Process for the acetoxylation of olefins in the gas phase

a technology of olefins and gas phases, which is applied in the preparation of carboxylic acid esters, chemistry apparatus and processes, and organic chemistry, etc., can solve the problems of increasing the total oxidation of the reaction mixture, limiting the concentration of starting materials, and reducing the yield of olefins, so as to improve the selectivity and the effect of low by-product formation and space-time yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Pd / Au Type Catalyst with Differing Promoter Contents

[0065]For this purpose, a catalyst was produced as described in WO 2008 / 071610 with the exception that the catalyst of the 1st zone contains 6.5% by weight of potassium and the catalyst in the 2nd zone contains 3.0% by weight of potassium.

[0066]

Designation1st Zone2nd Zone3rd Zonerelative5050—length [%]SiO2 support200200—BET (m2 / g)Pd (% by2.02.0—weight)Au (% by2.02.0—weight)K (% by6.53.0—weight)

[0067]This catalyst system according to the invention makes it possible to achieve maximum space-time yields of 980 g (VAM) / l of cat.*h at maximum ethene selectivities of 93.2% in the test in the reactor under the conditions described.

example 2

Pd / Au Type Catalyst Having Differing Support BET Surface Areas and Promoter Contents

[0068]Two catalysts were synthesized as described in WO 2008 / 071610; these differed in that the catalyst in the 1st zone was produced on SiO2 supports having a BET surface area of 150 m2 / g and a potassium content of 6.5% by weight and the catalyst in the 2nd zone was produced on SiO2 supports having a BET surface area of 220 m2 / g and a potassium content of 3.0% by weight.

[0069]

Designation1st Zone2nd Zone3rd Zonerelative5050—length [%]SiO2 support150220—BET (m2 / g)Pd (% by2.02.0—weight)Au (% by2.02.0—weight)K (% by6.53.0—weight)

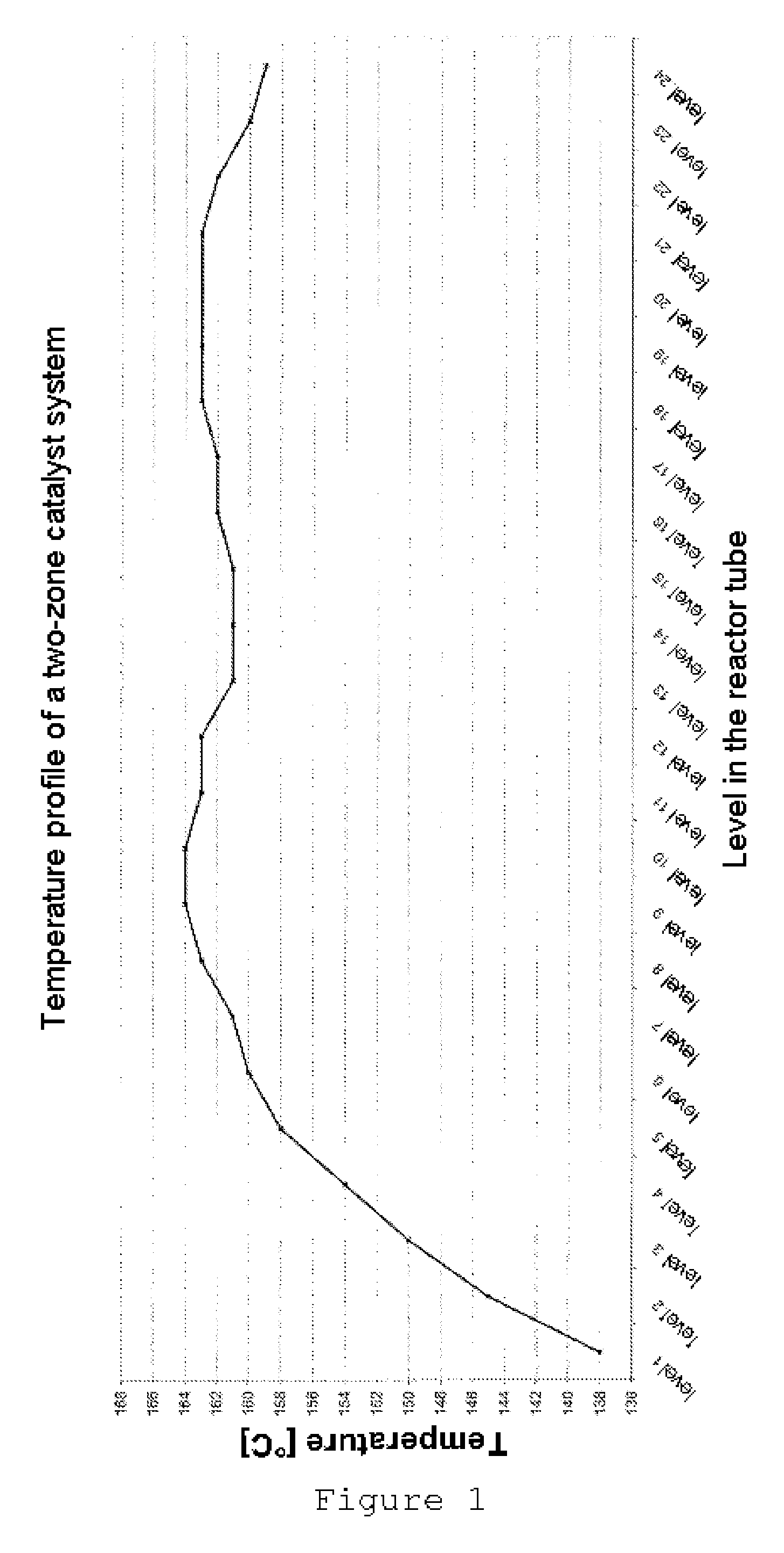

[0070]This catalyst system according to the invention makes it possible to achieve maximum space-time yields of 1050 g (VAM) / l of cat.*h at maximum ethene selectivities of 93.5% in the test in the reactor under the conditions described. FIG. 1 shows the temperature profile of this two-zone catalyst system with a largely isothermal temperature profile with optimized catalyst util...

example 3

Pd / Au Type Catalyst with Differing EM Contents

[0071]Two catalysts were synthesized as described in WO 2008 / 071610; these differed in that the catalyst in the 1st zone was produced on SiO2 supports having a BET surface area of 180 m2 / g and a Pd and Au content of 2.0% by weight in each case and the catalyst in the 2nd zone was produced on SiO2 supports having a BET surface area of 220 m2 / g and a Pd and Au content of 2.3% by weight in each case.

[0072]

Designation1st Zone2nd Zone3rd Zonerelative6040—length [%]SiO2 support180220—BET (m2 / g)Pd (% by2.02.3—weight)Au (% by2.02.3—weight)K (% by6.53.0—weight)

[0073]This catalyst system according to the invention makes it possible to achieve maximum space-time yields of 1200 g (VAM) / l of cat.*h at ethene selectivies of 94.0% in the test in the reactor under the conditions described.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com