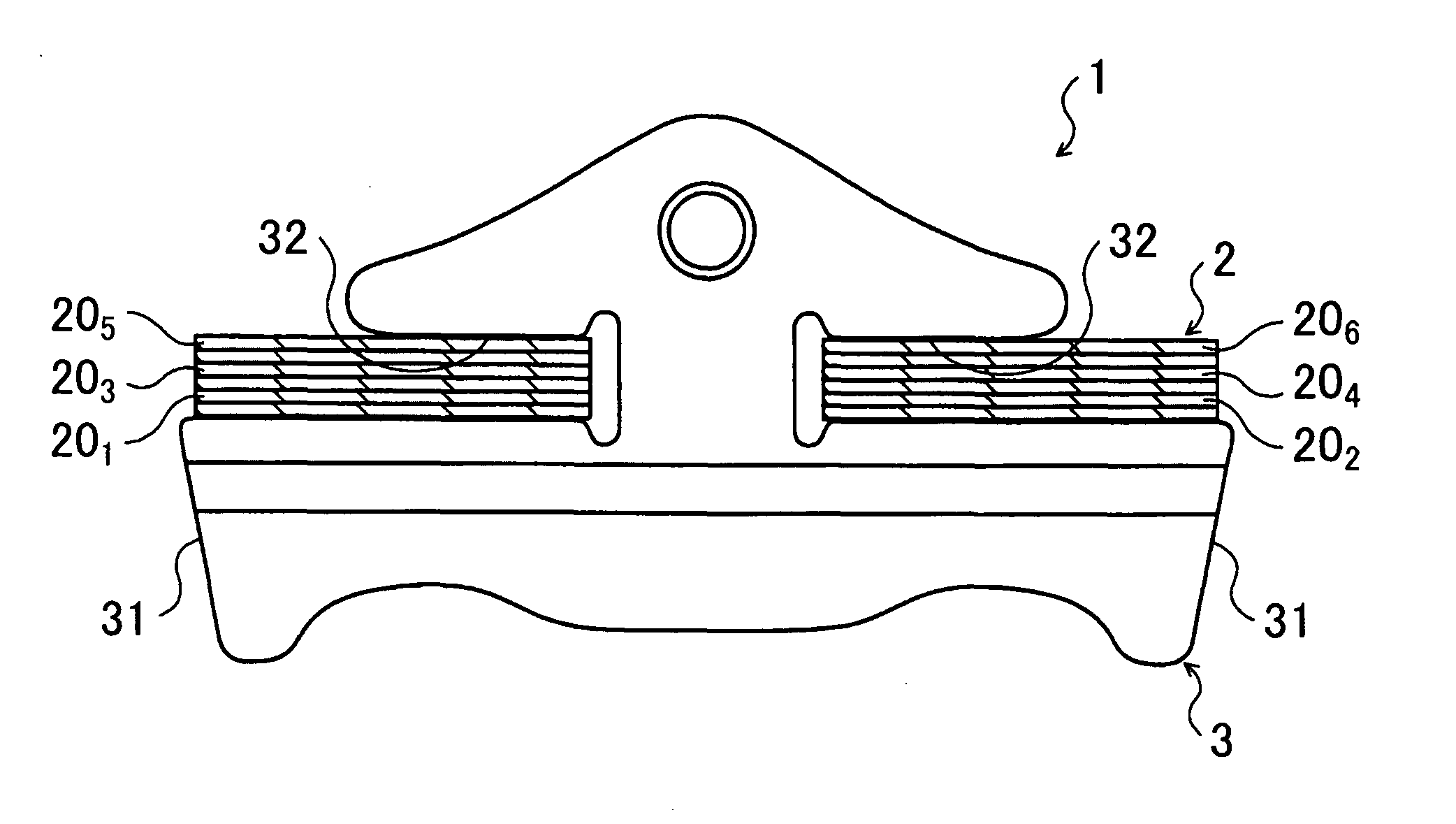

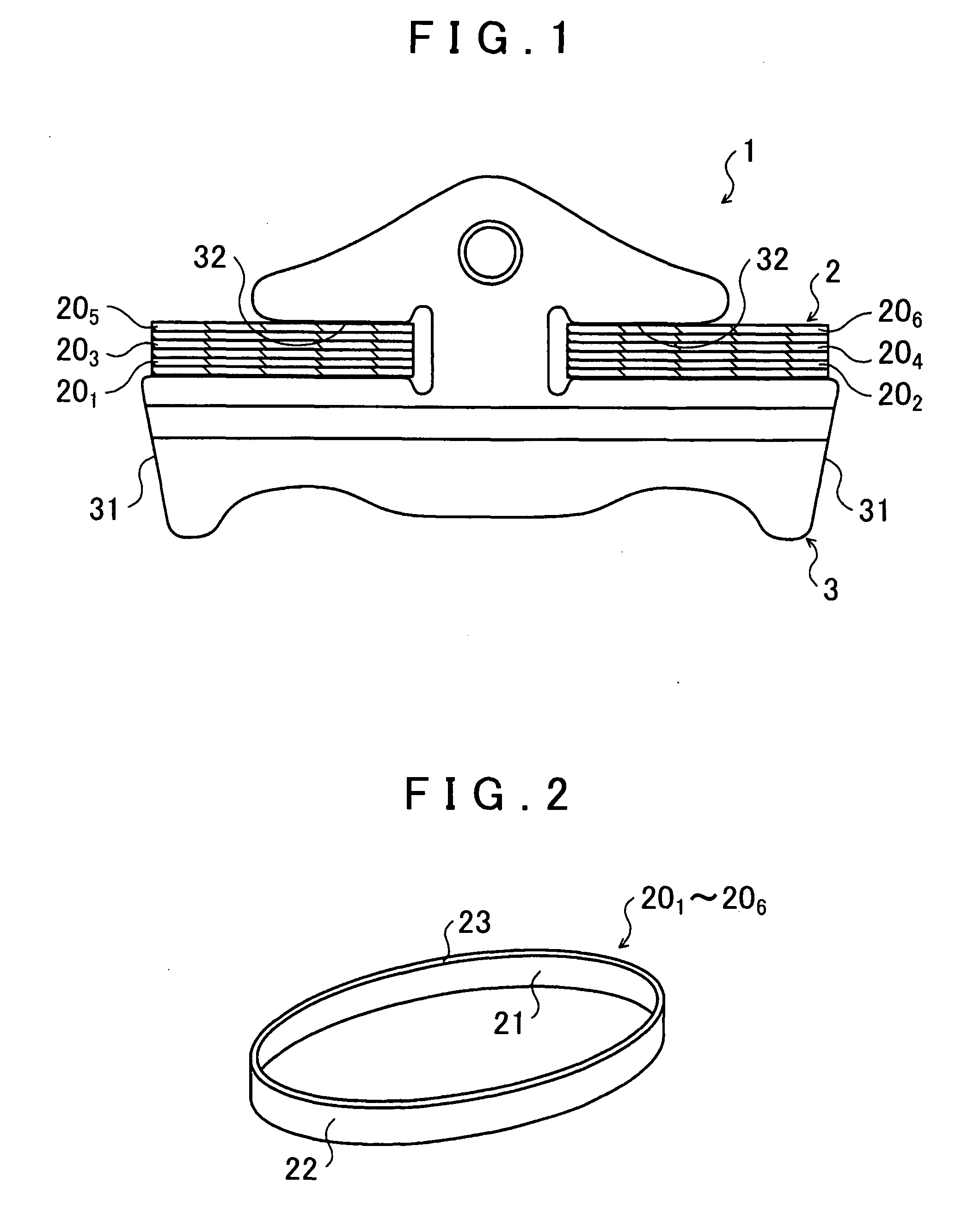

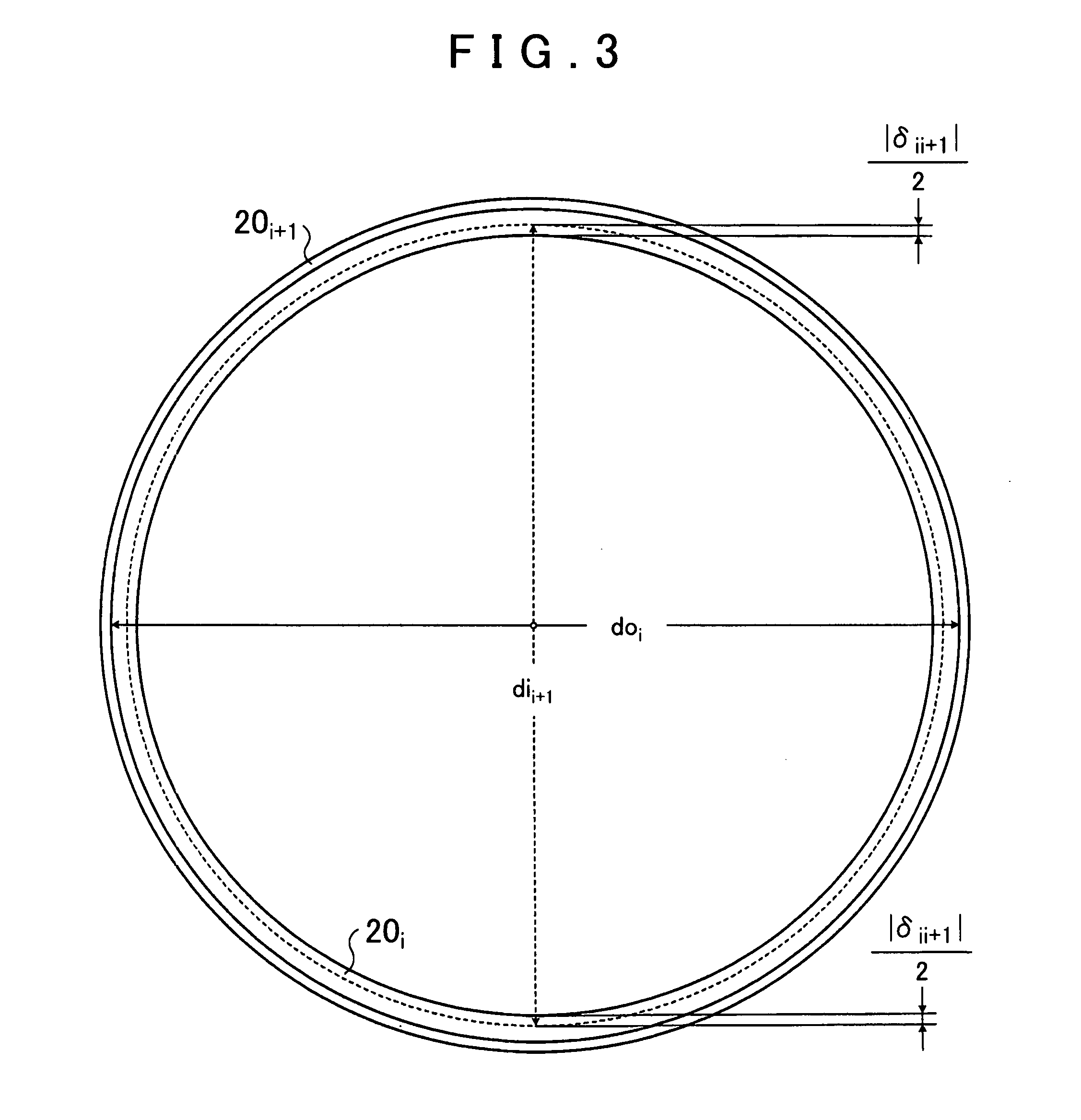

[0026]FIG. 1 is a partial cross-sectional view showing an example of a transmission belt 1 of the present invention. The transmission belt 1 shown in the drawing forms a continuously variable transmission (CVT), together with a primary pulley provided on a primary shaft as a drive-side rotating shaft, and a secondary pulley provided on a secondary shaft as a driven-side rotating shaft placed parallel to the primary shaft and a secondary pulley (none of these elements are shown). The transmission belt 1 is wrapped around a groove (a V-groove) of the primary pulley formed by a movable sheave and a fixed sheave, and a groove (a V-groove) of the secondary pulley similarly formed by a movable sheave and a fixed sheave, and transmits power applied to the primary shaft to the secondary shaft. At this time, by changing the groove width of at least one of the primary pulley and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com