Method of using a water transport plate

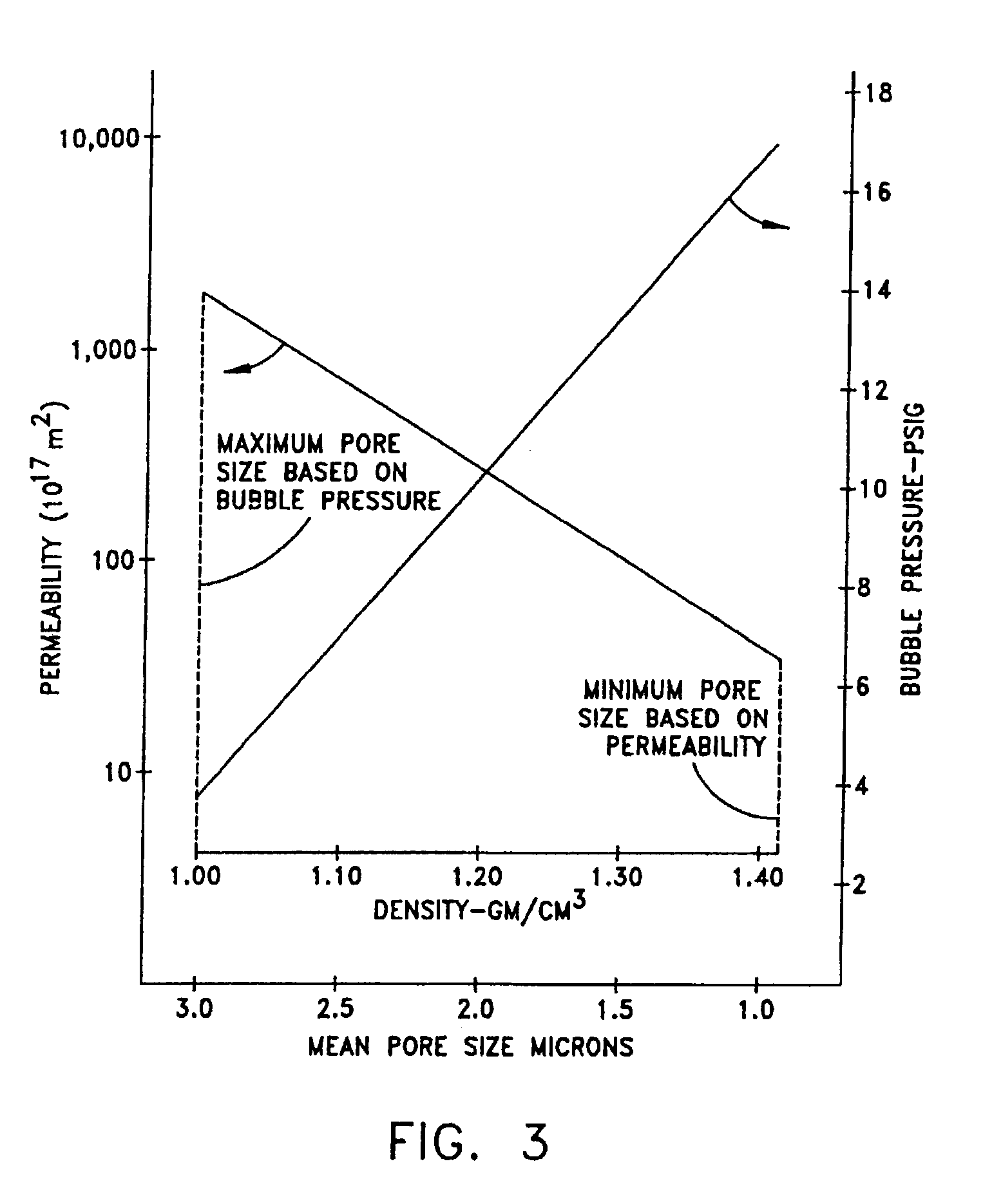

a technology of water transport plate and water permeability, which is applied in the direction of sustainable manufacturing/processing, final product manufacturing, electrochemical generators, etc., can solve the problems of high cost of manufacture, limited strength, and difficult to achieve the solution of water management and cell cooling in ion-exchange membrane fuel cell power plants, etc., to achieve optimal pore size, resistivity and yield strength, and optimal balance of bubble pressure and water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0037]The following process can be utilized to form a 40 wt % AirCo 90 graphite powder, 5 wt % FORTAFIL ½ inch unsized carbon fiber, 28 wt % OXYCHEM Phenolic resin, and 27 wt % Softwood Pulp.

1. Water is mixed with the solids in a portion of 0.4 g graphite powder, 0.05 g carbon fibers, 0.28 g Oxy-Chem Phenolic Resin, and 0.27 g Softwood Pulp to form a slurry having about 1 v / o solids.

2. Once thoroughly blended, the slurry is showered onto a horizontally moving screen to form a planar sheet with a basis weight of 250 lb. / ream or 12 oz / sq.-yard, plus or minus 5%.

3. The screen is passed over a vacuum to remove some of the remaining water, and thereby partially dry the planar sheet.

4. The partially dried planar sheet is then directed over rollers and oil heated drums to volatilize residual water and form the dried paper. The drums are heated to 250° F.

5. The dried paper is spooled on a cardboard tube for collection.

6. The spooled paper is cut into 10-12 inch by 6 inch sheets.

7. The sheet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| compressive yield strength | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com