Optical module

a technology of optical modules and optical components, applied in the field of optical modules, can solve the problems of complex structure and increase in the price of parts, and achieve the effects of reducing the error of light alignment, simple process and equipment, and aligning light with small expenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045]Advantages and features of the present invention, and implementation methods thereof will be clarified through following embodiments described with reference to the accompanying drawings. The present invention may, however, be embodied in different forms and should not be construed as limited to the embodiments set forth herein. Throughout this specification and the claims that follow, when it is described that an element is “connected” to another element, the element may be “directly connected” to the other element or “electrically connected” to the other element through a third element. In the accompanying drawings, a portion irrelevant to description of the present invention will be omitted for clarity. Like reference numerals refer to like elements throughout.

[0046]Hereinafter, embodiments will be described in detail so that those skilled in the art may easily perform the present invention with reference to the accompanying drawings.

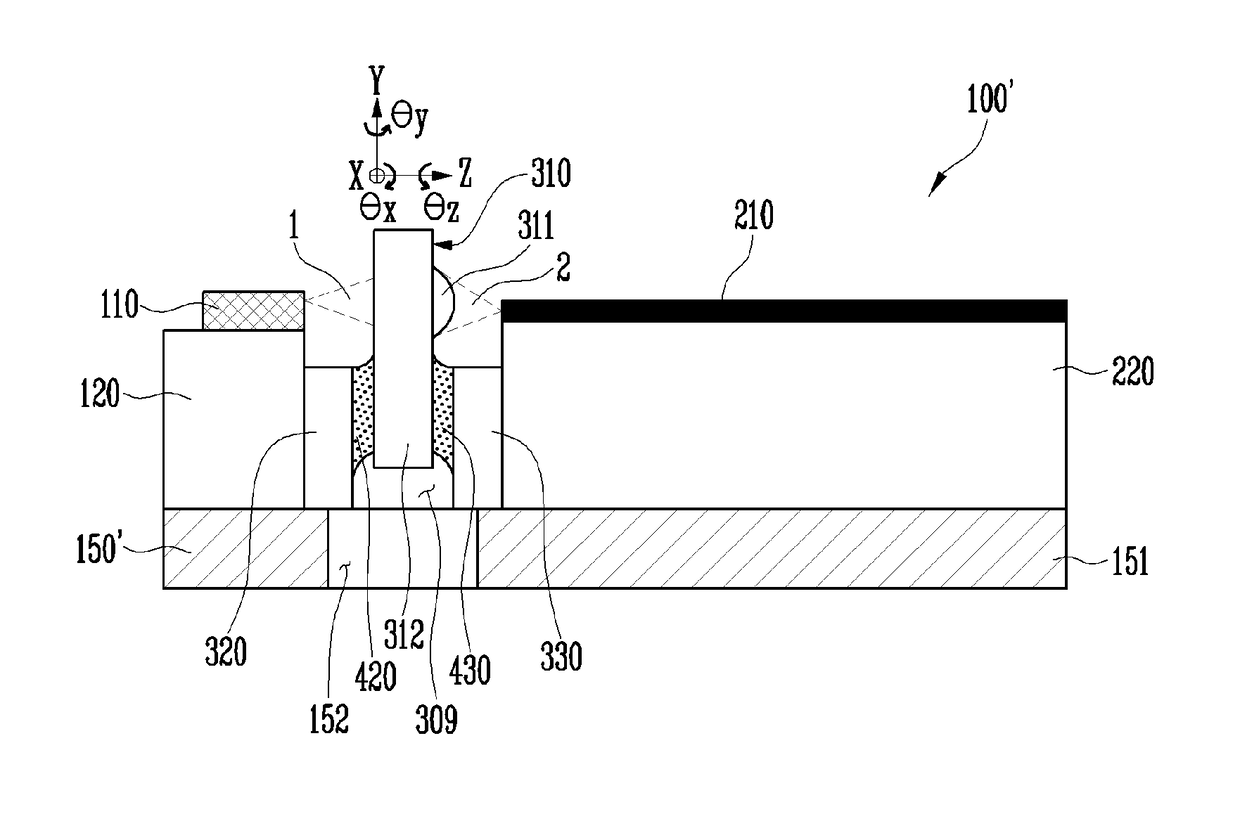

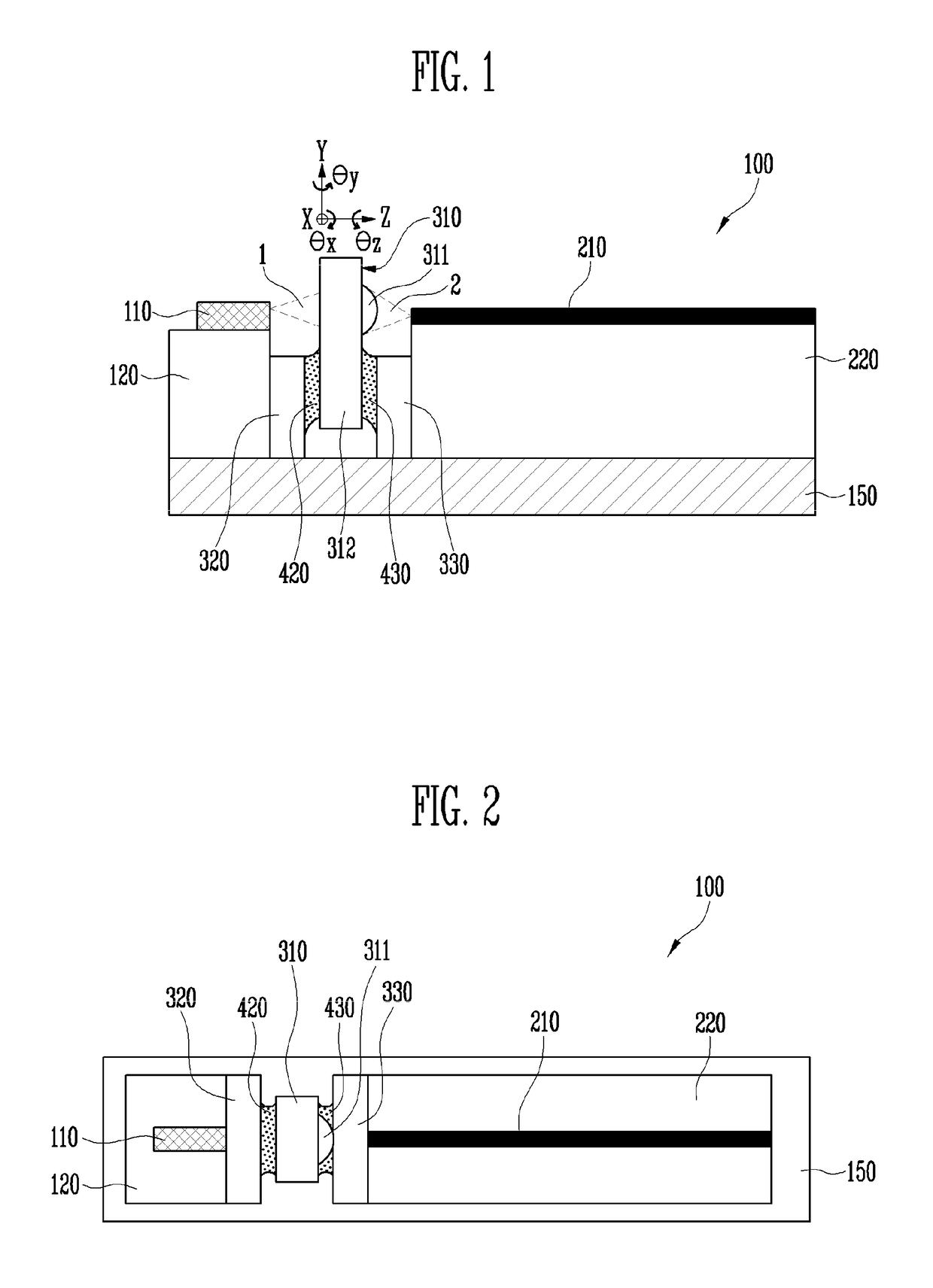

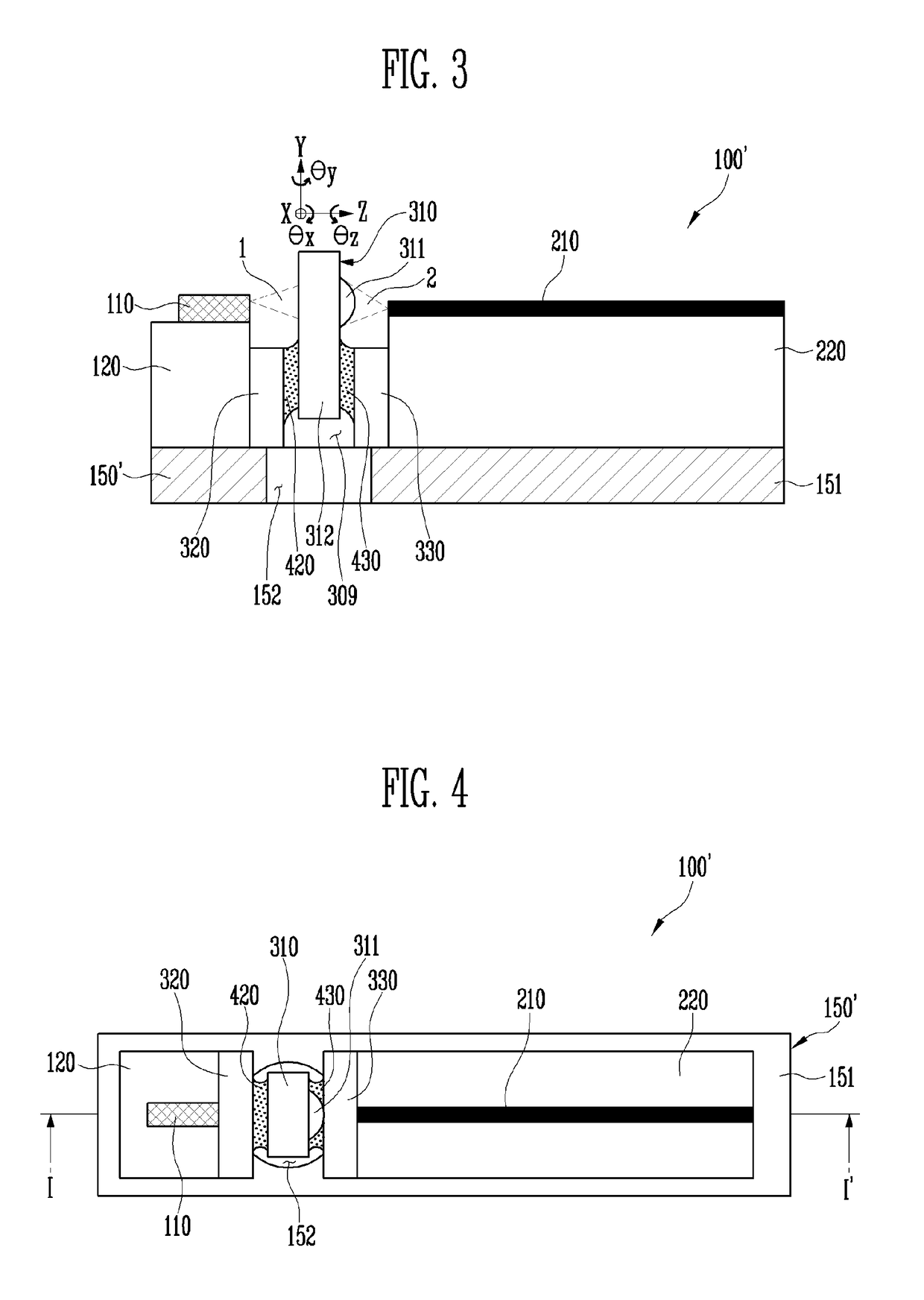

[0047]FIG. 1 is a side view of an optica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com