Method for recovering rhodium complex catalyst

A technology of catalysts and complexes, which is applied in the field of complex catalysts remaining in the recovery device, and can solve problems such as expensive, difficult recovery, and uneconomical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

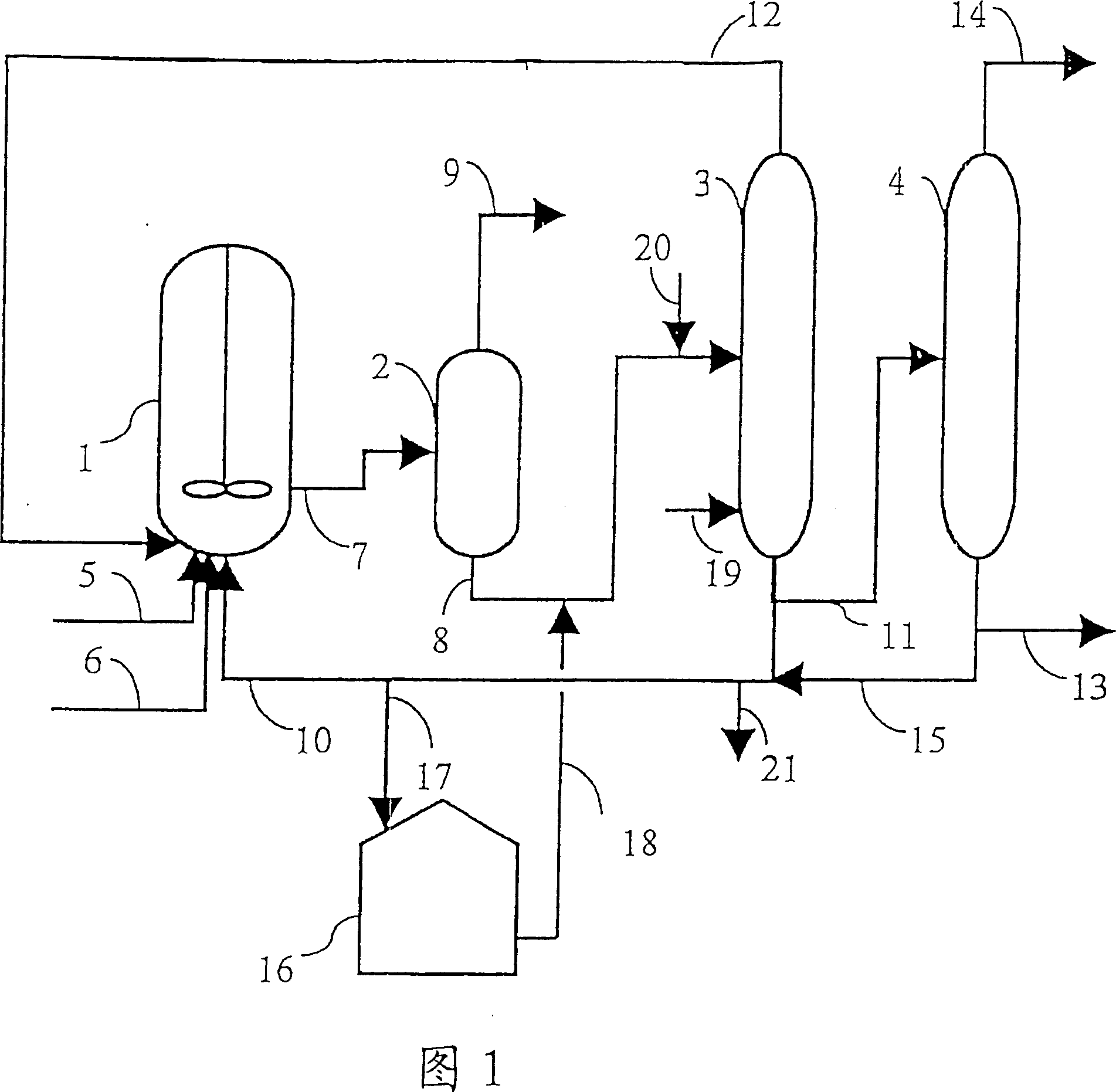

[0068]Use CSTR type reactor 1, take toluene as reaction solvent, under the existence of the rhodium complex catalyst that ligand is triphenylphosphine, make the propylene supplied by pipeline 5 and the molar ratio supplied by pipeline 6 be 1 :1 hydrogen and carbon monoxide mixed gas (hereinafter referred to as "oxygen-containing gas") react to continuously produce butyraldehyde. The reaction product liquid taken out from the reactor 1 is introduced into the gas-liquid separator 2 through the pipeline 7 , and the product liquid is supplied to the distillation column 3 through the pipeline 8 after gas-liquid separation. Butyraldehyde is distilled out from the pipeline 12 at the top of the tower, and the bottom liquid of the rhodium-containing complex catalyst is taken out from the pipeline 10 at the bottom of the tower, and it is circulated in the reactor 1 as a catalytic liquid. In addition, a part of the catalytic liquid was supplied to the distillation column 4 from the line ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com