Biological safety cabinet with improved air flow

a technology of biological safety cabinets and air flow, which is applied in the field of biological safety cabinets, can solve the problems of contaminated air, adversely affecting the air flow of the safety cabinets, and large portion of the perforations in the safety cabinets becoming blocked, so as to effectively prevent contaminated air from leaving the cabinets and effectively draw air into the cabinets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

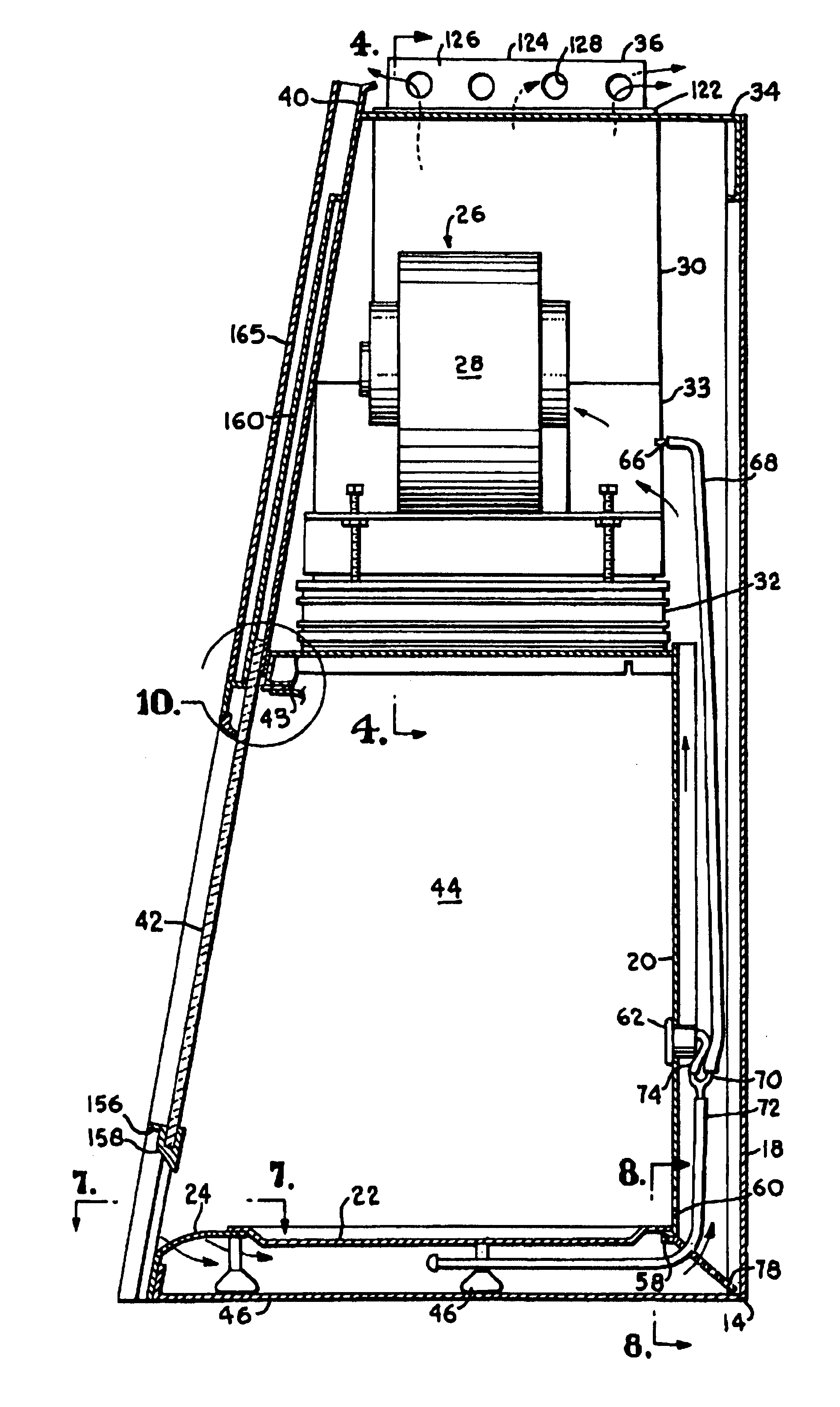

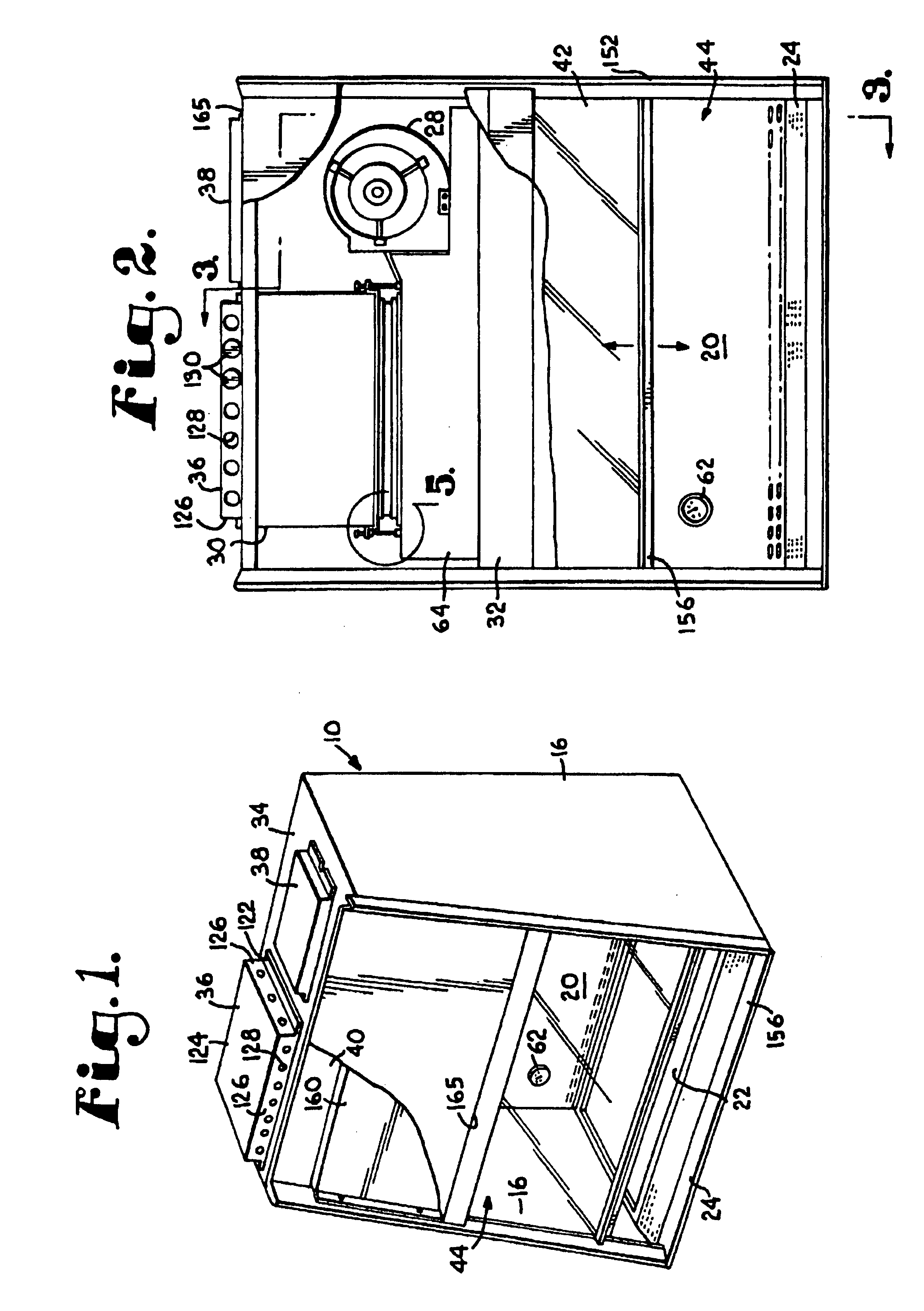

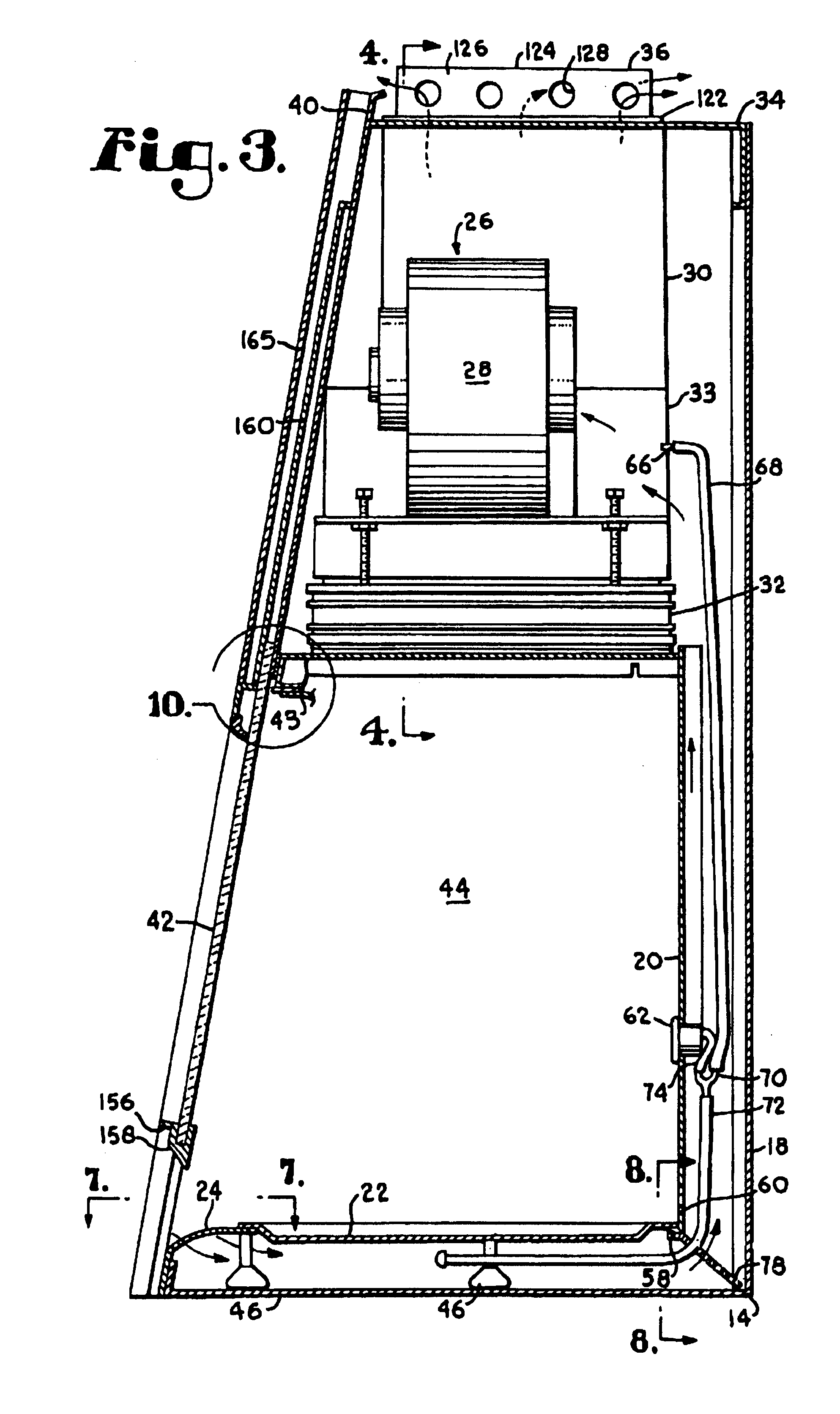

[0040]Referring initially to FIG. 1, a biological safety cabinet according to the present invention is broadly designated in the drawings by the reference numeral 10. A broad overview of the construction of cabinet 10 is set forth below, followed by a more detailed description of certain features of the cabinet. Broadly, cabinet 10 has a bottom panel 14 and a pair of upwardly extending opposing side panels 16 which are rigidly coupled to bottom panel 14, such as by welding. Extending upwardly from the bottom panel 14 and rigidly coupled between side panels 16 is a rear panel 18, as best seen in FIG. 3. Rear panel 18 extends upwardly from bottom panel 14 as do side panels 16. Bottom panel 14, side panels 16 and rear panel 18 form apartial frame in which the other components of cabinet 10 are held. A baffle 20 is coupled between side panels 16 and is spaced outwardly away from real panel 18. The bottom of baffle 20 is spaced upwardly away from bottom panel 14. Panels 14, 16 and 18, as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com