Patents

Literature

32results about How to "Solve the problem of smooth feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

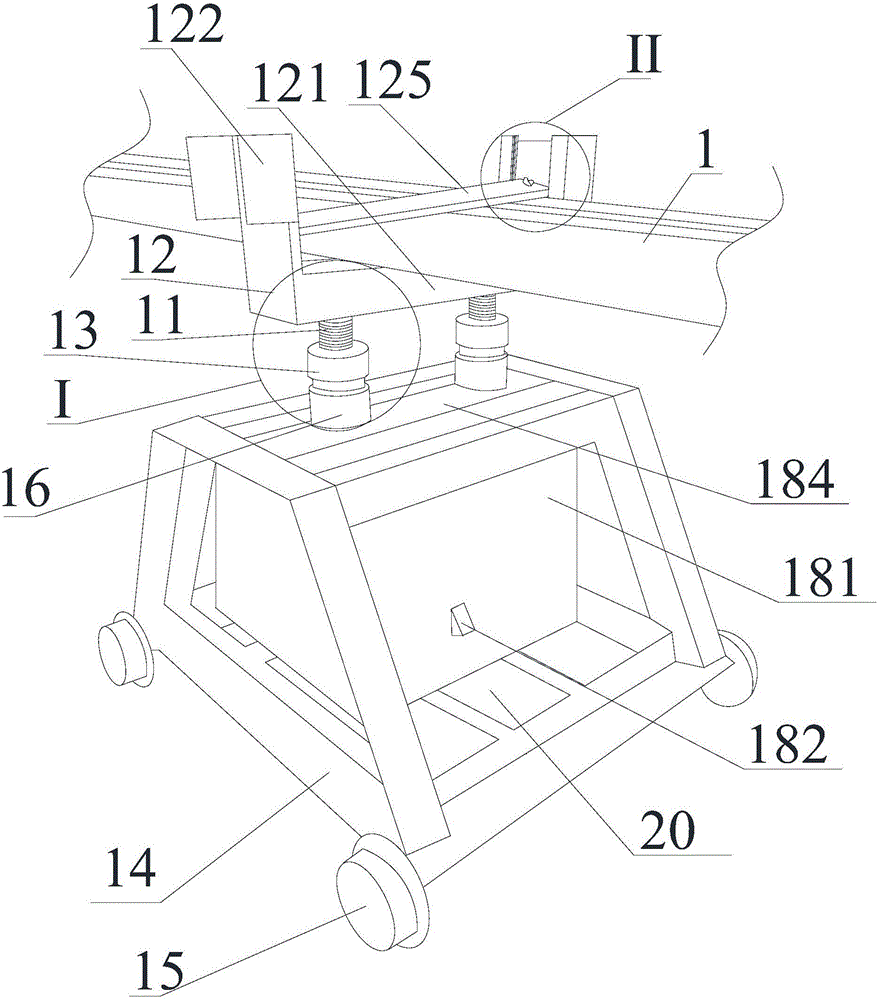

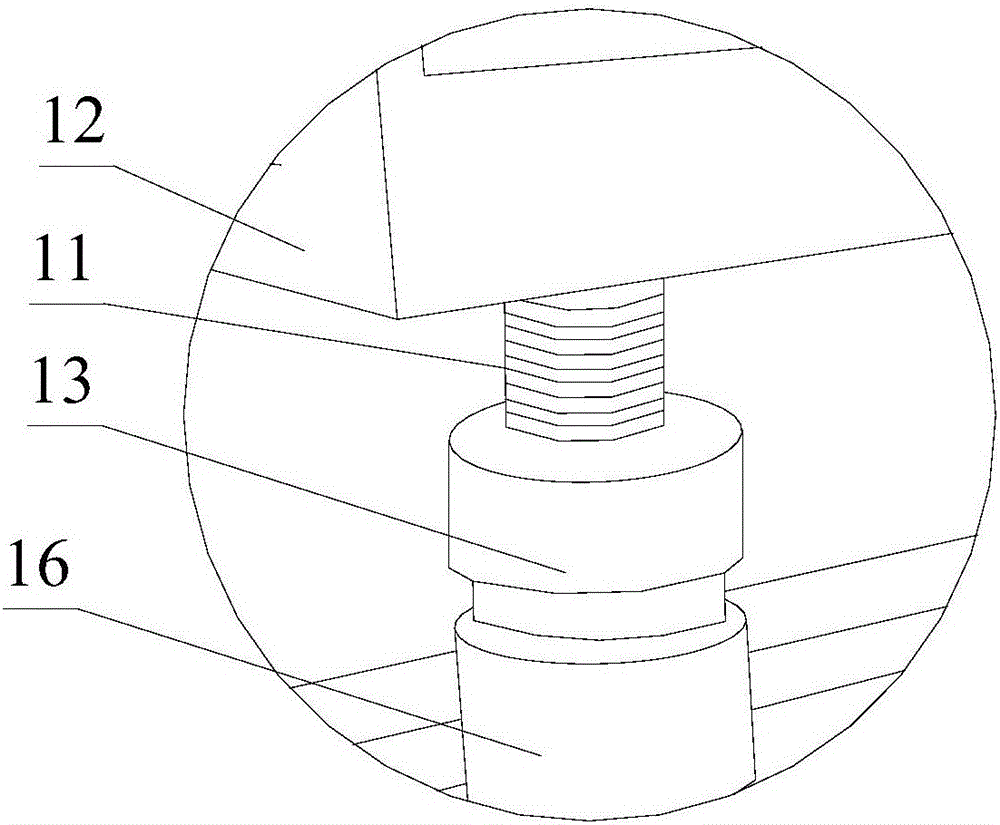

Dual-adjusting type feeding supporting device

InactiveCN105922070ASolve the problem of smooth feedingEasy to operateMetal working apparatusEngineeringMechanical engineering

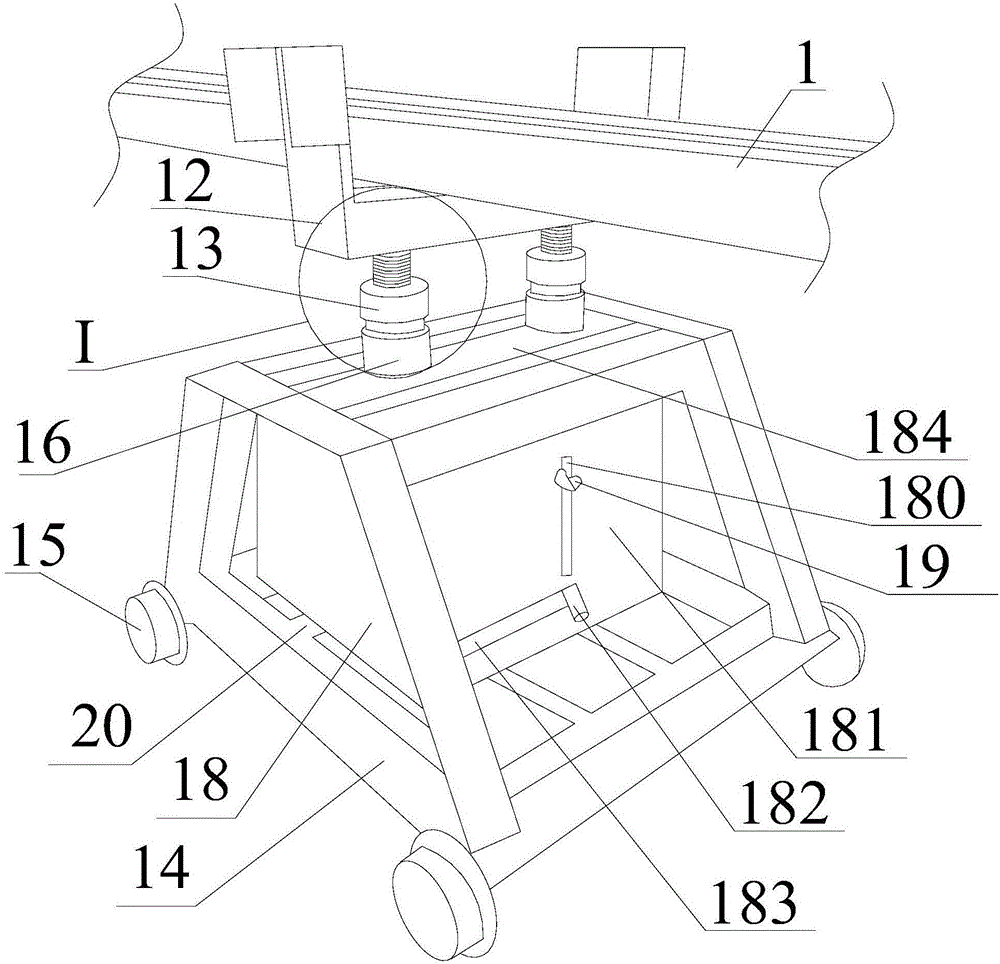

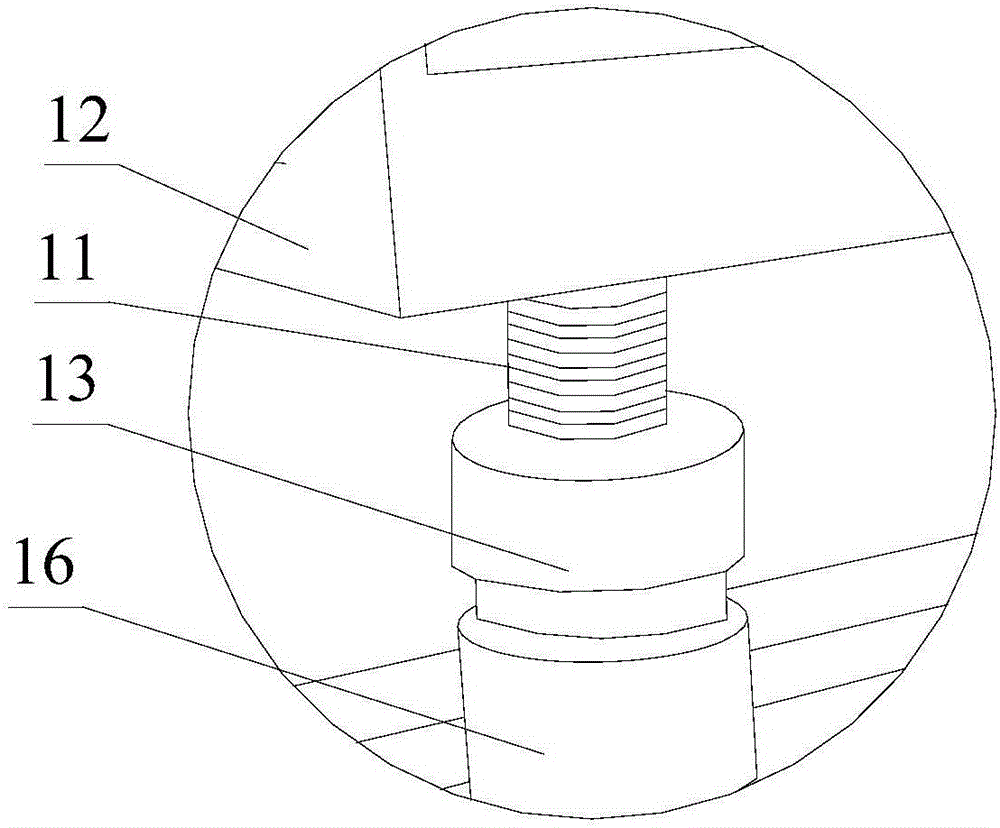

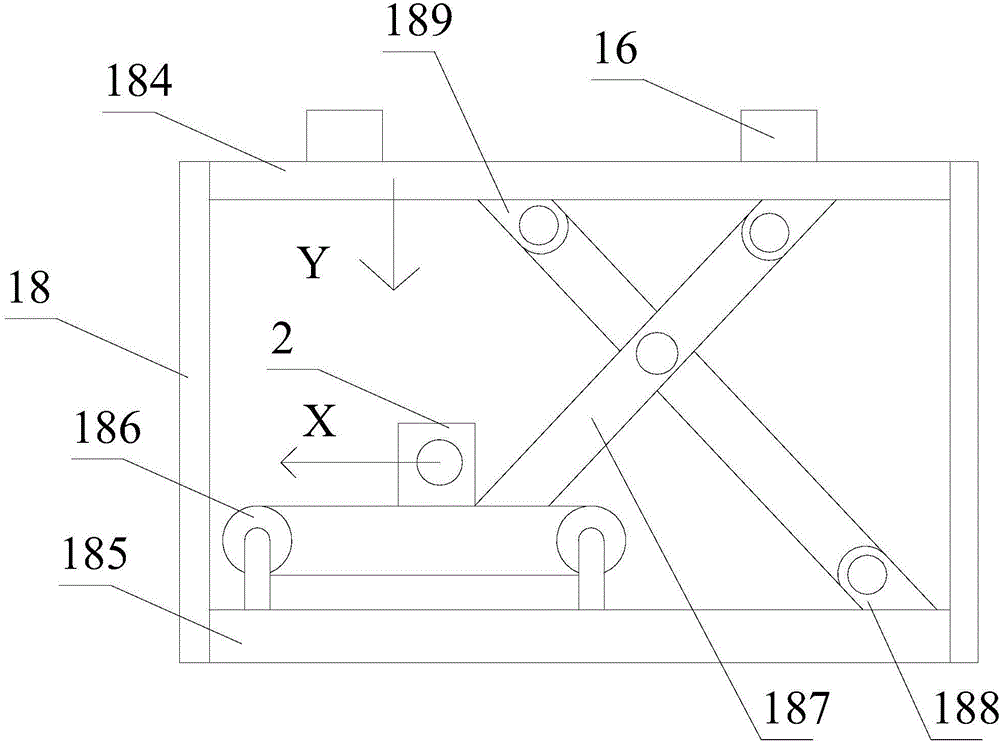

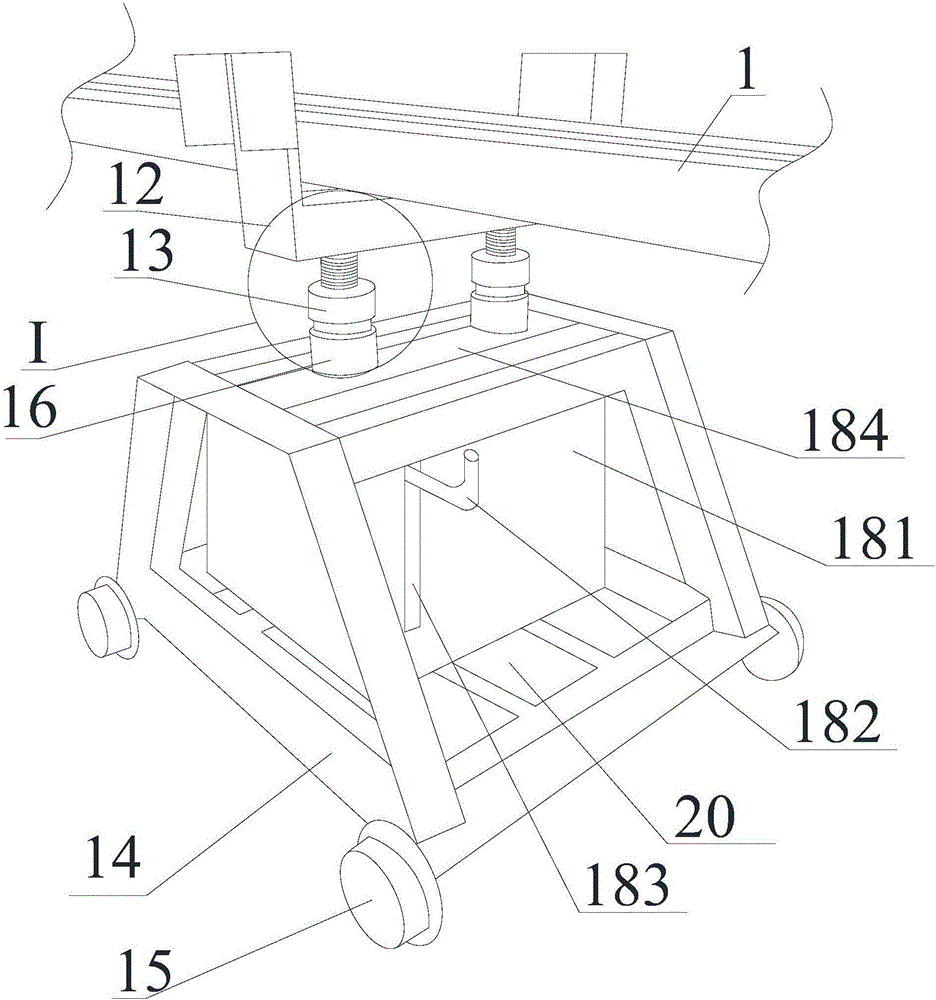

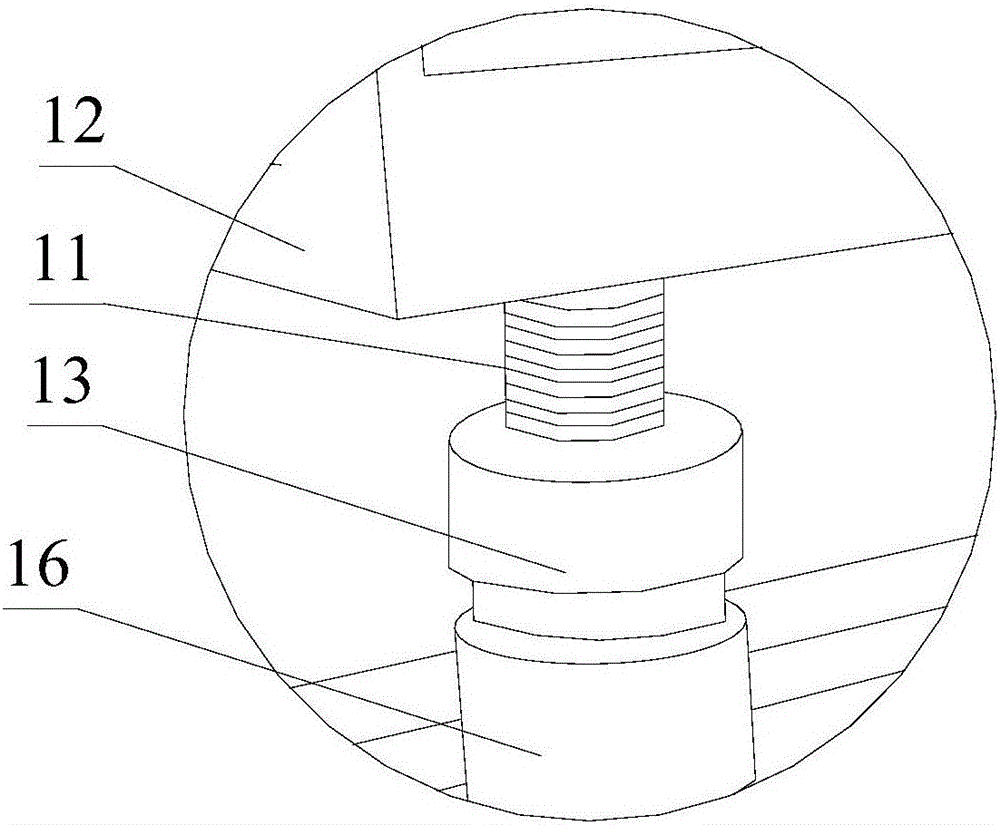

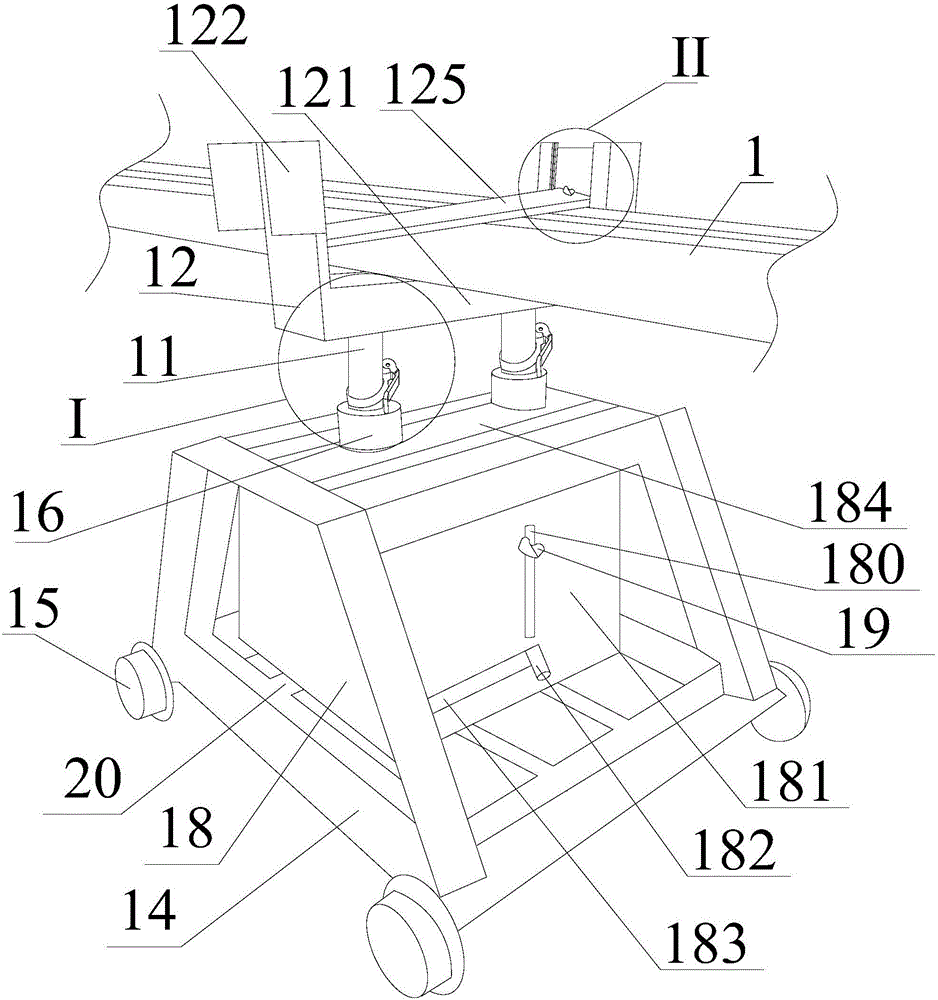

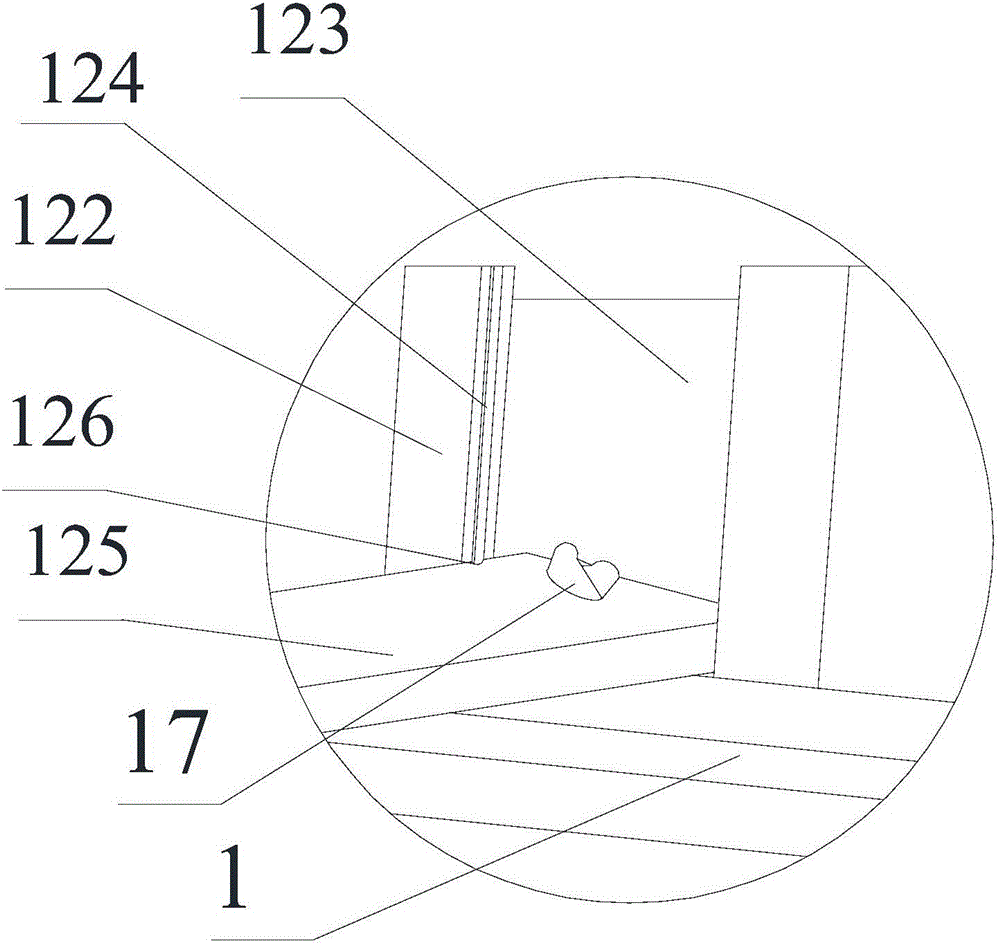

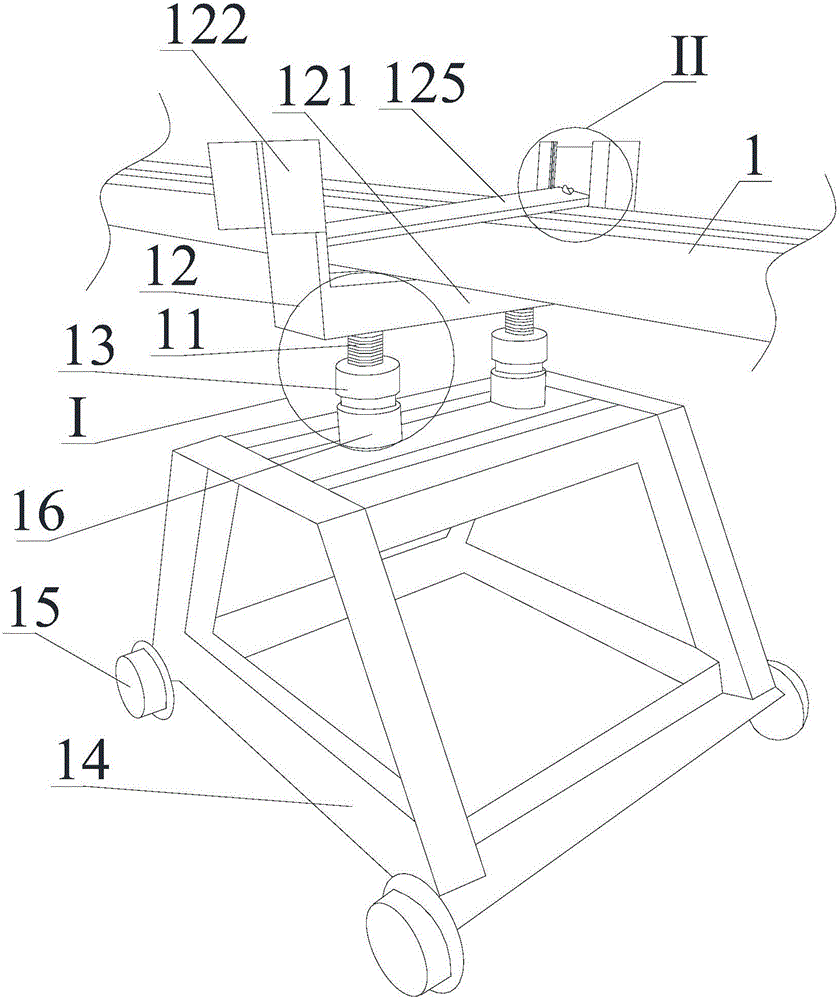

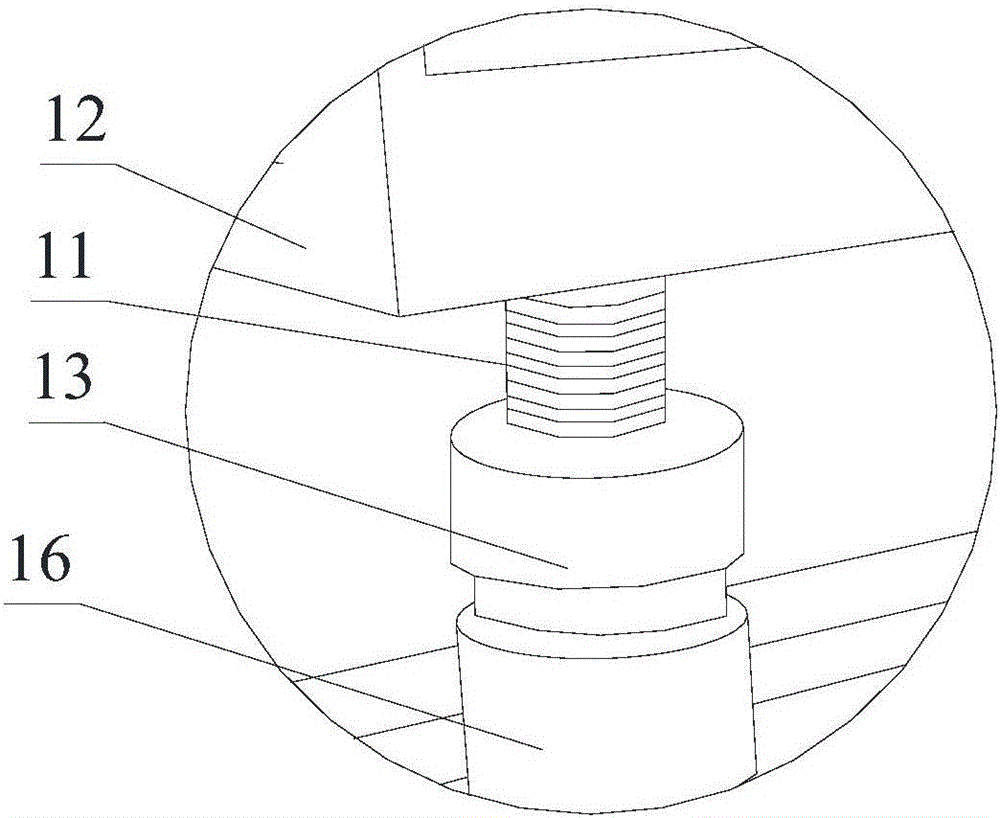

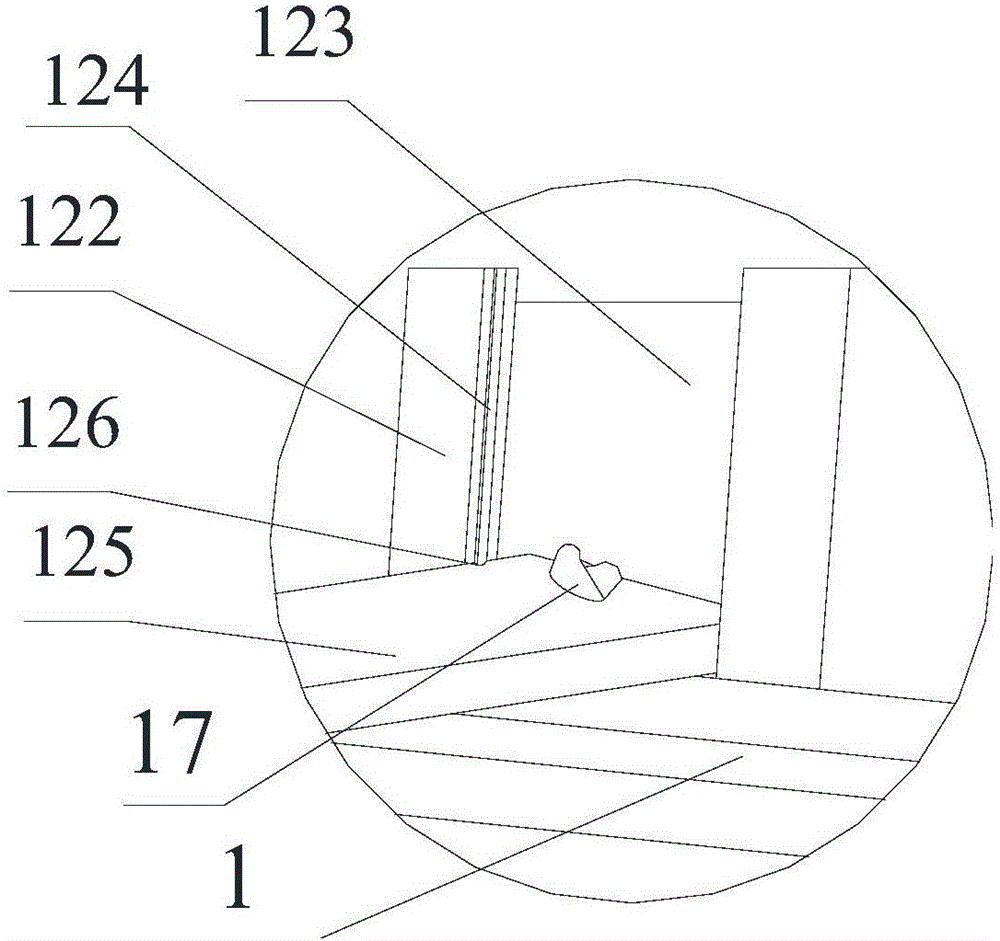

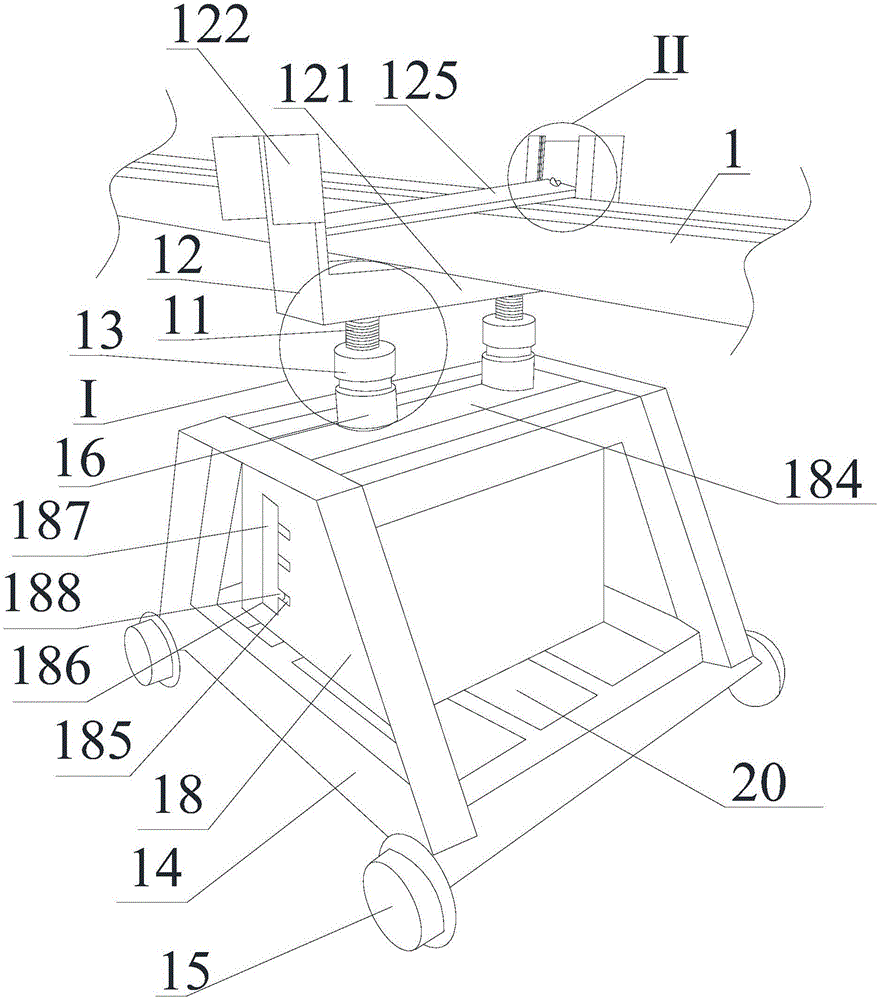

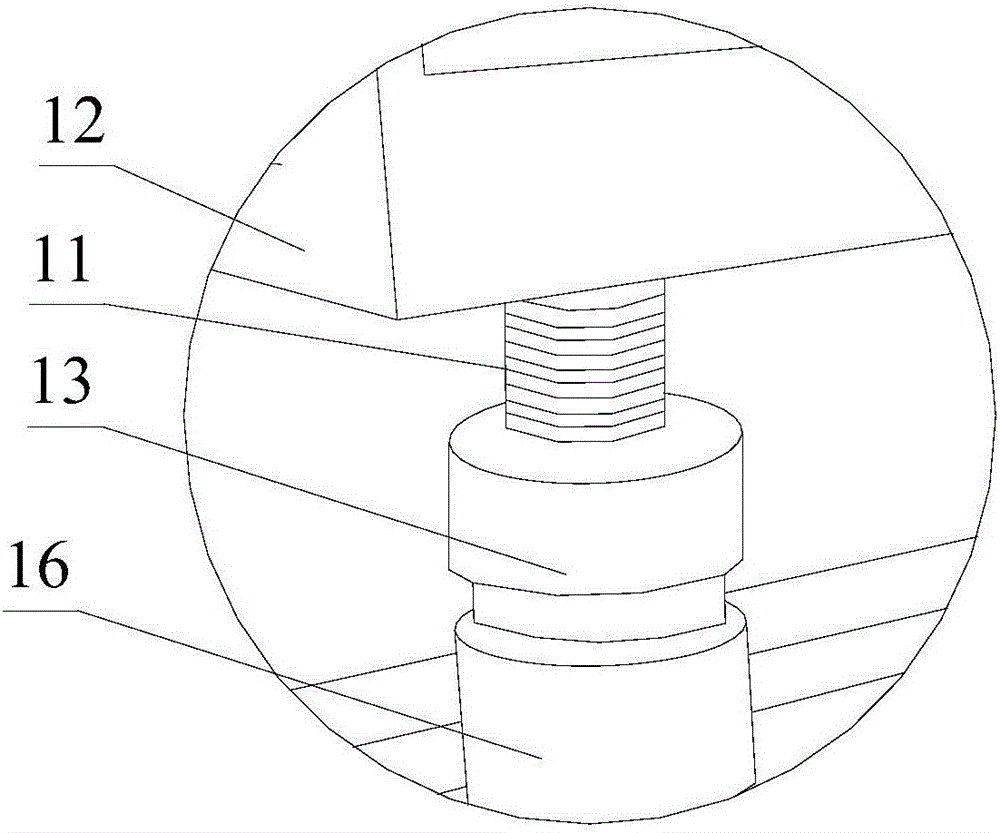

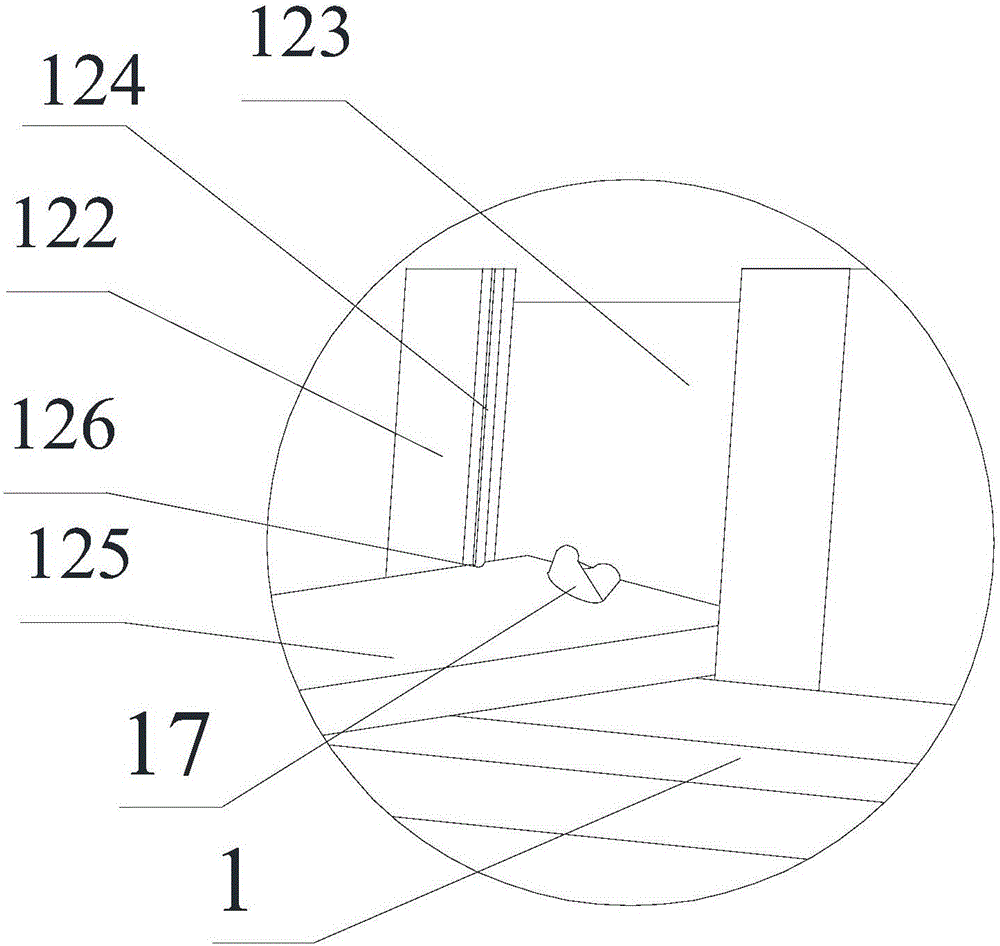

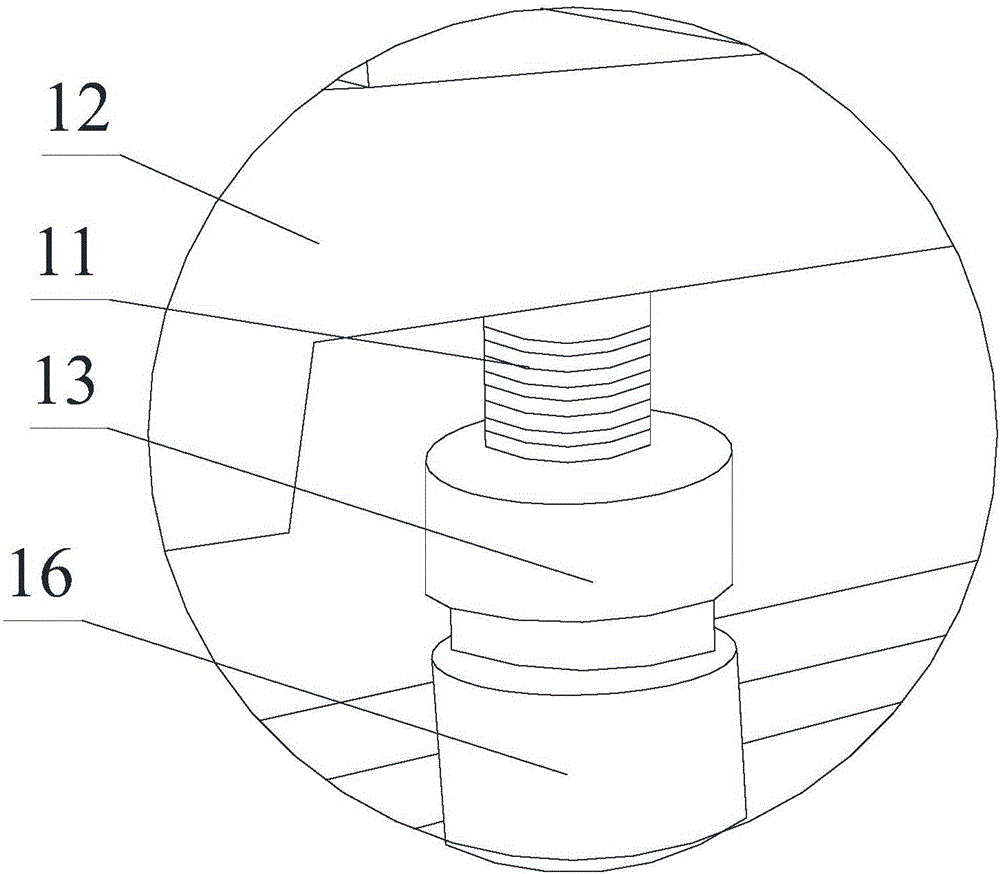

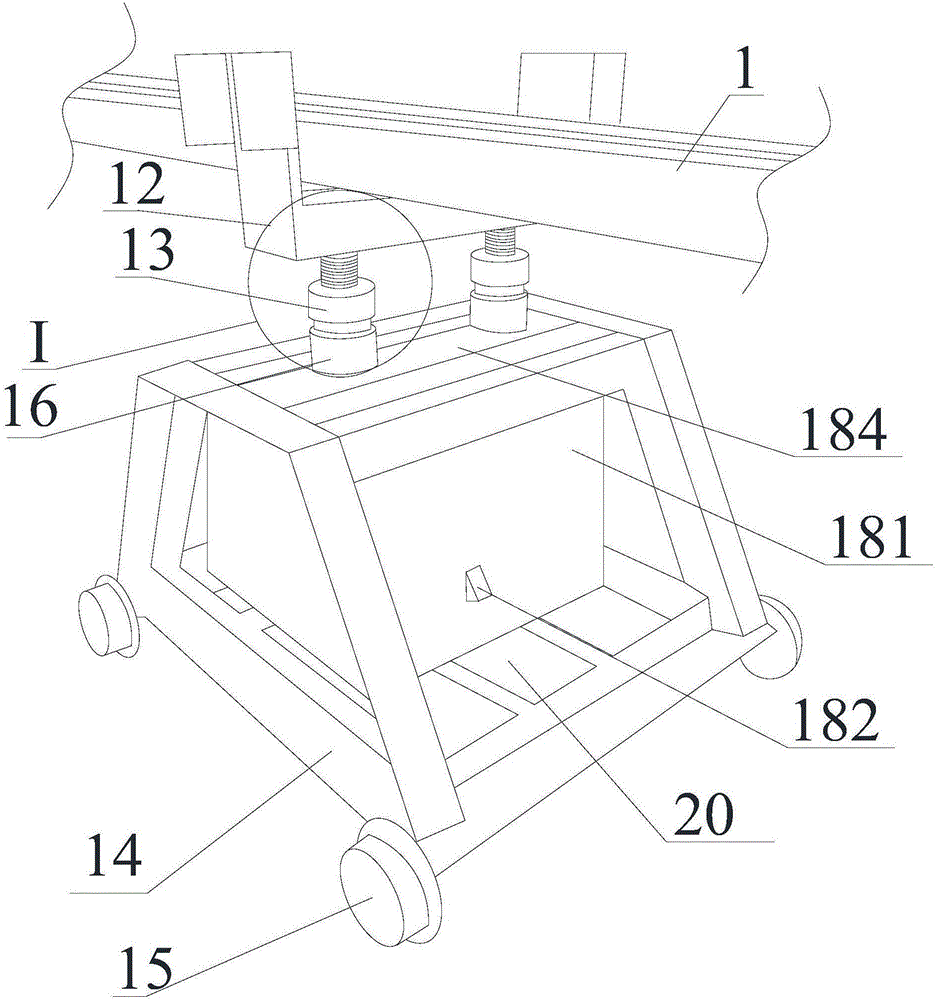

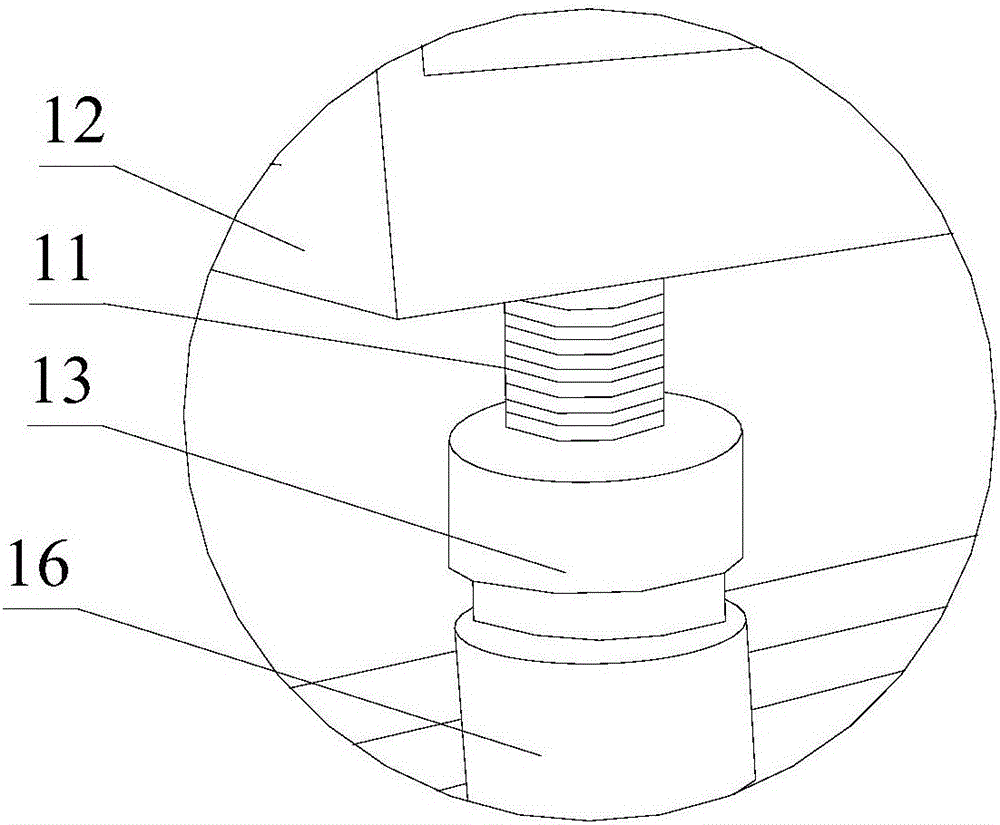

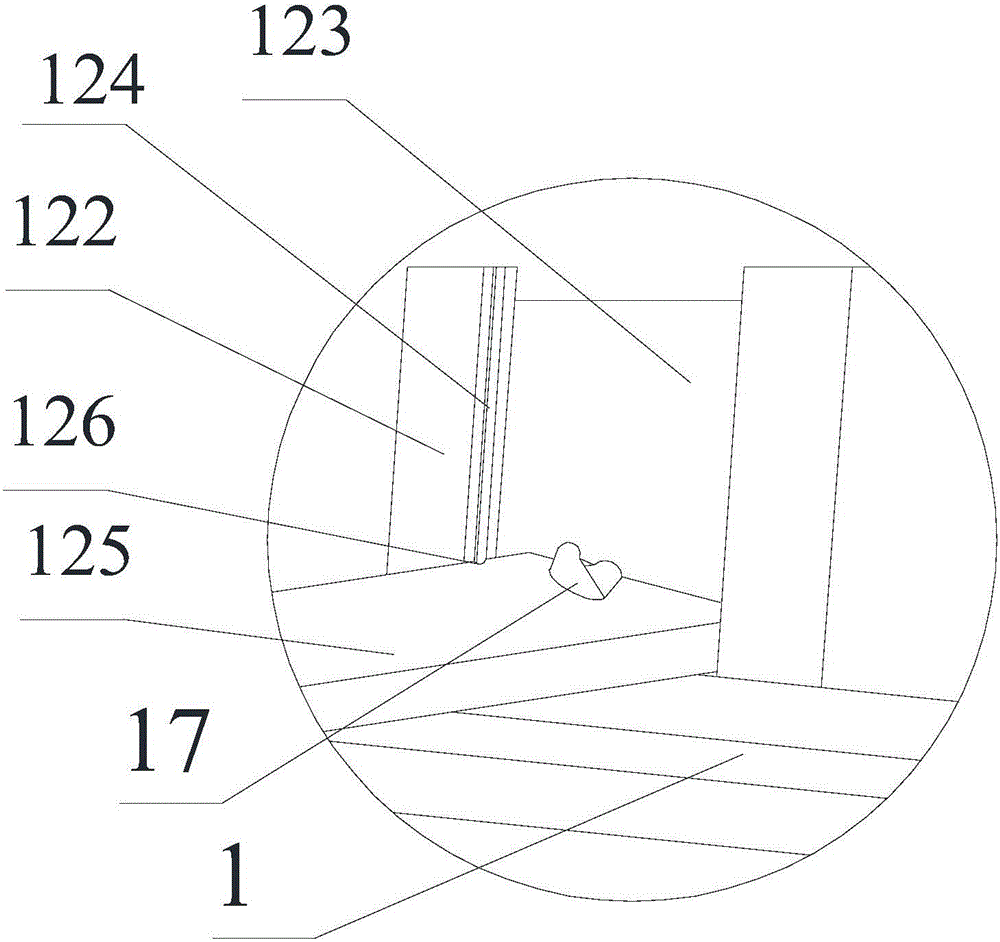

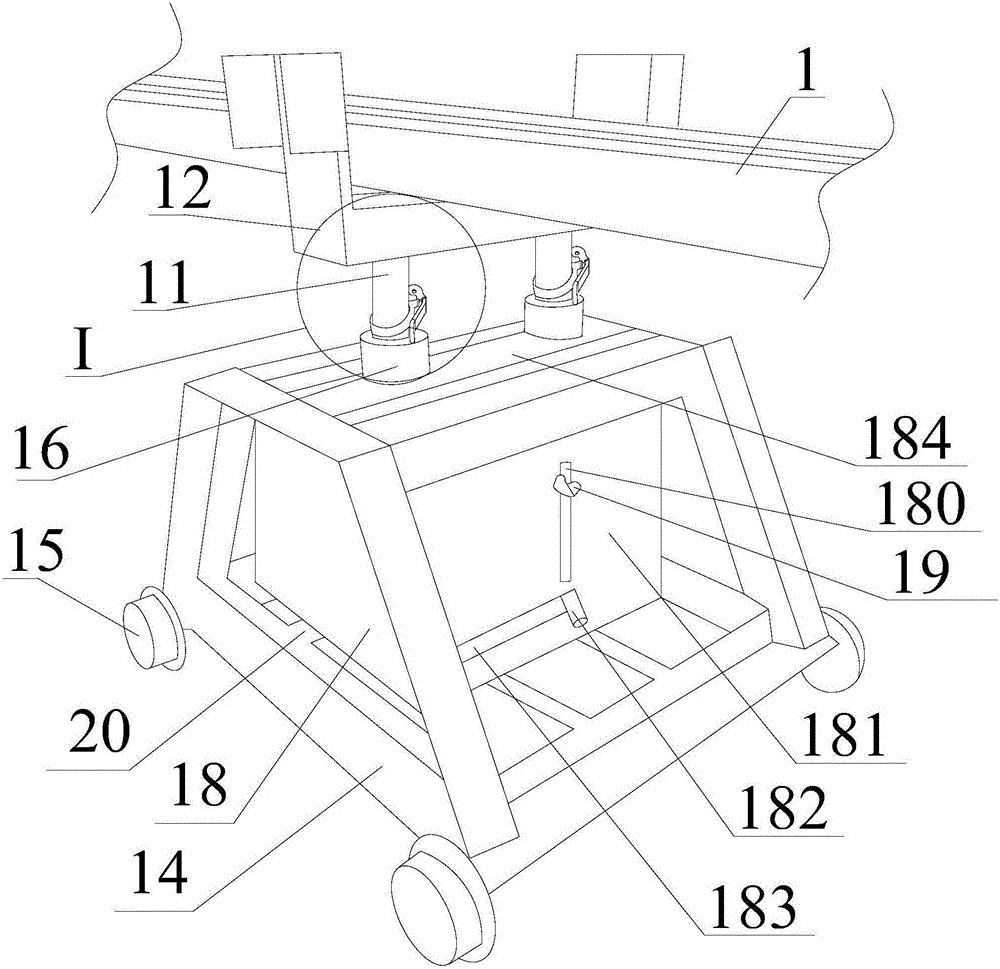

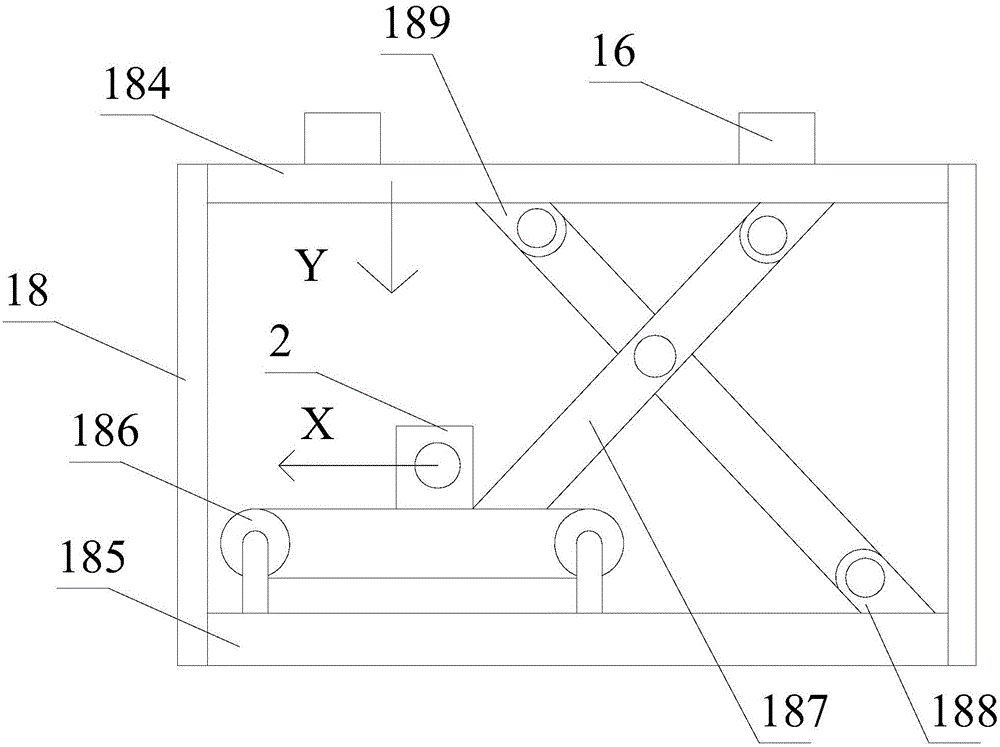

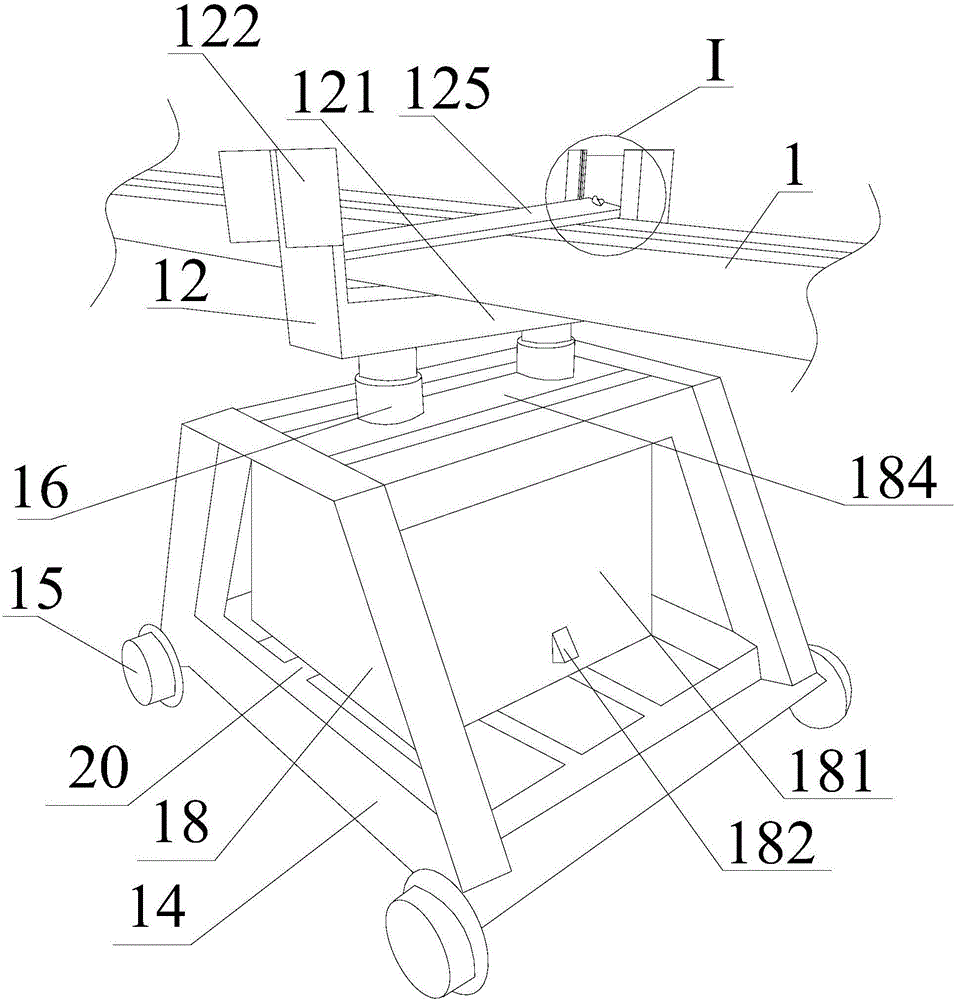

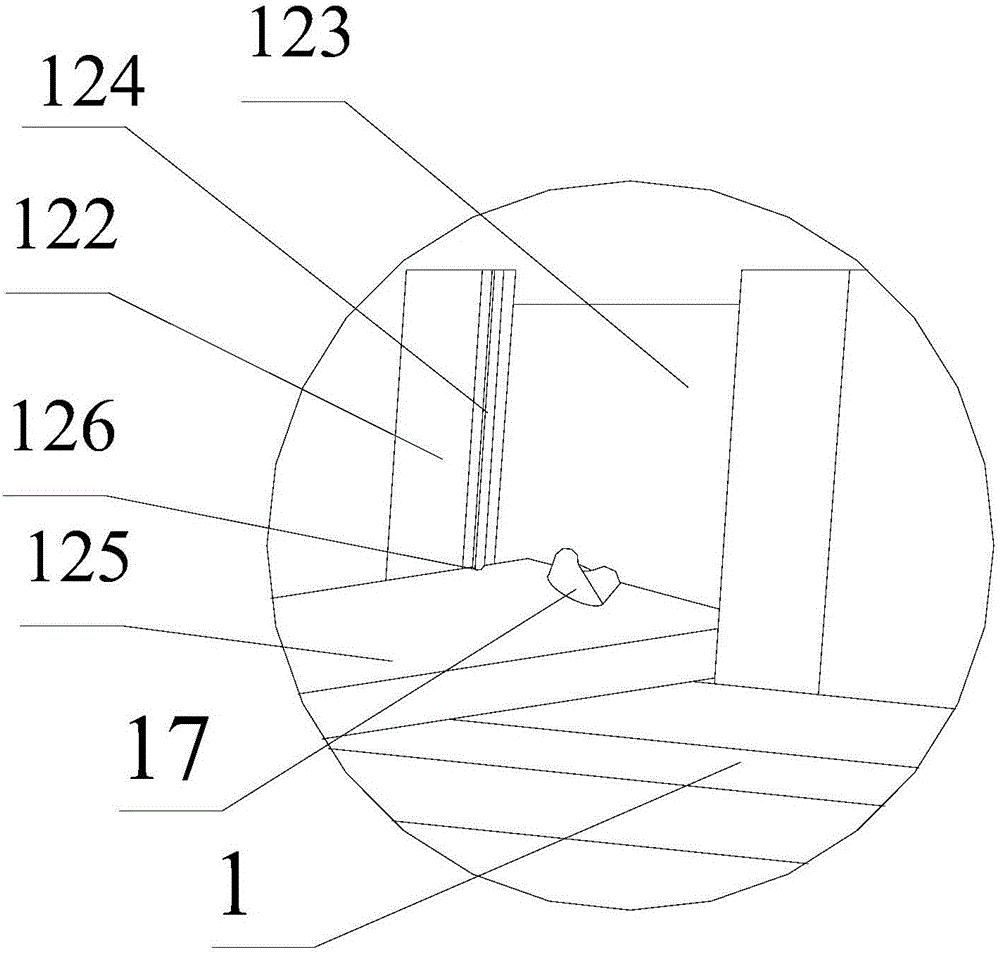

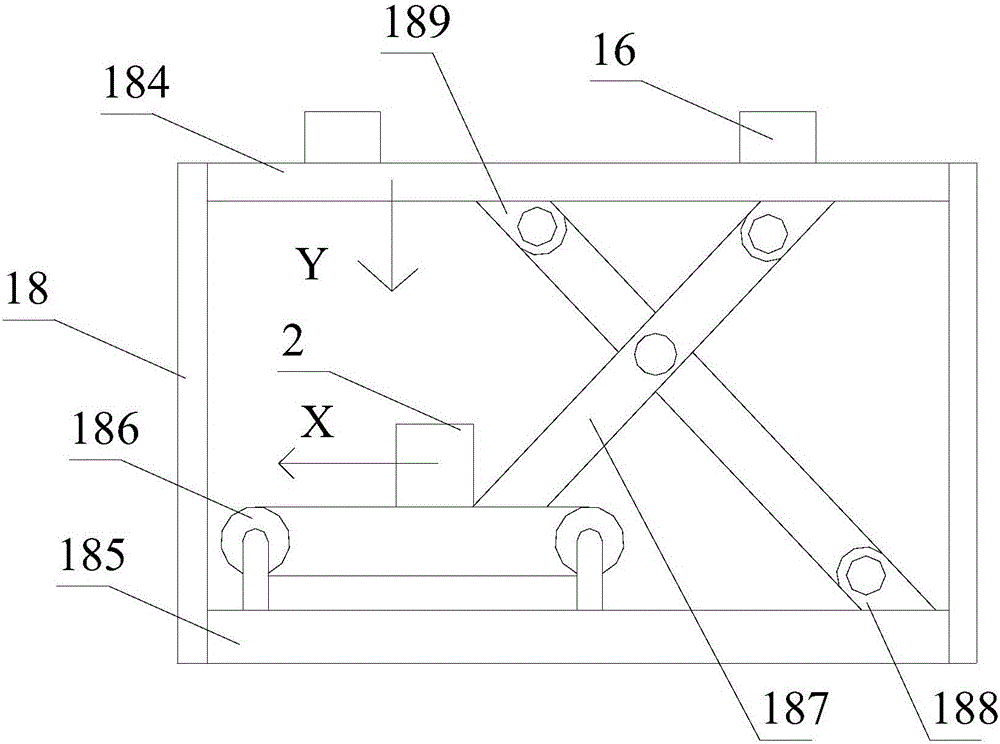

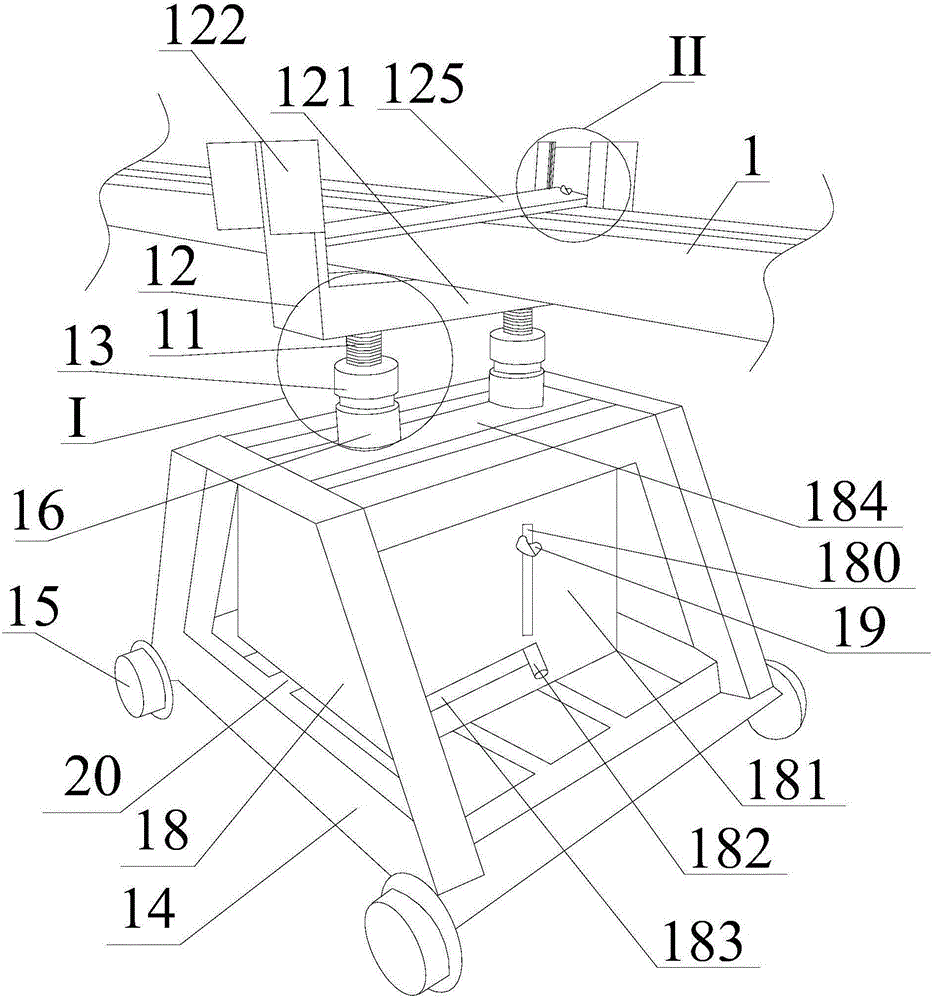

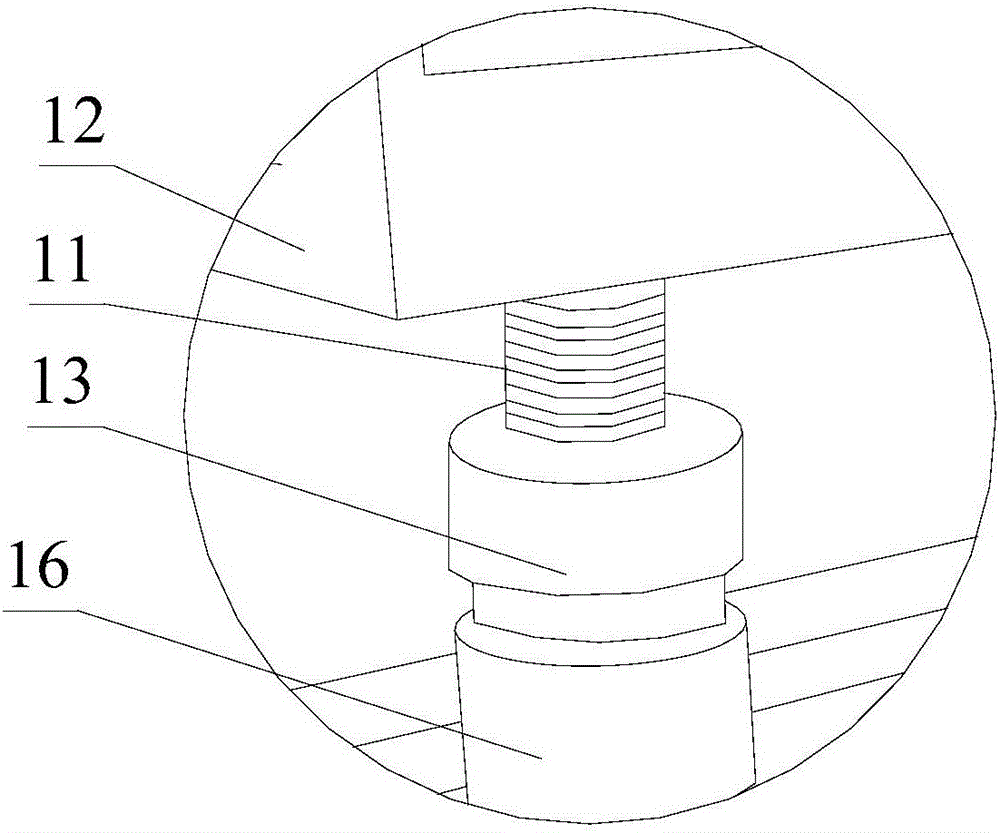

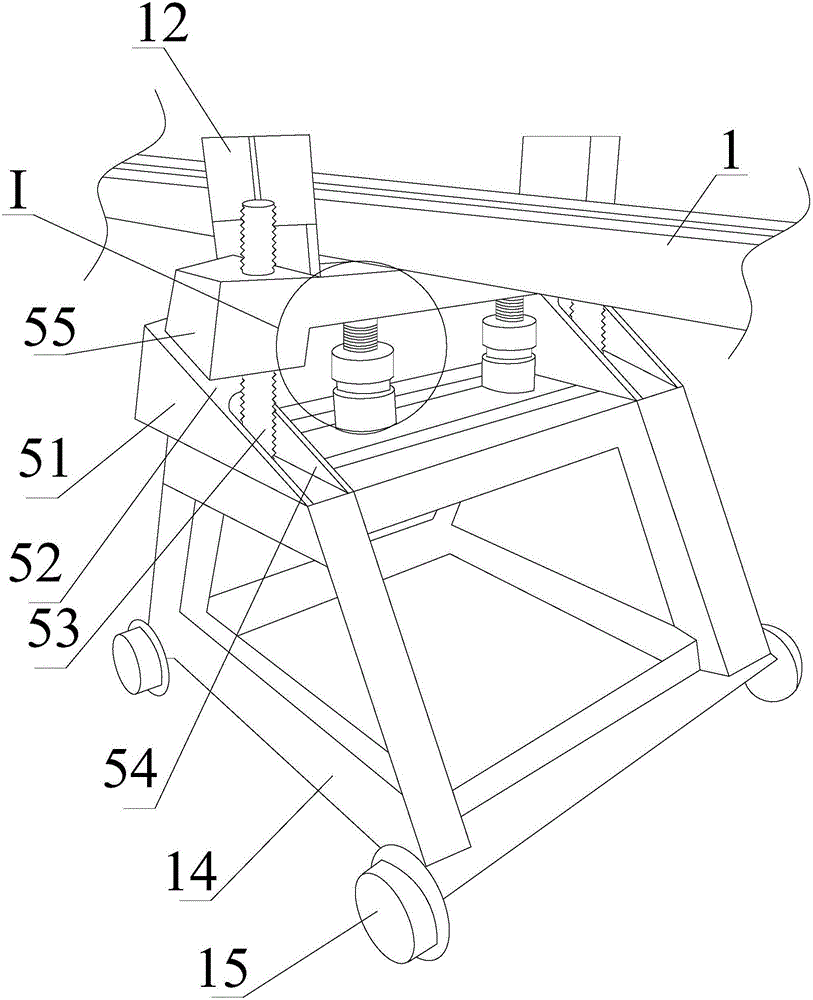

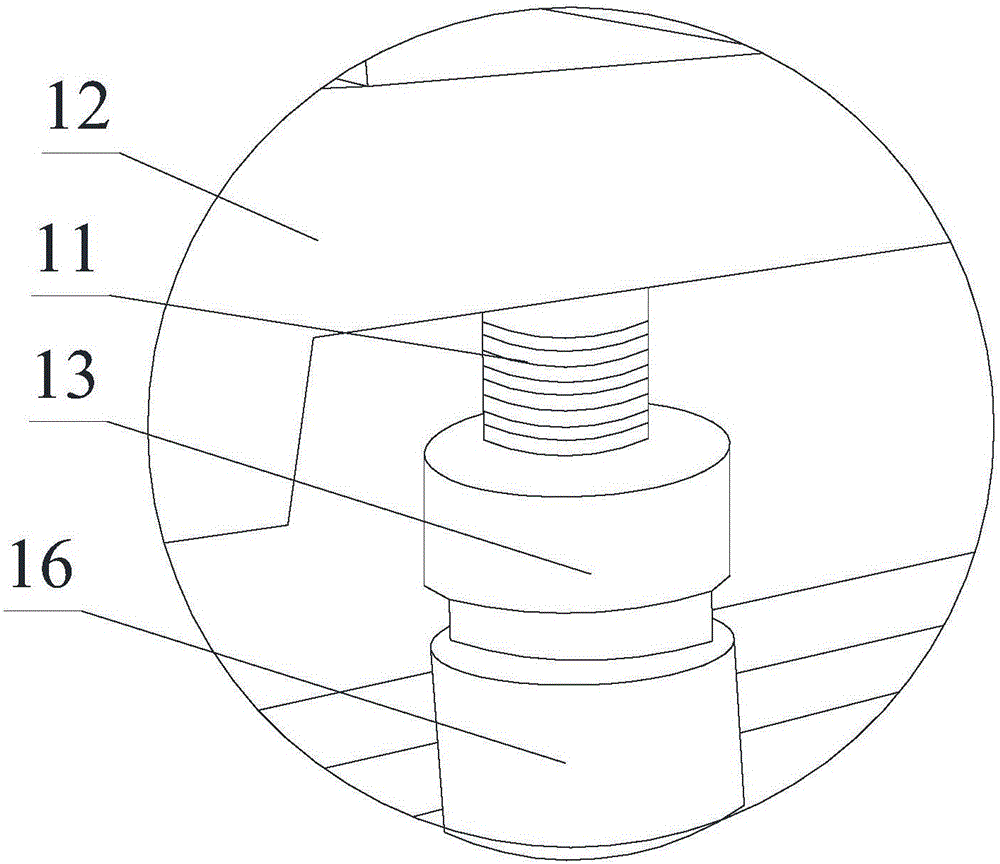

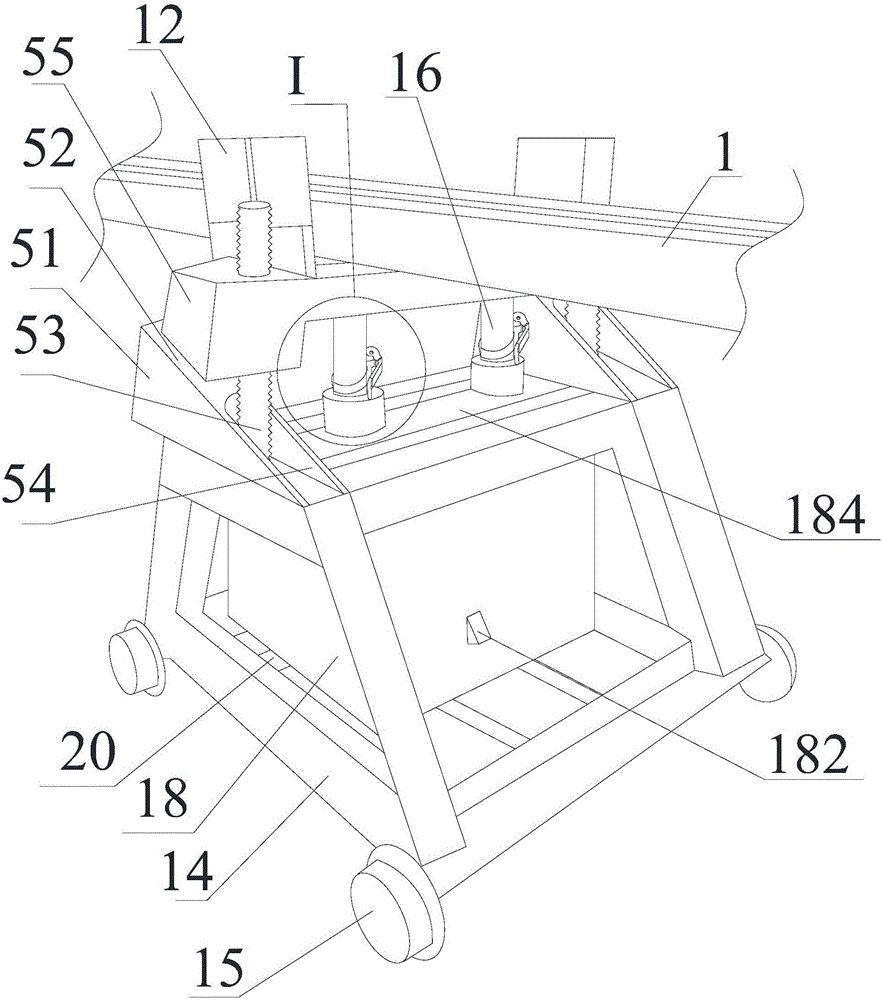

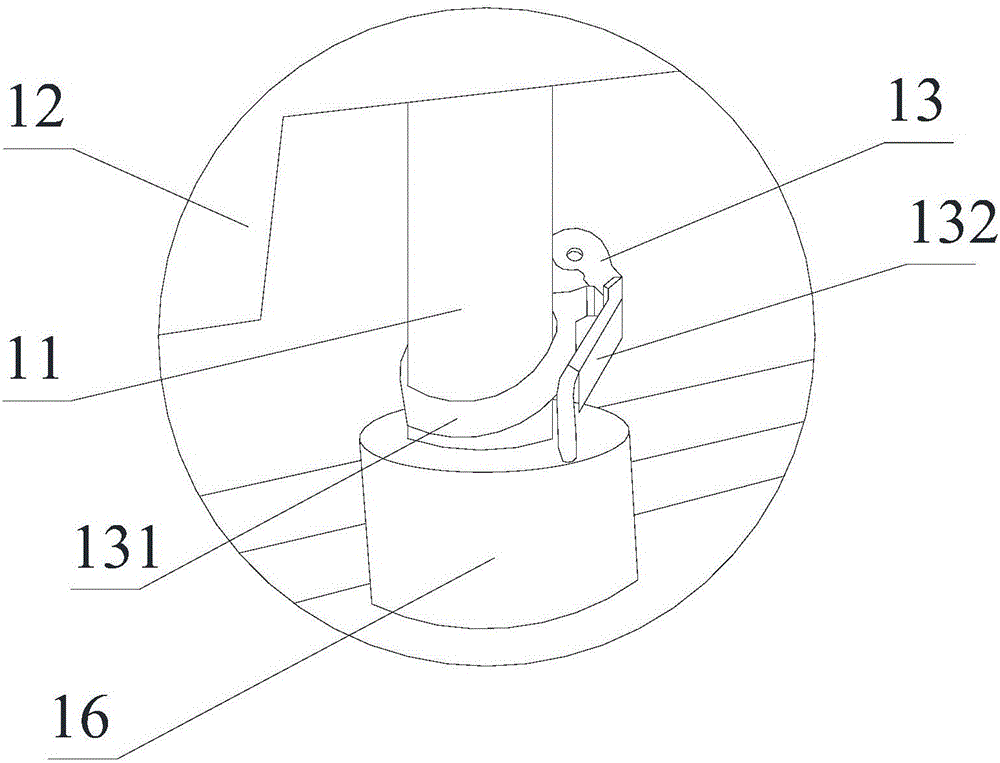

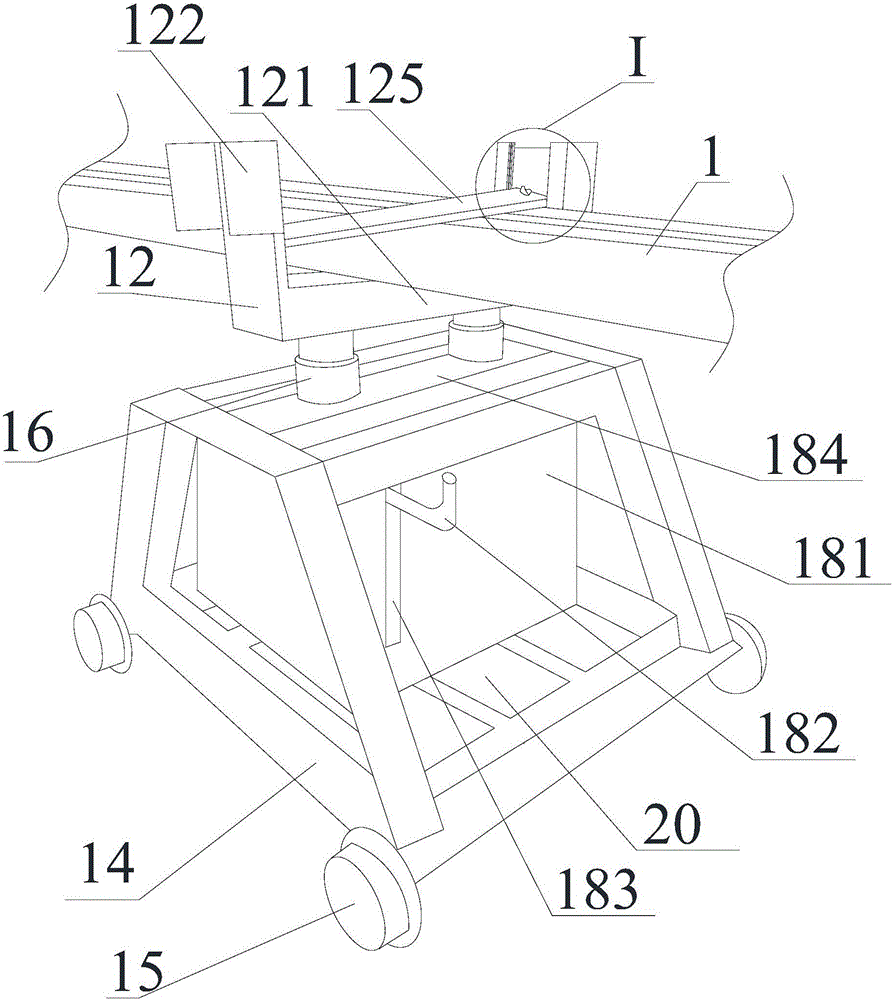

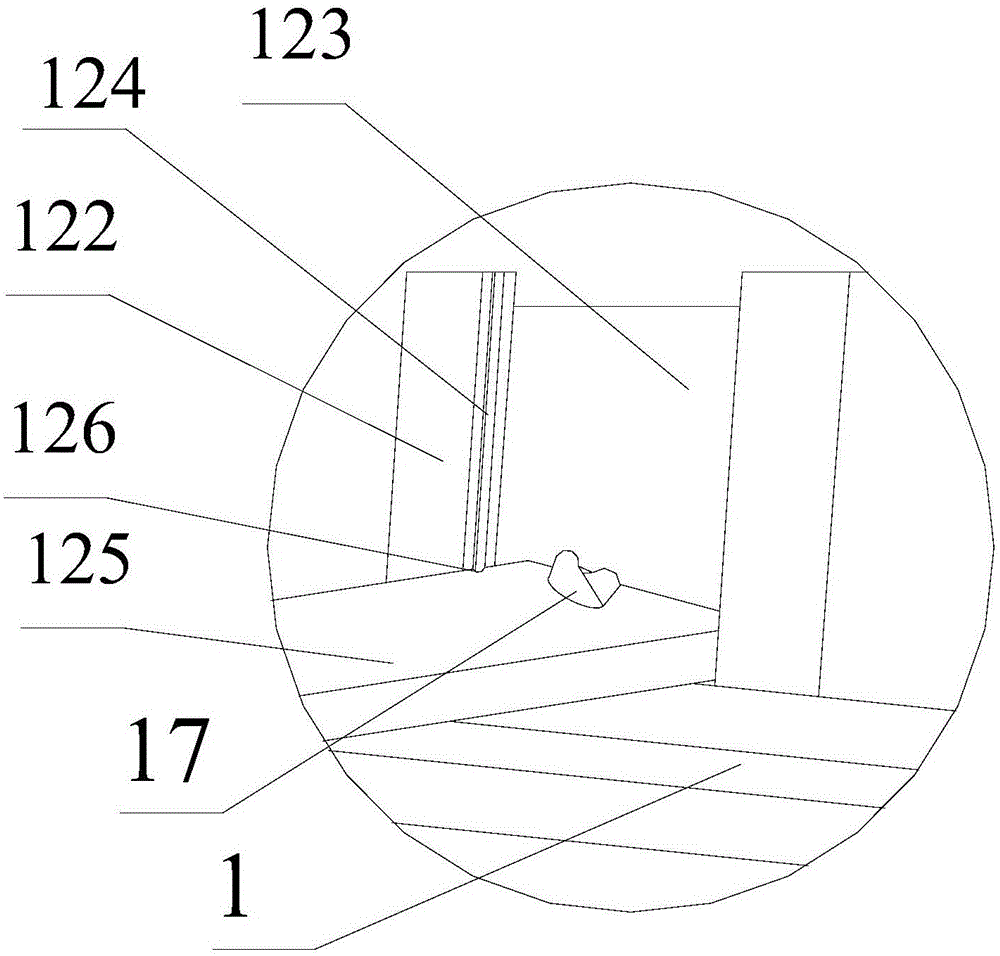

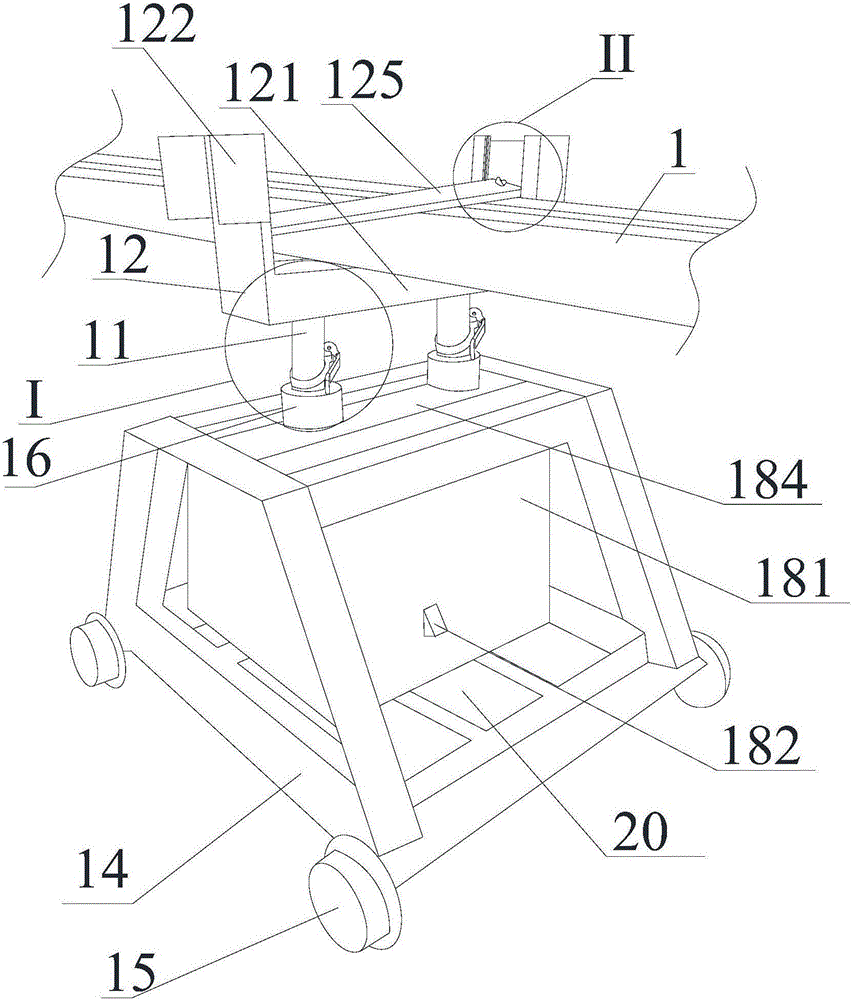

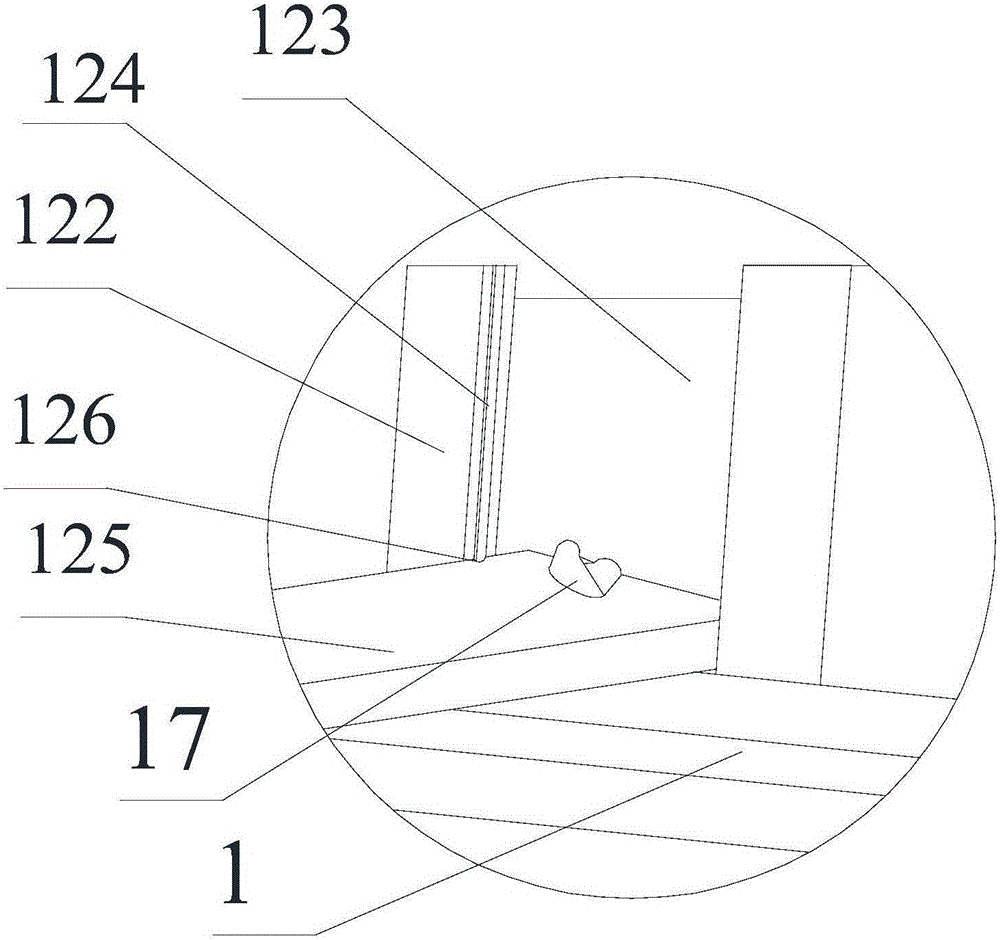

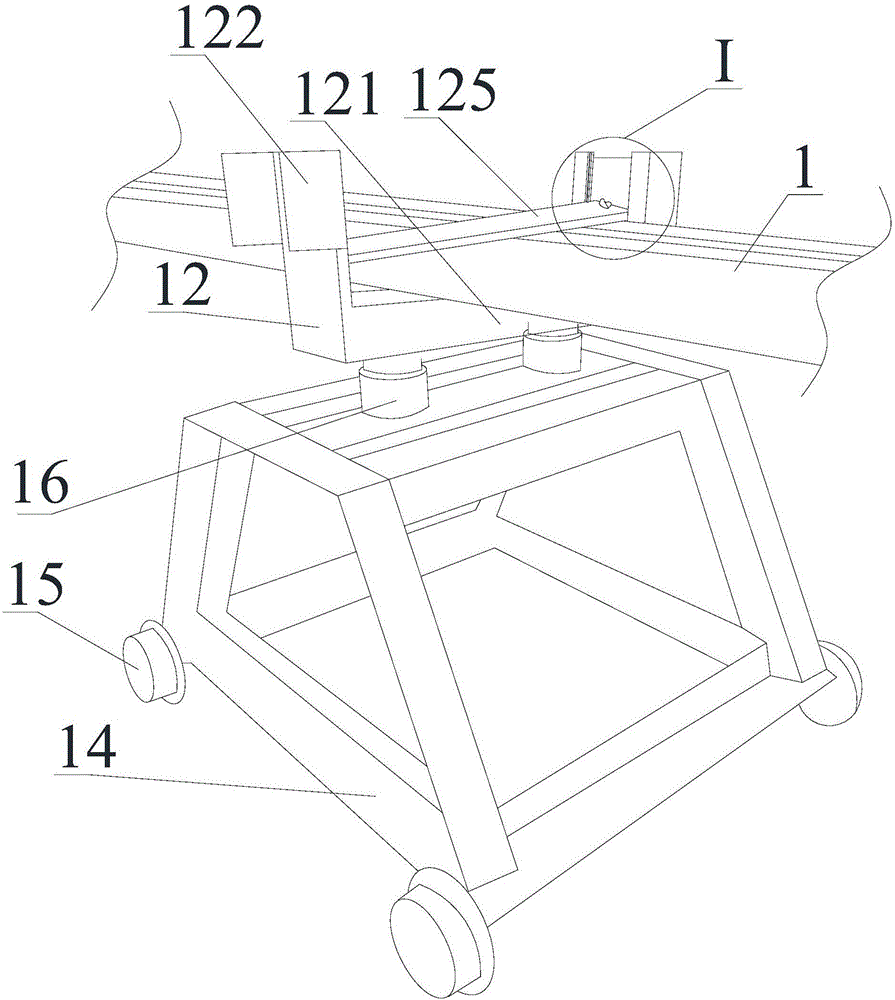

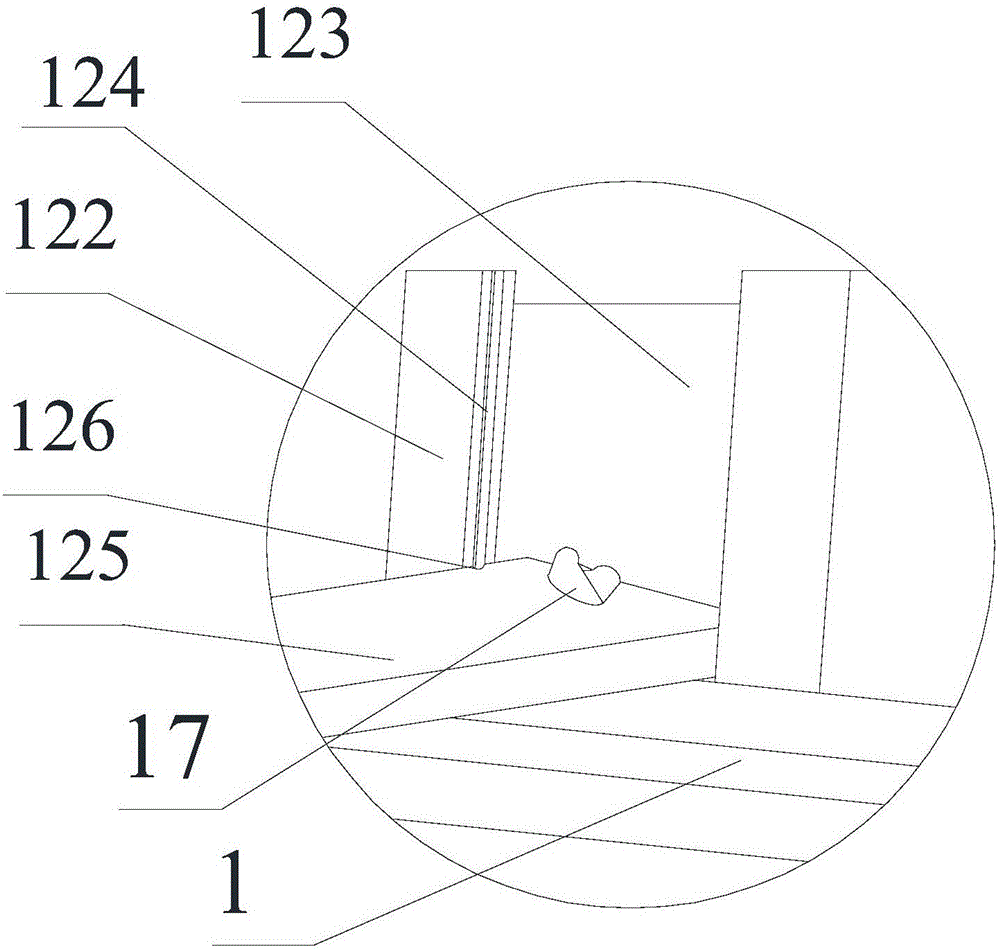

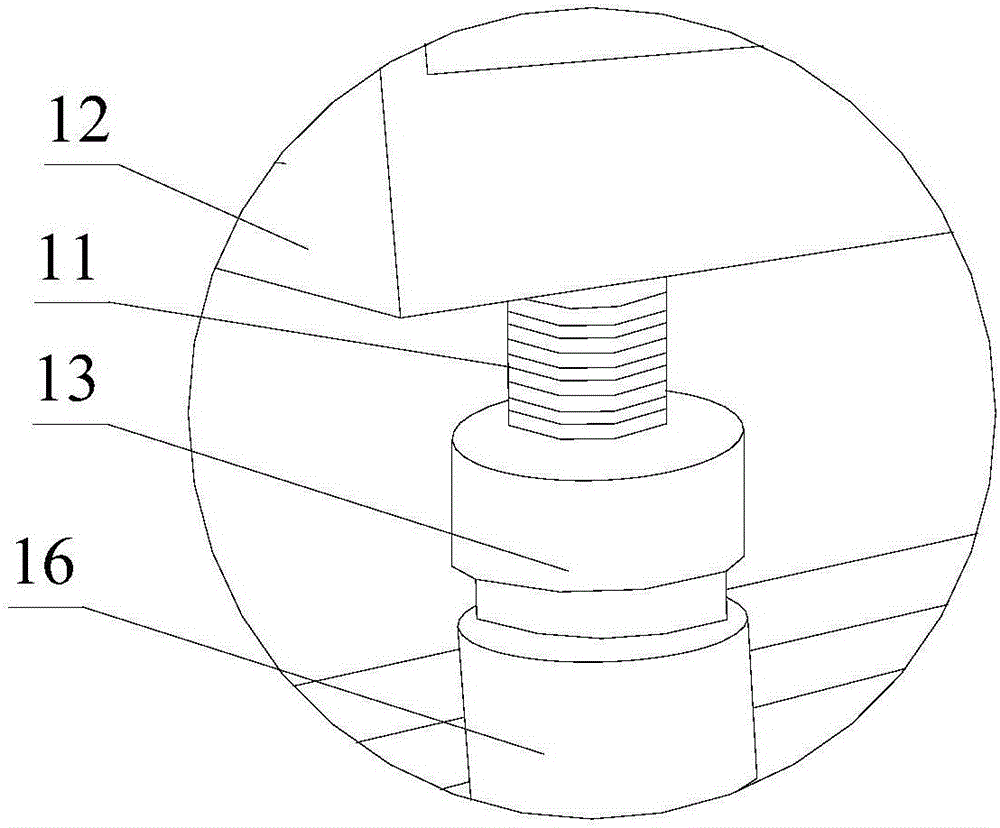

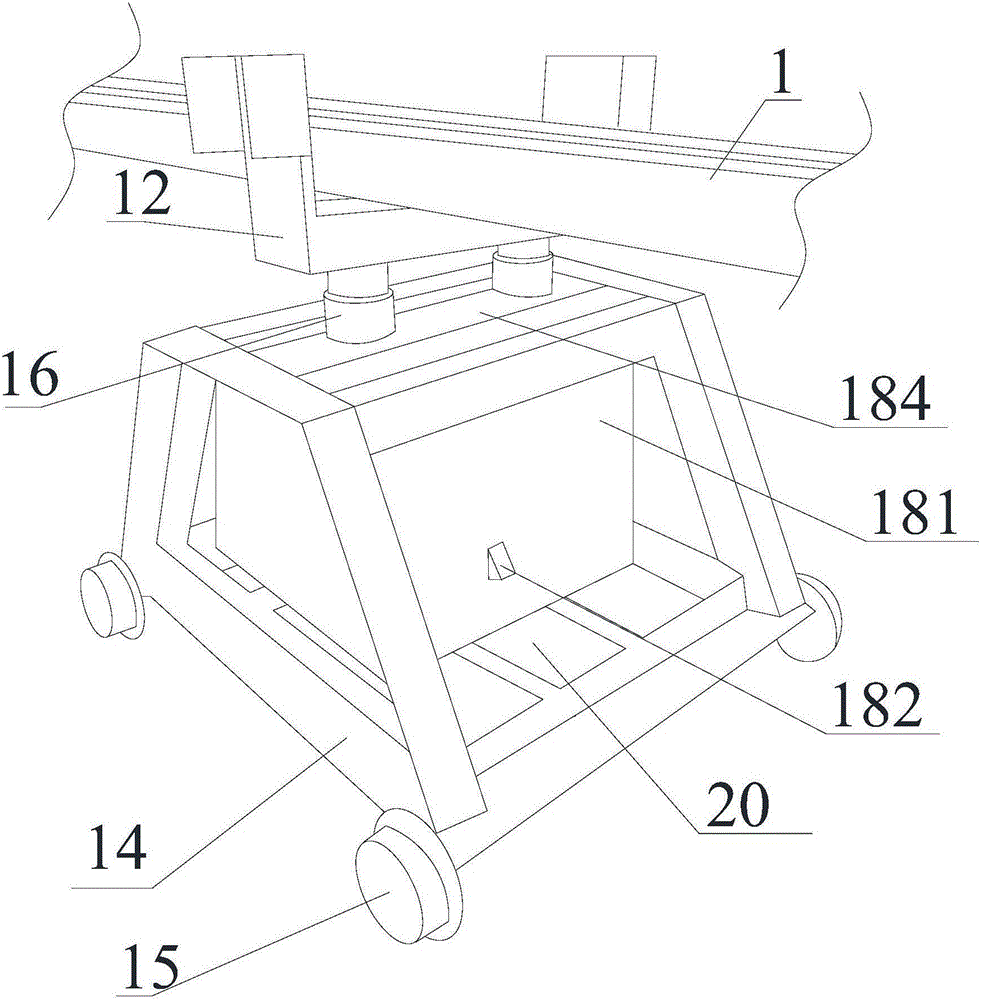

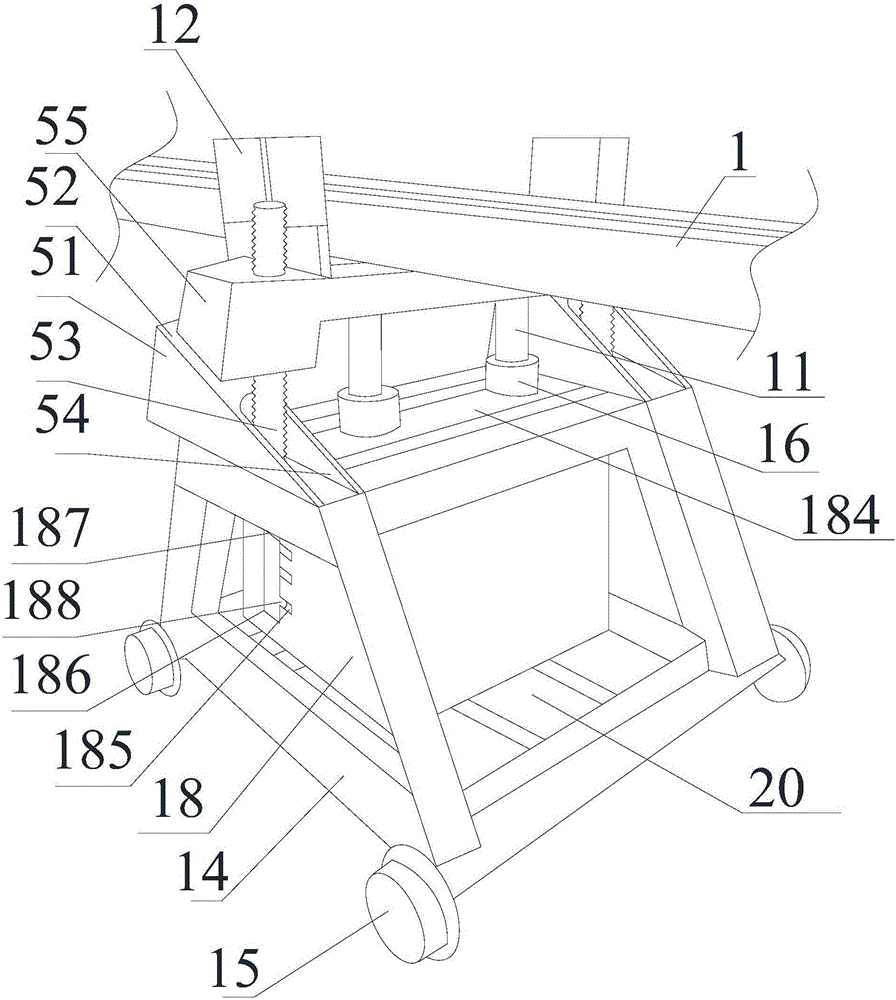

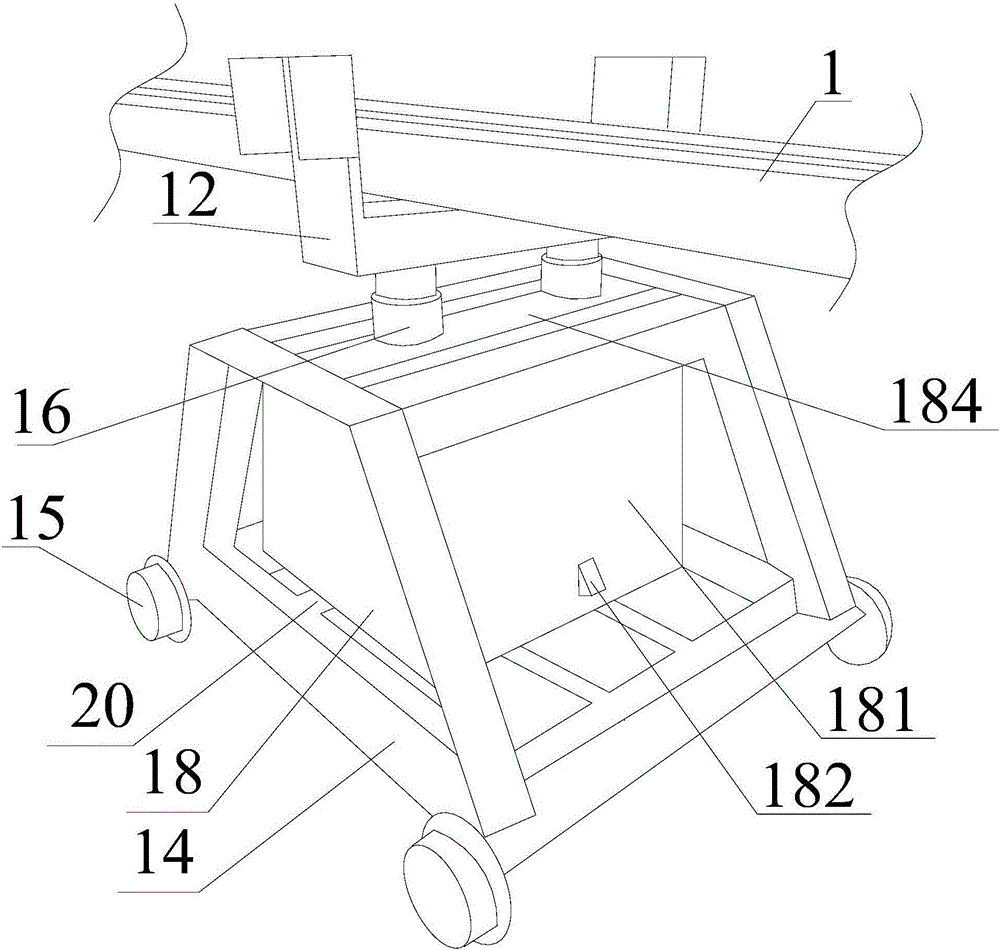

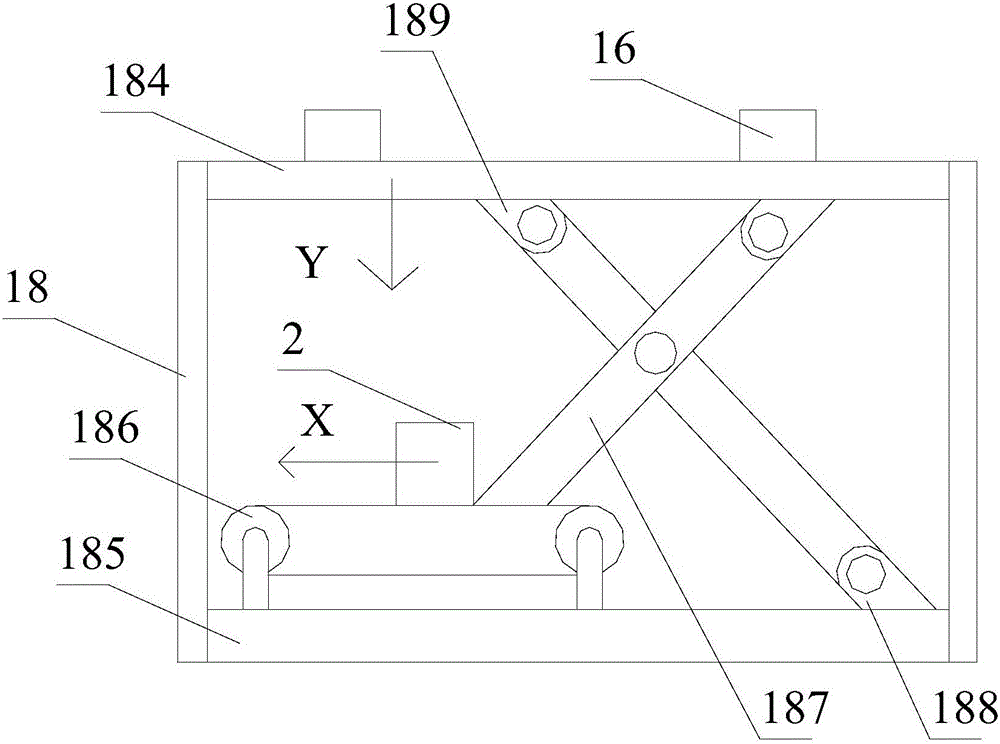

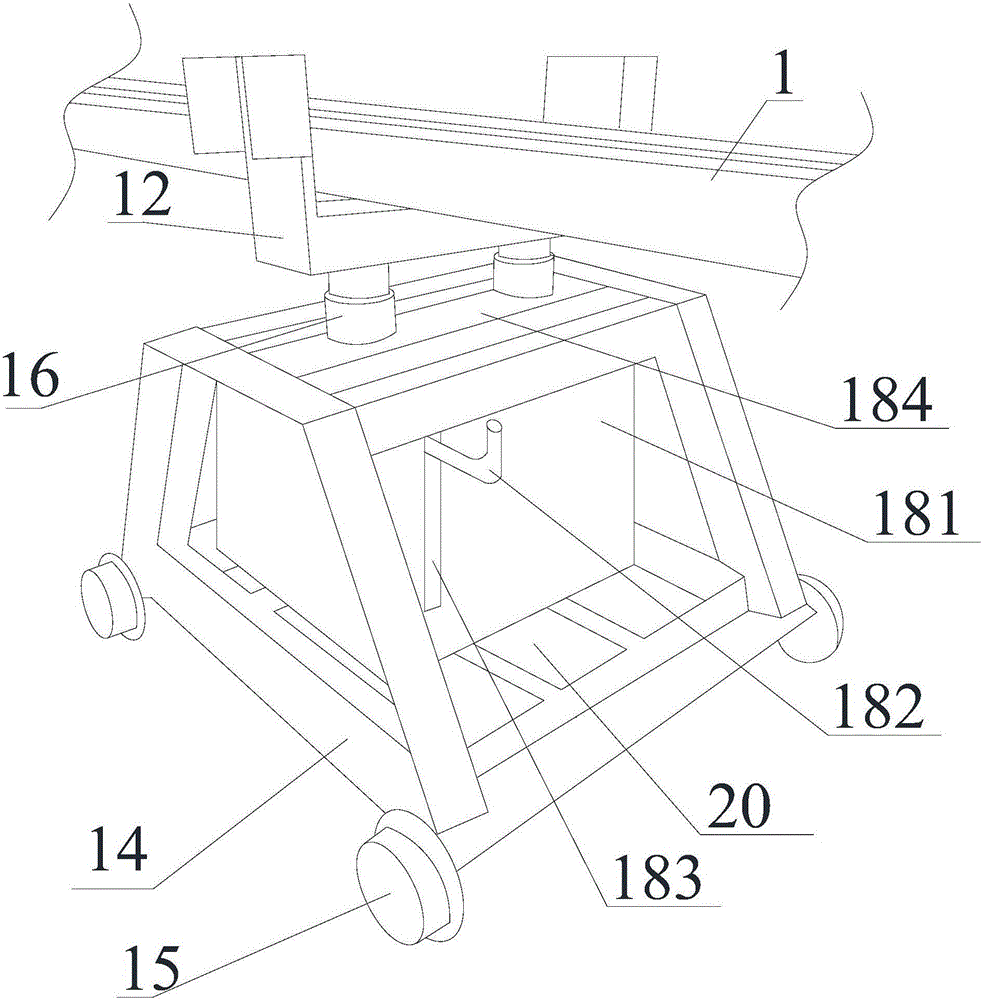

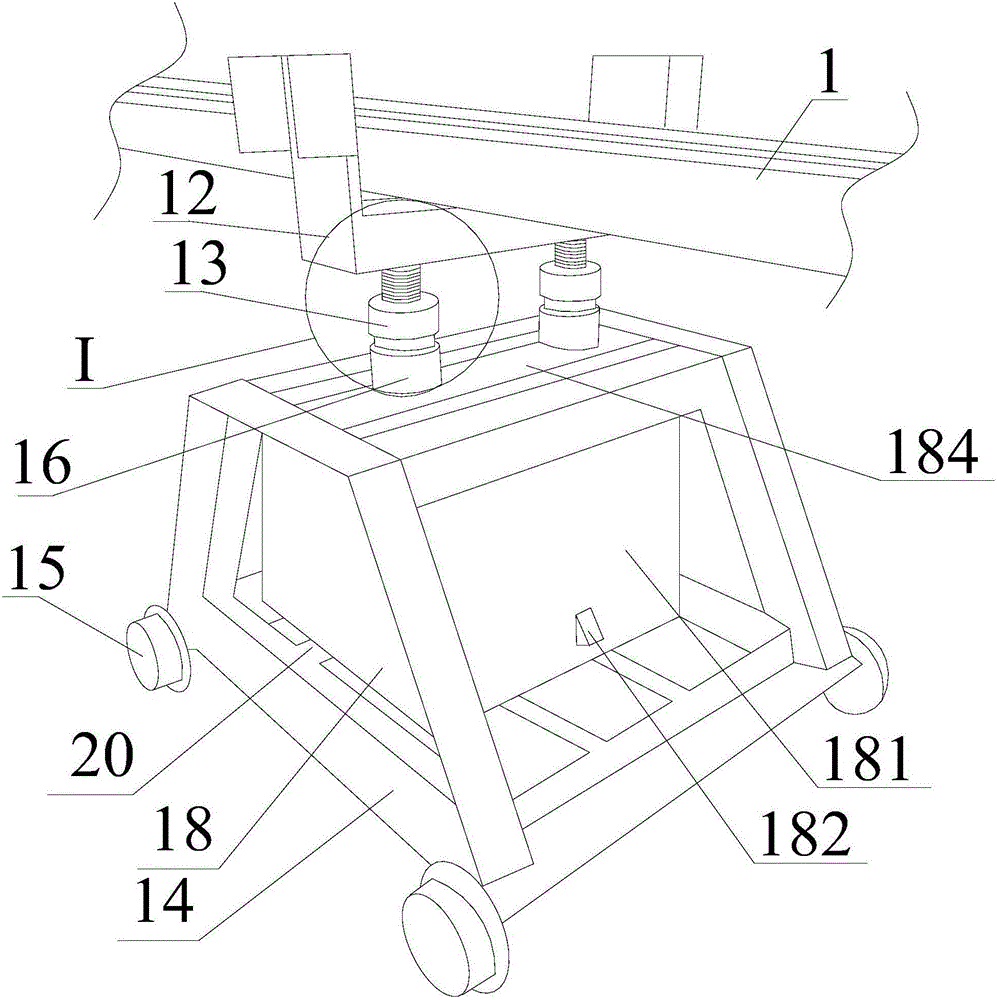

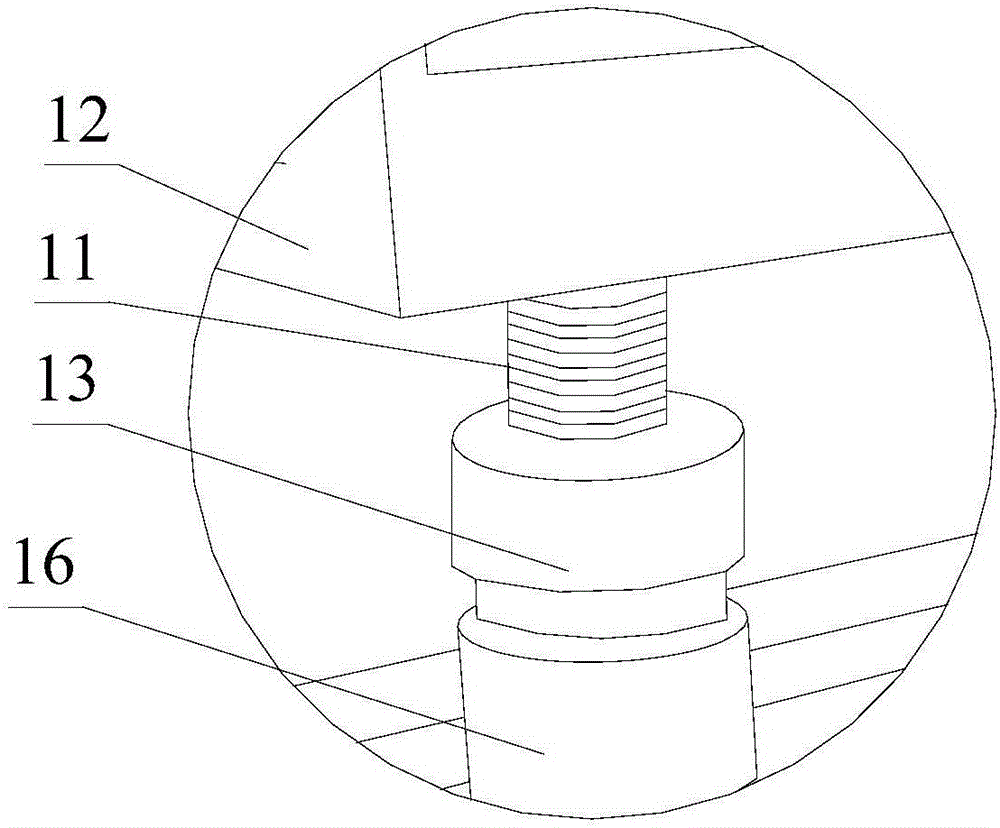

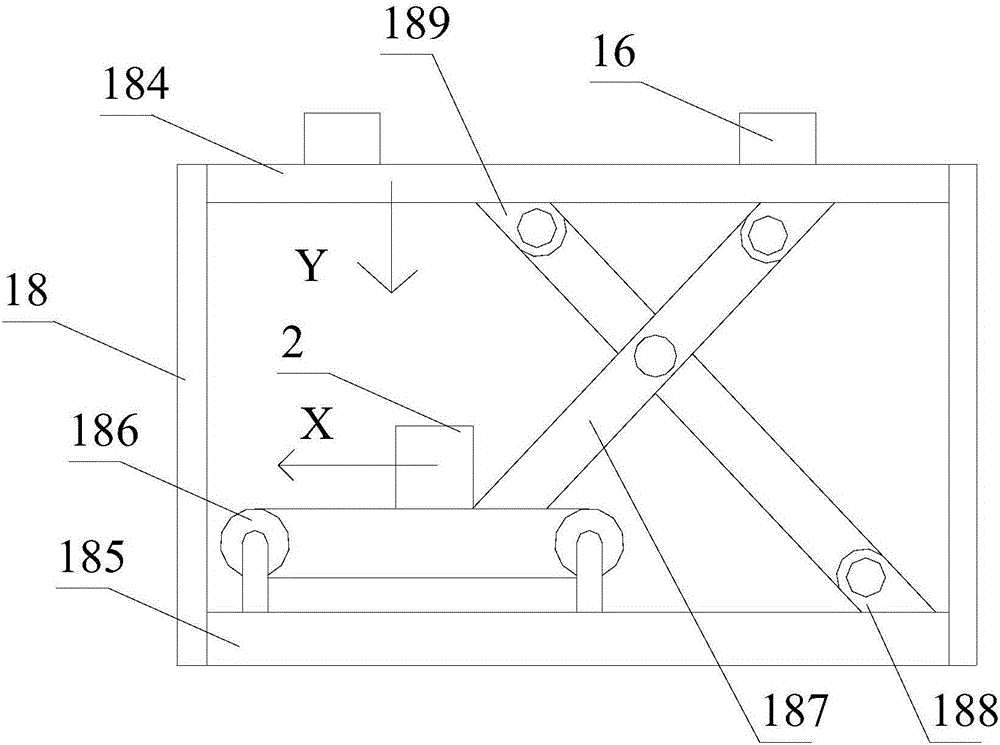

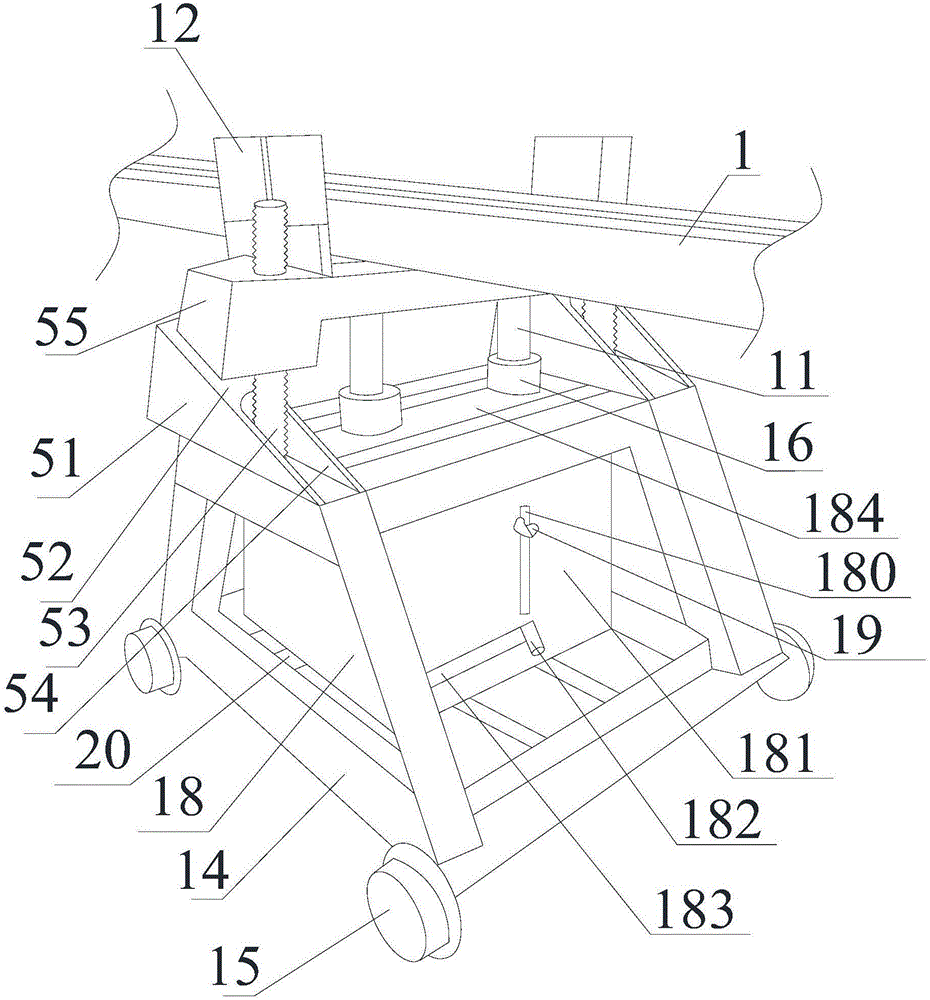

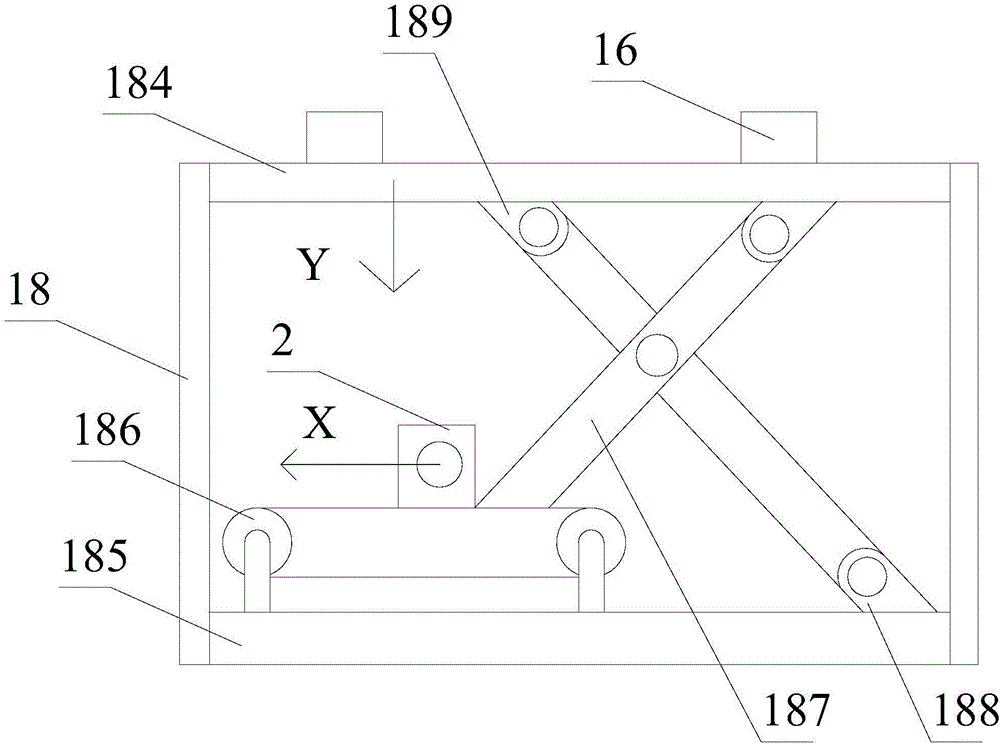

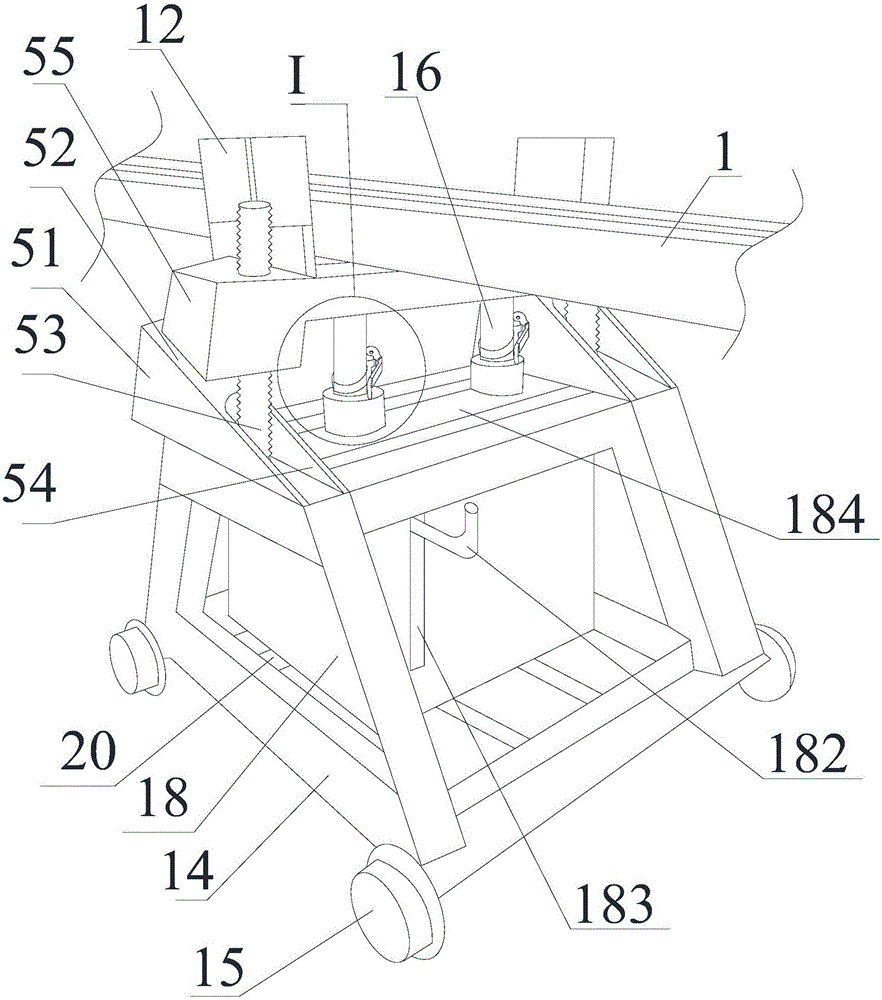

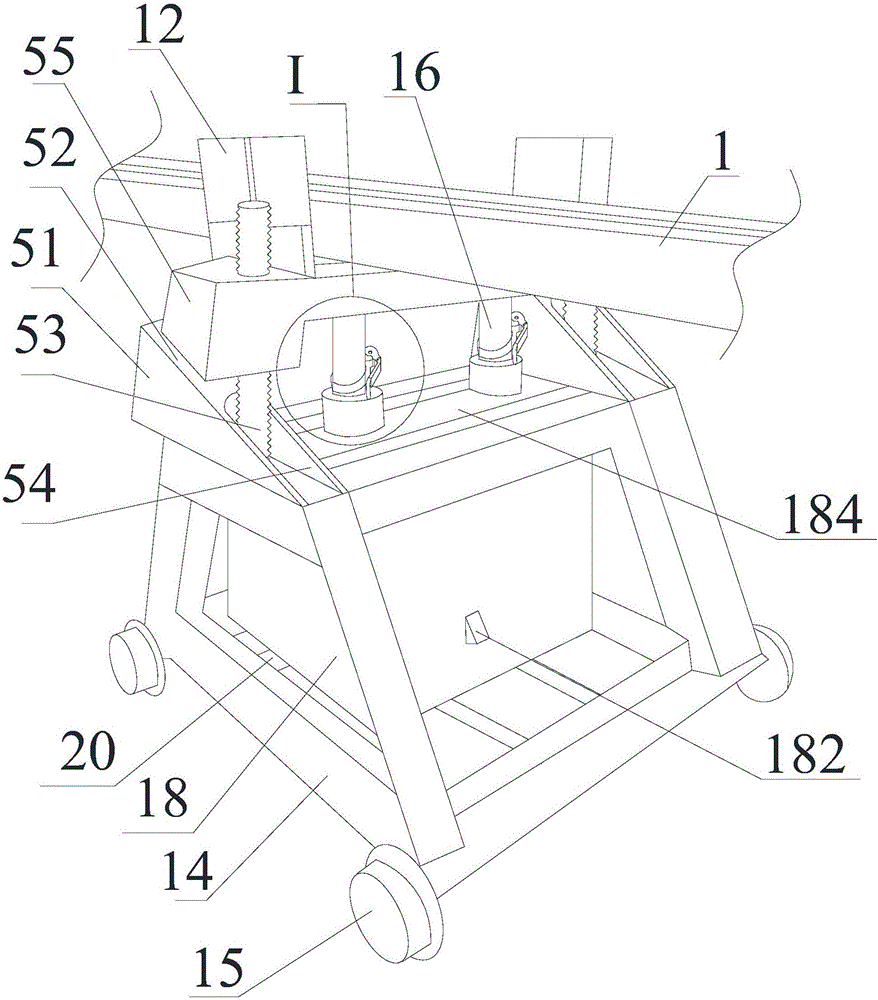

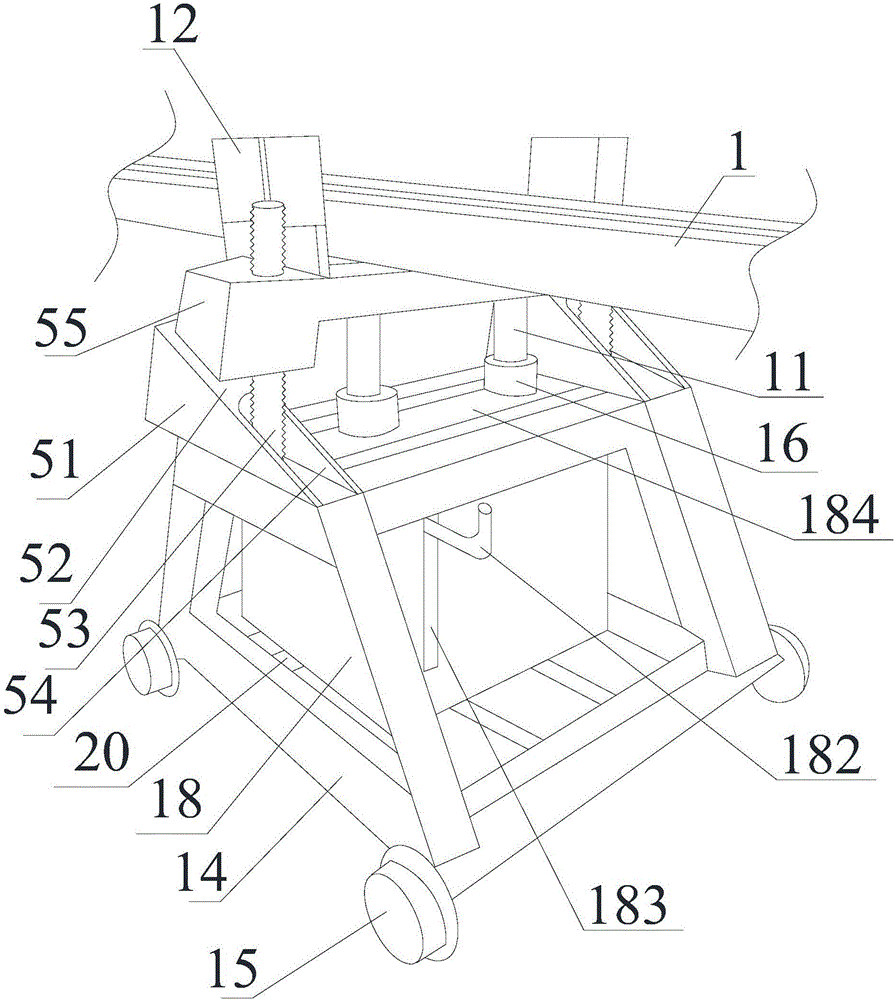

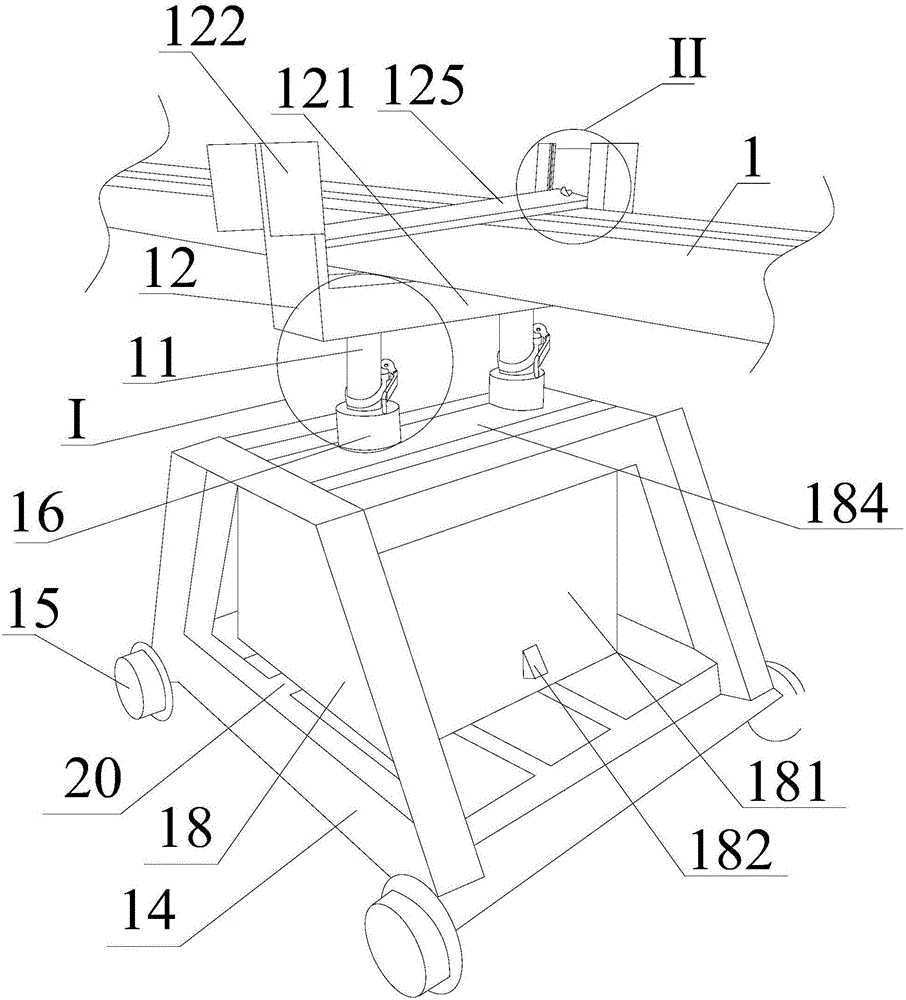

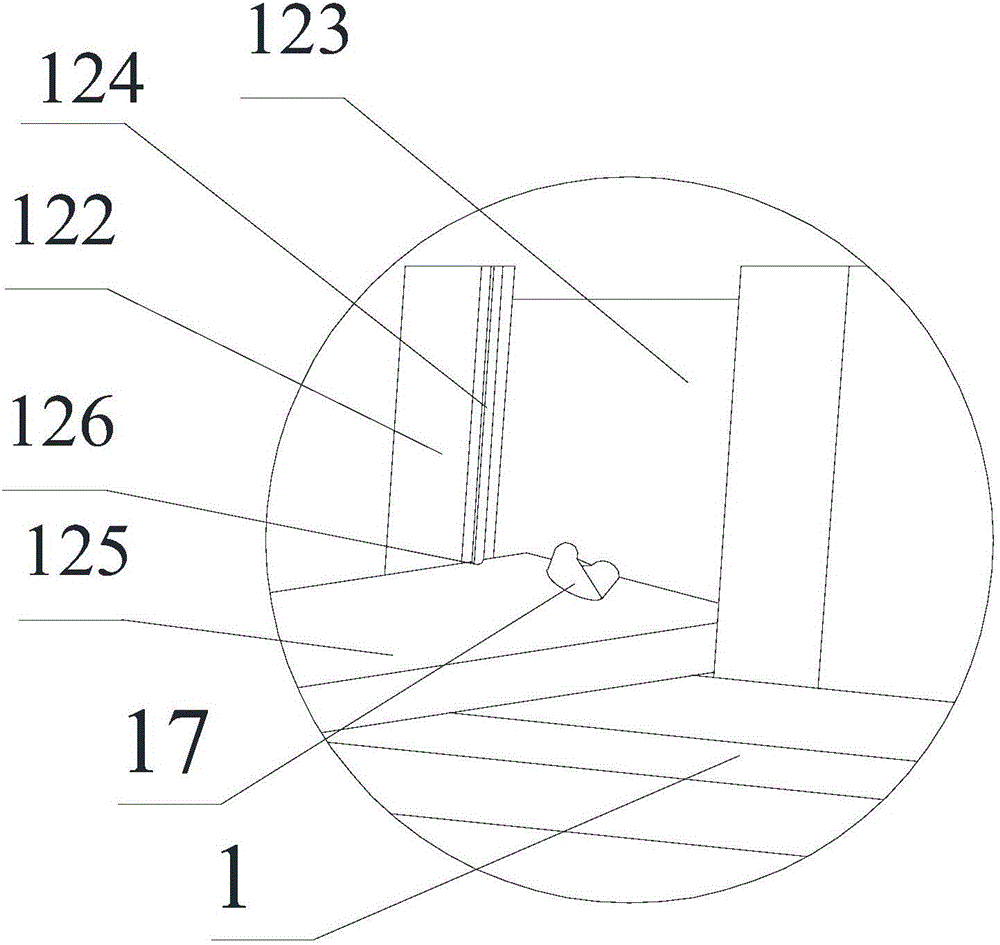

The invention relates to a dual-adjusting type feeding supporting device which comprises a base, a supporting seat and a lifting mechanism. The lifting mechanism comprises a box body, a supporting frame and a conveying mechanism, wherein the supporting frame and the conveying mechanism are arranged in the box body. The supporting seat is fixed to the top face of the box body and driven by the lifting mechanism to ascend and descend. The supporting frame comprises two supporting legs which are movably installed in a crossed mode. One ends of the two supporting legs are both movably installed on the top face of the box body. The other end of the first supporting leg is movably installed on the bottom face of the box body. The other end of the second supporting leg is arranged on a conveying belt of the conveying mechanism and abuts against a limiting block fixed to the conveying belt. A handle is arranged on the limiting block. The supporting frame is provided with a butterfly-shaped locking nut capable of keeping the current state of the supporting frame in a locking mode at the joint of the two supporting legs. At least one positioning pile is fixed to the top face of the box body. The feeding supporting device further comprises at least one stud corresponding to the positioning piles. The supporting seat is positioned above the top face of the box body through the studs, and the distance between the supporting seat and the base is adjusted by rotating the studs.

Owner:ANQING TIANRUN ENG MACHINERY

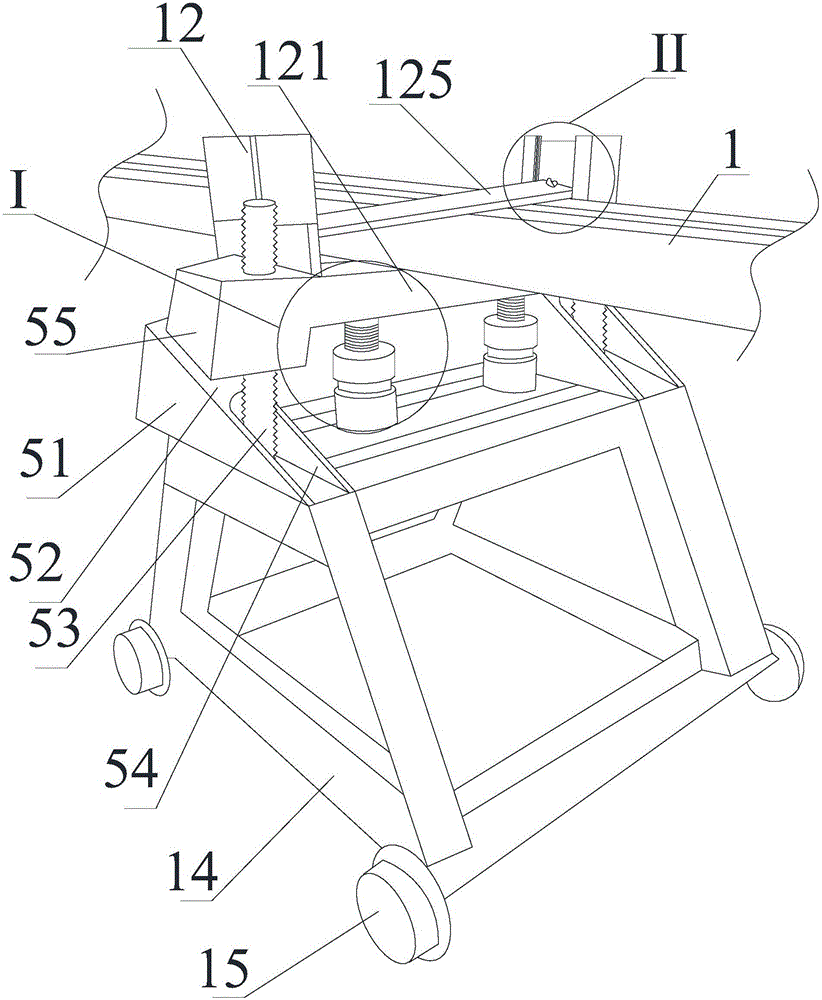

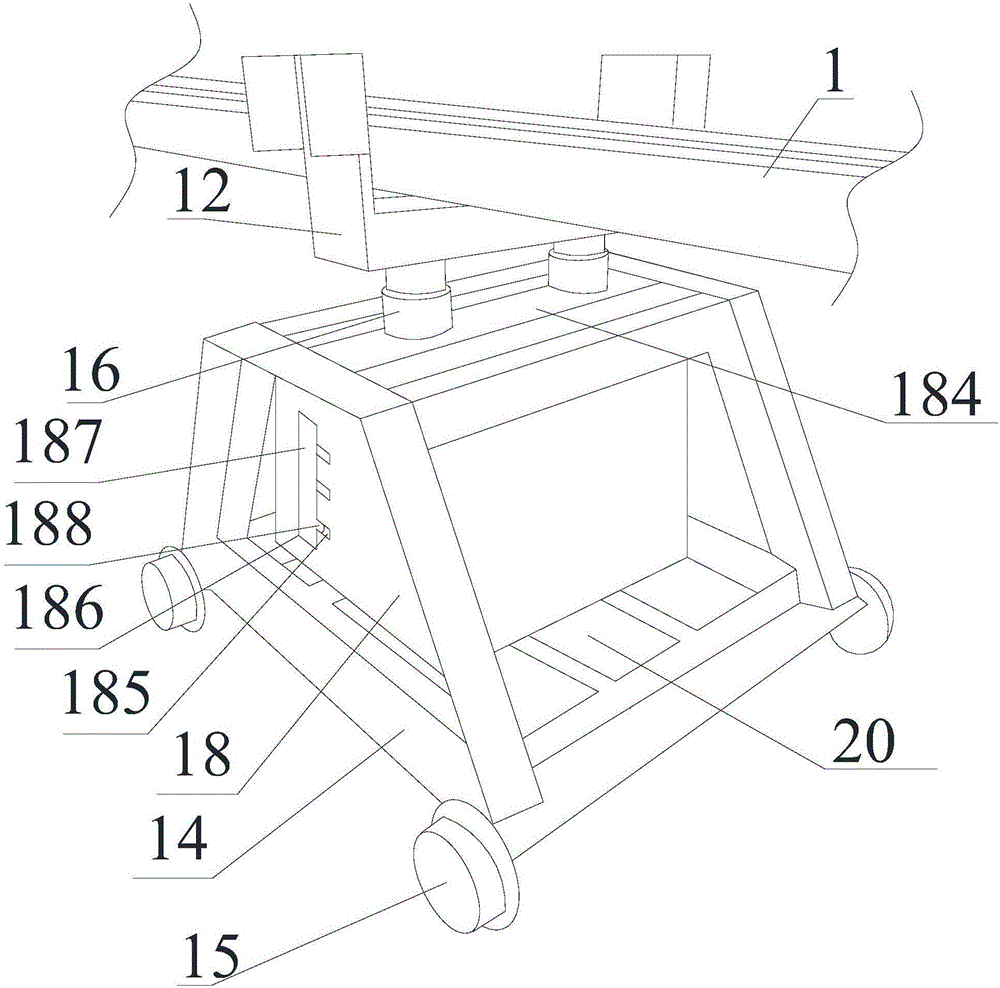

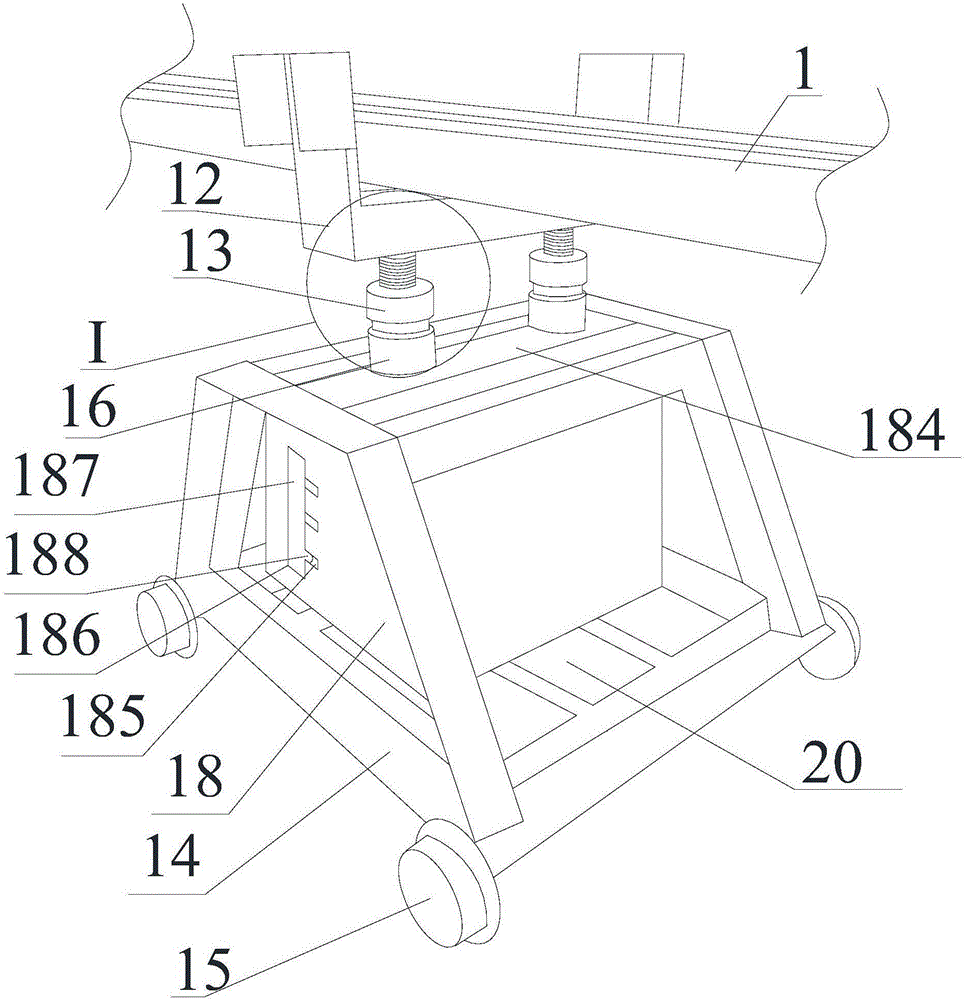

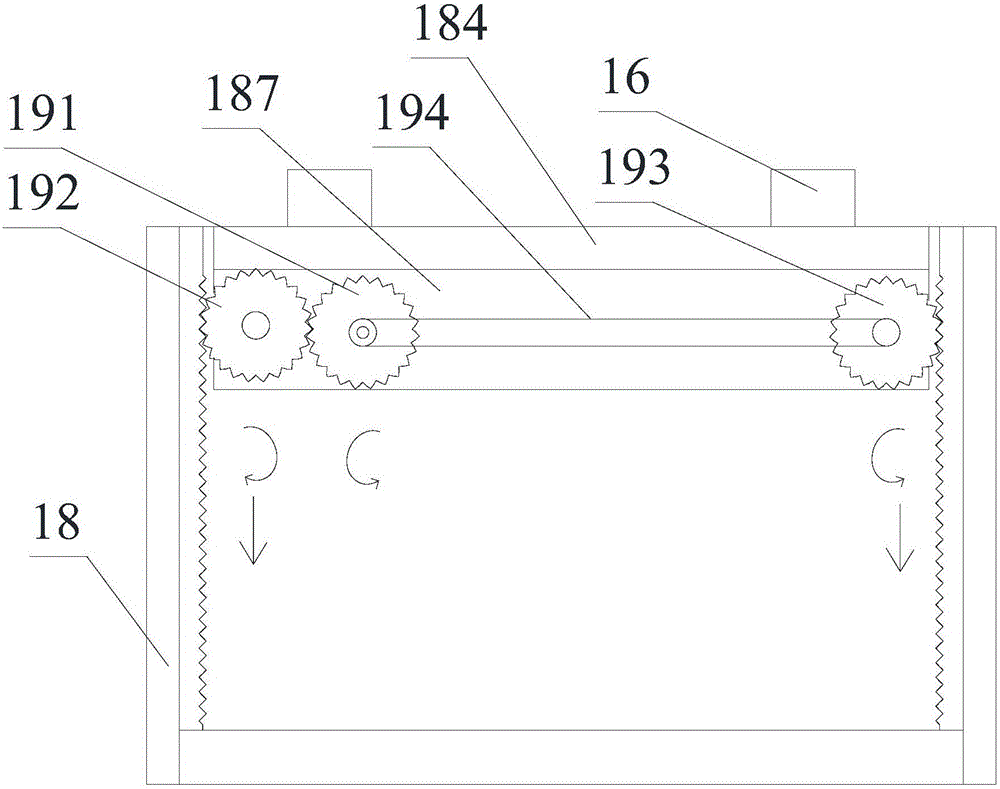

Rocking handle type double-adjustable feeding supporting device

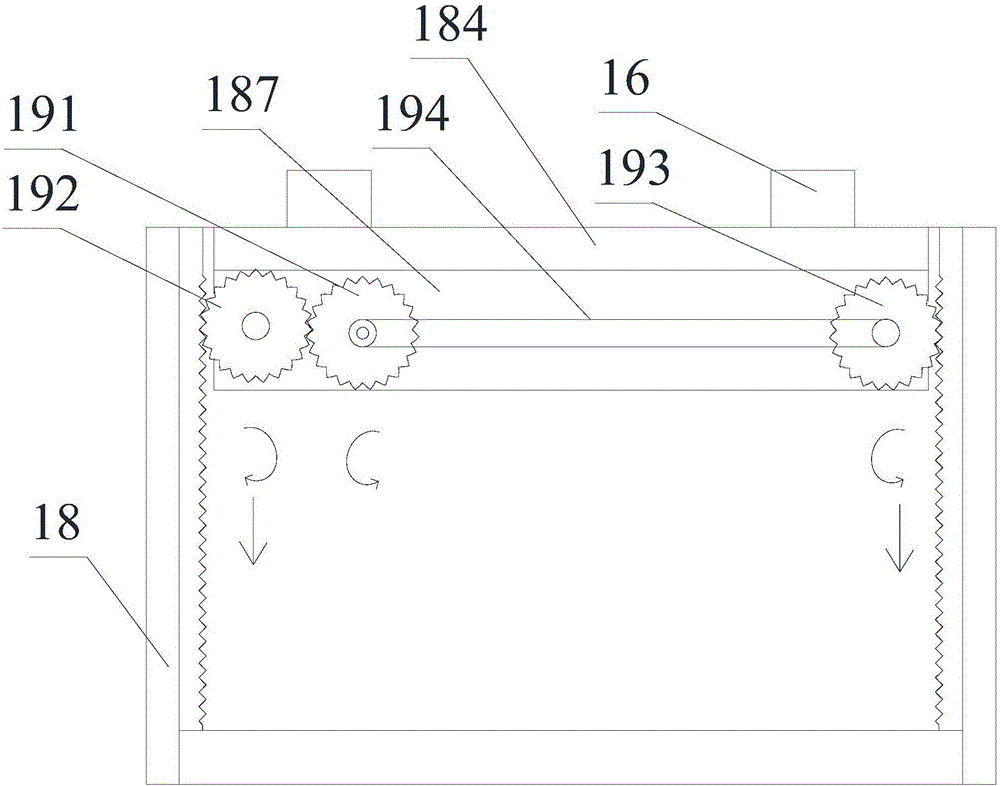

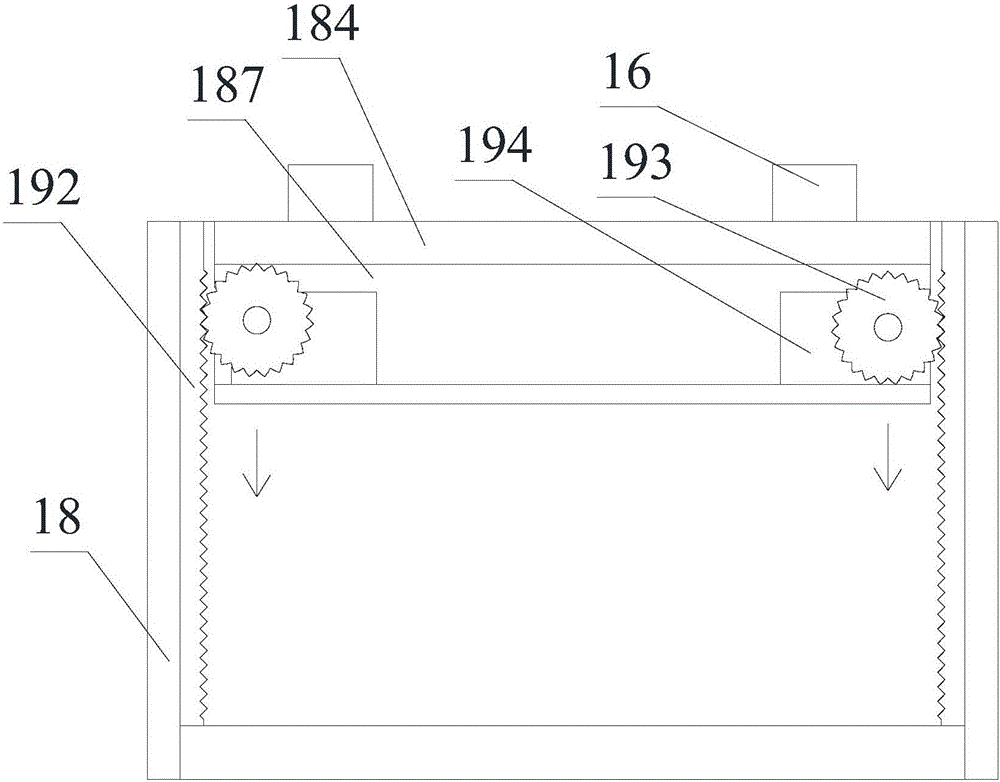

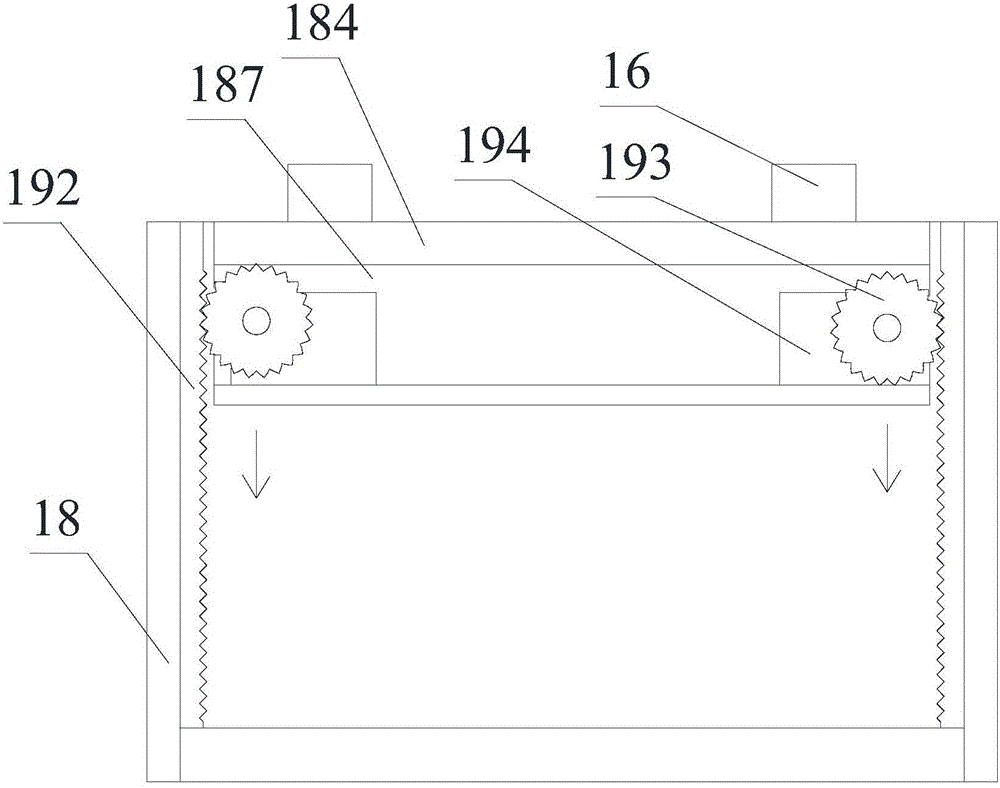

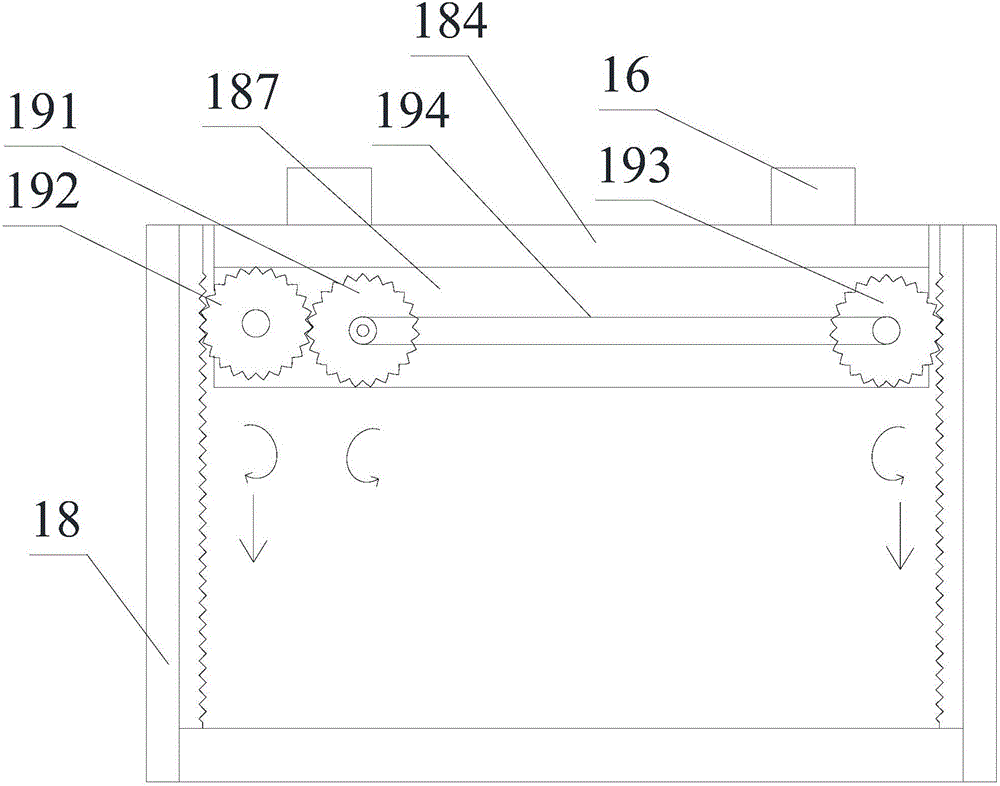

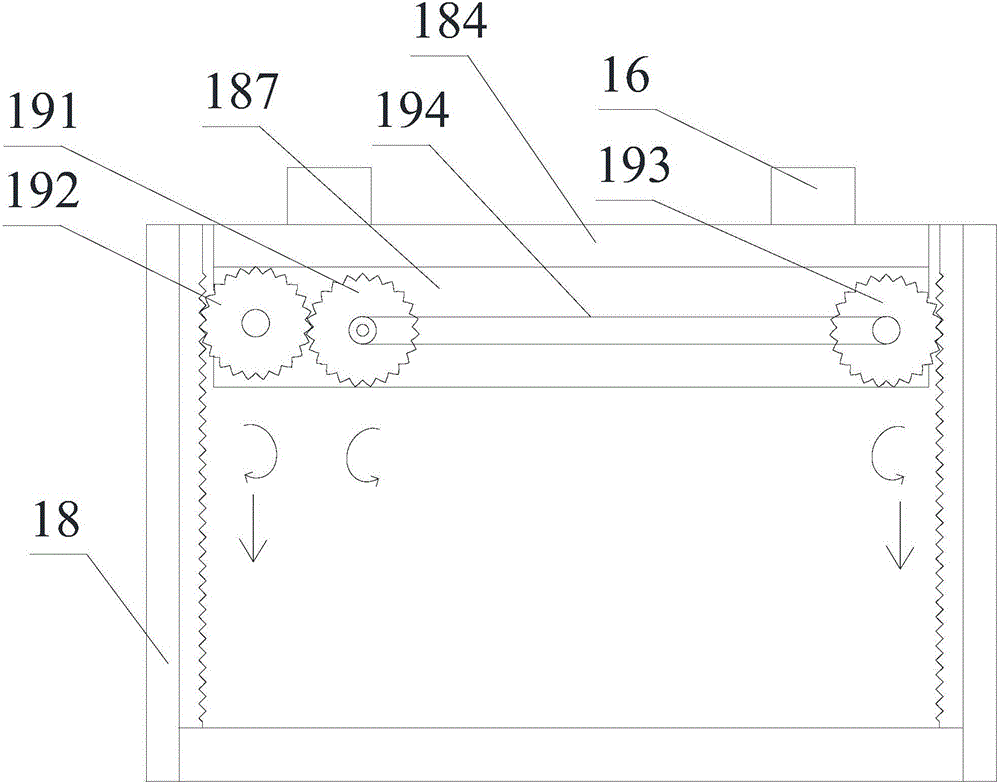

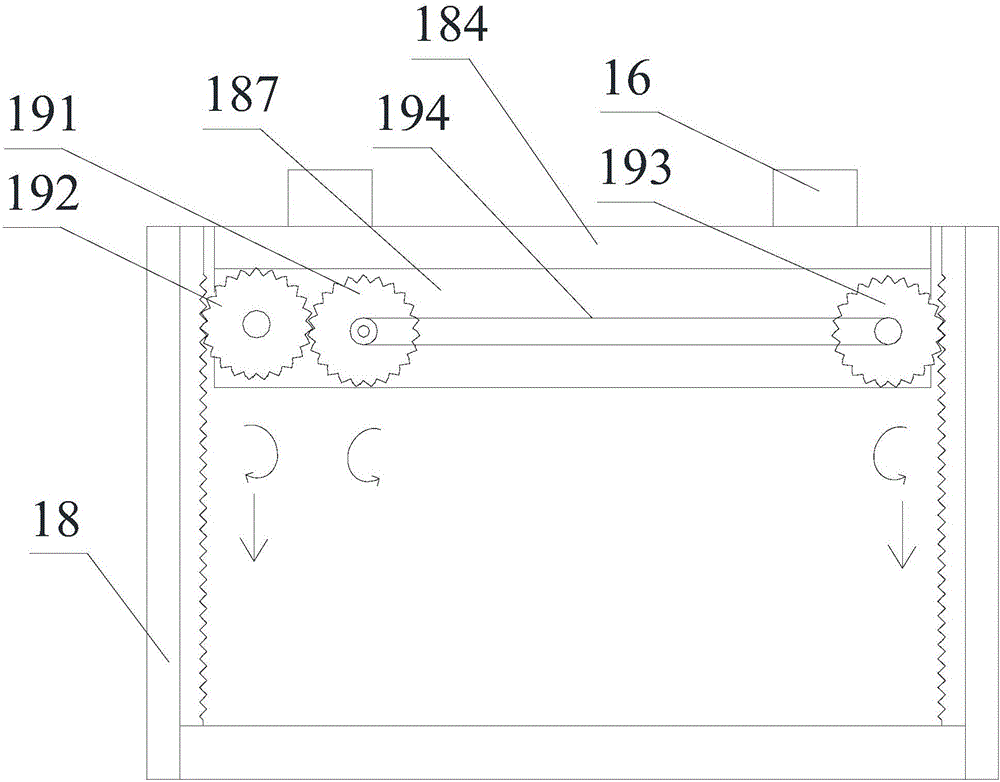

InactiveCN105945641ASolve the problem of smooth feedingSimple structureMetal working apparatusDrive wheelCentre of rotation

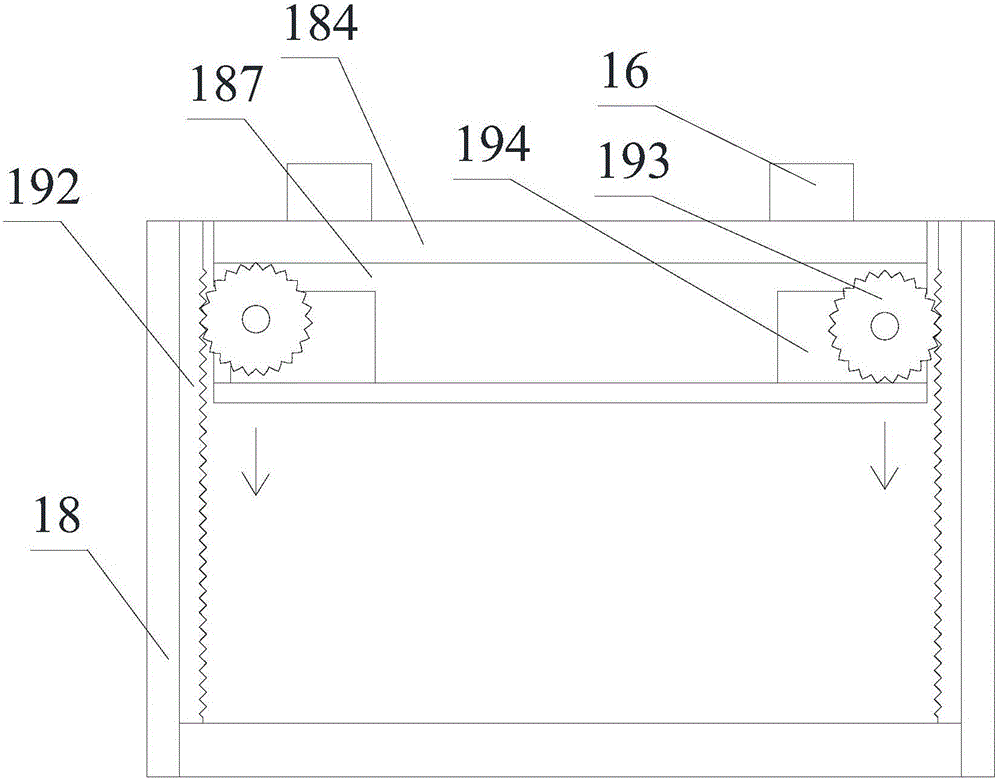

The invention relates to a rocking handle type double-adjustable feeding supporting device. The device comprises a pedestal, a supporting base and a lifting mechanism, wherein the lifting mechanism comprises a box body, a supporting rack and a transmission mechanism; the box body is fixedly arranged on the pedestal, and the supporting base is fixedly arranged on the top face of the box body; the supporting rack is fixedly arranged in the bottom of the top face; the transmission mechanism, which is integrally mounted on the supporting rack, comprises a driving wheel, a driven wheel I, a driven wheel II and a conveyer belt; one side of the driving wheel is in engaging transmission with the driven wheel I while the relative other end of the driving wheel drives the driven wheel II to rotate through the conveyer belt, and the driving wheel drives the two driven wheels to mutually rotate in opposite directions; a rocking handle is arranged at the rotating center of the driving wheel; at least one positioning pile is fixedly arranged on the top face; the feeding supporting device further comprises at least one double-screw bolt corresponding to the at least one positioning pile; and the supporting base is positioned above the top face through the double-screw bolts, and the distance between the supporting base and the pedestal is adjusted by rotating the double-screw bolts.

Owner:ANQING TIANRUN ENG MACHINERY

Dual-lifting type feeding clamping device

InactiveCN105922062ASolve the problem of smooth feedingEasy to operateMetal working apparatusEngineeringConveyor belt

The invention relates to a dual-lifting type feeding clamping device which comprises a base, a support seat and a lifting mechanism. The lifting mechanism comprises a box, a supporting frame and a conveying mechanism, wherein the supporting frame and the conveying mechanism are both arranged in the box. The support seat is fixed to a top face of the box and is driven by the lifting mechanism to go up and down. The supporting frame comprises two support legs which are movably mounted in a scissor shape. One end of one support leg is arranged on a conveyor belt of the conveying mechanism, and a limiting block fixed on the conveyor belt abuts against the end of the support leg. A handle is arranged on the limiting block, and a butterfly-shaped lock nut capable of locking the current state of the supporting frame is arranged at the joint of the two support legs of the supporting frame. The support seat is positioned above the top face through cylindrical rods. The distance between the support seat and the base is adjusted by rotating levers of buckles. The support seat comprises a clamping plate, a supporting beam used for supporting multiple workpieces to be positioned, and two limiting columns fixed to the two opposite ends of the supporting beam. The clamping plate is locked on the supporting beam through a plurality of bolts with butterfly-shaped operating portions on the tops so that the workpieces can be clamped on the supporting beam.

Owner:ANQING TIANRUN ENG MACHINERY

Adjustable feeding support device

InactiveCN105922061AEasy to disassembleEasy to cleanMetal working apparatusEngineeringMechanical engineering

The invention relates to an adjustable feeding support device which comprises a base and a support seat fixed to the base. Positioning piles are fixed to the base. The adjustable feeding support device further comprises studs corresponding to the positioning piles. First screw holes and second screw holes corresponding to the first screw holes are formed in the bottoms of the positioning piles and the bottom of the support seat correspondingly. One end of each stud is inserted into the first screw hole of the corresponding positioning pile in a screwed mode, and the other end of each stud is inserted into the corresponding second screw hole of the support seat in a screwed mode. The support seat is positioned above the base through the studs, and the distance between the support seat and the base is adjusted by rotating the studs. The support seat comprises a clamping plate, a supporting beam and two limiting columns fixed to the two opposite ends of the supporting beam. Slide grooves are formed in the two opposite sides of the clamping plate. Accommodating grooves are formed in the opposite side faces of the two limiting columns, and two slide strips are arranged on the two opposite sides of the accommodating grooves and clamped in the two slide grooves correspondingly. The clamping plate is locked on the supporting beam through a plurality of bolts with butterfly-shaped operating portions on the tops.

Owner:ANQING TIANRUN ENG MACHINERY

Hand hoisting double adjustable feed clamping device

InactiveCN105945643AEasy to observe mobile positioningSolve the problem of smooth feedingMetal working apparatusEngineeringMechanical engineering

Owner:ANQING TIANRUN ENG MACHINERY

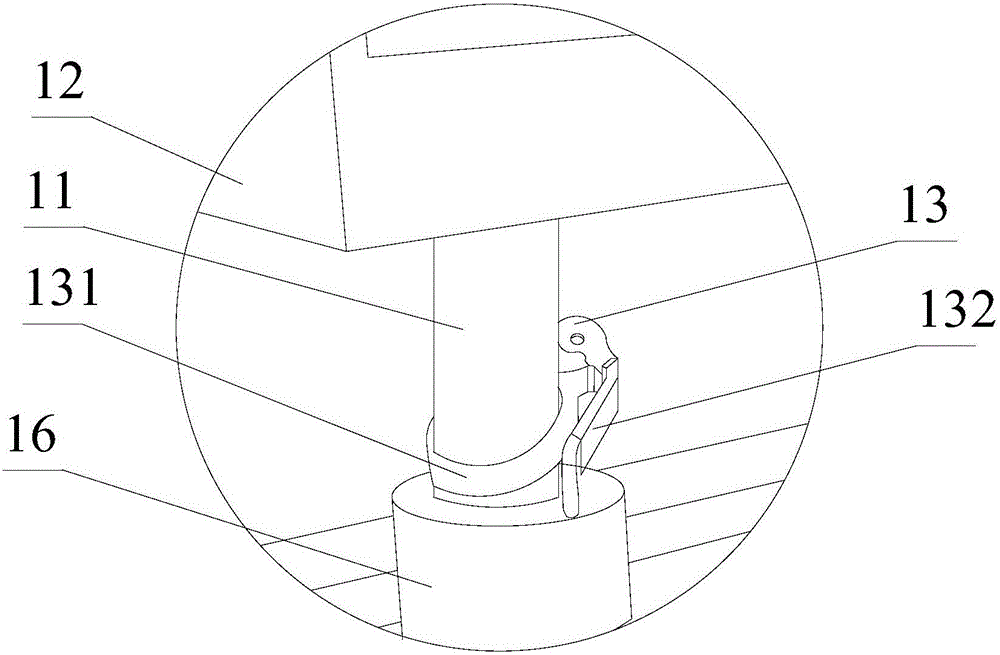

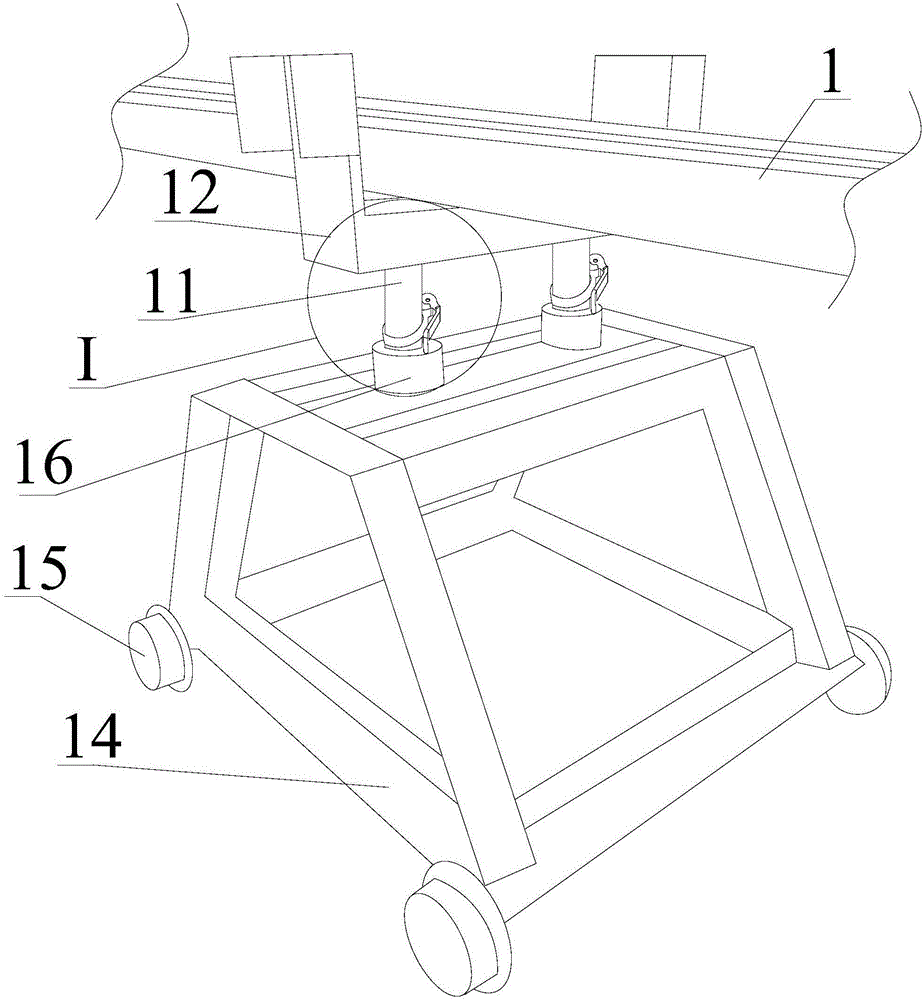

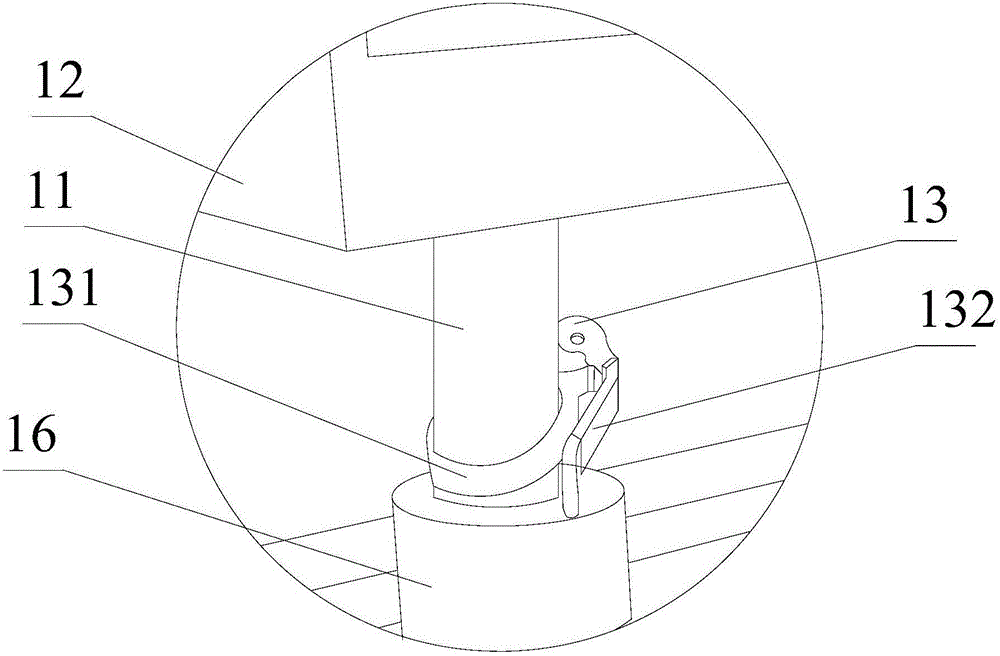

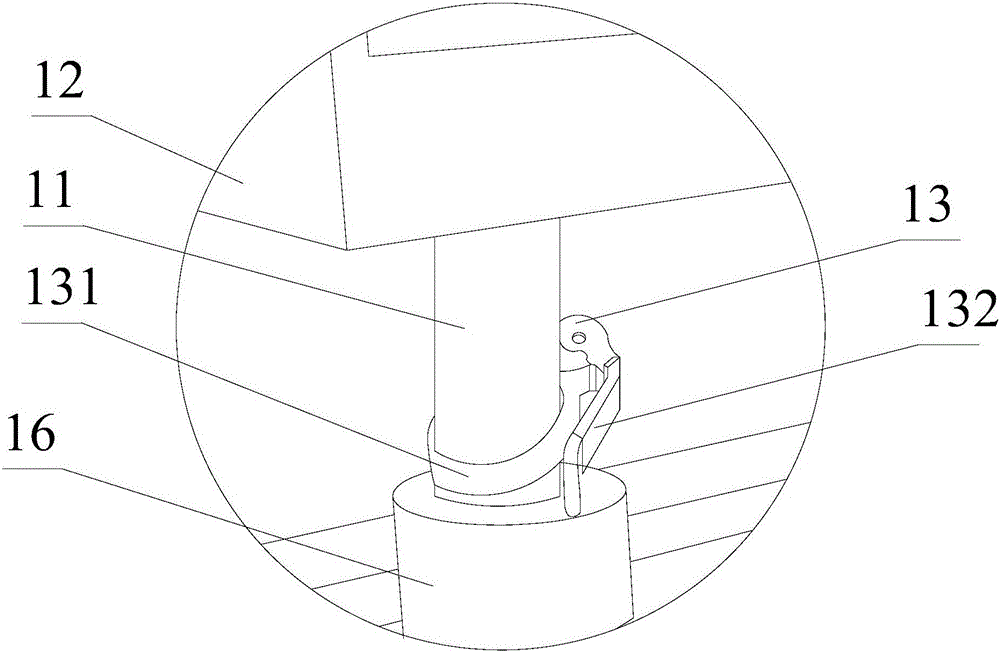

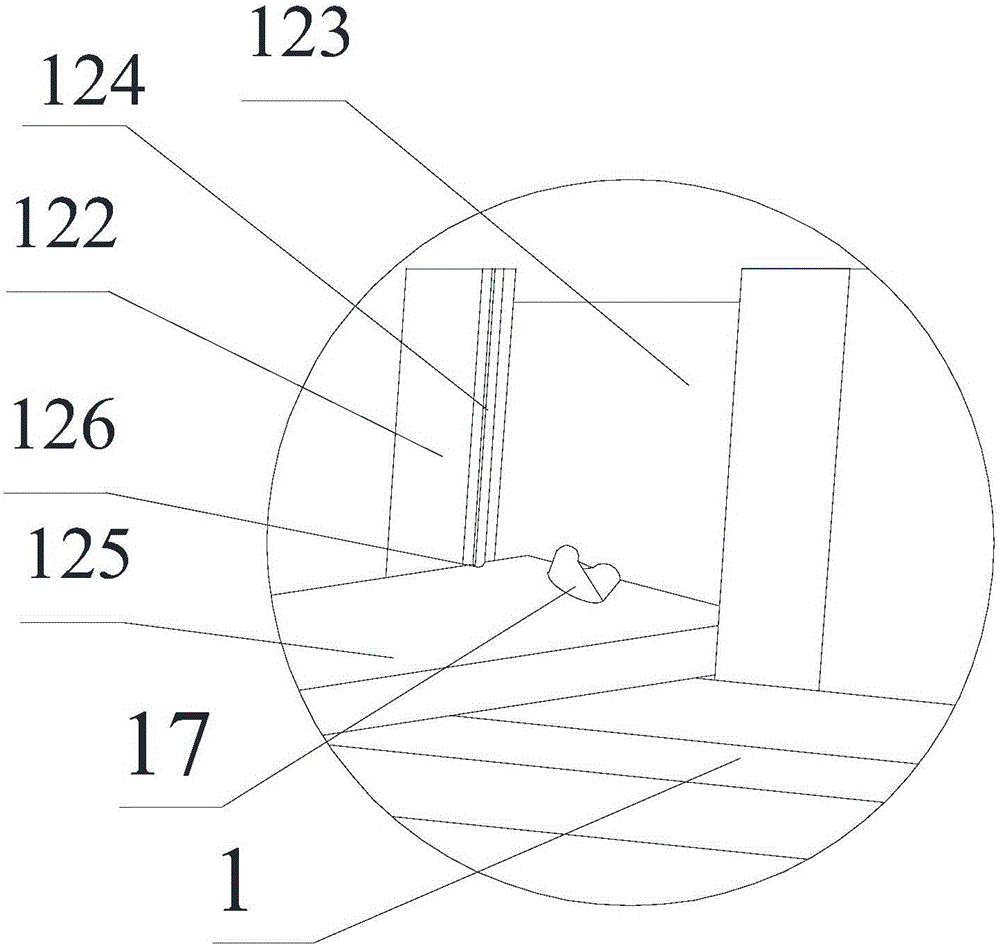

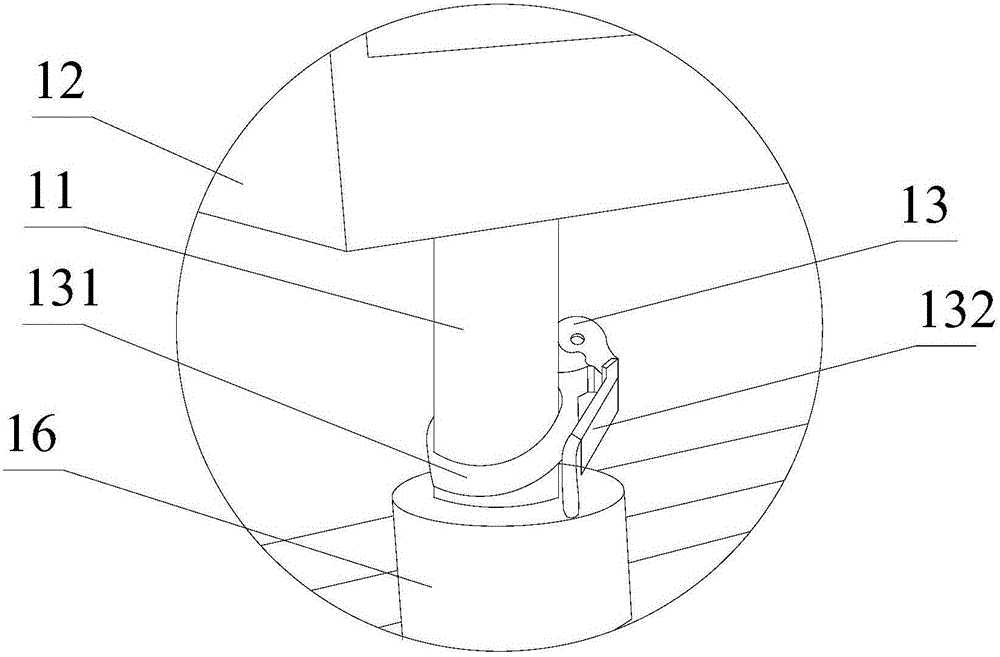

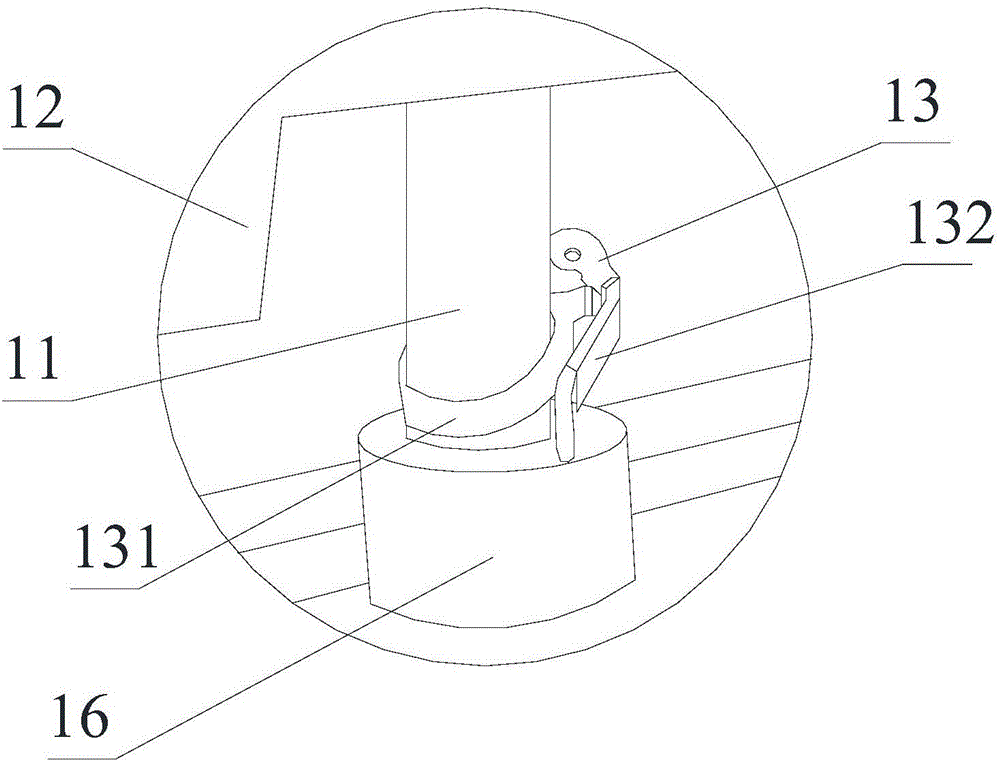

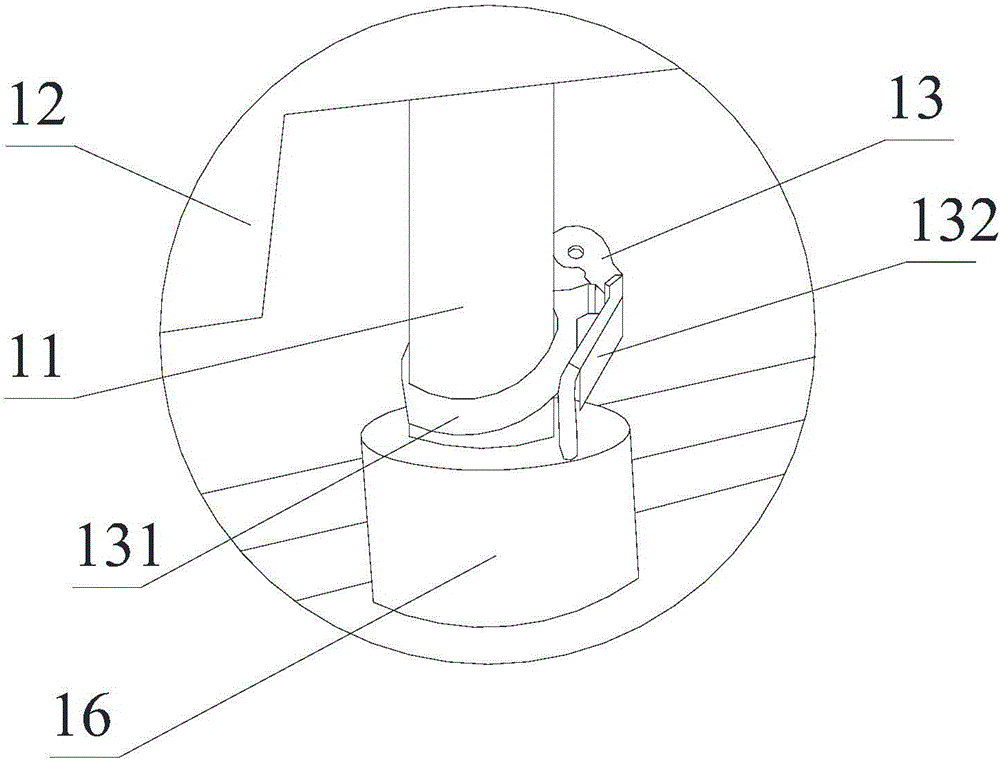

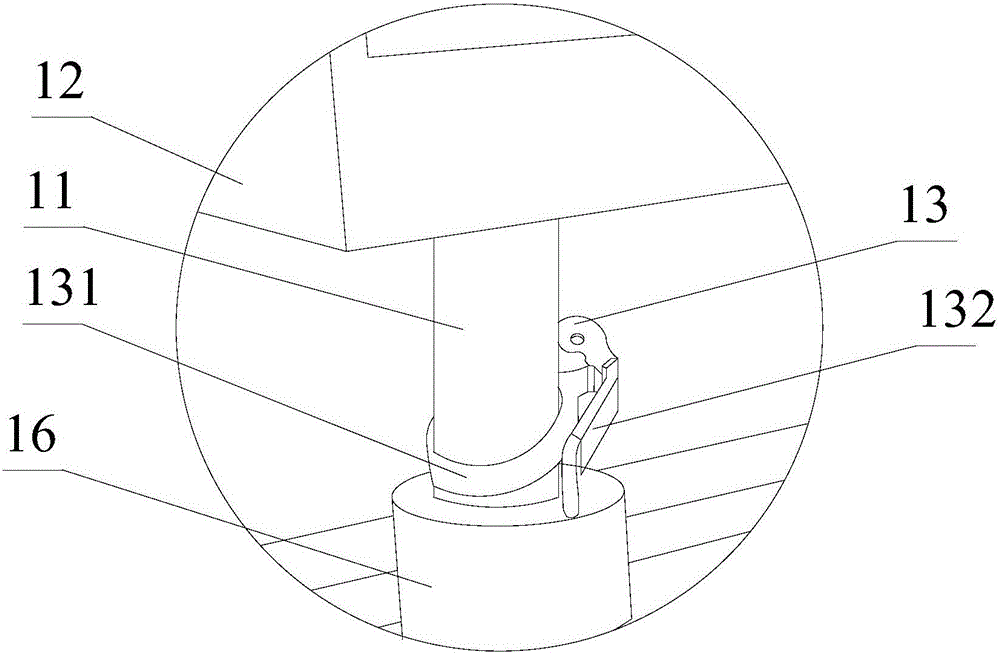

Feed supporting device provided with buckles

The invention relates to a feed supporting device provided with buckles. The feed supporting device provided with the buckles comprises a base and a supporting base fixed to the base. At least one positioning piles is fixed to the base. The feed supporting device provided with the buckles further comprises at least one cylindrical rod corresponding to the positioning piles, and at least one buckle corresponding to the cylindrical rods. Containing holes are formed in the positioning piles. One end of each cylindrical rod is inserted in the containing hole of the corresponding positioning pile, and the other end of each cylindrical rod is fixed to the bottom of the supporting base. Each buckle comprises a lantern ring and a lock catch, wherein the lantern ring is arranged on the corresponding cylindrical rod in a sleeving mode, and the lock catch is rotatably fixed to the lantern ring. Each lock catch comprises an oval locking part and a spanner fixed to the oval locking part. The spanners can rotate the oval locking parts to make the oval locking parts clamp the cylindrical rods, so that the whole buckles are positioned on the cylindrical rods. According to the feed supporting device provided with the buckles, stable feeding of cylinder barrels with different diameters can be achieved by adjusting the interval between the supporting base and the base.

Owner:ANQING TIANRUN ENG MACHINERY

Feeding supporting double adjusting device

InactiveCN106002448AReduce lossAdjustable spacingMetal working apparatusEngineeringMechanical engineering

The invention relates to a feeding supporting double adjusting device. The feeding supporting double adjusting device comprises a base, a supporting seat and a lifting mechanism, wherein the lifting mechanism comprises a tank, a wedge block, a driver, a threaded rod and a support frame and a transmission mechanism which are arranged inside the tank; the wedge block has a wedge surface; a notch for allowing the threaded rod to pass through is formed in the wedge surface; one end of the threaded rod is inserted in the base and is driven by the driver to rotate; after passing through the notch, the other end of the threaded rod is connected on the support seat in a threaded manner; the support seat has an inclined surface which fits the wedge surface; the wedge block fits the part between the base and the support seat; the support seat is fixed to the top surface of the tank; the support frame comprises two supporting legs which are movably mounted in a scissors form; one end of one supporting leg is arranged on a conveying belt of the transmission mechanism and is propped against a limiting block fixed to the conveying belt; and the conveying belt is controlled to move by a motor of the transmission mechanism.

Owner:ANQING TIANRUN ENG MACHINERY

Oblique inserting double-lifting feeding and clamping device

The invention relates to an oblique inserting double-lifting feeding and clamping device, which comprises a base, a supporting seat, a lifting mechanism and double-screw bolts. The lifting mechanism comprises wedge blocks, a driver and threaded rods. Each wedge block is provided with a wedge face; a gap for each thread rod to penetrate through is formed on each wedge face. One end of each threaded rod is inserted on the base in a penetrating way and driven by the driver to rotate, and the other end of each threaded rod penetrates through each gap so as to be screwed on the supporting seat. The supporting seat is provided with oblique faces matched with the wedge faces; the wedge blocks are matched between the base and the supporting seat. Dowel piles corresponding to the double-screw bolts are fixed onto the base. Two corresponding screw holes are respectively formed on the bottom parts of each dowel pile and the supporting seat. One end of each double-screw bolt is inserted into the screw hole I of the corresponding dowel pile in a screwing way, and the other end of each double-screw bolt is inserted into the screw hole II of the corresponding supporting seat in a screwing way. The supporting seat comprises a clamping plate, a supporting beam, and two limited posts fixed on two opposite ends of the supporting beam. The clamping plate is locked on the supporting beam through a plurality of bolts with butterfly operation parts on the top parts.

Owner:ANQING TIANRUN ENG MACHINERY

Electric-control dual-lifting feed supporting device

InactiveCN105922065ASolve the problem of smooth feedingEasy to operateMetal working apparatusEngineeringMotor drive

The invention relates to an electric-control dual-lifting feed supporting device. The electric-control dual-lifting feed supporting device comprises a base, a supporting base and a lifting mechanism. The lifting mechanism comprises a box, a supporting frame and a conveying mechanism. The box is fixed to the base. The box is provided with a top surface which can rise and fall. The supporting base is fixed to the top surface. Both the supporting frame and the conveying mechanism are arranged in the box. The supporting frame is fixed to the bottom of the top surface. The conveying mechanism is integrally installed on the supporting frame and comprises two racks which are arranged in parallel, two turning wheels engaged with the two racks correspondingly, and two motors driving the two turning wheels to rotate synchronously in opposite directions. At least one positioning pile is fixed to the top surface. The feed supporting device further comprises at least one stud corresponding to the positioning piles. The supporting base is positioned above the top surface through the studs, and the interval between the supporting base and the base is adjusted by rotating the studs.

Owner:ANQING TIANRUN ENG MACHINERY

Manual-lifting type feeding supporting device

InactiveCN105922024AEasy to observe mobile positioningSolve the problem of smooth feedingLarge fixed membersMetal working apparatusMachining processSupport plane

The invention relates to a manual-lifting type feeding supporting device which comprises a base, a supporting seat and a lifting mechanism. The lifting mechanism comprises a box body and a supporting frame. The box body is fixed to the base. The box body is provided with a top face capable of ascending and descending. The supporting seat is fixed to the top face. The supporting frame is arranged in the box body and fixed to the bottom of the top face. Clamping parts are arranged on the two opposite sides of the supporting frame. Vertical strip-shaped through holes are formed in the two opposite sides of the box body. A plurality of parallel clamping grooves which are located on different planes and used for containing the corresponding clamping part are formed in the vertical side of each vertical strip-shaped through hole. By horizontally moving the supporting frame, the two clamping parts are made to retreat from the current clamping grooves to be located in the vertical strip-shaped through holes, and the two clamping parts are made to be inserted into other clamping grooves by vertically moving the supporting frame. According to the manual-lifting type feeding supporting device, operation is easy, a worker just needs to lift the supporting seat and move the supporting seat with hands in the whole process, the worker can go on duty without training, and application and popularization in the production and machining process are easy.

Owner:ANQING TIANRUN ENG MACHINERY

Electronically controlled double-adjustable feed clamping device

InactiveCN106002453ARealize adjustment spacingAdjustable spacingMetal working apparatusMechanical engineering

Owner:ANQING TIANRUN ENG MACHINERY

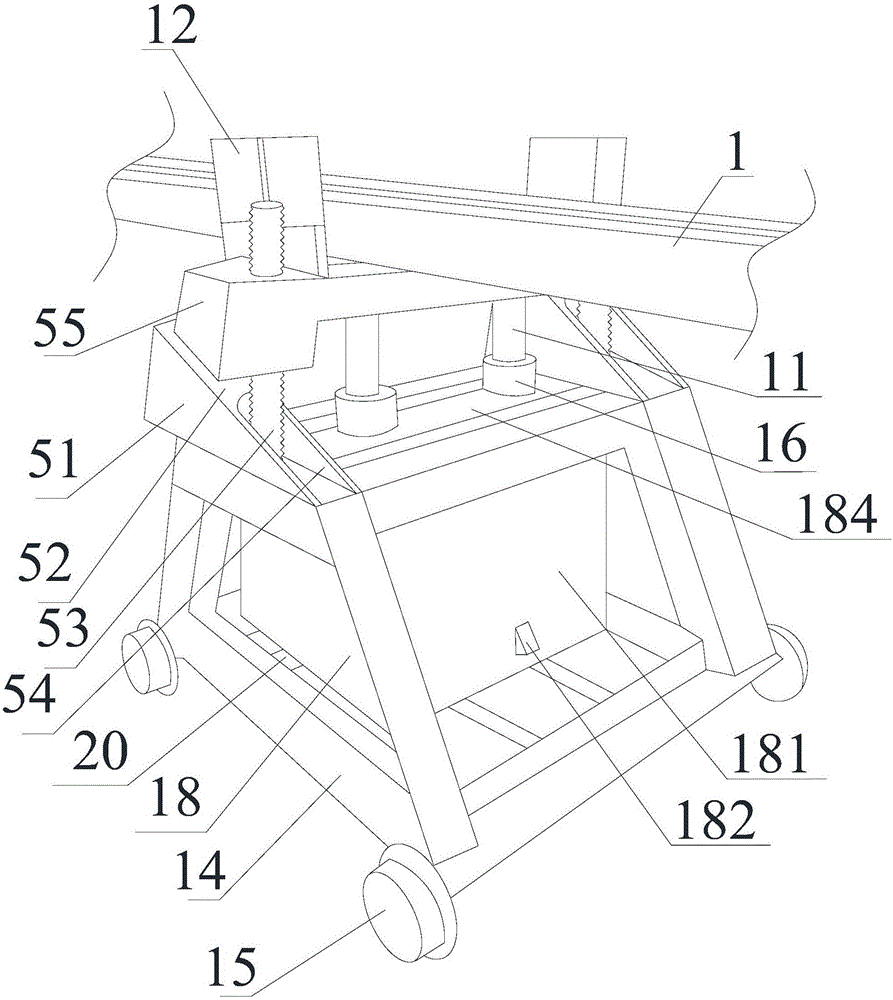

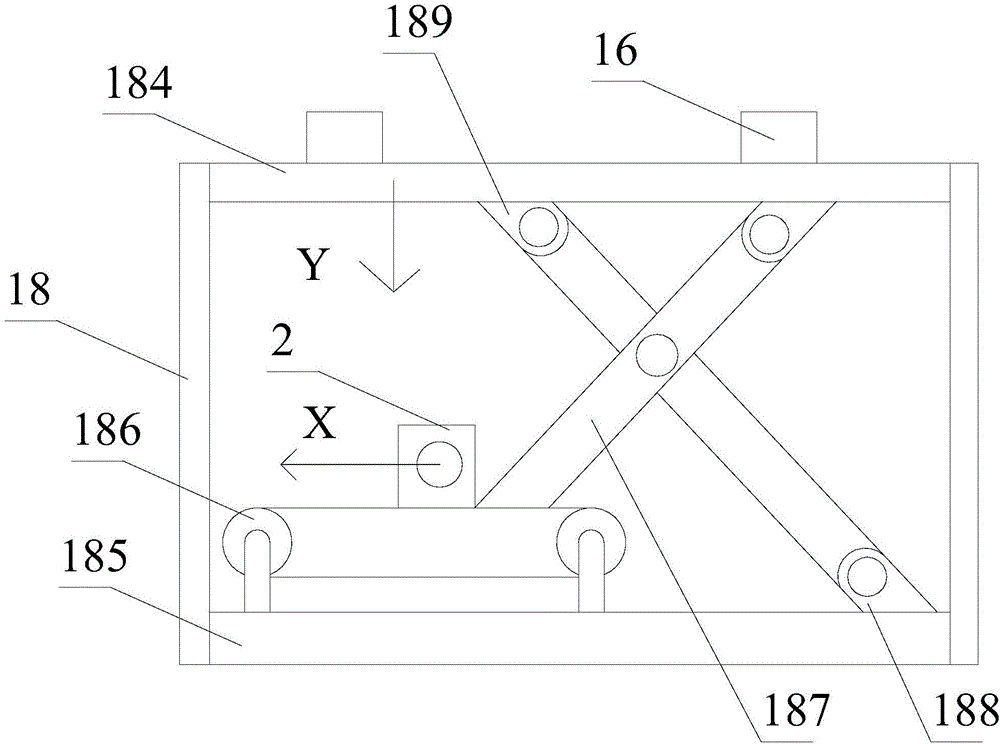

Double-lifting type feeding supporting device

InactiveCN105922067ASolve the problem of smooth feedingEasy to operateMetal working apparatusWrenchEngineering

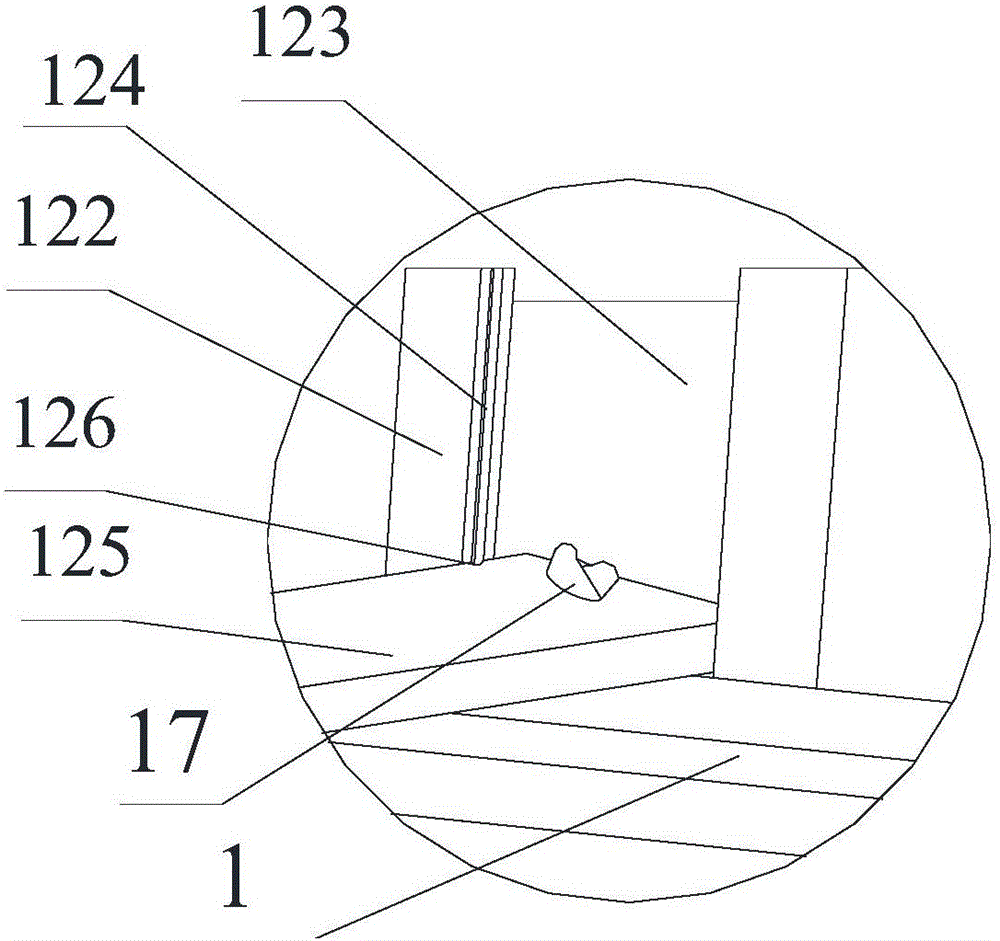

The invention relates to a double-lifting type feeding supporting device which comprises a base, a supporting seat, a lifting mechanism, cylindrical rods and buckles. The lifting mechanism comprises a box body, a supporting frame arranged in the box body, and a conveying mechanism. The supporting seat is fixed to the top face of the box body. The supporting frame comprises two supporting legs which are movably installed in a crossed mode. One ends of the two supporting legs are both movably installed on the top face of the box body. The other end of the first supporting leg is movably installed on the bottom face of the box body. The other end of the second supporting leg is arranged on a conveying belt of the conveying mechanism and abuts against a limiting block fixed to the conveying belt. A handle is arranged on the limiting block. The supporting frame is provided with a butterfly locking nut capable of keeping the current state of the supporting frame in a locking mode at the joint of the two supporting legs. Positioning piles are fixed to the top face of the box body. One end of each cylindrical rod is inserted into the corresponding positioning pile, and the other end of the cylindrical rod is fixed to the bottom of the supporting seat. Each buckle comprises a lantern ring and a lock catch, wherein the lantern ring is arranged on the corresponding cylindrical rod in a sleeving mode, and the lock catch is rotatably fixed to the lantern ring. Each lock catch comprises an oval locking part and a wrench fixed to the oval locking part.

Owner:ANQING TIANRUN ENG MACHINERY

Feeding clamping adjusting device

InactiveCN106002454AAdjustable spacingSolve the problem of smooth feedingMetal working apparatusEngineeringMechanical engineering

Owner:ANQING TIANRUN ENG MACHINERY

Dual-adjusting type feeding clamping device

InactiveCN105922076ASolve the problem of smooth feedingEasy to operateWork tools storageOther workshop equipmentEngineeringMechanical engineering

The invention relates to a dual-adjusting type feeding clamping device which comprises a base, a supporting seat and a lifting mechanism. The lifting mechanism comprises a box body, a supporting fame and a conveying mechanism, wherein the supporting frame and the conveying mechanism are arranged in the box body. The supporting seat is fixed to the top face of the box body and driven by the lifting mechanism to ascend and descend. The supporting frame comprises two supporting legs which are movably installed in a crossed mode. One end of one of the two supporting legs is arranged on a conveying belt of the conveying mechanism and abuts against a limiting block fixed to the conveying belt. A handle is arranged on the limiting block. The supporting frame is provided with a butterfly-shaped locking nut capable of keeping the current state of the supporting frame in a locking mode at the joint of the two supporting legs. The supporting seat is positioned above the top face of the box body through studs. The distance between the supporting seat and the base is adjusted by rotating the studs. The supporting seat comprises a clamping plate, a supporting beam used for supporting a plurality of workpieces to be positioned, and two limiting columns fixed to the two opposite ends of the supporting beam. The clamping plate is locked to the supporting beam through a plurality of bolts so that the multiple workpieces to be positioned can be clamped on the supporting beam, wherein a butterfly-shaped operating part is located at the top of each bolt.

Owner:ANQING TIANRUN ENG MACHINERY

Obliquely inserted type double-adjusting feeding supporting device

InactiveCN106002449ASolve the problem of smooth feedingEasy to operateMetal working apparatusEngineeringMechanical engineering

The invention relates to an oblique insertion type double-adjustment feeding support device, which comprises a base, a support seat, a lifting mechanism and a stud. The lifting mechanism includes a wedge block, a driver, and a threaded rod. The wedge-shaped block has a wedge-shaped surface, and a notch for the passage of the threaded rod is opened on the wedge-shaped surface. One end of the threaded rod is inserted on the base and driven to rotate by the driver, and the other end is screwed on the supporting base after passing through the gap. The supporting seat has an inclined surface matching the wedge-shaped surface, and the wedge-shaped block fits between the base and the supporting seat. A positioning pile corresponding to the stud is fixed on the base, a screw hole 1 is provided on the positioning pile, and a screw hole 2 corresponding to the screw hole 1 is provided at the bottom of the supporting seat. One end of the stud is inserted in the screw hole 1 of the corresponding positioning pile by screwing, and the other end is inserted in the screw hole 2 of the corresponding support seat by screwing, so that the support seat is positioned above the base through the stud and Adjust the distance between the support seat and the base by rotating the stud.

Owner:ANQING TIANRUN ENG MACHINERY

Oblique-inserting type feeding clamping adjusting device

InactiveCN105922071ASolve the problem of smooth feedingEasy to operateMetal working apparatusEngineeringThreaded rod

The invention relates to an oblique-inserting type feeding clamping adjusting device which comprises a base, a supporting seat and a lifting mechanism. The lifting mechanism comprises a box body, a supporting frame, a conveying mechanism, wedge-shaped blocks, a driver and threaded rods. Notches are formed in wedge-shaped faces of the wedge-shaped blocks. One end of each threaded rod is inserted into the base in a penetrating mode and driven by the driver to rotate, and the other end of each threaded rod penetrates through the corresponding notch and is screwed on the supporting seat. The supporting seat is provided with oblique faces matched with the wedge-shaped faces. The wedge-shaped blocks are arranged between the base and the supporting seat in a matched mode. The supporting seat is fixed to the top face of the box body. Both the supporting frame and the conveying mechanism are arranged in the box body. The supporting frame is fixed to the bottom of the top face of the box body. The conveying mechanism is integrally installed on the supporting frame. The conveying mechanism comprises two racks arranged in parallel, two rotary wheels engaged with the two racks correspondingly, and two motors used for driving the two rotary wheels to rotate oppositely and synchronously. The supporting seat is positioned above the top face of the box body through cylindrical rods. The distance between the base and the supporting seat is adjusted by rotating wrenches of buckles.

Owner:ANQING TIANRUN ENG MACHINERY

Rocking handle type feeding clamping device

InactiveCN105945630ASolve the problem of smooth feedingSimple structureMetal working apparatusEngineeringMechanical engineering

The invention relates to a rocking handle type feeding clamping device. The device comprises a pedestal, a supporting base and a lifting mechanism, wherein the lifting mechanism comprises a box body, a supporting rack and a transmission mechanism; the box body is fixedly arranged on the pedestal, and the supporting base is fixedly arranged on the top face of the box body; the supporting rack is fixedly arranged in the bottom of the top face; the transmission mechanism, which is integrally mounted on the supporting rack, comprises a driving wheel, a driven wheel I, a driven wheel II and a conveyer belt; one side of the driving wheel is in engaging transmission with the driven wheel I while the relative other end of the driving wheel drives the driven wheel II to rotate through the conveyer belt, and the driving wheel drives the two driven wheels to mutually rotate in opposite directions; a rocking handle is arranged at the rotating center of the driving wheel; the supporting base comprises a clamping plate, a supporting beam for supporting a plurality of to-be-positioned workpieces and two limiting columns fixed on two relative ends of the supporting beam; and the clamping plate is locked on the supporting beam through a plurality of bolts with the top parts being butterfly-shaped operating parts, so that the workpieces are clamped on the supporting beam.

Owner:ANQING TIANRUN ENG MACHINERY

Electric-control double-lifting feeding clamping device

InactiveCN105922053ARealize adjustment spacingAdjustable spacingMetal working apparatusElectric controlWrench

Owner:ANQING TIANRUN ENG MACHINERY

Feeding clamping device

InactiveCN105922068ASolve the problem of smooth feedingReduce loadMetal working apparatusEngineeringMechanical engineering

The invention relates to a feeding clamping device which comprises a base and a supporting seat fixed to the base. The supporting seat comprises a clamping plate, a supporting beam used for supporting a plurality of workpieces to be positioned, and two limiting columns fixed to the two opposite ends of the supporting beam. Sliding grooves are formed in the two opposite sides of the clamping plate. Containing grooves are formed in the opposite side faces of the two limiting columns correspondingly. Sliding strips are arranged on the two opposite sides of each containing groove. The two sliding strips of each containing groove are clamped in the two sliding grooves correspondingly. The clamping plate can slide in the containing grooves relative to the limiting columns through the guidance of the sliding strips. The clamping plate is locked to the supporting beam through a plurality of bolts so that the multiple workpieces to be positioned can be clamped on the supporting beam, wherein a butterfly-shaped operating part is located at the top of each bolt. Compared with a traditional clamping mode, the multiple workpieces to be positioned do not deform unless the feeding clamping device integrally moves, however, a clamping plate is prone to being wholly disengaged from a supporting beam according to the traditional clamping mode. The structural design is simple and can be implemented easily, and the cost is greatly reduced; and meanwhile, the weight is reduced, and the traction load of a cutting machine is relieved.

Owner:ANQING TIANRUN ENG MACHINERY

Hand-lifting type dual-adjustment feeding support device

InactiveCN105922052AAchieve liftingEasy to observe mobile positioningMetal working apparatusEngineeringMechanical engineering

The invention relates to a hand-lifting type dual-adjustment feeding support device which comprises a base, a support seat and a lifting mechanism. The lifting mechanism comprises a box and a supporting frame. The box is fixed to the base and provided with a lifting top face, and the support seat is fixed to the top face. The supporting frame is arranged in the box and fixed to the bottom of the top face. Clamping parts are arranged on the two opposite sides of the supporting frame correspondingly. Vertical strip-shaped through holes are formed in the two opposite sides of the box correspondingly, and a plurality of parallel clamping grooves which are located in different planes and used for accommodating the clamping parts are formed in one vertical side of each vertical strip-shaped through hole. At least one positioning pile is fixed to the top face. The feeding support device further comprises at least one stud corresponding to the at least one positioning pile. The support seat is positioned on the top face through the studs, and the distance between the support seat and the base is adjusted by rotating the studs.

Owner:ANQING TIANRUN ENG MACHINERY

Electric-control feeding supporting device

InactiveCN105922069ASolve the problem of smooth feedingEasy to operateLarge fixed membersMetal working apparatusEngineeringSupport plane

Owner:ANQING TIANRUN ENG MACHINERY

Feeding supporting double-lifting device

InactiveCN105922073AAchieve liftingEasy to observe mobile positioningMetal working apparatusArchitectural engineeringThreaded rod

The invention relates to a feeding supporting double-lifting device which comprises a base, a supporting seat and a lifting mechanism. The lifting mechanism comprises a box body, wedge-shaped blocks, a driver, threaded rods and a supporting frame. The wedge-shaped blocks are provided with wedge-shaped faces. A notch used for allowing the corresponding threaded rod to penetrate through is formed in each wedge-shaped face. One end of each threaded rod is inserted into the base in a penetrating mode and driven by the driver to rotate, and the other end of each threaded rod penetrates through the corresponding notch and then is screwed on the supporting seat. The supporting seat is provided with oblique faces matched with the wedge-shaped faces. The wedge-shaped blocks are arranged between the base and the supporting seat in a matched mode. The box body is fixed to the base. The box body is provided with a top face capable of ascending and descending. The supporting seat is fixed to the top face of the box body. The supporting frame is arranged in the box body and fixed to the bottom of the top face of the box body. Clamping parts are arranged on the two opposite sides of the supporting frame correspondingly. Vertical strip-shaped through holes are formed in the two opposite sides of the box body correspondingly. A plurality of parallel clamping grooves which are located on different planes and used for containing the corresponding clamping part are formed in the vertical side of each vertical strip-shaped through hole.

Owner:ANQING TIANRUN ENG MACHINERY

Feeding support adjusting device

InactiveCN105922060AAdjustable spacingSolve the problem of smooth feedingMetal working apparatusEngineeringConveyor belt

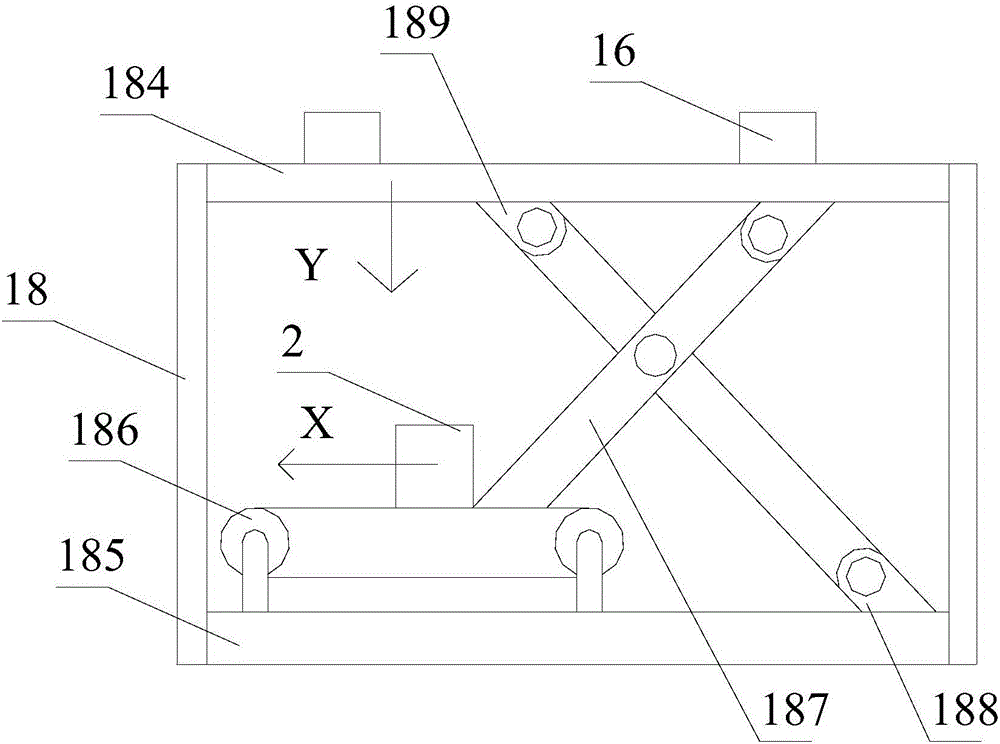

The invention relates to a feeding support adjusting device which comprises a base, a support seat and a lifting mechanism. The lifting mechanism comprises a box, a supporting frame and a conveying mechanism. The box is fixed to the base and provided with a lifting top face, and the support seat is fixed to the top face. The supporting frame and the conveying mechanism are both arranged in the box. The supporting frame comprises a first support leg and a second support leg, wherein the first support leg and the second support leg are movably mounted in a scissor shape. One end of the first support leg is movably mounted on the top face, and the other end of the first support leg is movably mounted on the bottom face of the box. One end of the second support leg is movably mounted on the top face, the other end of the second support leg is arranged on a conveyor belt of the conveying mechanism, and a limiting block fixed to the conveyor belt abuts against the other end of the second support leg so as to limit the other end of the second support leg on the conveyor belt. The conveyor belt is controlled to move by a motor of the conveying mechanism.

Owner:ANQING TIANRUN ENG MACHINERY

Rocking handle type feeding support device

InactiveCN105923328ASolve the problem of smooth feedingSimple structureConveyorsDrive wheelEngineering

The invention relates to a rocking handle type feeding support device which comprises a base, a support seat and a lifting mechanism. The lifting mechanism comprises a box, a supporting frame and a conveying mechanism. The box is fixed to the base and provided with a lifting top face, and the support seat is fixed to the top face. The supporting frame and the conveying mechanism are both arranged in the box, and the supporting frame is fixed to the bottom of the top face. The whole conveying mechanism is mounted on the supporting frame and comprises a driving wheel, a first driven wheel, a second driven wheel and a conveyor belt. One side of the driving wheel is in engaged transmission with the first driven wheel, the opposite other side of the driving wheel drives the second driven wheel for transmission through the conveyor belt, and the driving wheel drives the two driven wheels to rotate in opposite directions. A rocking handle is arranged in the rotating center of the driving wheel. The rocking handle type feeding support device is simple in structure, low in cost and easy to operate; the rocking handle just needs to be operated and rocked in the whole process, workers can work without training, and the device is easy to apply and popularize in the production and machining process.

Owner:ANQING TIANRUN ENG MACHINERY

Adjustable feed support adjusting device

InactiveCN106002452AAdjustable spacingSolve the problem of smooth feedingMetal working apparatusEngineeringConveyor belt

The invention relates to an adjustable feeding support adjustment device, which includes a base, a support seat and a lifting mechanism. The lifting mechanism includes a box body, a support frame and a transmission mechanism arranged in the box body. The support seat is fixed on the top surface of the box body and is driven up and down by the lifting mechanism. The supporting frame includes two supporting legs which are movably installed in a scissors shape. One end of the two outriggers is movably installed on the top surface, the other end of outrigger one is movably installed on the bottom surface of the box, and the other end of outrigger two is placed on the conveyor belt of the transmission mechanism and is controlled by a limiter fixed on the conveyor belt. Bit block backing. The conveyor belt is moved by the motor control of the conveyor mechanism. At least one positioning pile is fixed on the top surface, and the feeding supporting device further includes at least one stud corresponding to the at least one positioning pile. The supporting base is positioned above the top surface through the studs, and the distance between the supporting base and the base is adjusted by rotating the studs.

Owner:ANQING TIANRUN ENG MACHINERY

Double-lift type feeding supporting and adjusting device

The invention relates to a double-lift type feeding supporting and adjusting device. The double-lift type feeding supporting and adjusting device comprises a base, a supporting base and a lifting mechanism. The lifting mechanism comprises a box, wedge blocks, a driver, threaded rods, a supporting frame and a conveying mechanism, wherein the supporting frame and the conveying mechanism are arranged in the box. The wedge blocks are provided with wedged surfaces which are provided with notches for allowing the threaded rods to pass through. One end of each threaded rod is inserted into the base in a penetrating mode and driven by the driver to rotate. The other ends of the threaded rods penetrate through the corresponding notches to be screwed onto the supporting seat. The supporting seat is provided with inclined surfaces matched with the wedged surfaces. The wedge blocks are arranged between the base and the supporting seat in a matched mode. The supporting seat is fixed to the top face of the box. The supporting frame comprises two supporting legs which are movably mounted in a scissors shape. One end of one supporting leg is arranged on a conveyor belt of the conveying mechanism, and a limiting block fixed to the conveyor belt abuts against the supporting leg. The limiting block is provided with a handle. A butterfly-shaped lock nut capable of locking the current state of the supporting frame is arranged at the junction of the first supporting leg and the second supporting leg of the supporting frame.

Owner:ANQING TIANRUN ENG MACHINERY

Feeding clamping double-adjusting device

The invention relates to a feeding clamping double-adjusting device which comprises a base, a supporting seat, a lifting mechanism, cylindrical rods and buckles. The lifting mechanism comprises a box body, a supporting frame, a conveying mechanism, wedge-shaped blocks, a driver and threaded rods. One end of each threaded rod is inserted into the base in a penetrating mode and driven by the driver to rotate, and the other end of each threaded rod penetrates through a notch of a wedge-shaped face of the corresponding wedge-shaped block and then is screwed on the supporting seat. The supporting seat is provided with oblique faces matched with the wedge-shaped faces. The wedge-shaped blocks are arranged between the base and the supporting seat. The supporting seat is fixed to the top face of the box body. The conveying mechanism is integrally installed on the supporting frame. The conveying mechanism comprises a driving wheel, a first driven wheel, a second driven wheel and a conveying belt. One side of the driving wheel is in engagement transmission with the first driven wheel. The other opposite side of the driving wheel drives the second driven wheel to rotate through the conveying belt. An operating crank is arranged in the rotating center of the driving wheel. The supporting seat is positioned above the top face of the box body through the cylindrical rods. The distance between the supporting seat and the base is adjusted by rotating wrenches of the buckles.

Owner:ANQING TIANRUN ENG MACHINERY

Feeding clamping double-lifting device

InactiveCN105922077ASolve the problem of smooth feedingEasy to operateMetal working apparatusEngineeringThreaded rod

The invention relates to a feeding clamping double-lifting device which comprises a base, a supporting seat and a lifting mechanism. The lifting mechanism comprises a box body, a supporting frame, a conveying mechanism, wedge-shaped blocks, a driver and threaded rods. Notches are formed in wedge-shaped faces of the wedge-shaped blocks. One end of each threaded rod is inserted into the base in a penetrating mode and driven by the driver to rotate, and the other end of each threaded rod penetrates through the corresponding notch and then is screwed on the supporting seat. The supporting seat is provided with oblique faces matched with the wedge-shaped faces. The wedge-shaped blocks are arranged between the base and the supporting seat in a matched mode. The supporting seat is fixed to the top face of the box body and driven by the lifting mechanism to ascend and descend. The supporting frame comprises two supporting legs which are movably installed in a crossed mode. One ends of the two supporting legs are movably installed on the bottom face of the box body and a conveying belt of the conveying mechanism correspondingly, and the ends which are arranged on the conveying belt abuts against a limiting block fixed to the conveying belt. The conveying belt is controlled by a motor of the conveying mechanism to move. The supporting seat is positioned above the top face of the box body through cylindrical rods. The distance between the supporting seat and the base is adjusted by rotating wrenches of buckles.

Owner:ANQING TIANRUN ENG MACHINERY

Feeding supporting electric-control lifting device

InactiveCN105923346AEasy to operateSolve the problem of smooth feedingConveyorsSupporting framesEngineeringWedge shape

The invention relates to a feeding supporting electric-control lifting device which comprises a base, a supporting seat and a lifting mechanism. The lifting mechanism comprises wedge-shaped blocks, a driver, threaded rods, a box body, a supporting frame and a conveying mechanism. The box body is fixed to the base. The supporting seat is fixed to the top face of the box body. Both the supporting frame and the conveying mechanism are arranged in the box body. The supporting frame is fixed to the bottom of the top face. The conveying mechanism is integrally installed on the supporting frame. The conveying mechanism comprises a driving wheel, a first driven wheel, a second driven wheel and a conveying belt. An operating crank is arranged in the rotating center of the driving wheel. Each wedge-shaped block is provided with a wedge-shaped face. A notch used for allowing the corresponding threaded rod to penetrate through is formed in each wedge-shaped face. One end of each threaded rod is inserted into the base in a penetrating mode and driven by the driver to rotate, and the other end of the threaded rod penetrates through the corresponding notch and is screwed in the supporting seat. The supporting seat is provided with oblique faces matched with the wedge-shaped faces. The wedge-shaped blocks are arranged between the base and the supporting seat in a matched mode.

Owner:ANQING TIANRUN ENG MACHINERY

Dual-lifting feed clamping device provided with buckles

Owner:ANQING TIANRUN ENG MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com