Method of forming pre-metal dielectric film on a semiconductor substrate including first layer of undoped oxide of high ozone:TEOS volume ratio and second layer of low ozone doped BPSG

a dielectric film and semiconductor substrate technology, applied in the field of semiconductor processing, can solve problems such as void-free dielectric film surface, achieve good gettering capability, good as-deposited gapfill characteristics, and sacrifice good mobile-ion gettering properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

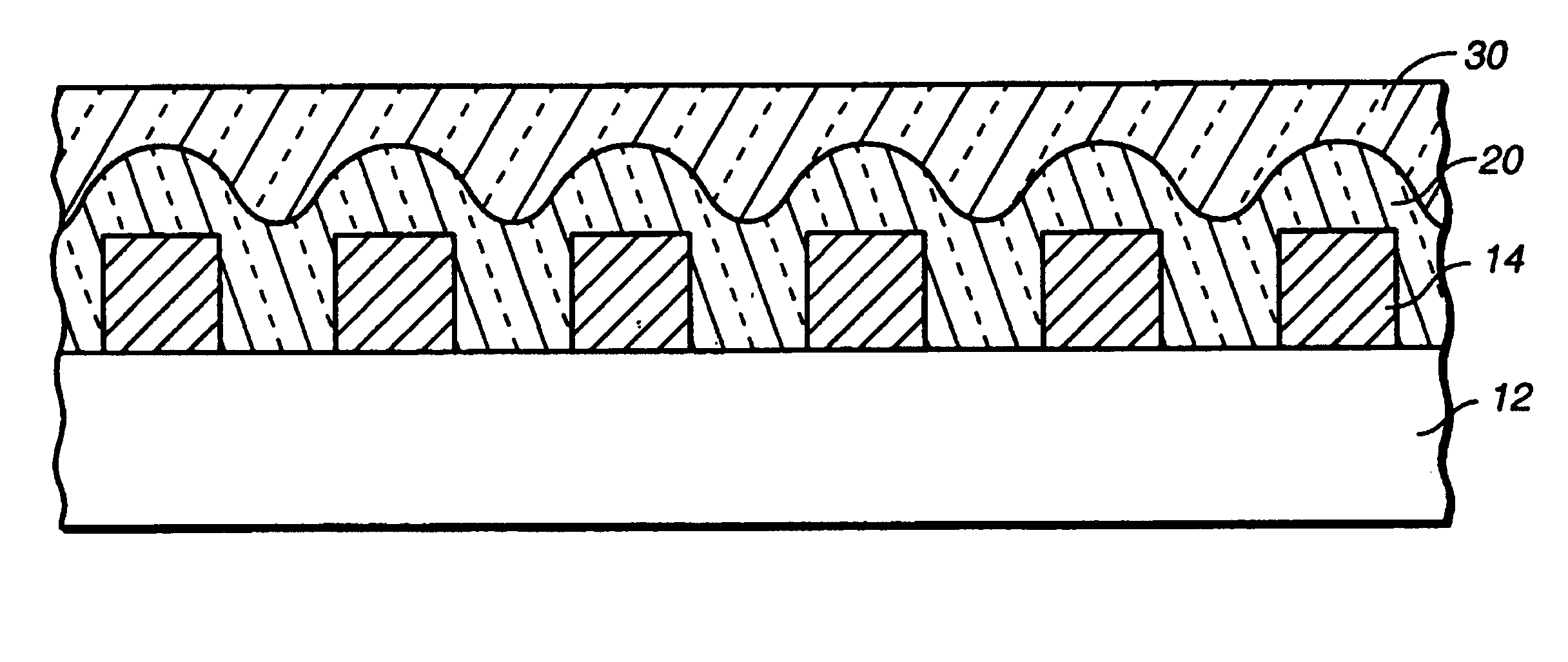

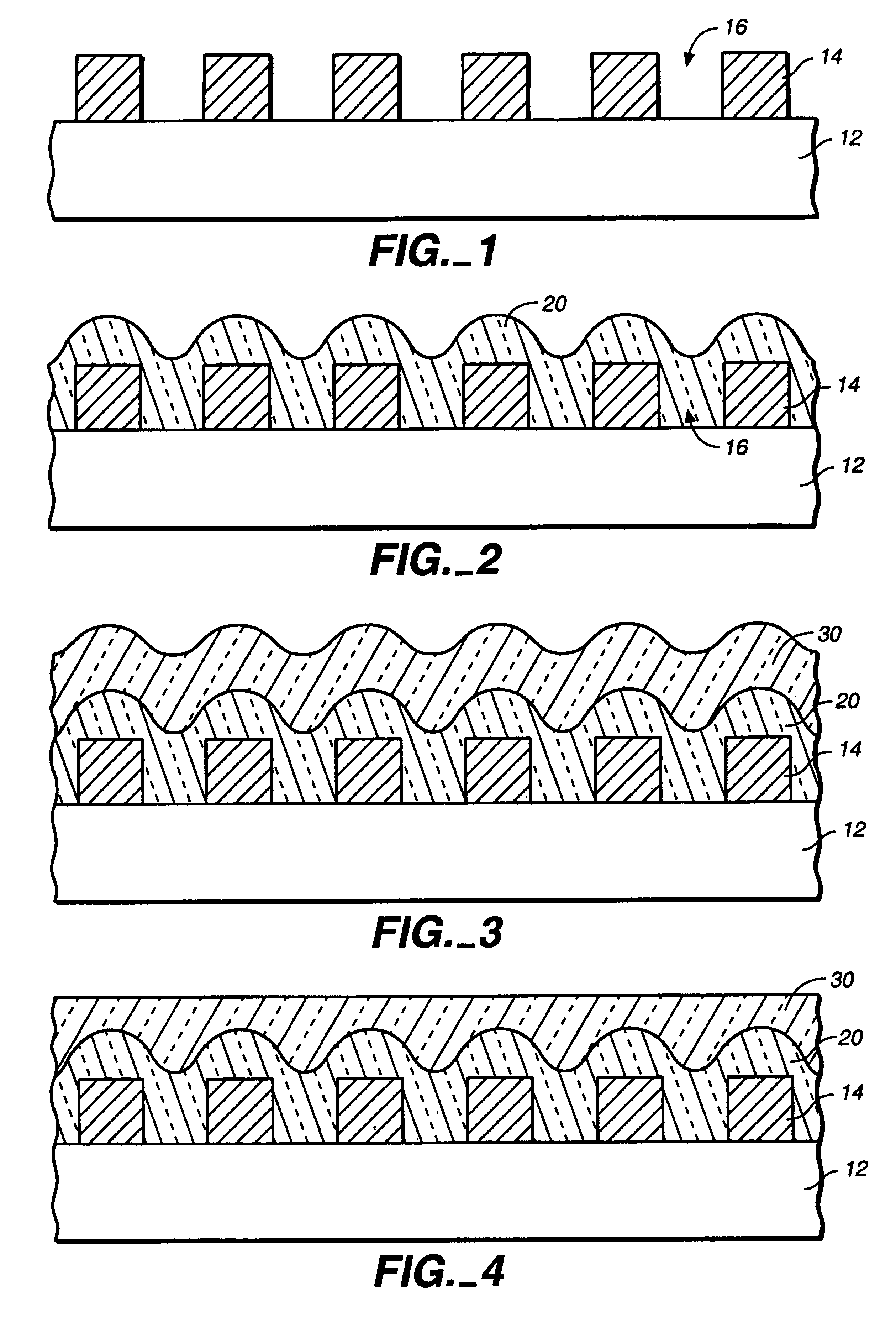

[0016]With reference to FIG. 1, a silicon substrate 12 has a plurality of polysilicon conductors 14 formed on a top surface thereof. It is understood that the silicon substrate 12 has undergone the various steps of wafer preparation previous to the method of the present invention in order to form the various diodes, transistors, and resistors and other components on the substrate. This is done by adding dopants to the pure silicon in a manner that is well known in the art. The polysilicon conductors 14 are also formed on the top surface of the substrate in a manner that is known in the art. Between each of the polysilicon conductors 14 are gaps 16 which will need to be filled with electrically isolating dielectric film.

[0017]With reference to FIG. 2, a layer of high ozone undoped silicon dioxide film 20 is deposited on top of the semiconductor substrate 12 and the polysilicon conductors 14. The high ozone undoped silicon dioxide film covers the polysilicon conductors 14 and fills th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap